Capacitance diaphragm gauge and vaccum apparatus

一种电容式、真空计的技术,应用在测量装置、利用电容变化的流体压力测量、通过电磁元件测量流体压力等方向,能够解决隔膜真空计成本增加等问题,达到低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

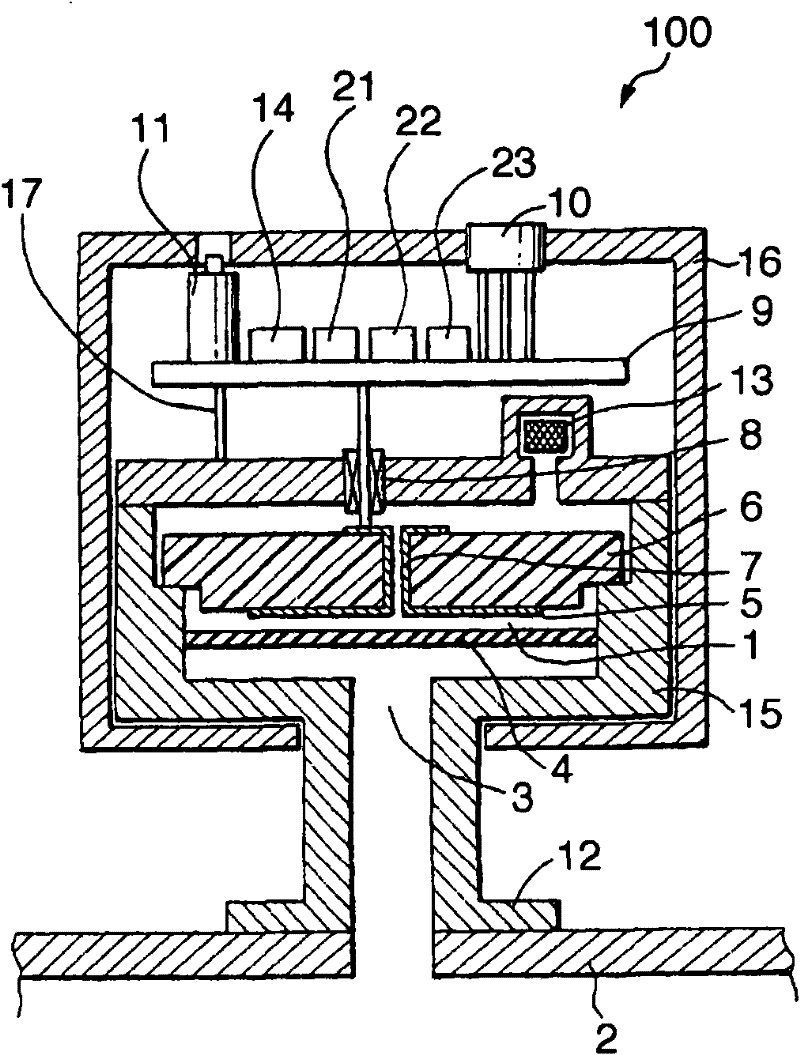

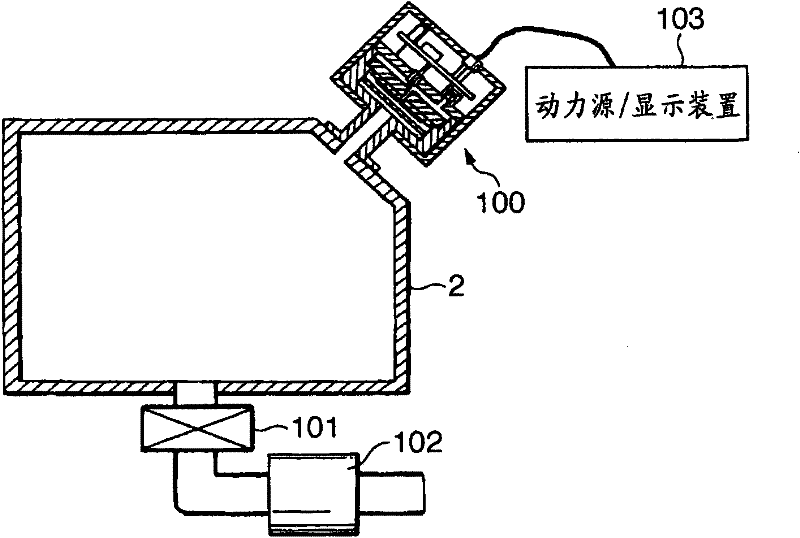

[0037] The best mode for carrying out the present invention will be described in detail below with reference to the accompanying drawings. figure 1 is a schematic cross-sectional view showing one embodiment of the capacitive diaphragm vacuum gauge according to the present invention. and figure 1 The same reference numbers in Figure 5 Indicates the same parts.

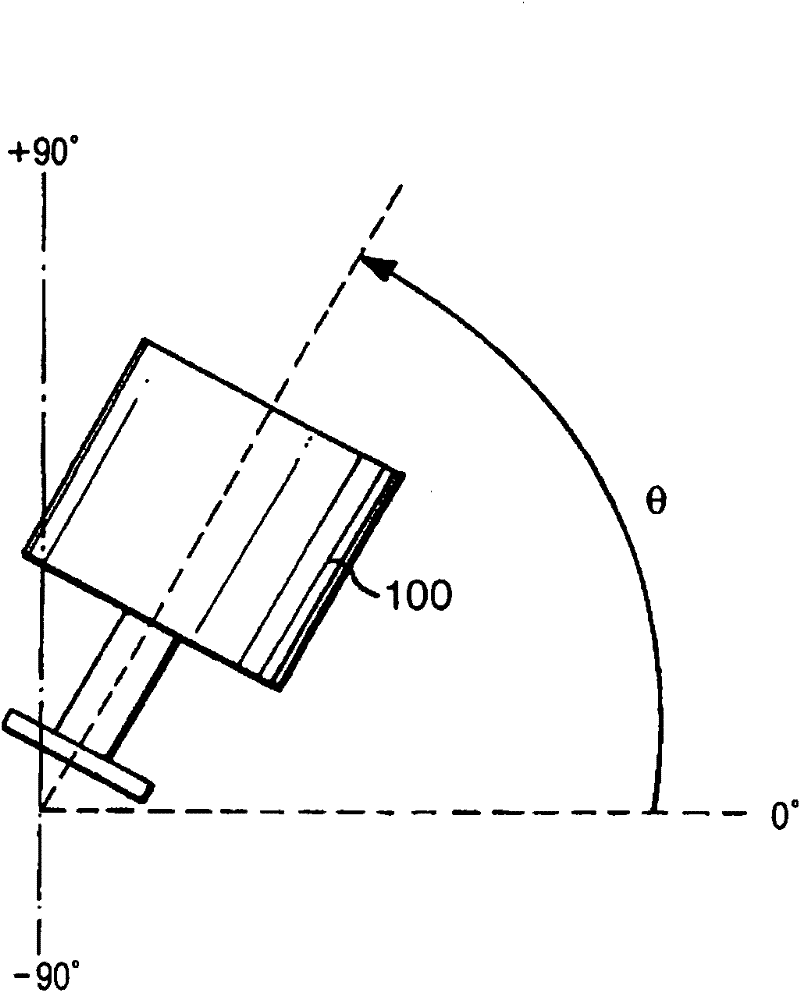

[0038] exist figure 1 On the circuit board 9 shown in , the zero point adjustment potentiometer 11, the inclination angle sensor 14, the capacitance detection unit 21, the pressure correction unit 22 and the storage unit 23 are fixed. figure 1 and Figure 5 The difference is that the capacitive diaphragm vacuum gauge includes an inclination angle sensor 14 and a storage unit 23 . The pressure correction unit 22 and the storage unit 23 correct the pressure measurement value based on the inclination angle of the capacitive diaphragm vacuum gauge 100 detected by the inclination angle sensor 14, which will be descri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com