Method and special apparatus for refuse leachate disposal

A technology of landfill leachate and treatment device, which is applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Zero emission and other issues to achieve sustainable utilization, water quality improvement, and good ventilation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

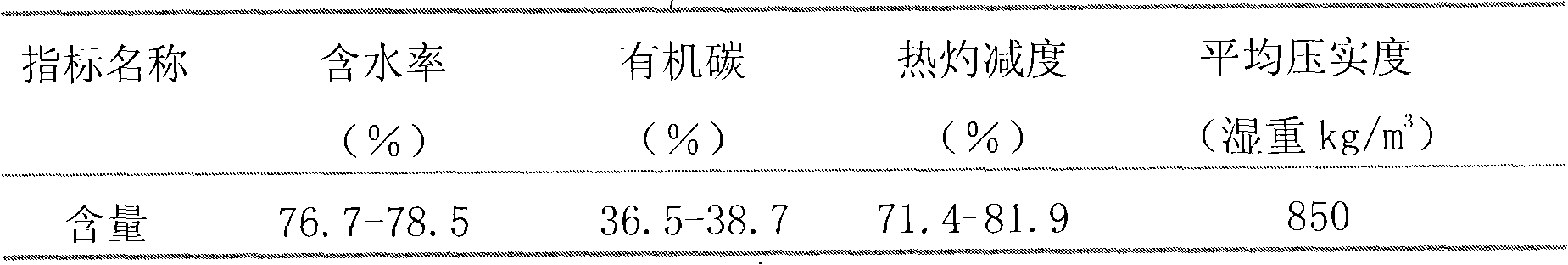

[0042] Embodiment 1, utilize landfill leachate treatment device to carry out garbage treatment

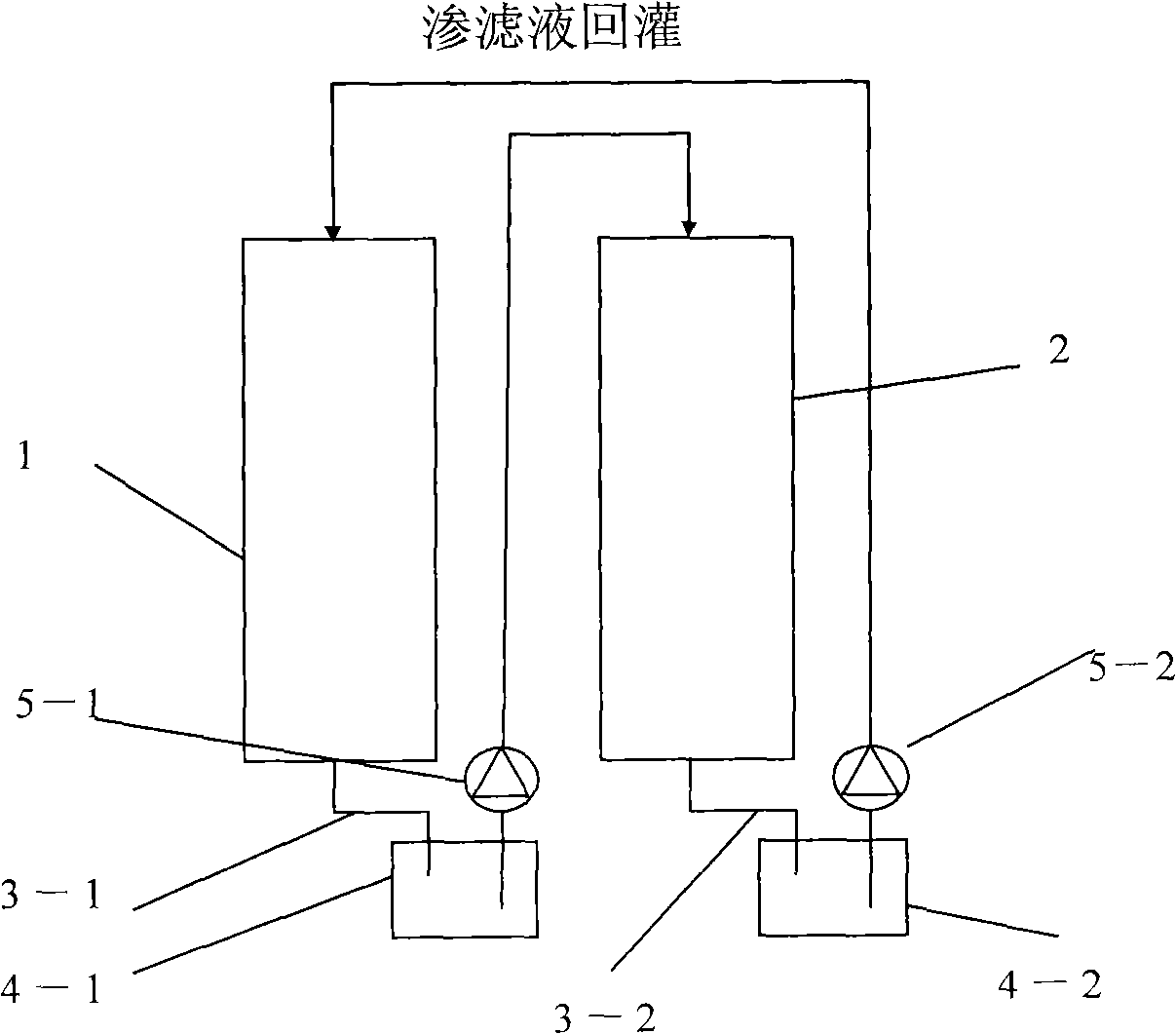

[0043] 1. Assembly of landfill leachate treatment device

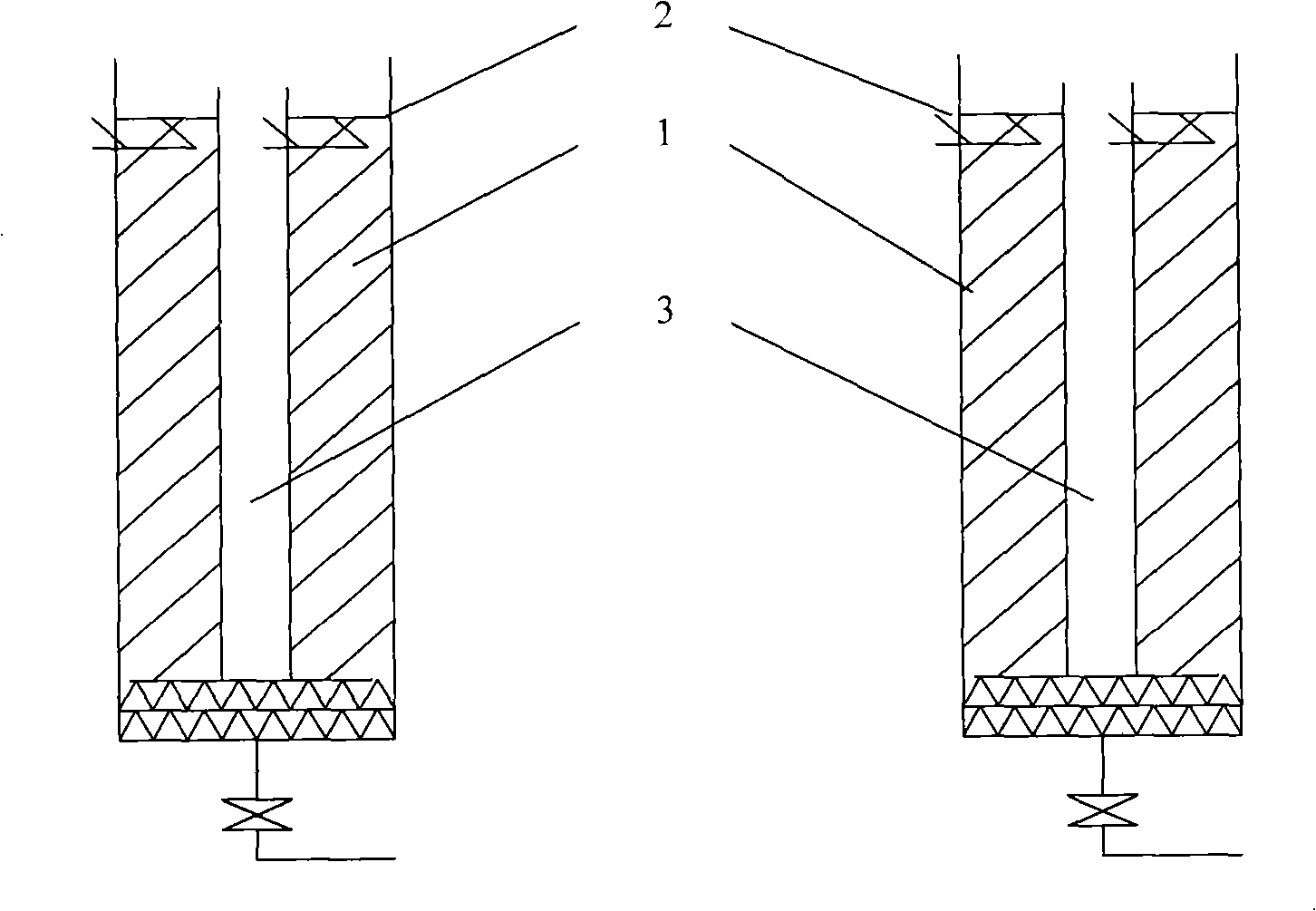

[0044] The garbage leachate treatment device of the present invention includes two garbage reactors 1 and 2, a water pump and a collecting pipe.

[0045]Garbage reactors 1 and 2 consist of PVC columns with a height of 1.3m and a diameter of 0.3m, pools with open tops and through holes at the bottom, water distribution devices and ventilation pipes with through holes on the pipe walls. The diameter of the through hole at the bottom of the pool body is 1.5 cm, 1 in total; the diameter of the through hole on the wall of the ventilation pipe is 0.3 cm, 100 in total. The inner diameter of the ventilation pipe is 3 cm, and a total of 1 ventilation pipe is arranged, which are vertically placed in the garbage reactor 1 and 2 respectively, and the bottom of the ventilation pipe is 10 cm away from the bottom of the pool body. In or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com