Low-modulus single-component silane modified polyether sealing gum and preparation method thereof

A technology of silane-modified polyether and silane polyether, which is applied in the direction of polyether adhesives, chemical instruments and methods, adhesives, etc., can solve problems such as difficult control of silane end-capping rate, and no manufacturer has yet produced sealants. Achieve the effects of easy control of product quality, good storage stability, and excellent cohesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

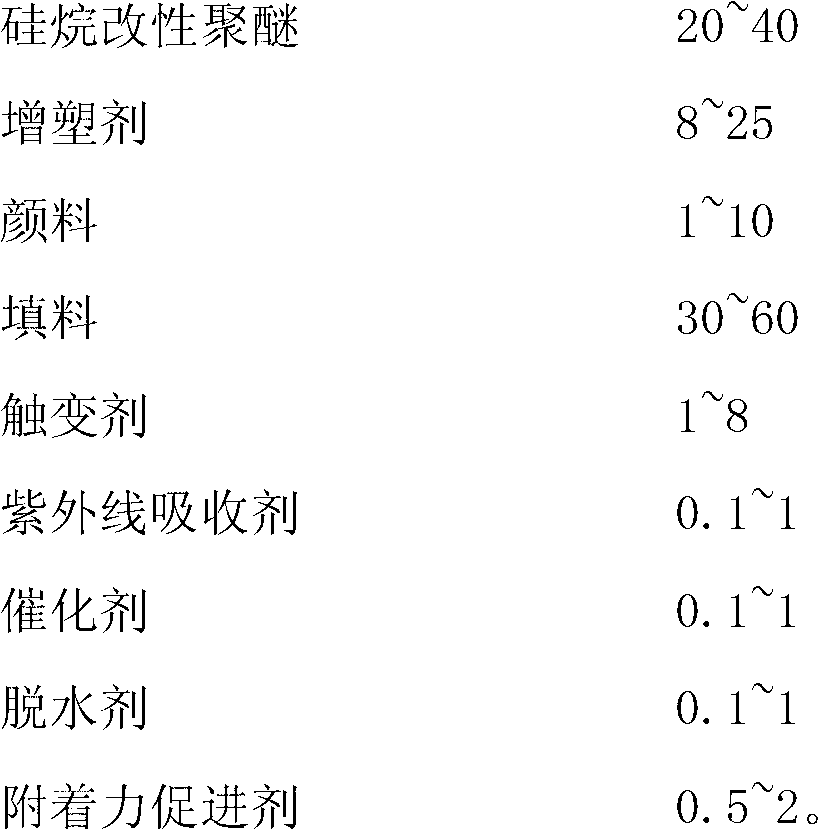

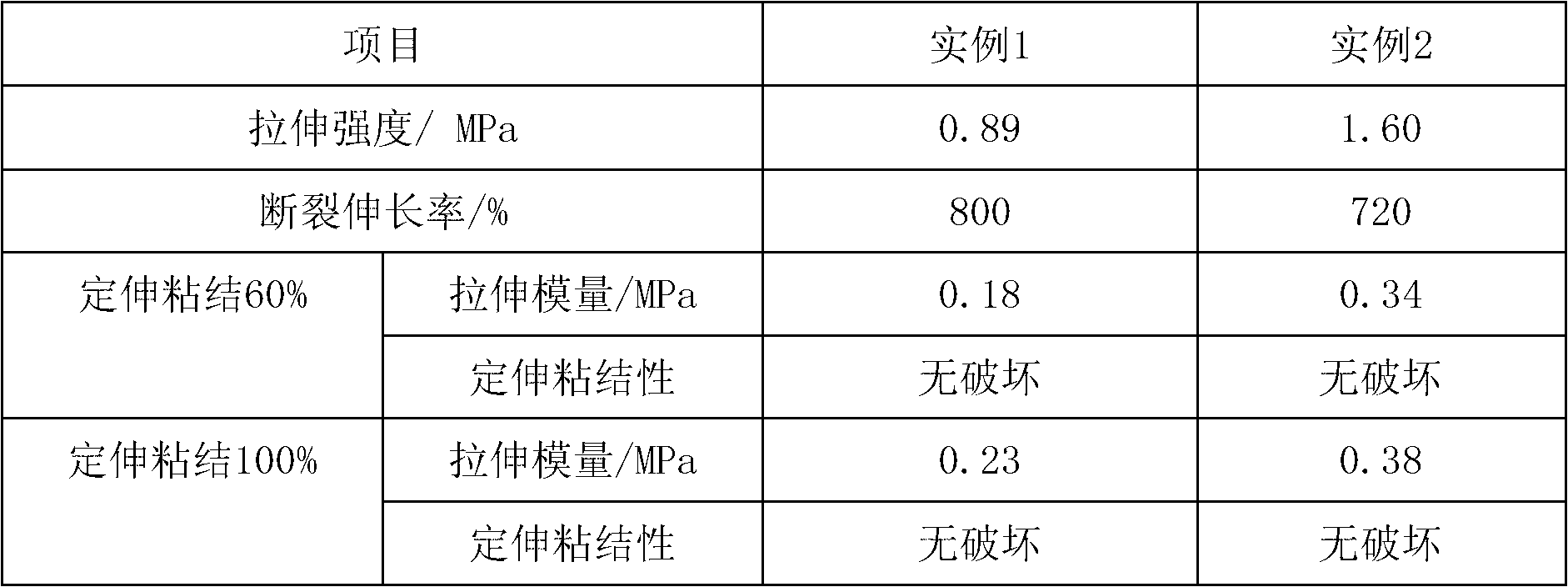

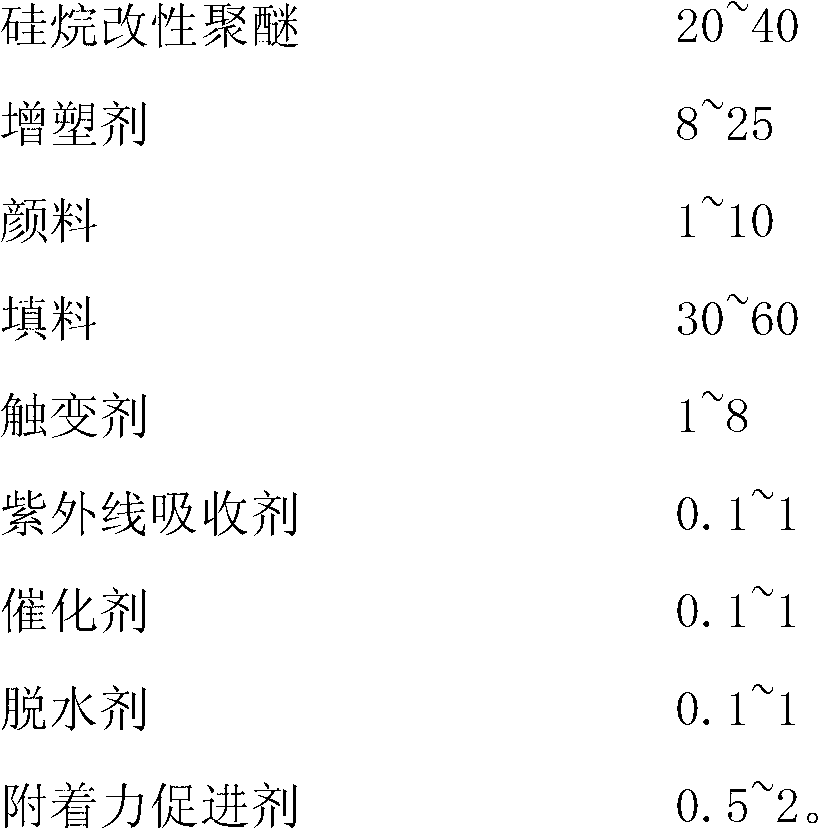

Embodiment 1

[0026] MS polymer S203H 32.7%; plasticizer (dinonyl phthalate) 14.4%; titanium dioxide 6.5%; light calcium carbonate 40.5%; polyamide wax 3.0%; 0.7% dibutyltin acid; 0.7% vinyltrimethoxysilane; 1.0% N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane.

[0027] Preparation method: Add S203H, DINP, titanium dioxide, and ultraviolet absorber in sequence to a biaxial planetary stirring tank at room temperature, mix evenly for 30 minutes, then add light calcium carbonate and polyamide wax, and heat at 105±5°C at high speed Stir and vacuum dehydrate for 2 hours, take a sample to measure the moisture, if the moisture content is below 5 / 10,000, lower the temperature, if the moisture content is above 5 / 10,000, continue vacuum dehydration until it is below 5 / 10,000. When the temperature drops below 50°C, add catalyst, water remover, and adhesion promoter, stir at high speed for 30 minutes, vacuum defoam for 10 minutes, and then fill to obtain a one-component silane-terminated polyether seala...

Embodiment 2

[0029] MS Polymer S203H 6.7%; MS Polymer S303H 15.7%; Plasticizer (Dinonyl Phthalate) 20.1%; Titanium Dioxide 4.5%; Light Calcium Carbonate 35.8%; Heavy Calcium Carbonate 12.1%; Polyamide Wax 2.9%; UV absorber Tinuvin3260.4%; Dibutyltin dilaurate 0.4%; Vinyl trimethoxysilane 0.7%; N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane 0.7% .

[0030] Preparation method: add S203H, S303H, DINP, titanium dioxide, and ultraviolet absorber in sequence to a biaxial planetary stirring tank at room temperature, mix evenly for 30 minutes, then add light calcium carbonate, heavy calcium carbonate and polyamide wax, High-speed stirring and vacuum dehydration at 105±5°C for 2 hours, sampling and measuring moisture, if the moisture content is below 5 / 10,000, lower the temperature, if the moisture content is above 5 / 10,000, continue vacuum dehydration until it is below 5 / 10,000. When the temperature drops below 50°C, add catalyst, water remover, and adhesion promoter, stir at high speed for 30 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com