Method for processing landfill leachate and special device thereof

A landfill leachate and treatment device technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., to shorten the treatment cycle, solve the problem of poor treatment effect and blockage, and accelerate dissolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. Assembly of landfill leachate treatment device

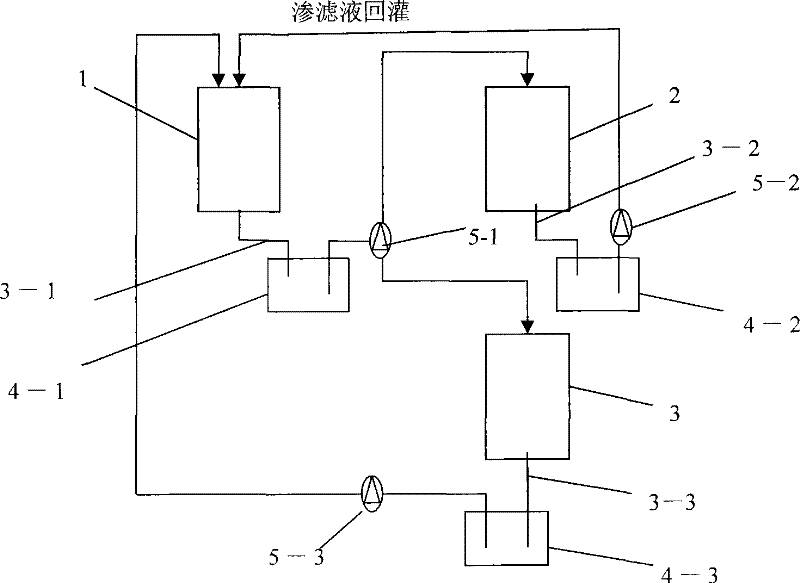

[0059] The landfill leachate treatment device of the present invention includes a reactor A for filling garbage to be treated, two reactors for filling mineralized garbage connected in series with the reactor A for filling garbage to be treated respectively Reactors B and C, water pumps and collection tubes.

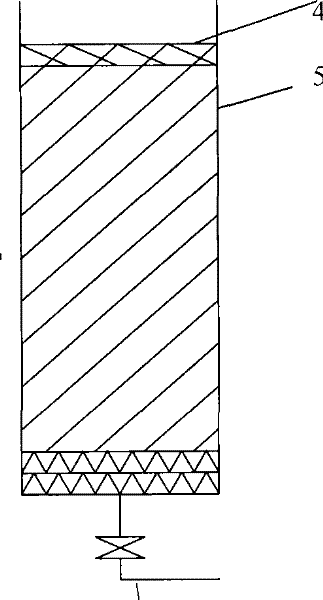

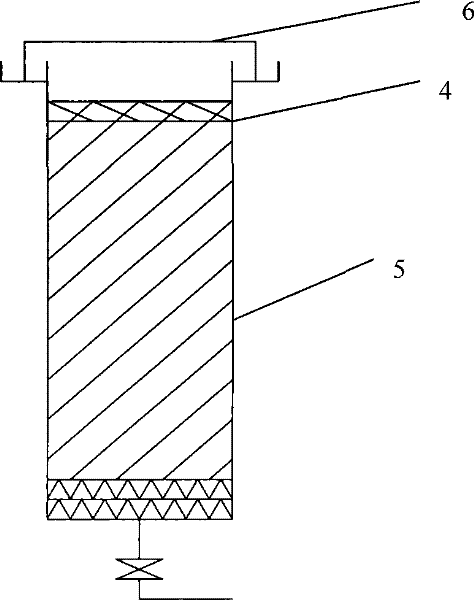

[0060] Reactor A for filling garbage to be treated and reactors B and C for filling mineralized garbage include PVC columns with a height of 1.3m and a diameter of 0.3m, which are open at the top and have through holes at the bottom. Pool body, water distribution device and valves. The diameter of the through hole at the bottom of the pool body is 1.5 cm, and there is one in total.

[0061] In order to facilitate the observation of the degradation state of the garbage to be treated, the reactor A for filling the garbage to be treated is also provided with a garbage sampling port.

[0062] In practical applicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com