Coking waste water joint-treatment process

A coking wastewater and combined treatment technology, applied in water/sewage treatment, aerobic process treatment, anaerobic digestion treatment, etc., can solve problems such as high toxicity, unreachable biochemical process, complex and changeable components, etc., to improve impact resistance Load performance, enhanced anoxic degradation function, and the effect of reducing COD concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A: Biochemical treatment of coking wastewater:

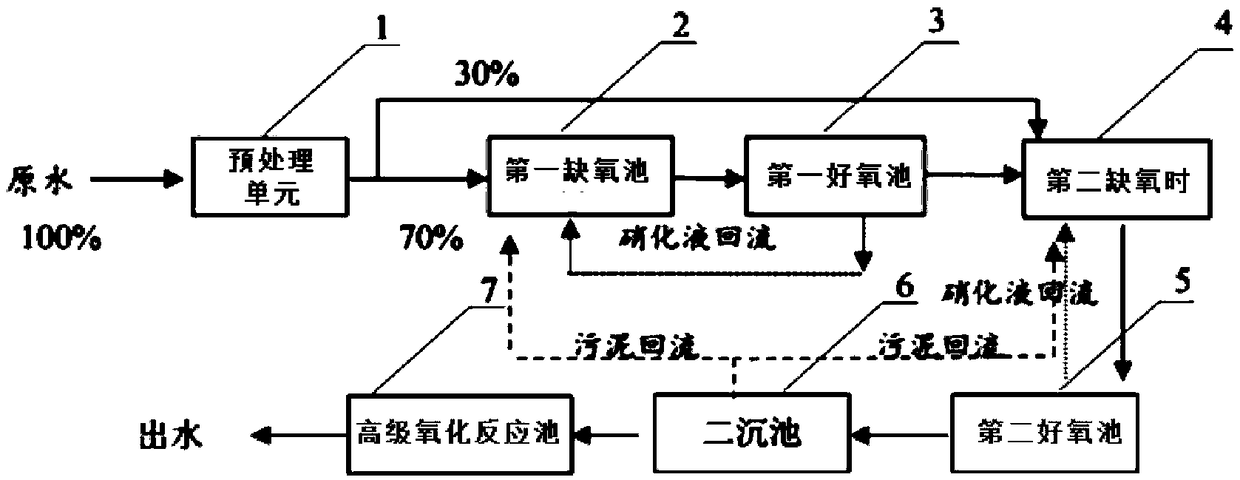

[0038] A two-stage A / O process with staged water inflow, that is, anoxic-aerobic-anoxic-aerobic biological denitrification process, adopts the activated sludge method, and the activated sludge is inoculated with the sewage from the secondary sedimentation tank of the coking wastewater treatment plant. mud. First, the raw water of coking wastewater is pretreated in the pretreatment unit 1, that is, the temperature is kept at 38°C through a heat exchanger to adapt to the subsequent biological treatment, and then part of the oil contained in the wastewater is removed through the oil removal tank, and then The water quality is adjusted through the homogenizing tank to prevent the impact of the biochemical system caused by the violent fluctuation of the water quality. The bottom of the homogenizing tank is equipped with an aeration head. After aeration, some volatile toxic substances can be preliminarily removed, which is cond...

Embodiment 2

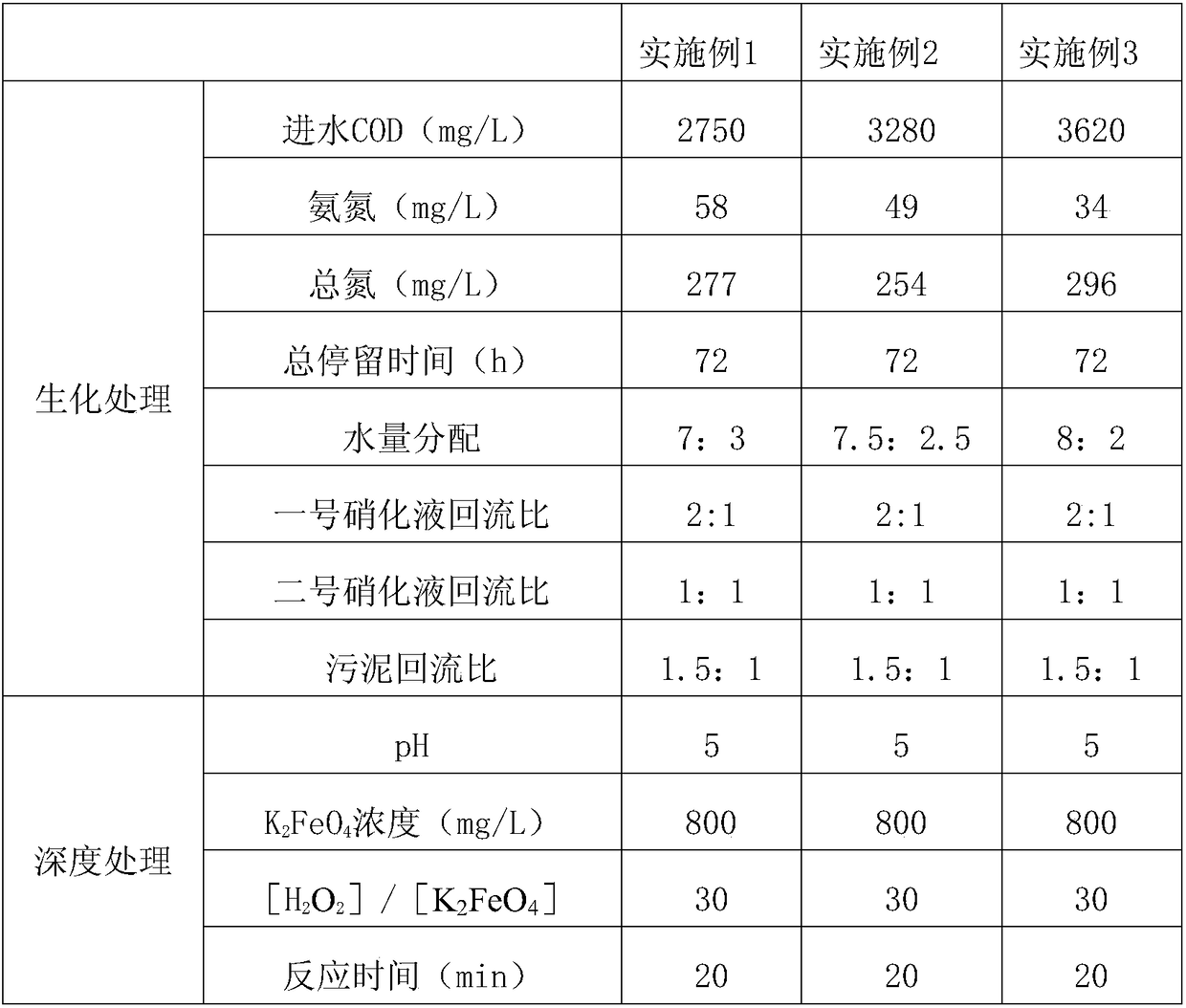

[0046] The experimental parameters in embodiment 2 and embodiment 3 are selected with reference to table 1.

[0047] After the above-mentioned biochemical treatment+advanced treatment of each embodiment, the main indicators of the effluent are shown in Table 2. Each embodiment of table 2 is to the removal effect of pollutant

[0048] From the results in Table 2, it can be seen that the coking wastewater after the above-mentioned biochemical treatment + advanced treatment has COD≤80mg / L, ammonia nitrogen≤10mg / L, and total nitrogen≤50mg / L. Emission Standard (GB16171-2012)" emission requirements.

[0049]

[0050] Table 1

[0051]

[0052] Table 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com