Method and equipment for cross backflow two-stage double-expansion granular sludge treatment of coking wastewater

A technology for granular sludge and coking wastewater, which is applied in water/sludge/sewage treatment, metallurgical wastewater treatment, biological water/sewage treatment, etc. It can solve problems such as difficulty in improving denitrification efficiency and difficulty in effluent COD reaching discharge standards. To achieve the effect of tight arrangement of microorganisms, rich species of microorganisms, and fast mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

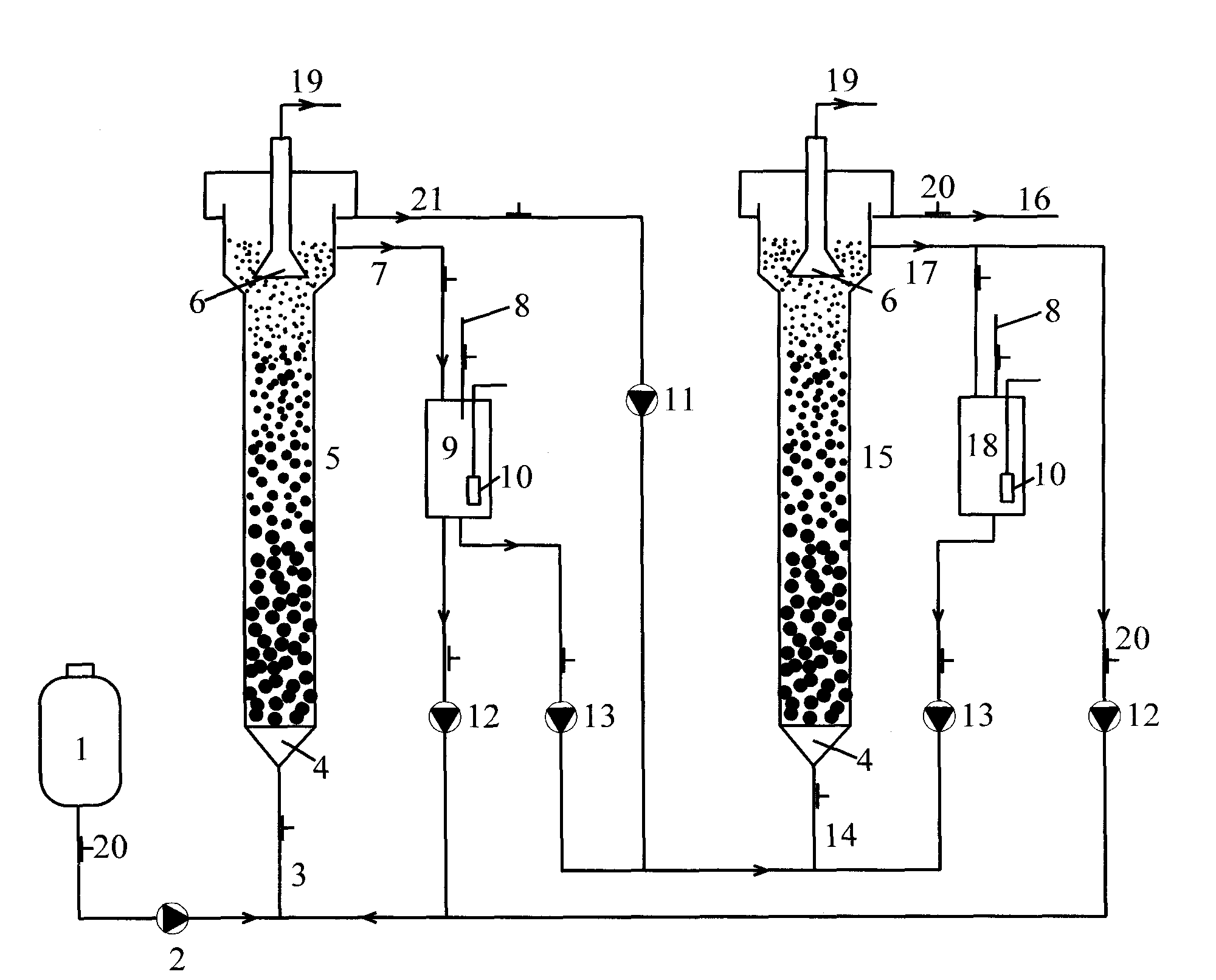

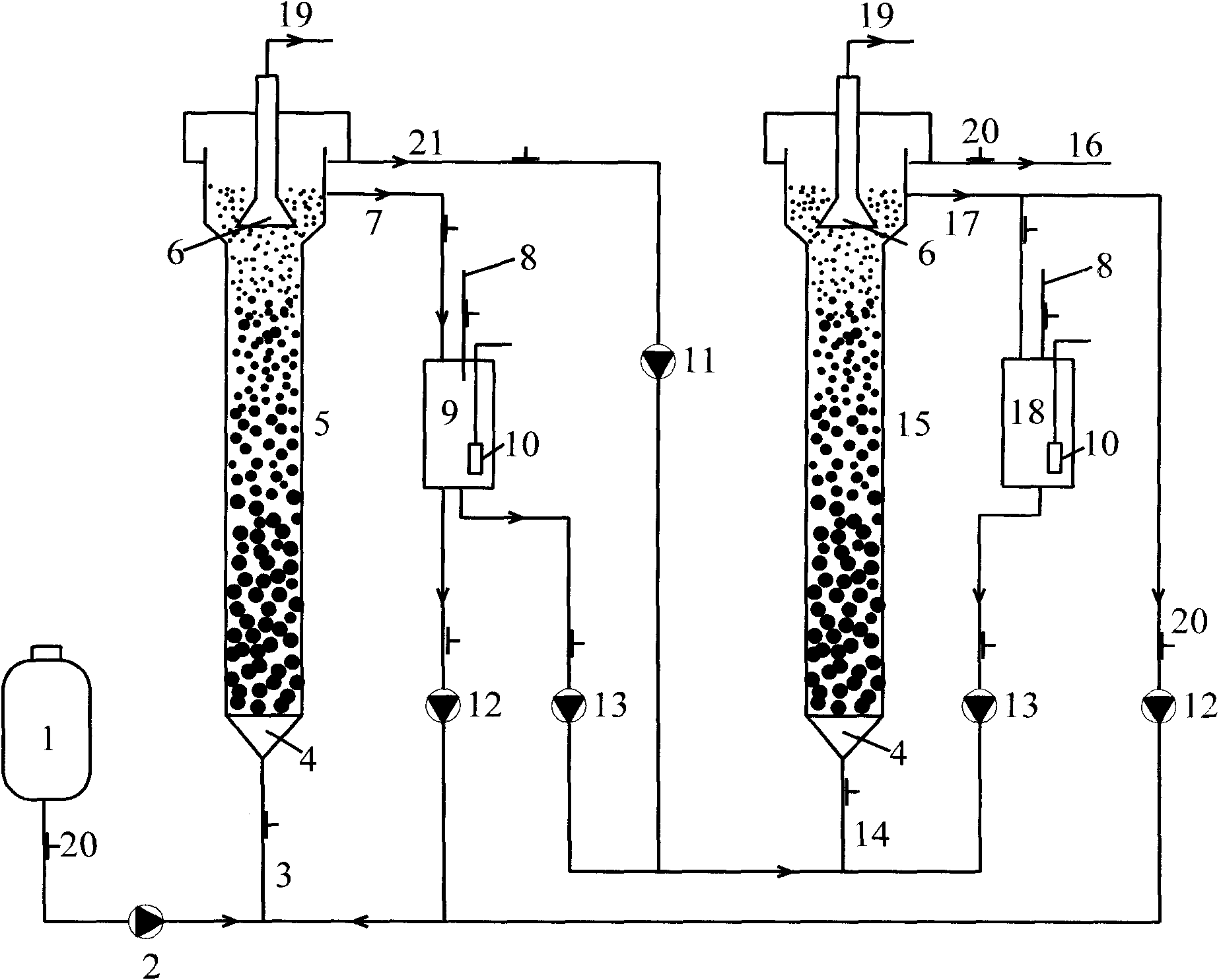

[0057] Cross-reflux two-stage double-expansion granular sludge coking wastewater treatment device such as figure 1 As shown, it consists of a primary reactor 5 and a secondary reactor 15, two double-expanded granular sludge reactors, and is equipped with a waste water storage tank 1, a primary aeration reflux column 9 and a secondary aeration reflux column 18.

[0058]Double-expanded granular sludge reactors 5 and 15 are made of plexiglass. The whole reactor is divided into two parts: the reaction zone and the sedimentation zone. Among them, the inner diameter of the reaction zone is 100mm, the height is 1.7m, and the volume is 12L; the inner diameter of the sedimentation zone is 140mm, the height 0.6m, volume 6L. The interior of the reactor is filled with granular sludge that is moderately expanded due to the moderate growth of filamentous bacteria used to degrade pollutants in wastewater. The granular sludge bed formed by these granular sludge is in an expanded state under t...

Embodiment 2

[0074] The dewatered sludge from the digestion tank of a sewage treatment plant in Taiyuan was taken for activity recovery and inoculated into the experimental reactor. The coking wastewater was taken from the second coking plant of Taiyuan Coal Chemical Group. The influent COD and ammonia nitrogen concentrations were 1140-1792 mg·L -1 and 56~179mg·L -1 . Using self-prepared beer wastewater, inoculate a small amount of granular sludge and municipal digested sludge into the reactor at a mass ratio of 1:6, start the operation at 35°C, maintain HRT3.4h, and reduce the influent COD from 200mg·L -1 Increase to 1000mg·L -1 , the influent load is 1.58kgCOD·m -3 d -1 Increase to 7.5kgCOD·m -3 d -1 , quickly formed granular sludge, successfully started the reactor, and the sludge concentration reached 32.7g·L -1 , VSS / SS reached 0.66, COD removal rate reached 94.7%. The two-stage reactors are directly domesticated with coking wastewater, and adopt continuous micro-aerobic aerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com