Patents

Literature

50results about How to "Efficient mineralization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gradient Ozone Catalytic Oxidation Method for Degrading Organic Pollutants in Water

ActiveCN102276095AAchieving Gradient OxidationControl contentMultistage water/sewage treatmentWater/sewage treatment by oxidationNitrosoCatalytic oxidation

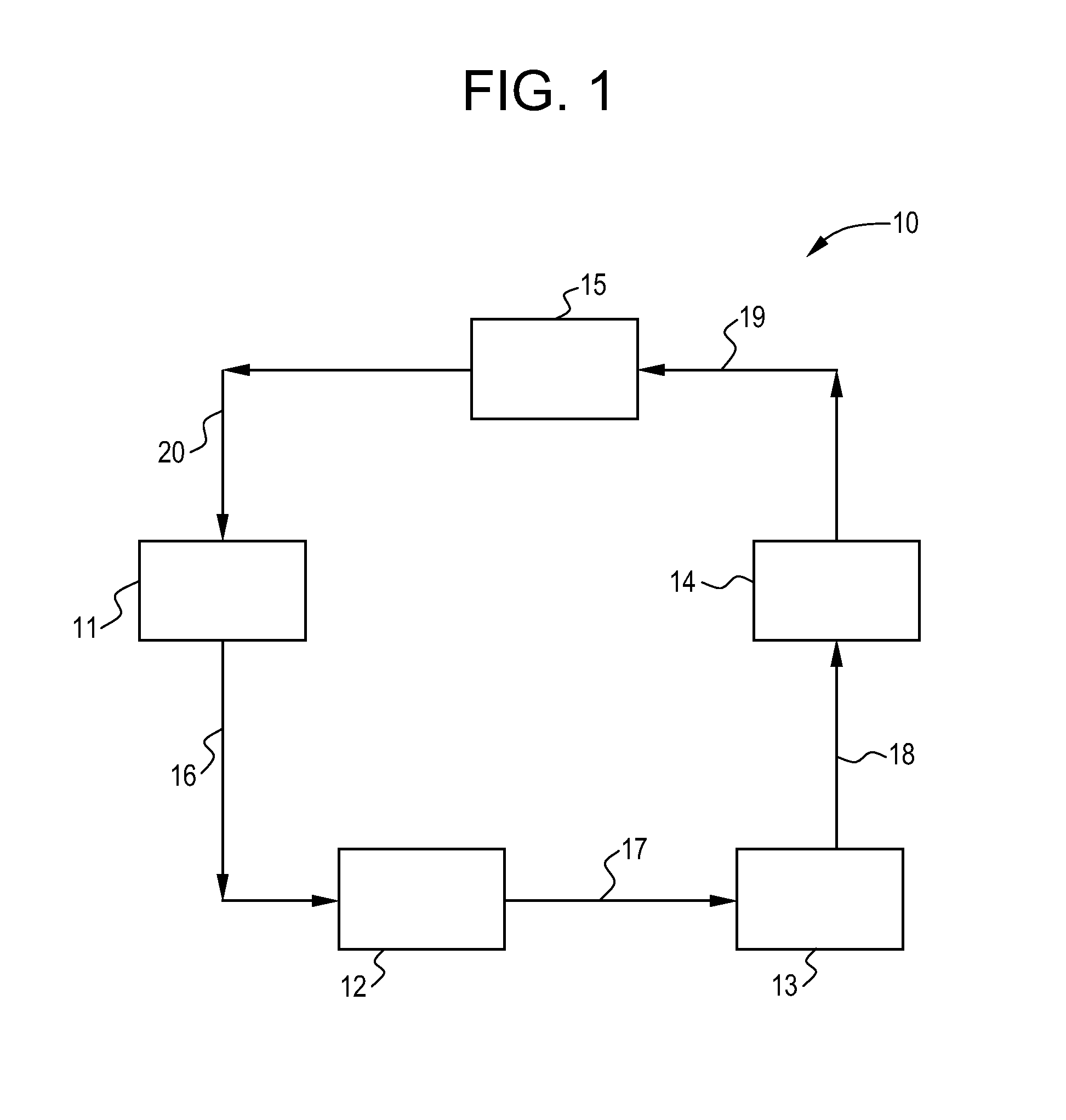

The invention relates to a method for degrading organic pollutants in water by gradient ozone catalytic oxidation, and relates to a gradient ozone catalytic oxidation combination method for degrading organic pollutants in water. By the method, the problem that the conventional advanced oxidation technology has defects during individual use, the problem that the organic pollutants in the water cannot be removed efficiently, the problem that the influence of the pH value and temperature of the water on the method is large, and the problem that high-toxicity byproducts are formed are solved. In the method, water treatment is realized by combining two or three of a process for treating O3 individually, an enhanced catalytic oxidation process for O3 and an O3 / ultraviolet (UV) process sequentially. By the reasonable optimizing and gradient combination of the three treatment modes, the method is suitable for wide pH values and a wide temperature range, the pollutants with intermediate toxicity are controlled to be formed, the toxicity of the pollutants is reduced, the pollutants in the water is degraded efficiently and completely, and the content of oxidative species in effluent is controlled. An efficient oxidation treatment effect is kept at low temperature, and the generation of bromate, nitroso dimethylamine, chlorate, perchlorate, iodate and periodate can be controlled greatly.

Owner:哈尔滨工投环保产业有限公司

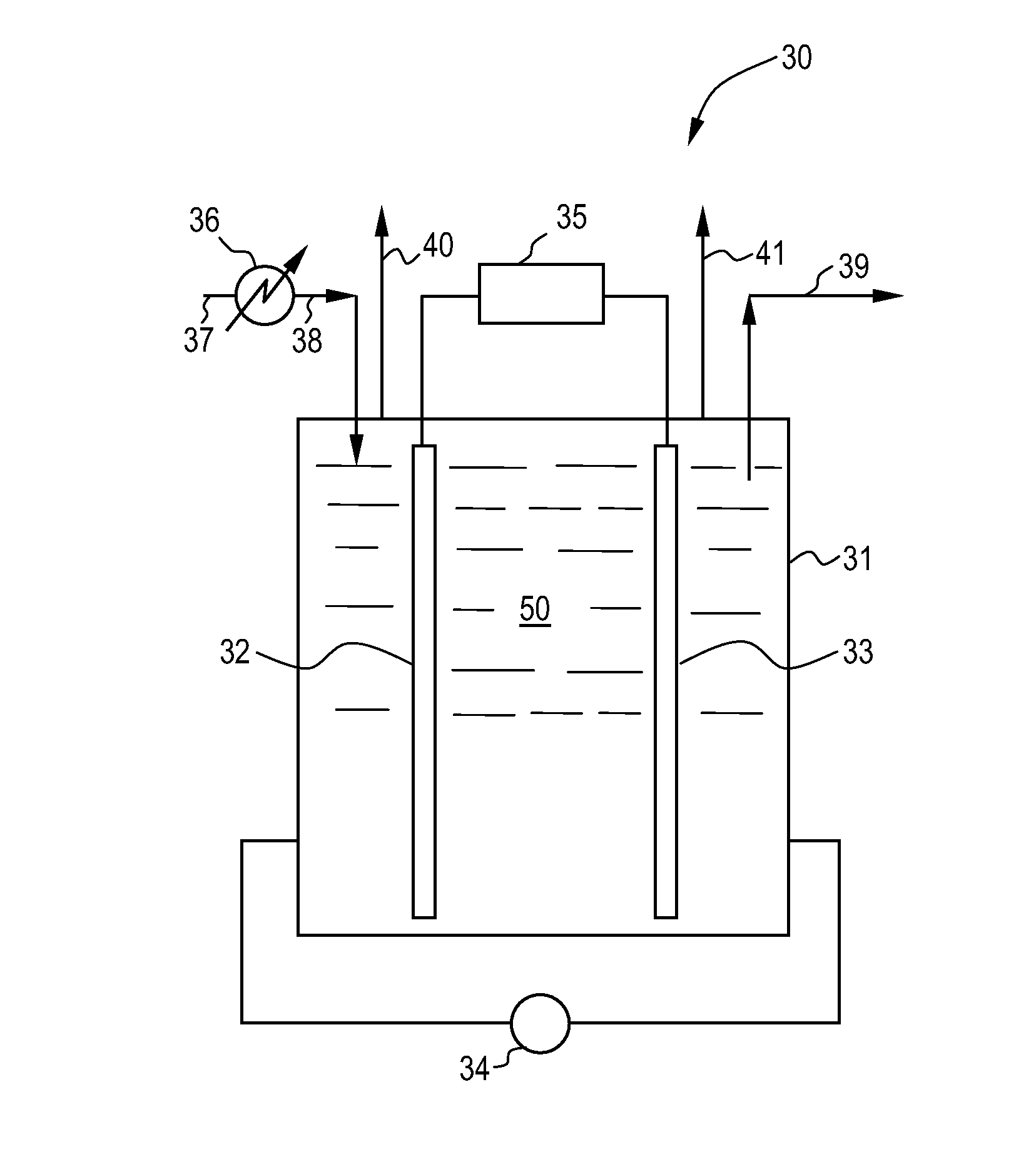

Brine purification

InactiveUS20100206744A1Increase contentLower levelFrom normal temperature solutionsLiquid separation by electricityOrganic contentOrganic matter

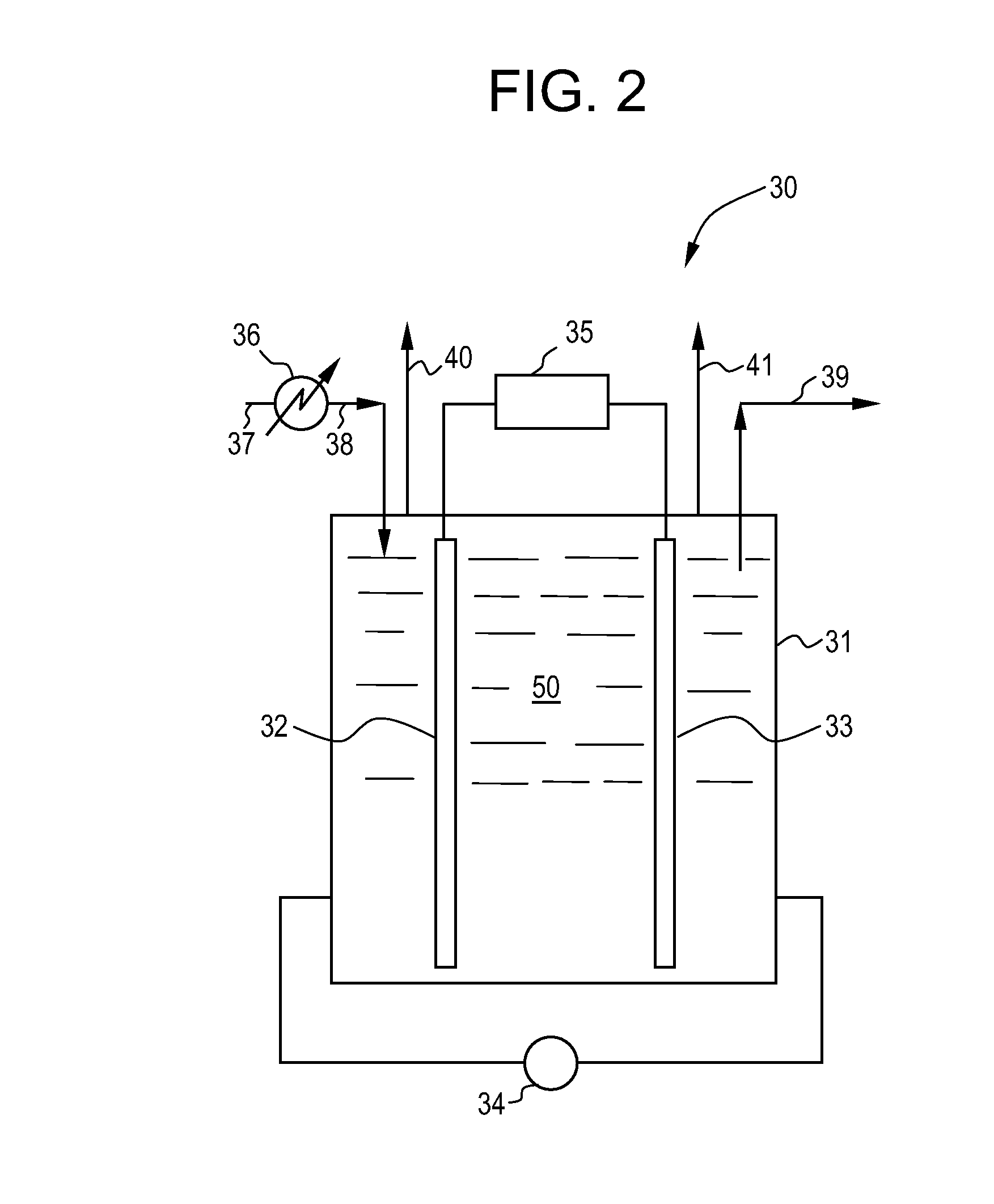

Process of reducing organic content of brine which includes subjecting a brine solution containing an organic content to an electrochemical process for a sufficient period of time and at a sufficient voltage to reduce the organic content of the brine to obtain a reduced organic content brine. Also provided is a process for reducing organic contamination of brine in a chemical process comprising subjecting a brine stream of the chemical process to electrochemical oxidation to obtain a reduced organic content brine stream.

Owner:DOW GLOBAL TECH LLC

Method and equipment for cross backflow two-stage double-expansion granular sludge treatment of coking wastewater

InactiveCN101786730AClosely arrangedRich varietyWaste water treatment from metallurgical processSustainable biological treatmentAs DirectedSludge

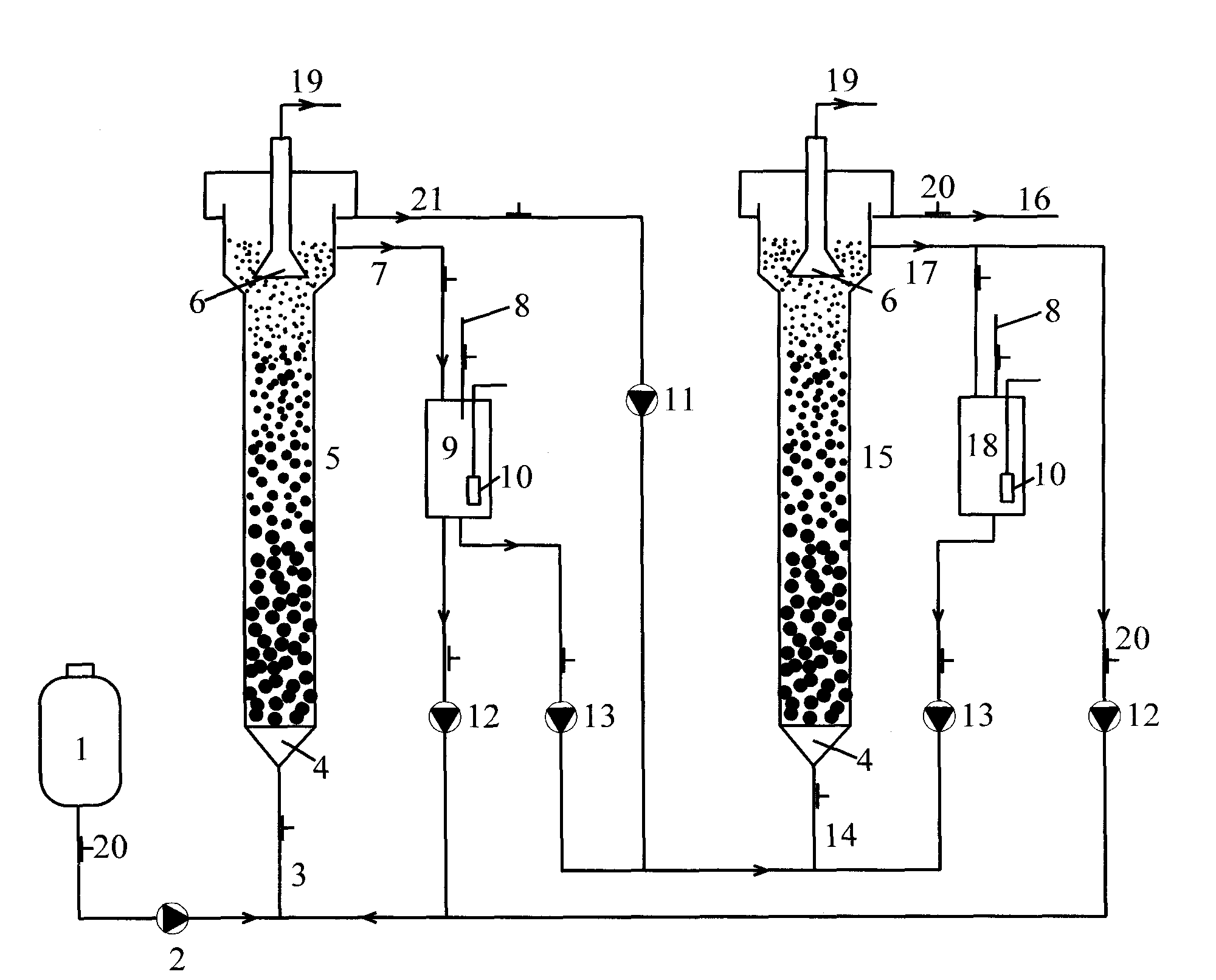

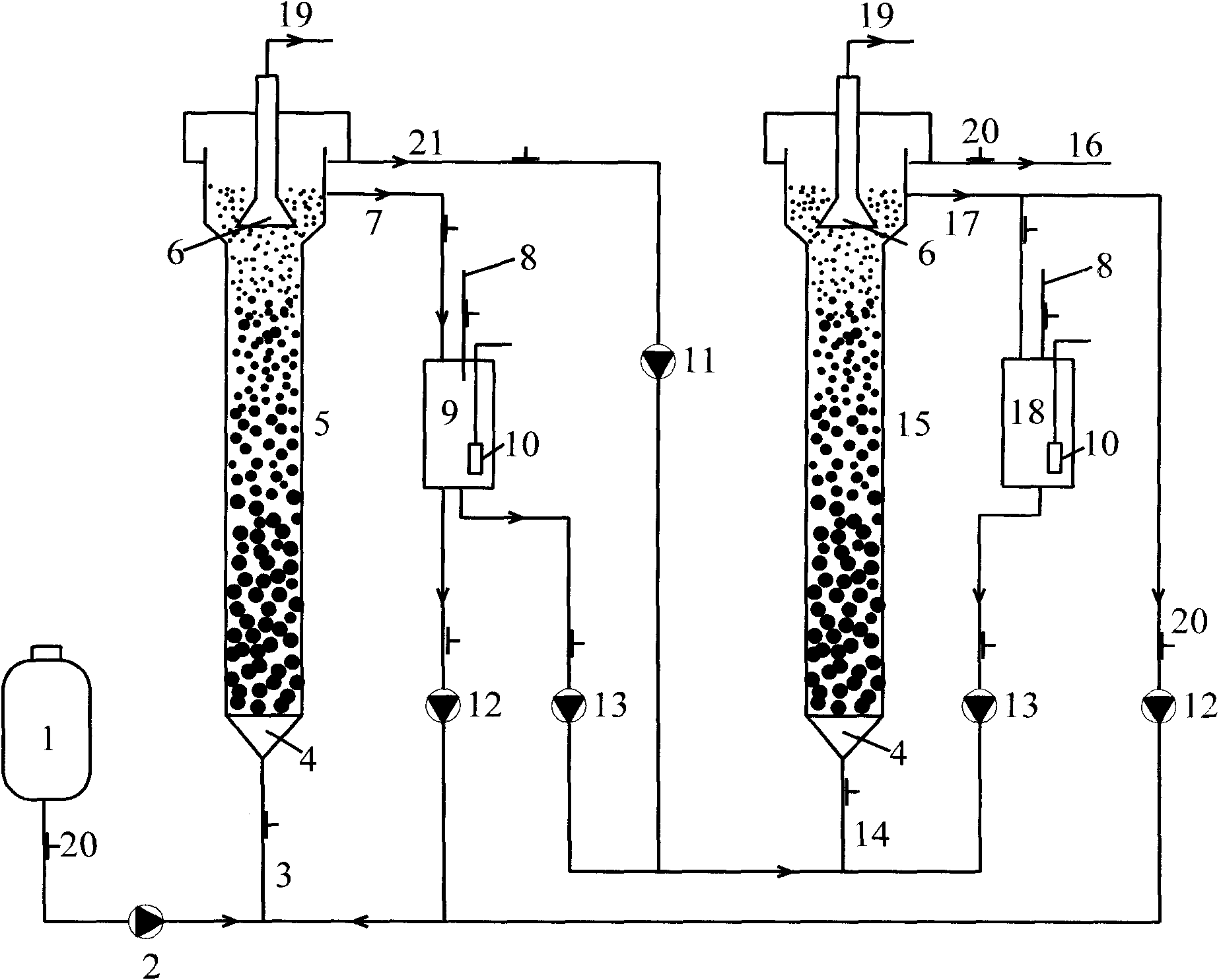

The invention relates to a method and equipment for cross backflow two-stage double-expansion granular sludge treatment of coking wastewater. The method comprises the following steps: introducing the coking wastewater to a first-stage double-expansion granular sludge reactor and degrading the coking wastewater to produce first-stage treated water; delivering a part of the first-stage treated water to a first-stage aeration backflow column and the other part of the first-stage treated water to a second-stage reactor directly; aerating the treated water which enters the first-stage aeration backflow column, allowing a part of the aerated water and return water of second-stage treatment mixed directly and flow to the first-stage reactor, and making the part of the aerated water and the aerated water of the second-stage treatment mixed and flow into the second-stage reactor; degrading the treated water which enters the second-stage reactor to produce water of the second-stage treatment, directly discharging a part of the water of the second-stage treatment, and making the other part of water of the second-stage treatment flow into a second-stage aeration backflow column; and aerating other part of the water of the second-stage treated treatment, and returning part of the aerated water of the second-stage treatment to the second-stage reactor, and returning the other part of the aerated water of the second-stage treatment to the first-stage reactor as direct return water of the second-stage treatment. The treatment method and equipment can realize the simultaneous efficient removal of COD and ammonia nitrogen from the coking wastewater.

Owner:太原大学

Ceramic products possessing antisepsis and water mineralization and activation functions, and its preparation method and uses

InactiveCN1733648AGood antibacterialSustainable accessWater/sewage treatment by substance additionCalcium carbonateActivation function

Ceramic products possessing antisepsis and water mineralization and activation functions, and its preparation method and uses, wherein the ceramic product is prepared from the following ingredients (by weight ratio): montmorillonite 25-60 parts, diatomite 10-30 parts, aluminum oxide 5-20 parts, silicon oxide 3-15 parts, calcium carbonate 15-45 parts, multifunctional health ceramic material 5-20 parts, adhesive 9-15 parts through proportioning, disintegrating, mixing, blank making and sintering.

Owner:淄博博纳科技发展有限公司

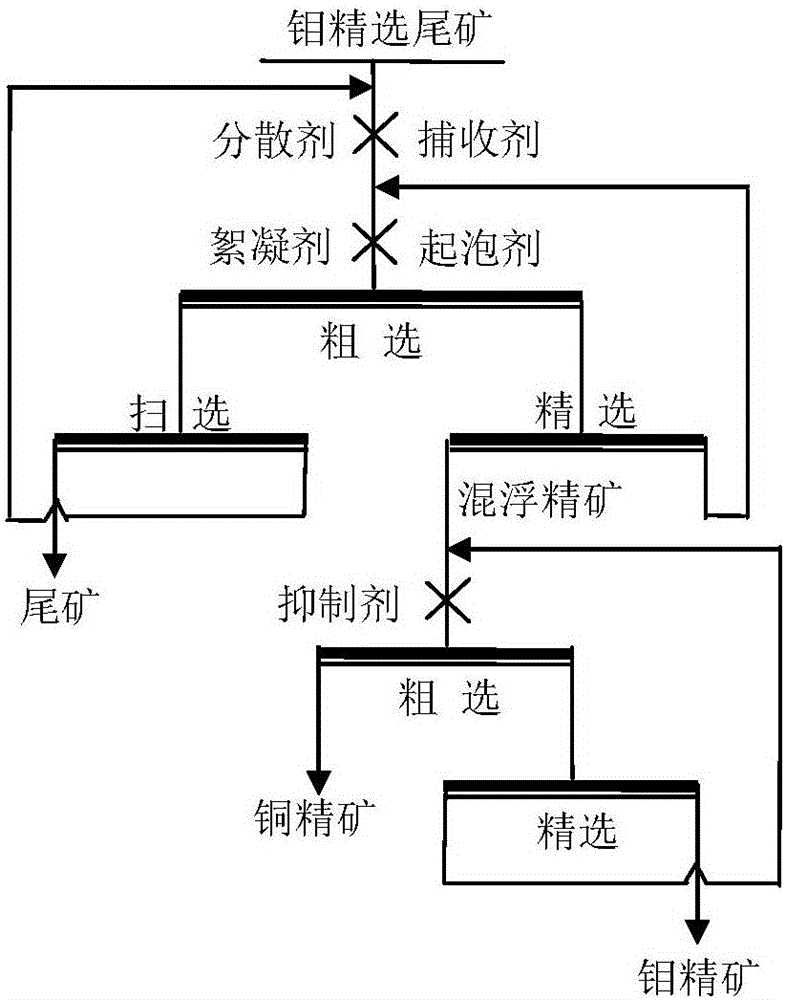

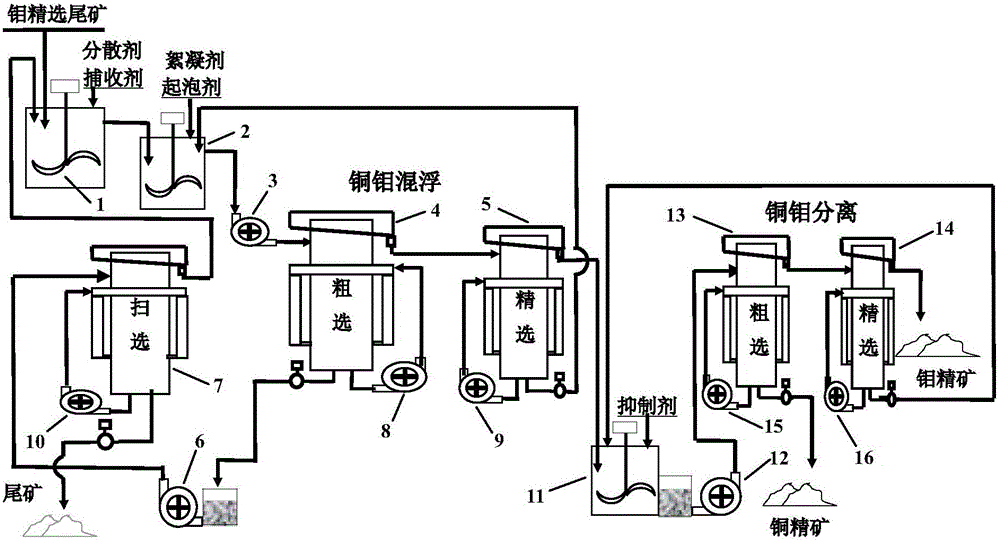

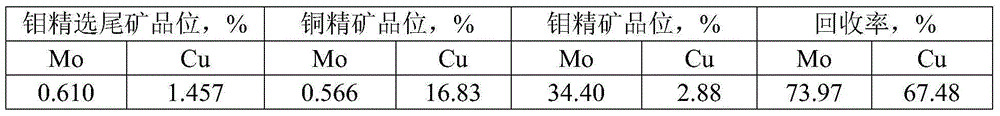

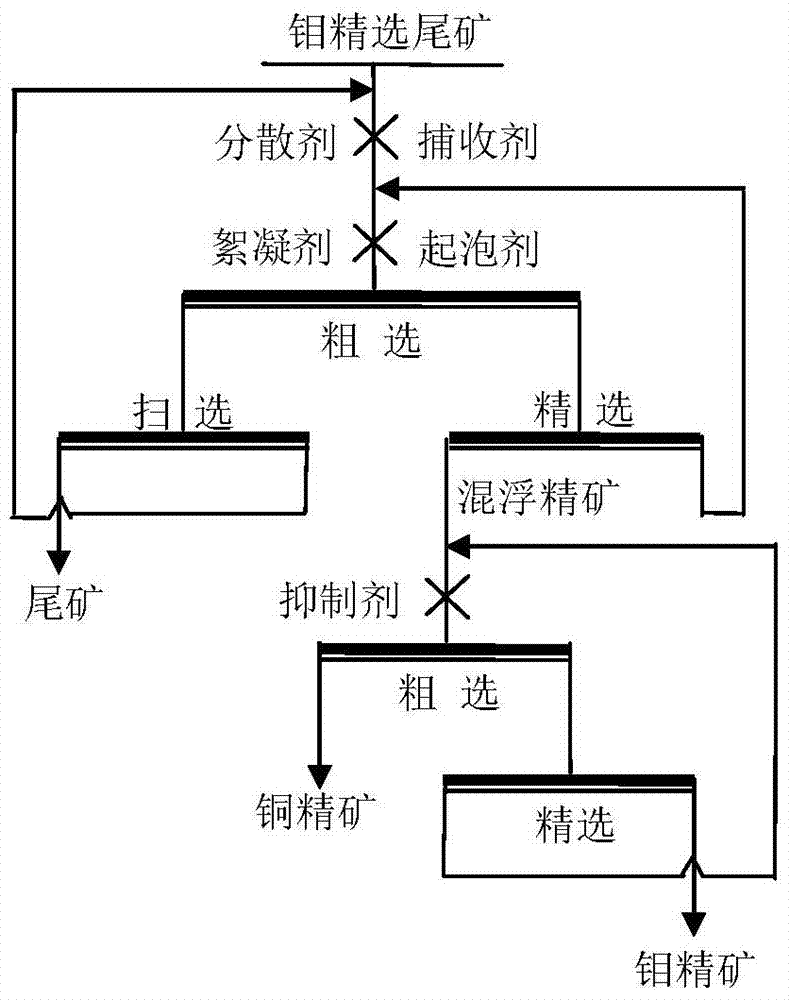

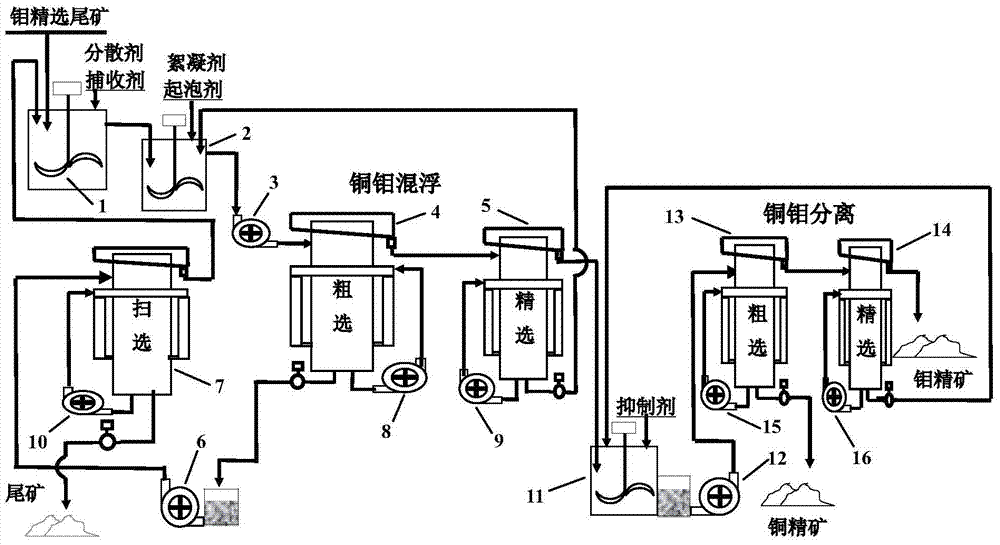

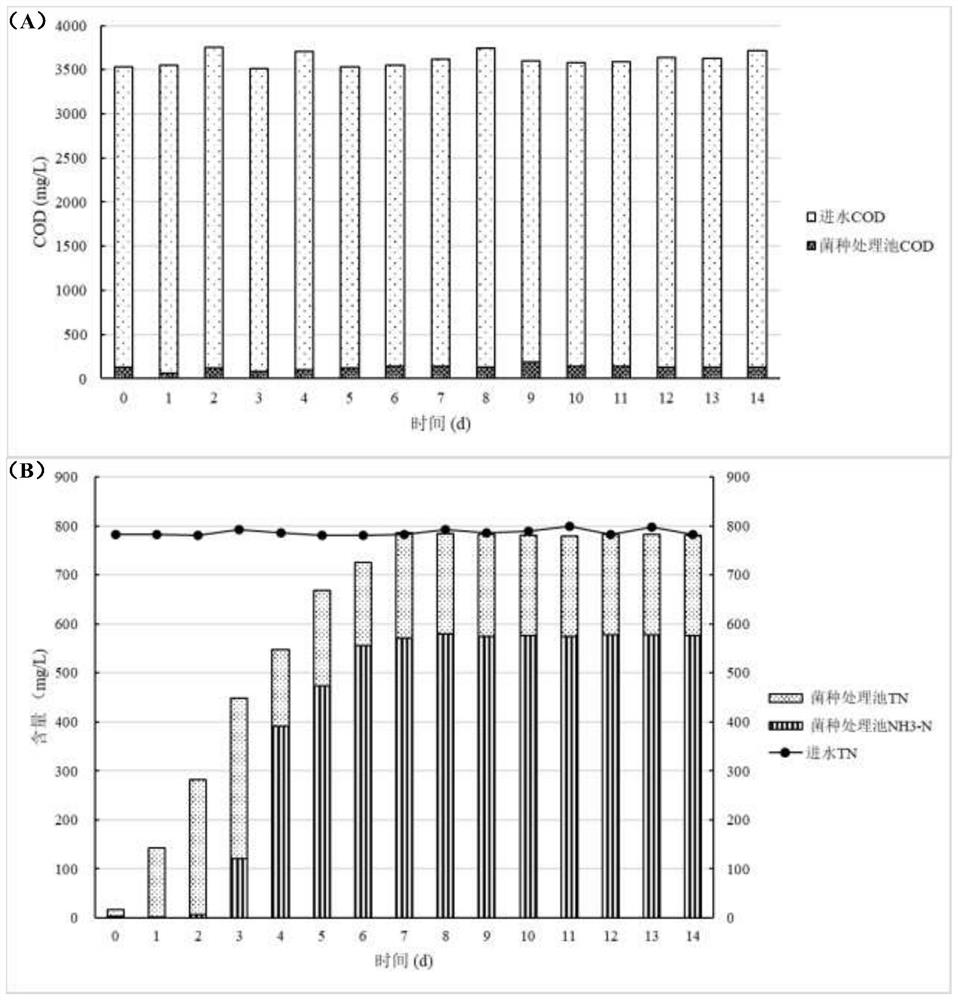

Selective flocculation-column flotation recovery method and system of micro-fine particle molybdenum cleaner tailings

InactiveCN104984835AEnsure efficient sortingGood sorting effectDifferential sedimentationFlotationParticle separationCopper

The invention discloses a selective flocculation-column flotation recovery method and system of micro-fine particle molybdenum cleaner tailings. The method includes the following steps that: a dispersing agent and a collecting agent are added, so that first stirring and pulp conditioning is performed, and therefore, mineral particles can be fully dispersed, and the surface hydrophobicity of target mineral particles can be improved; a flocculating agent and a foaming agent are added, so that second stirring and pulp conditioning is performed, and therefore, the target mineral particles can be flocculated selectively; the cyclonic-static fine bubble floatatation column is utilized to perform copper-molybdenum mixed floating, and a roughing-concentration-scavenging floatation process is adopted, and as a result, copper-molybdenum mixed floated concentrates and tailings can be obtained; an inhibitor is added in the copper-molybdenum mixed floated concentrates, so that third stirring and pulp conditioning is performed; and the cyclonic-static fine bubble floatatation column is utilized to perform copper-molybdenum separation, and a roughing-concentration floatation process is adopted, so that molybdenum concentrates and copper concentrates can be obtained. According to the selective flocculation-column flotation recovery method and system of micro-fine particle molybdenum cleaner tailings of the invention adopted, two kinds of micro-fine particle separation ways, namely, selective flocculation and column flotation, are adopted to recover molybdenum and copper in molybdenum concentrates and tailings, and therefore, the comprehensive utilization rate of mineral resources can be improved, and the selective flocculation-column flotation recovery method and system have excellent economic benefits and social benefits.

Owner:CHINA UNIV OF MINING & TECH

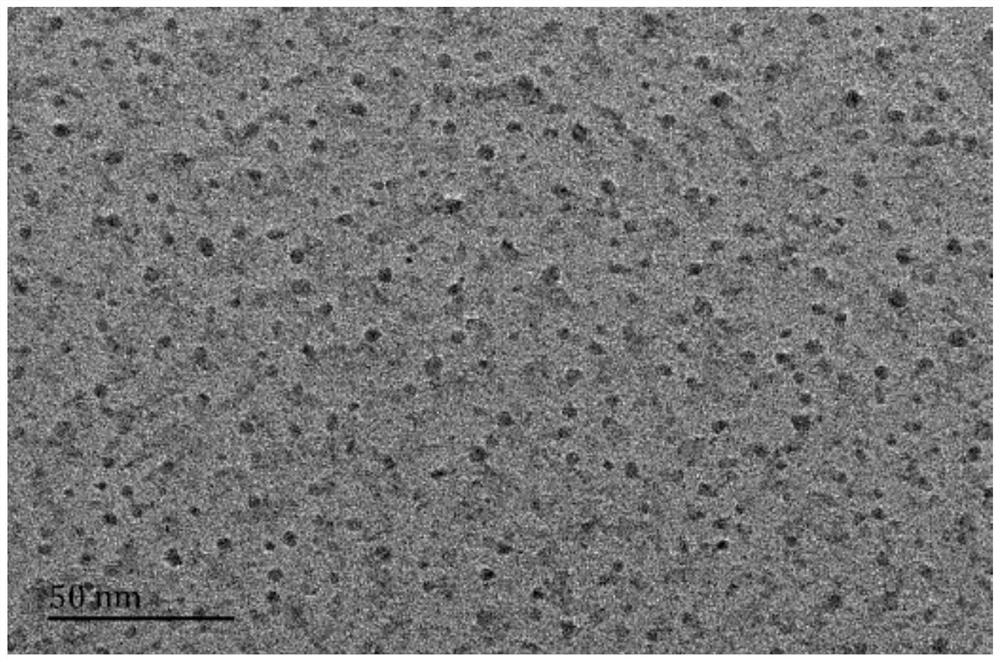

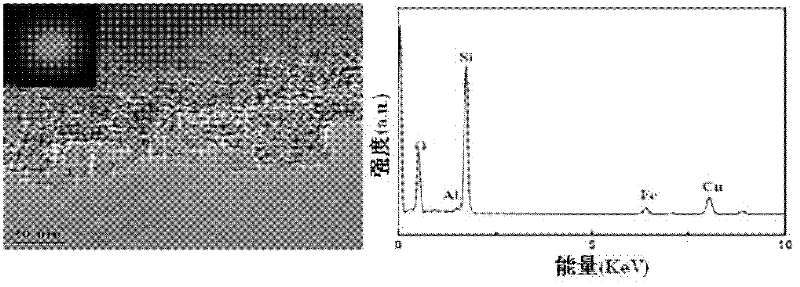

Nano zero-valent iron carbon material and preparation method and application thereof

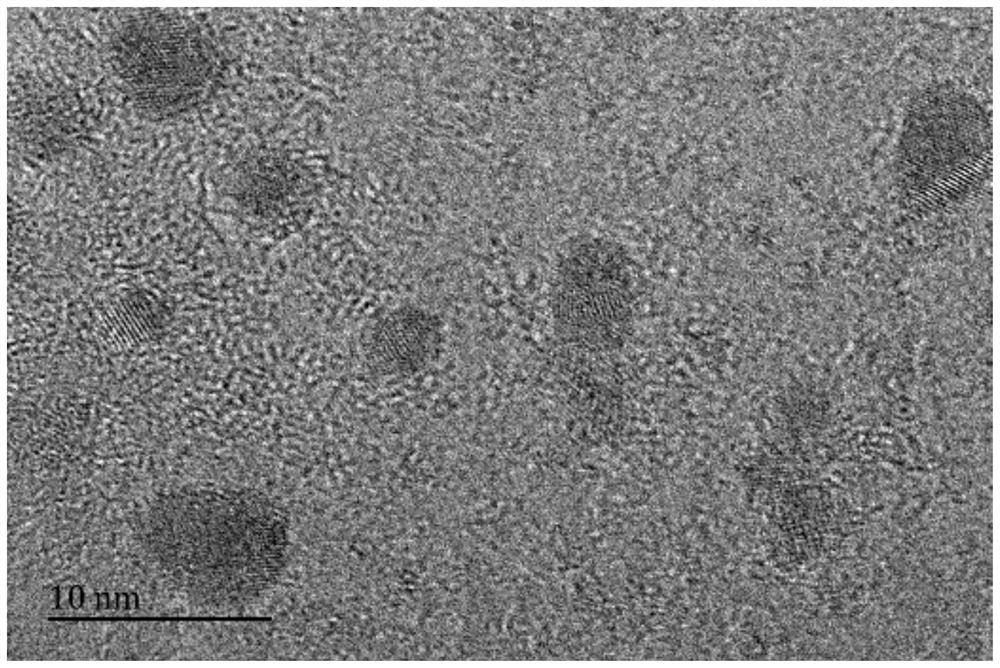

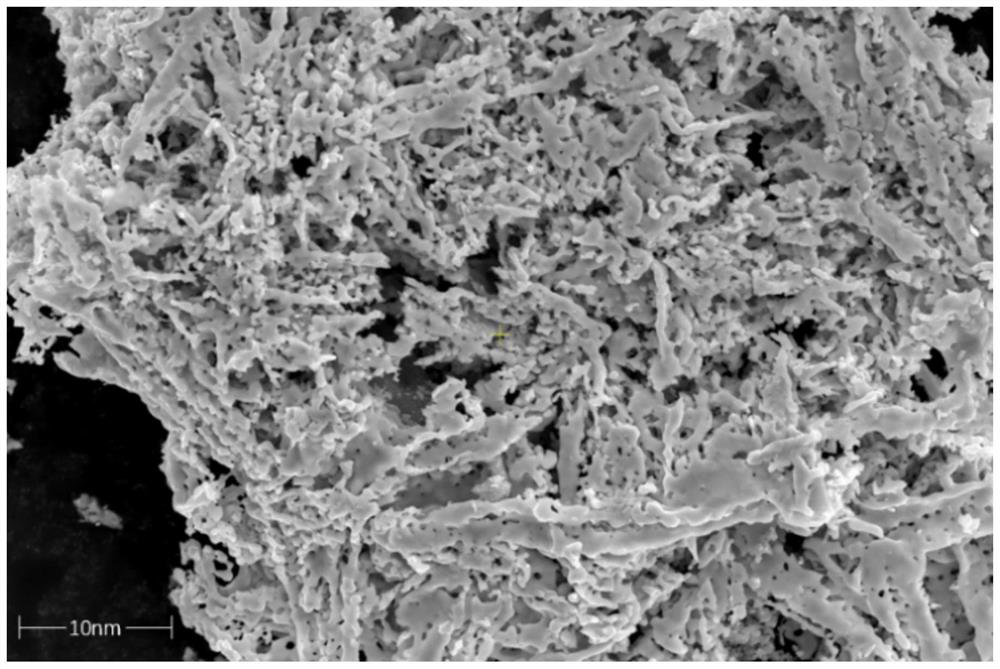

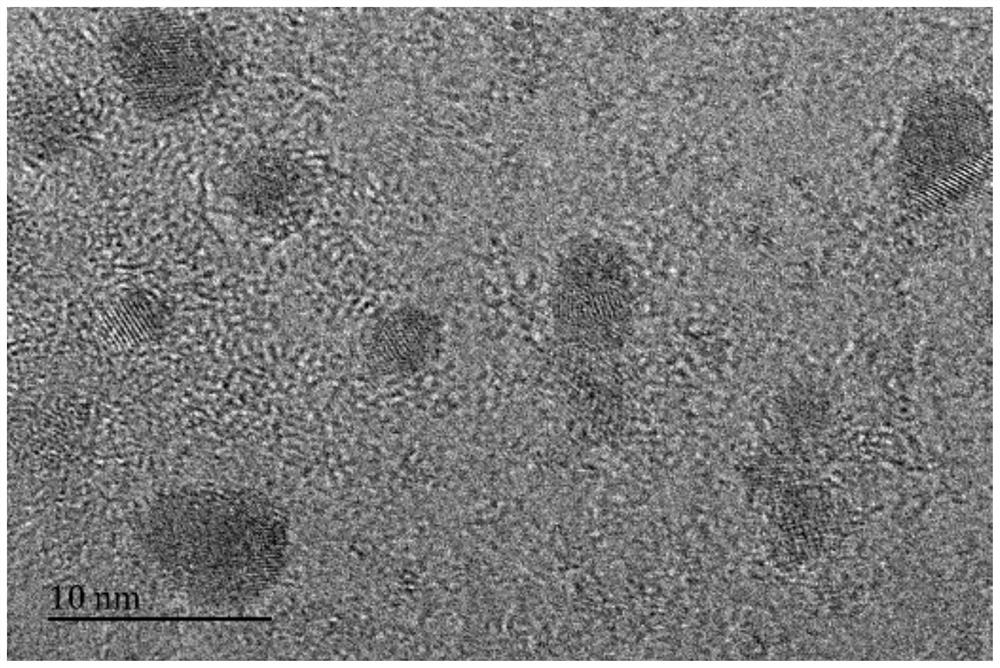

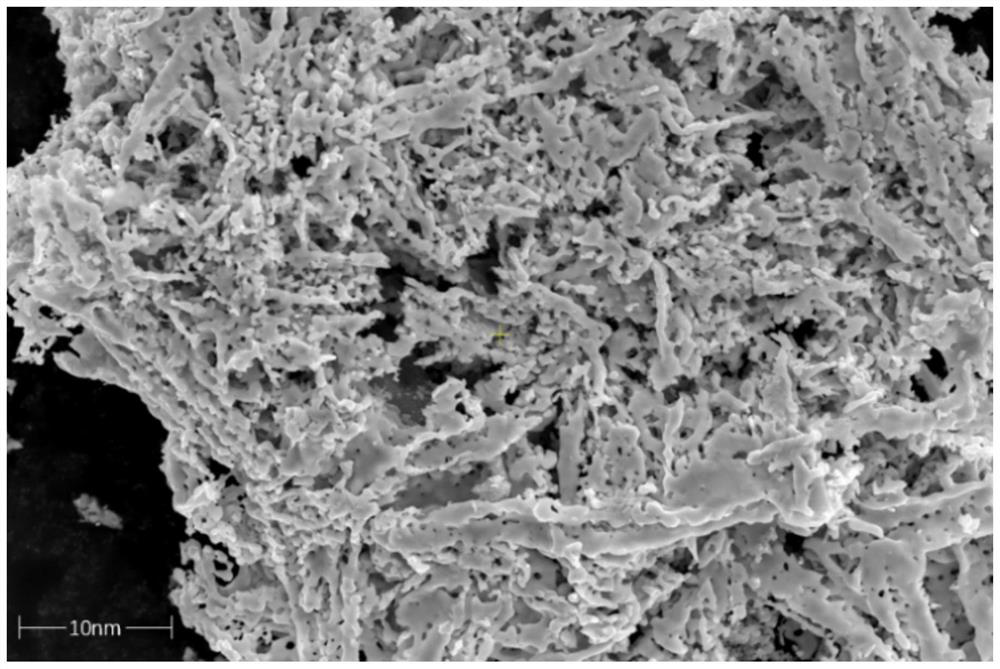

ActiveCN112607832AEffective size controlSmall sizeWater contaminantsWater/sewage treatment using germicide/oligodynamic-processCarbon layerPhysical chemistry

The invention relates to the field of nanometer materials, in particular to a nano zero-valent iron carbon material and a preparation method and application thereof. The material comprises a carbon layer and superfine nanoscale zero-valent iron uniformly distributed in the carbon layer, the iron content is as high as 92-97%, the particle size of the nanoscale zero-valent iron is 3-8 nm, further, the elemental composition of the nanoscale zero-valent iron carbon material further comprises at least one of oxygen and nitrogen, coordination bonds exist between iron and nitrogen, the nano zero-valent iron carbon material is a porous material, the specific surface area is 120-140 m < 2 > / g, the pore volume is 0.3-0.4 cm < 3 > / g, and the pore diameter is 2-3 nm. The nano zero-valent iron carbon material provided by the invention has good activity of degrading organic pollutants, and can be used in sewage treatment of organic matter pollution.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

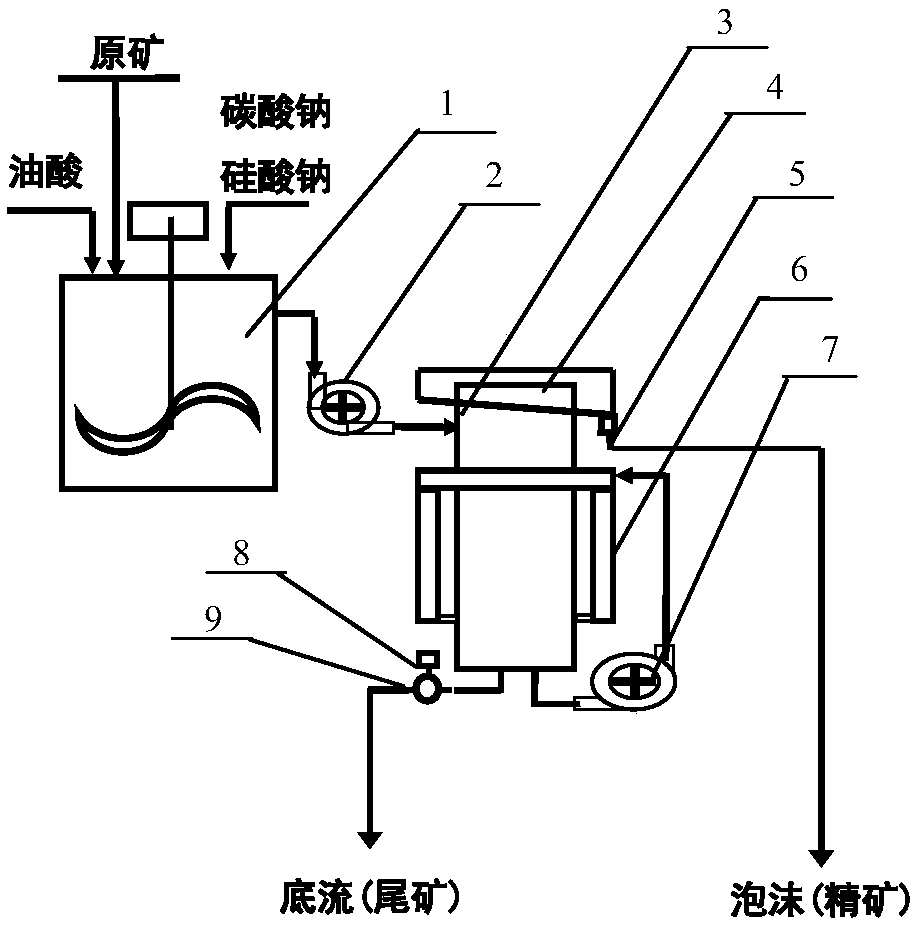

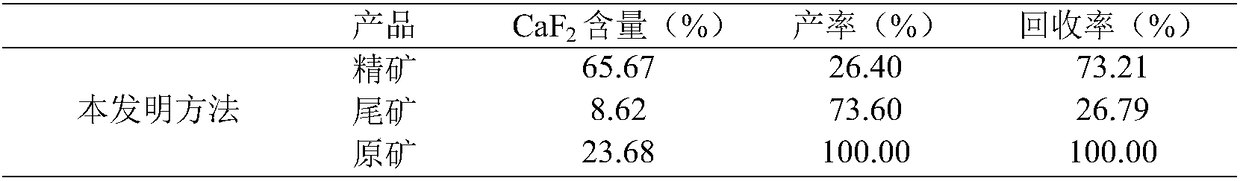

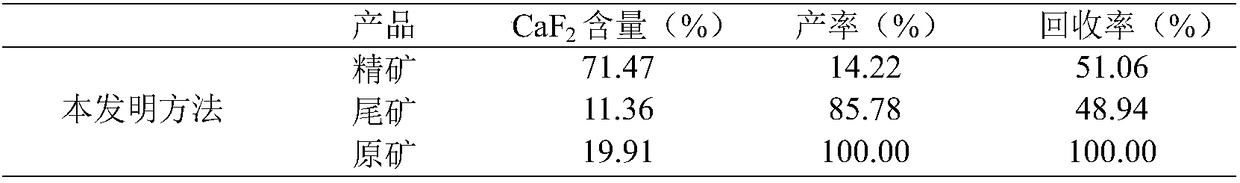

Method for recovering low-concentration calcite type fluorite tailing containing mica

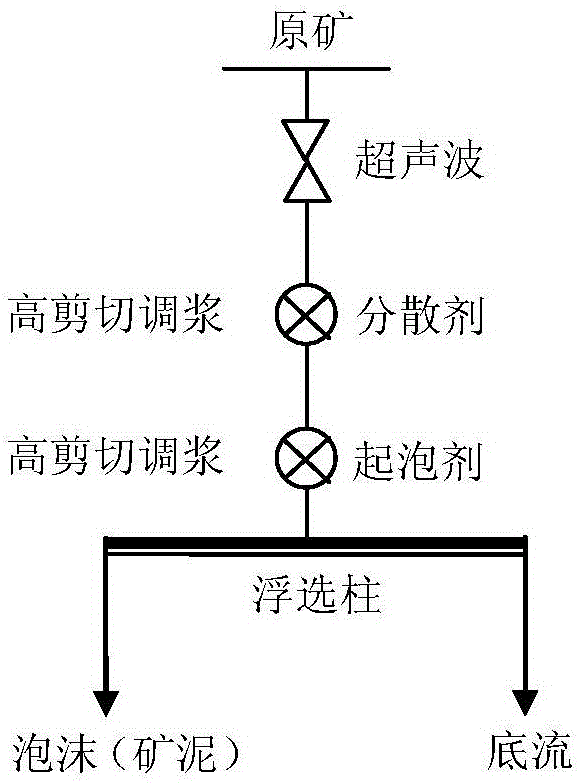

The invention relates to a method for recovering a low-concentration calcite type fluorite tailing containing a mica, and belongs to an efficient recovery method for comprehensive utilization of mineral resources. The method comprises the following steps that a swirling flow-static microbubble flotation column system is adopted, wherein the swirling flow-static microbubble flotation column systemcomprises a stirring barrel, a feeding pump, a feeding port, a flotation column, a concentrate port, a bubble generator, a circulating pump, an electric valve and a tailing port; a on-site low-concentration fluorite tailing containing the mica is directly sent into the stirring barrel as raw ore pulp, firstly, high-speed shearing and stirring pretreatment is carried out through the stirring barrel, then dispersant, inhibitor and collector are sequentially added according to the mass ratio to carry out stirring and size mixing, and then a mixture is sent into the flotation column from the feeding port through the feeding pump to be directly sorted and recovered, concentrate floats upwards and flows out from the concentrate port, the tailing flows out from the tailing port under the action of the electric valve, and thus the fluorite tailing can be quickly and effectively recovered. The problems of low utilization rate of an existing tailing pond, long process flow, high cost, poor separation efficiency, and the flocculation water pollution existing in tailing recovery are solved.

Owner:CHINA UNIV OF MINING & TECH

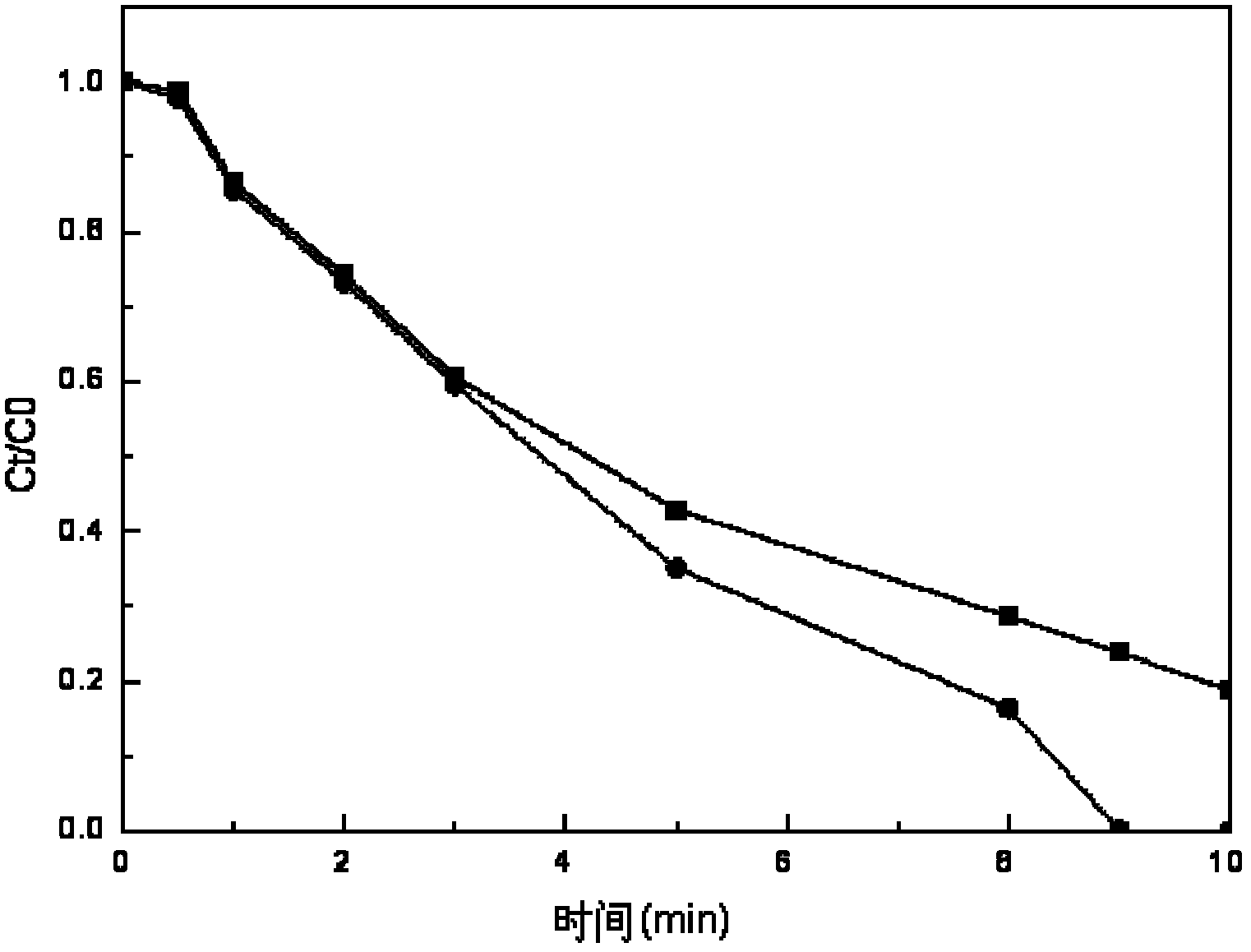

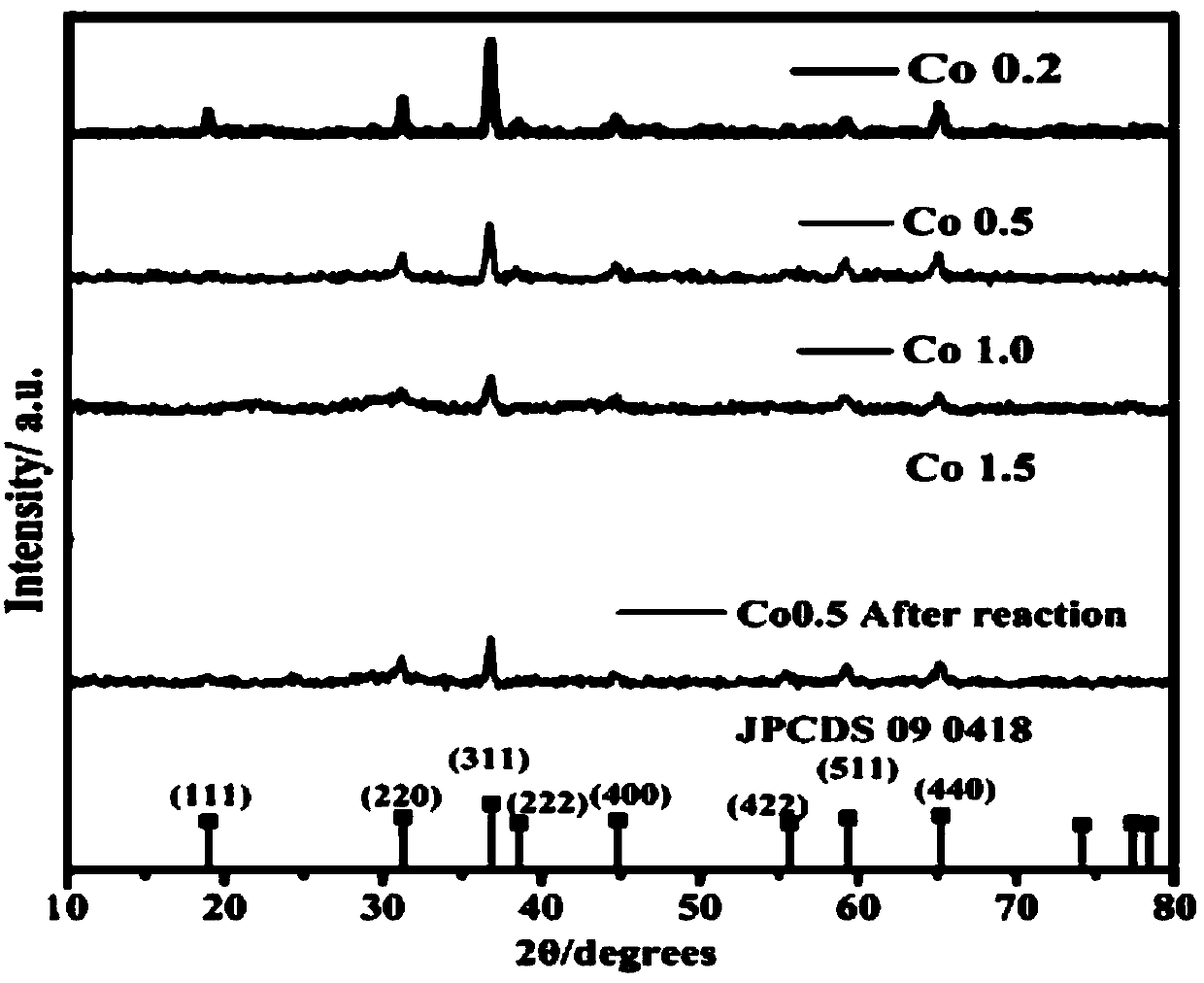

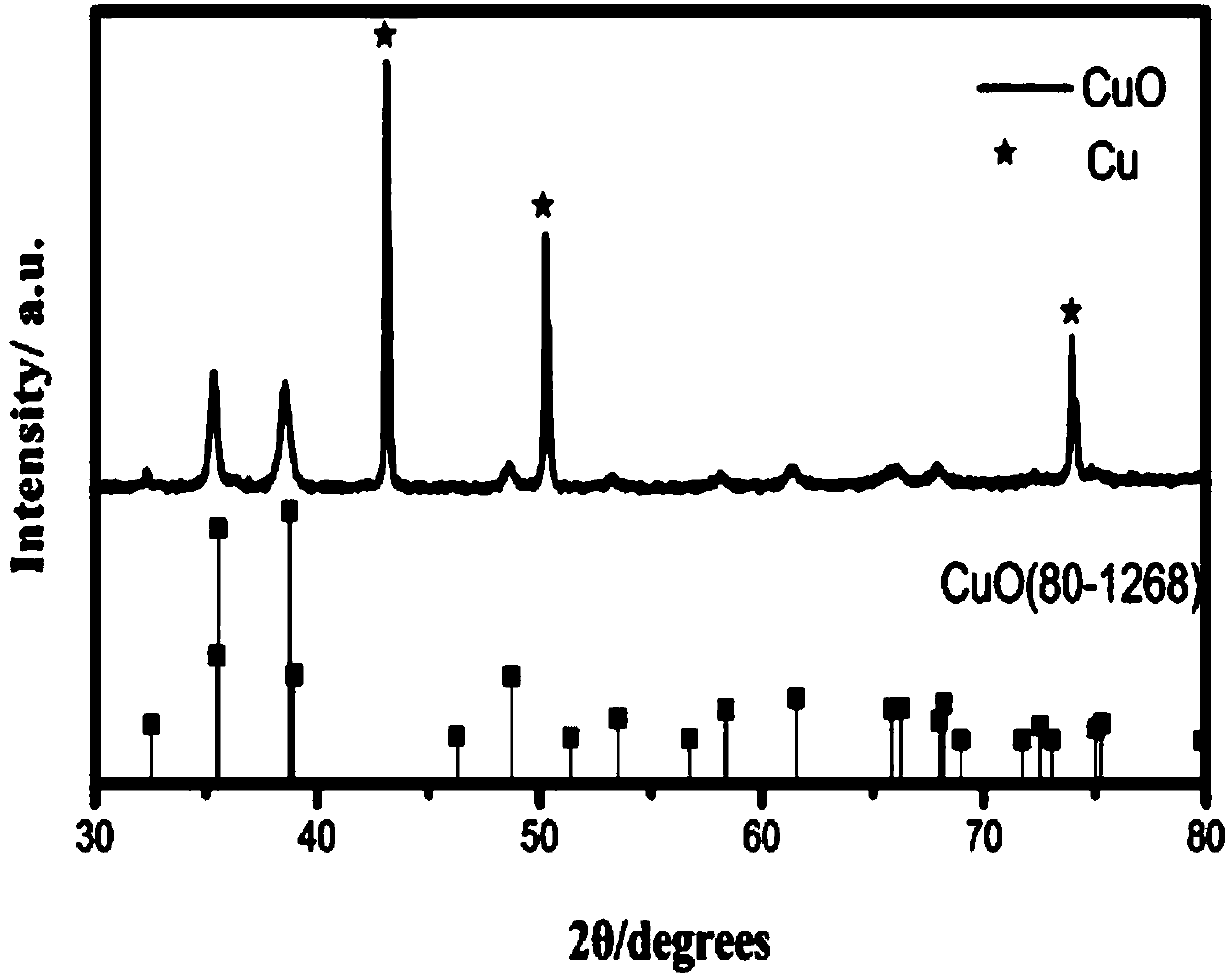

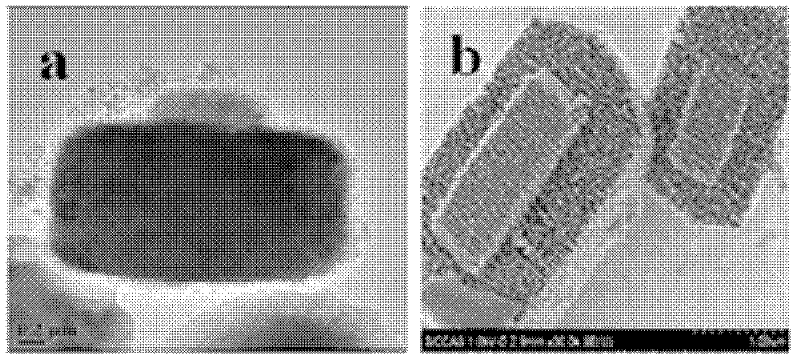

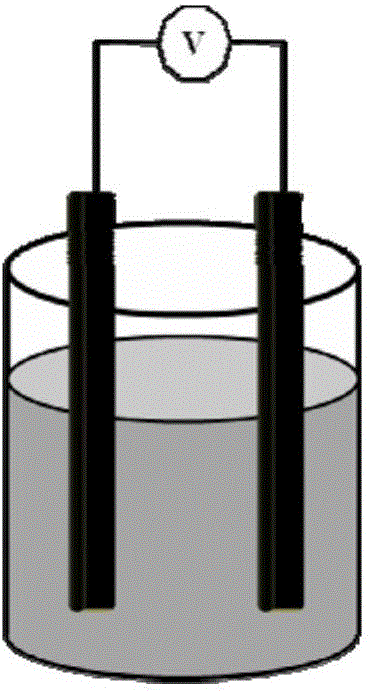

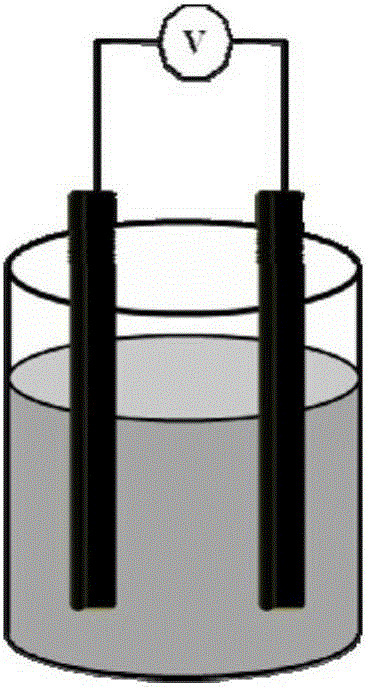

Electrocatalytic coupling advanced oxidation system

ActiveCN108033522AEfficient mineralizationEasy to recycleWater contaminantsWater/sewage treatment by oxidationHydrocarbonCarbon dioxide

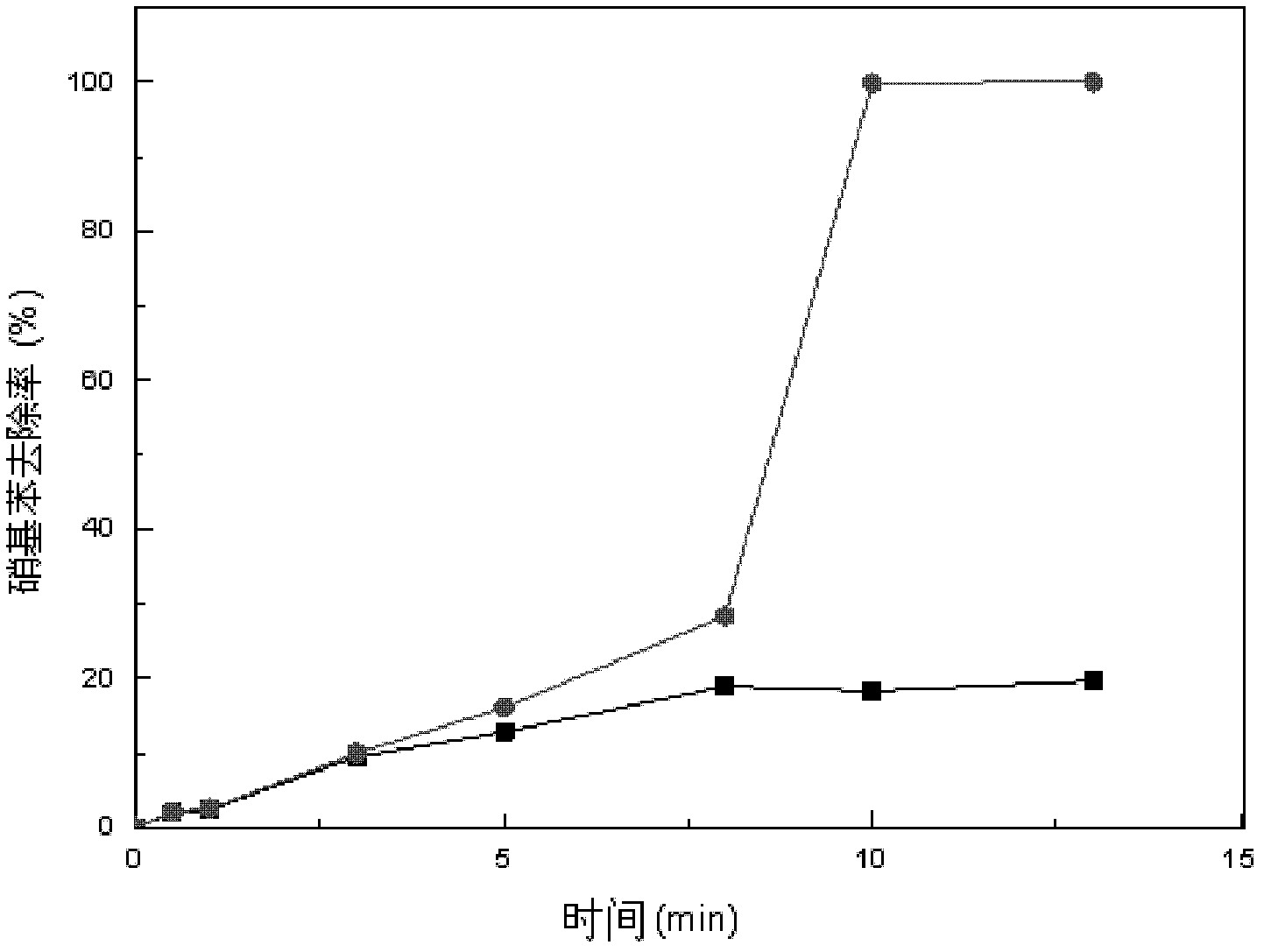

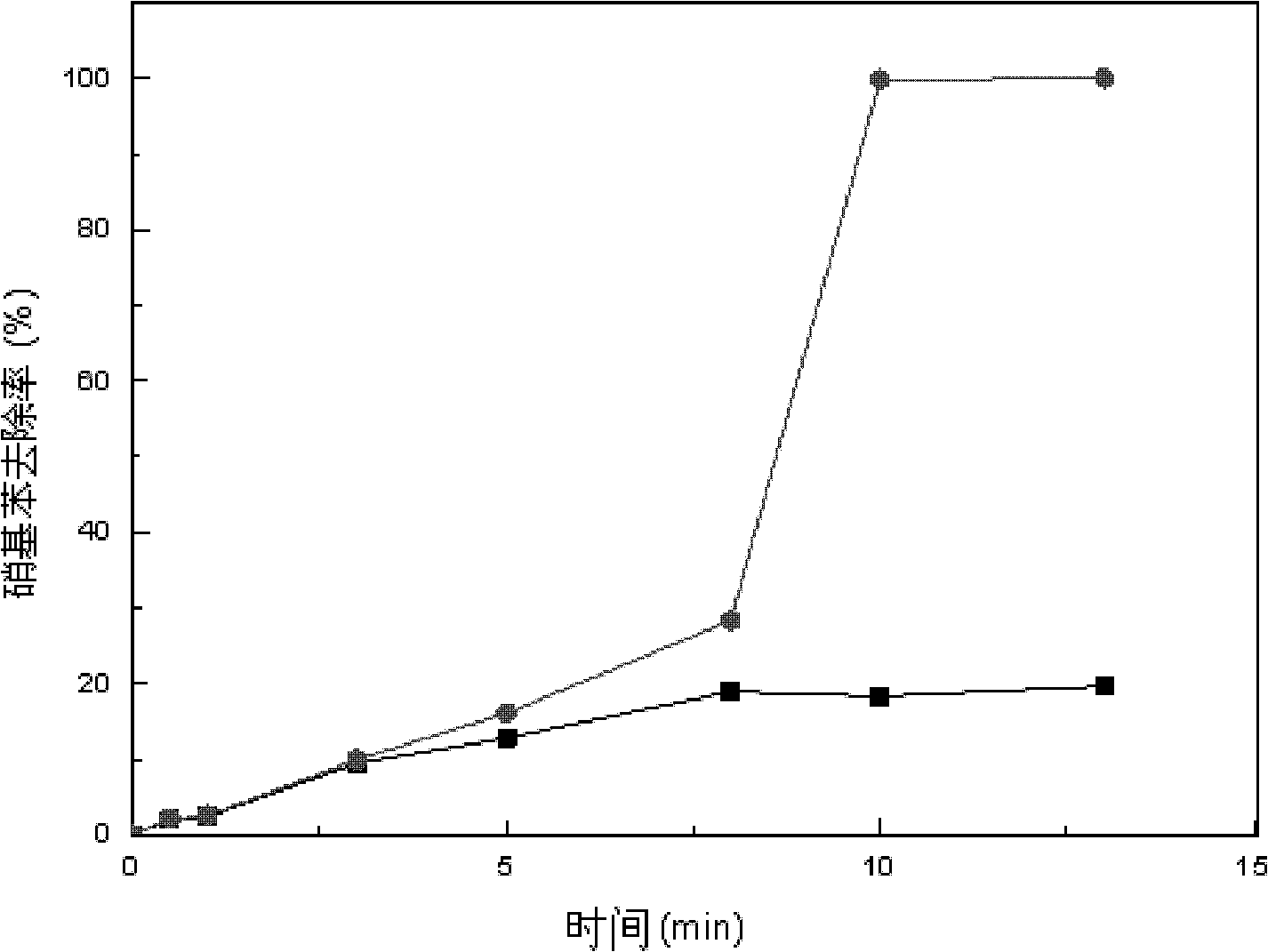

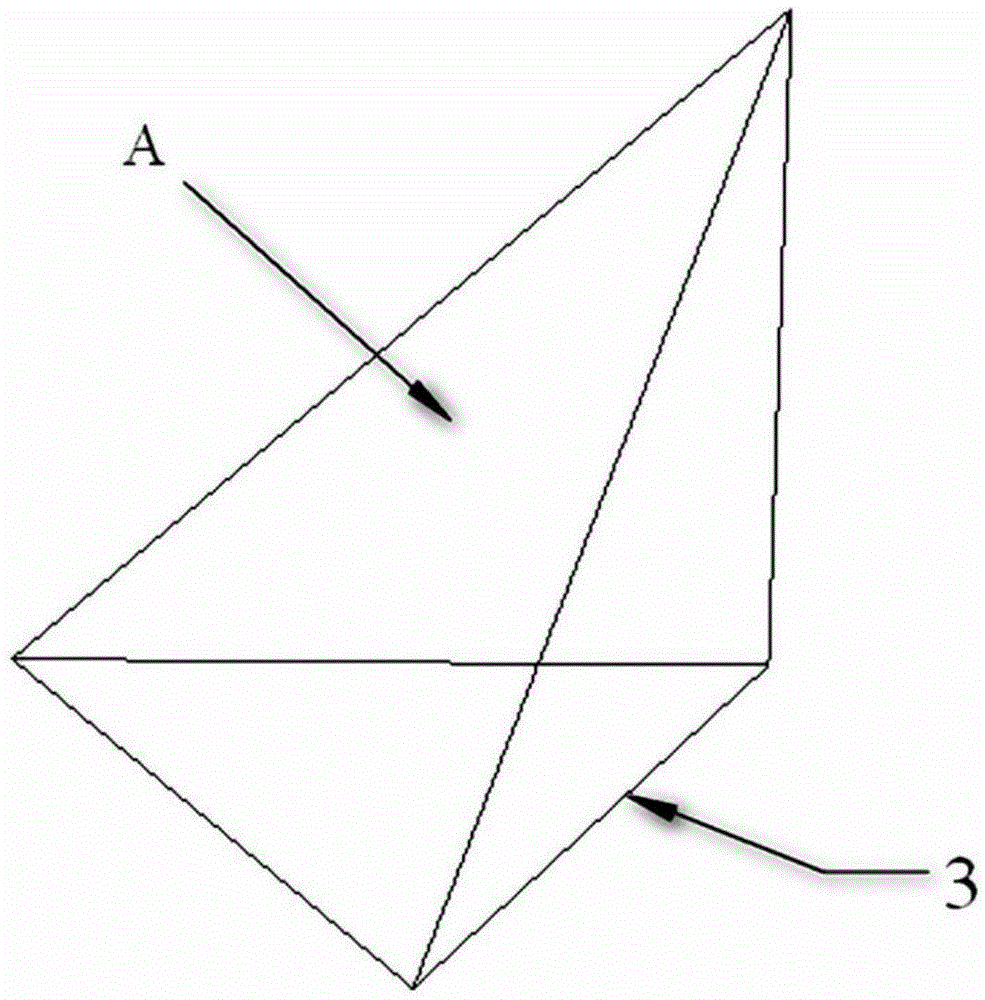

The invention provides an electrocatalytic coupling advanced oxidation system. The system can degrade organic pollutants into carbon dioxide and the carbon dioxide is synchronously electrocatalytically reduced to a hydrocarbon. In the catalytic system, three-dimensional hexagram-shaped Co3O4 and nano-sheet stack flower-shaped CuO are respectively used as an anode material and a cathode material, and the two electrode materials are prepared by a solvothermal method. In the three-electrode system electro-catalytic process, the Co3O4 electro-anode can thoroughly mineralize p-nitrophenol to CO2 and H2O, and the CuO electro-cathode can synchronously reduce the generated carbon dioxide into the useful hydrocarbon. When the additionally-applied bias voltage is 0.8V vs Ag / AgCl, the material has anoptimal catalytic effect, the removal rate of the p-nitrophenol can reach 98% or more, and the yields of methanol and ethanol reach 49.145 micromol / L / h and 20.475 micromol / L / h, respectively.

Owner:NANCHANG HANGKONG UNIVERSITY

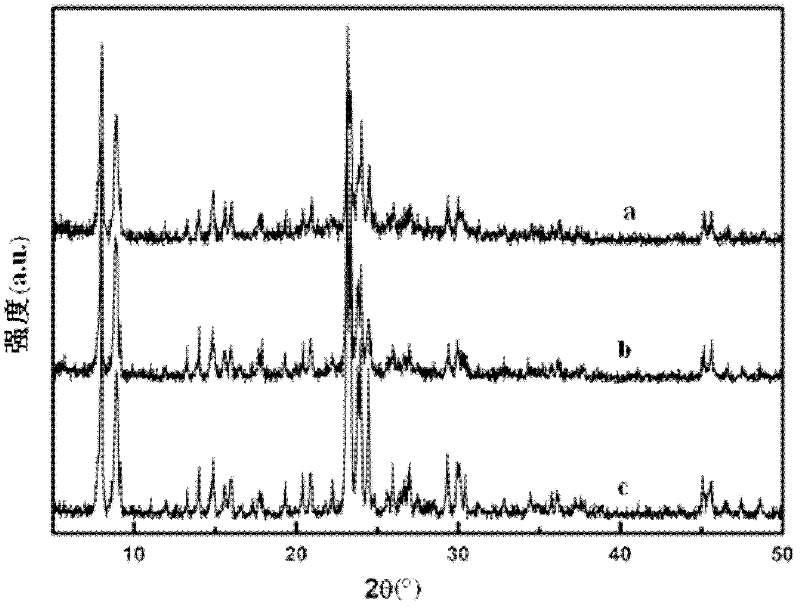

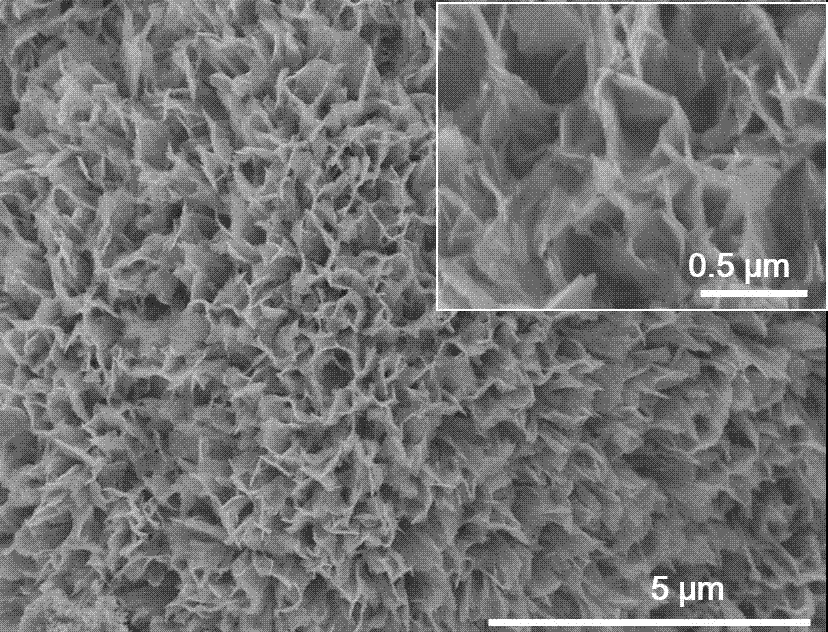

Photocatalyst and preparation method and application thereof

InactiveCN102513141AEfficient decolorizationStrong applicabilityWater/sewage treatment by irradiationMolecular sieve catalystsIonIon exchange

The invention discloses a photocatalyst and a preparation method and an application thereof. The photocatalyst is a mesoporous zeolite material loaded with iron ions, and the iron ions lie in the skeleton position and / or mesoporous channels of the mesoporous zeolite. The photocatalyst is prepared by using ion exchange method or insitu doping method to load the iron ions in the skeleton and / or the mesoporous channels of the mesoporous zeolite. The photocatalyst provided by the invention can efficiently decolor, degrade and mineralize organic dyes in ultraviolet lights, and can efficiently decolor, degrade and mineralize organic dyes in visible lights, thus the photocatalyst has strong applicability and has important meaning in practical application. In addition, the photocatalyst has good stability, can be recycled, and can be prepared and processed simply and practicably, thus the waste water treatment cost can be greatly reduced, the industrial requirements of scale and economy of the waste water treatment are satisfied, and the photocatalyst has significant effect and application values.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

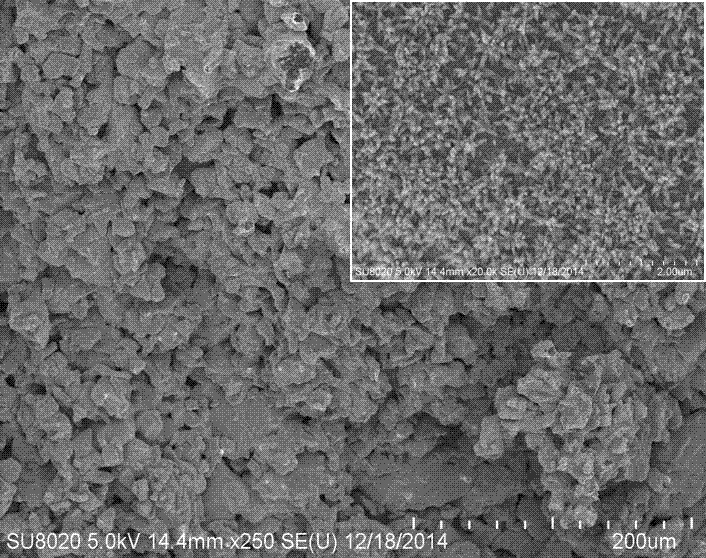

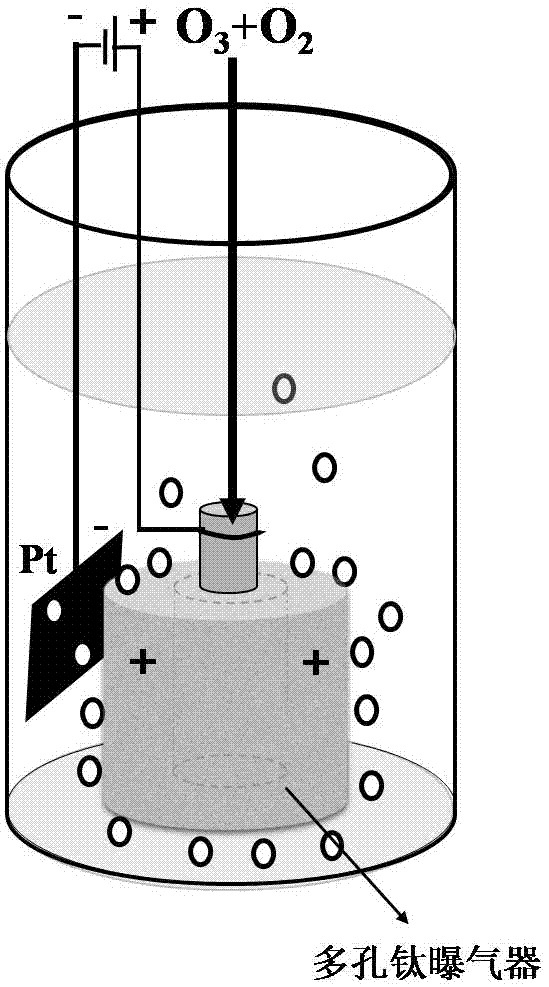

Porous titanium ozone aerator with ozone heterogeneous catalysis and electrocatalysis functions

ActiveCN107021583AEfficient mineralizationImprove degradation efficiencyWater contaminantsMultistage water/sewage treatmentTreatment effectNanowire

A porous titanium ozone aerator with ozone heterogeneous catalysis and electrocatalytic functions is disclosed, and the porous titanium ozone aerator comprises a porous titanium substrate and a catalytic layer loaded on the substrate. The catalyst layer is an oxide of Ti, Mn, Ce, Cu, Fe, Ni, Sn, Sb, Pb and the like or a composite of the metal oxides, and the oxide morphology can be nanoflowers, nanowires, nanorods and nanotubes. The porous titanium ozone aerator gives ozone ozone heterogeneous catalysis and electrocatalysis synergistic catalysis capability, and can achieve efficient catalytic reaction of gas, solid and liquid three phases of pollutants in the aerator to reach the object of high mineralization and removal of target pollutants. The porous titanium ozone aerator is used for drinking water treatment, wastewater treatment and other occasions using the ozone, and has the characteristics of strong oxidation ability, fast reaction speed, stable treatment effect, long service life, low investment, wide application scope, and the like, and has good application prospects.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

Micropore ceramic ball applying in preparing purified, antibiotic and activated water, and its preparation method

InactiveCN1733654AFit closelyEasy to handleWater/sewage treatment by substance additionCeramicwareAdhesiveCoal

Micropore ceramic ball applied for preparing purified, antibiotic and activated water, and its preparation method, which is prepared from ceramic raw materials, pore forming agent and adhesive through disintegrating, proportioning, ball forming, sintering, grinding and water scrubbing, the raw materials comprises glass, coal ash, alta-mud, active clay, grammite, multifunctional health ceramic material, pore forming agent and adhesive by the proportions of 60-75 parts, 5-15 parts, 0-20 parts, 0-20 parts, 5-15 parts, 0.1-1 part and 9-15 parts.

Owner:淄博博纳科技发展有限公司

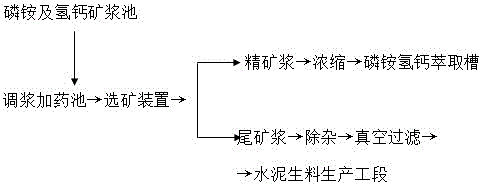

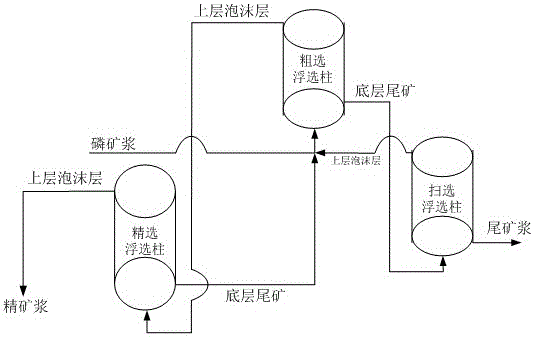

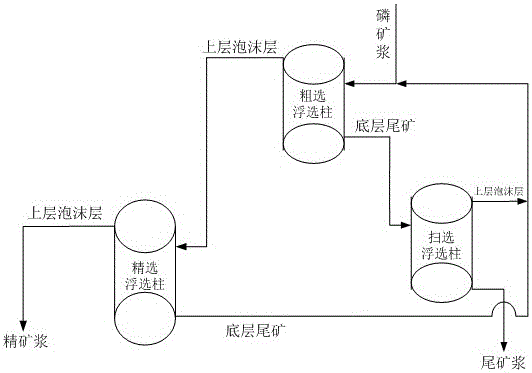

Collophanite dressing technology

The invention discloses a collophanite dressing technology. The treatment technology comprises: dressing phosphoric ore pulp by an ore dressing device, and respectively concentrating concentrate pulp and tailing pulp, obtained by ore dressing, so as to obtain phosphoric concentrate and tailing. Ore dressing verification is sequentially carried out medium and low grade phosphoric ore by the treatment technology. Superior phosphoric concentrate containing 31-33% of P2O5 is obtained through treating low-grade phosphoric ore containing 15-20% of P2O5. Superior phosphoric concentrate containing 32-35% of P2O5 is obtained through treating medium-grade phosphoric ore containing 25-27% of P2O5. The removal rate of MgO is 90%, and the removal rate of R2O3 (Fe2O3 and Al2O3) is 80-90%. The chemicals are nontoxic and harmless, are easy to degrade in life, are environment-friendly and meet environment protection requirements.

Owner:CENT SOUTH UNIV +1

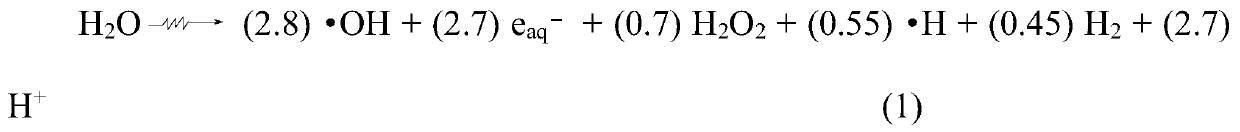

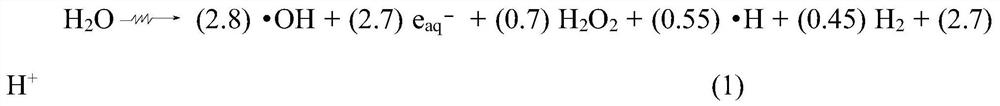

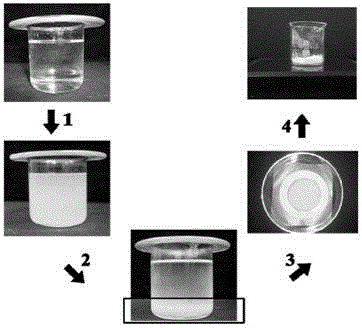

Method for degrading organic pollutants in water by ionization irradiation

ActiveCN111115745AEfficient degradation abilityEfficient mineralizationWater/sewage treatment by irradiationRadiation applicationsIndustrial waste waterSewage

The invention belongs to the technical field of sewage treatment, and particularly relates to a method for removing degradation-resistant organic pollutants in water by enhanced ionization irradiation. The method comprises the following steps: uniformly mixing wastewater containing organic pollutants with a certain amount of MOF or derivative materials thereof, and carrying out ionization irradiation treatment. The method is high in irradiation efficiency and can be carried out at normal temperature; the MOF material can be repeatedly used; and the method can be applied to treatment of urban sewage plant effluent, pharmaceutical wastewater, dye wastewater and other degradation-resistant industrial wastewater.

Owner:TSINGHUA UNIV

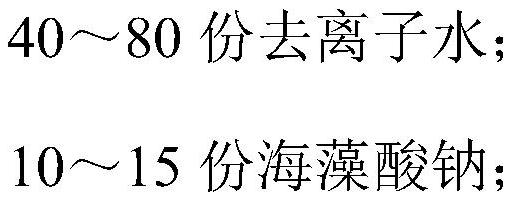

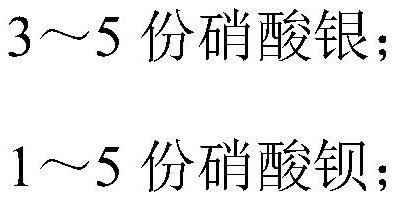

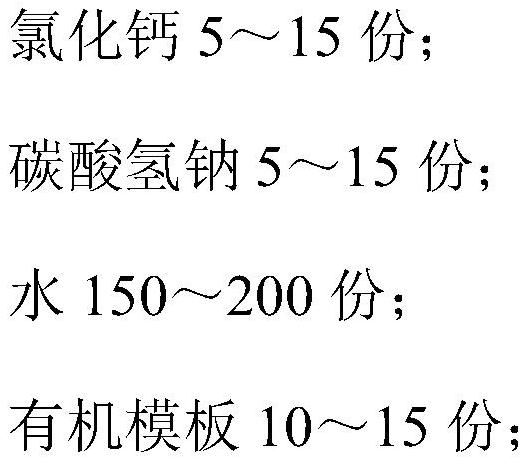

Concrete self-repairing material, and preparation method thereof and concrete with concrete self-repairing material

InactiveCN113149496AIncreased durabilityExtended service lifeCalcium/strontium/barium carbonatesMicroorganismInorganic particle

Owner:JIANGSU UNIV OF SCI & TECH

Electrocatalysis coupled advanced oxidation system and application thereof

ActiveCN110526343AImprove stabilityEfficient recyclingWater contaminantsWater/sewage treatment using germicide/oligodynamic-processElectricityPotassium persulfate

The invention provides an electrocatalysis coupled advanced oxidation system and an application thereof, and belongs to the technical field of sewage treatment. According to the electrocatalysis coupled advanced oxidation system, advanced oxidation and electrocatalysis are coupled on an anode, and a three-dimensional hexagonal star-shaped Co3O4 anode material can activate potassium persulfate to generate sulfate free radicals, can also electrocatalytically oxidize chloride ions to generate hypochlorous acid active substances, and can electrocatalytically catalyze an oxidation reaction of chloride ions and potassium persulfate to generate hypochlorous acid at the same time, so that organic pollutants can be efficiently and rapidly mineralized into CO2 and H2O.

Owner:NANCHANG HANGKONG UNIVERSITY

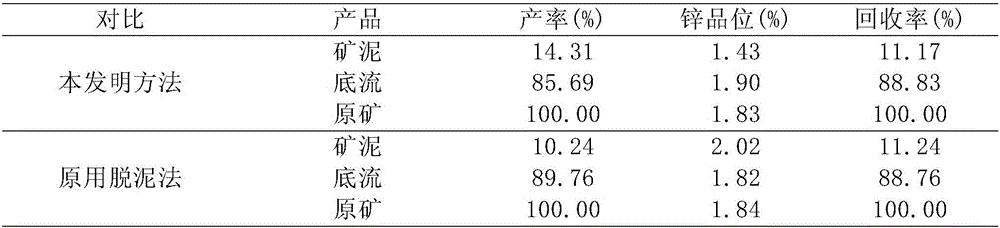

Efficient desliming method for low-grade argillaceous zinc oxide ores

The invention discloses an efficient desliming method for low-grade argillaceous zinc oxide ores, and belongs to efficient desliming methods for mineral products. The method comprises the following steps: pre-treating ore pulp by virtue of an ultrasonic wave at first, then adding a dispersant sodium carbonate and a foamer terpenic oil respectively, carrying out high-shearing and pulp mixing, and carrying out flotation desliming by virtue of a flotation column after uniformly mixing, wherein the frequency of the ultrasonic wave is 20-40kHz, and the power is 50-300W; the amount of the dispersant sodium carbonate is 1000-1500g / t; the amount of the foamer terpenic oil is 10-30g / t; the stirring rotational speed of the high-shearing and pulp mixing is 900-1500r / min; and the flotation column is a rotational flow-static micro-bubble flotation column. The method has the following advantages: the flow is simple, the selectivity and desliming efficiency are high, and the loss of valuable minerals is less during desliming, thus efficient desliming before flotation for the low-grade argillaceous zinc oxide ores is realized; and the loss of zinc metal is less during desliming through effective combination of the ultrasonic wave pre-treatment, the high-shearing and pulp mixing, and the flotation column.

Owner:CHINA UNIV OF MINING & TECH

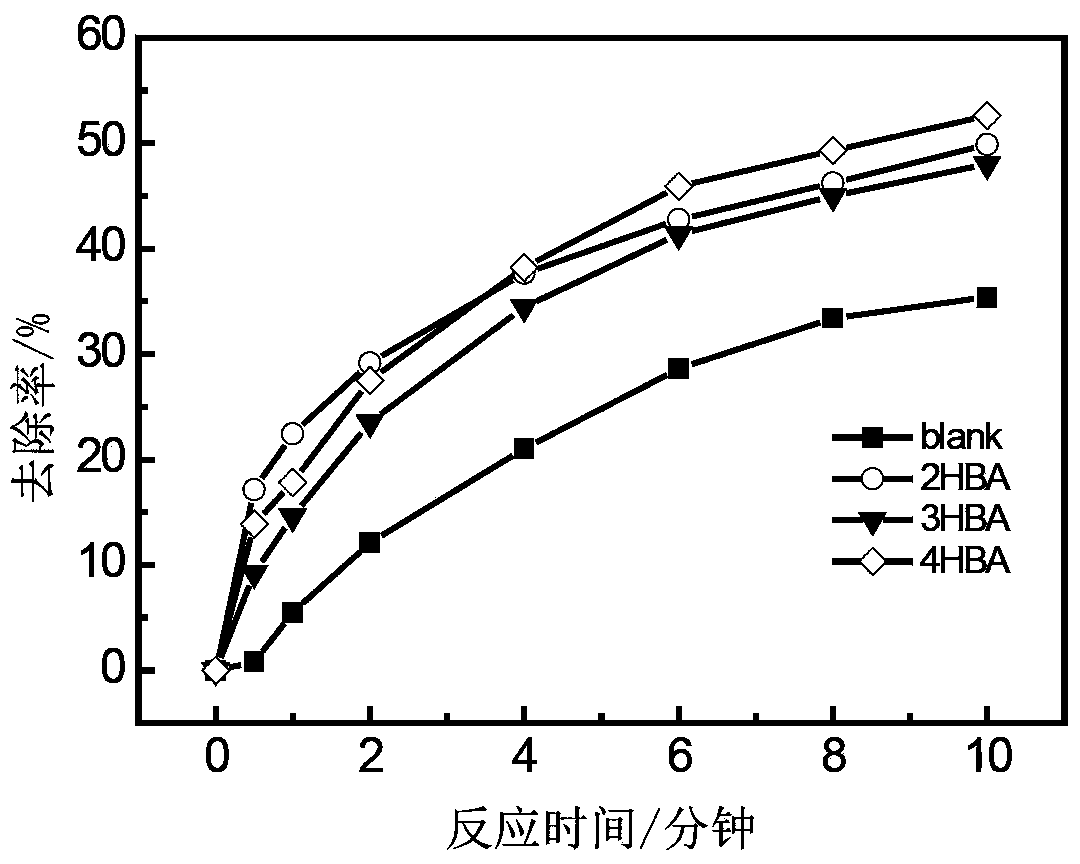

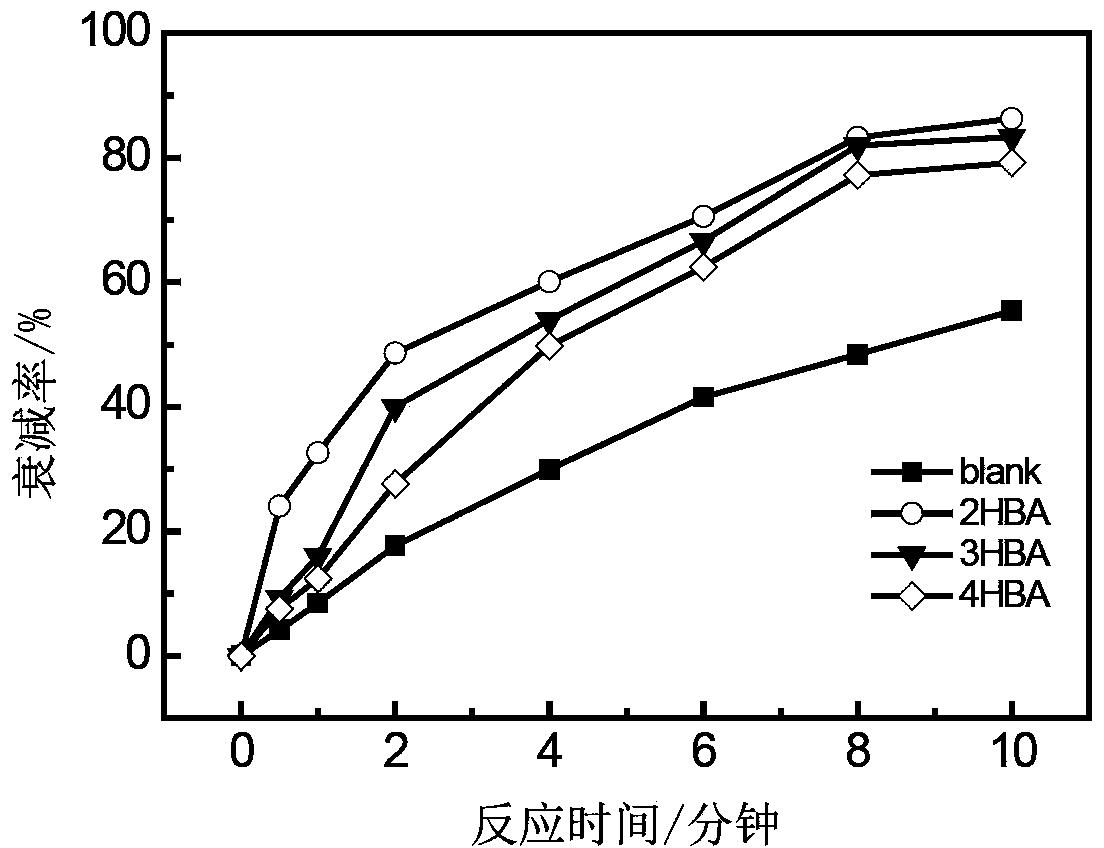

Strengthening method for pollution removing by ozone acidic oxidation

ActiveCN103466780ATurbidity UnlimitedChroma UnlimitedWater/sewage treatment by oxidationBenzoic acidSalicylic acid

The invention discloses a strengthening method for pollution removing by ozone acidic oxidation, and belongs to the technical field of water processing. The strengthening method comprises: simultaneously adding ozone and an intensifying agent into pollution-containing acidic water, then stirring uniformly by waterpower or machinery and reacting, wherein the adding amount of ozone is 0.5-30 mg / L and the molar ratio of the intensifying agent to ozone is 1:5-1000, and waterpower staying time is 1-20 min, and the intensifying agent is one kind or any combination of benzoic acid, salicylic acid, p-hydroxybenzoic acid, m-hydroxybenzoic acid, multihydroxybenzoic acid, phthalic acid, naphthoic acid, anthracenecarboxylic acid, phenanthrenecarboxylic acid, biphenylcarboxylic acid, 4,4'-biphenyldicarboxylic acid, phenol, aniline and anisole. The strengthening method is capable of effectively improving pollution-removing efficiency and expanding the conditions about pH and strong acidity of ozone technology application, has high ozone utilization rate, also is capable of effectively reducing processing cost of acidic water, and is applicable to processing of a plurality of substances.

Owner:NANJING UNIV

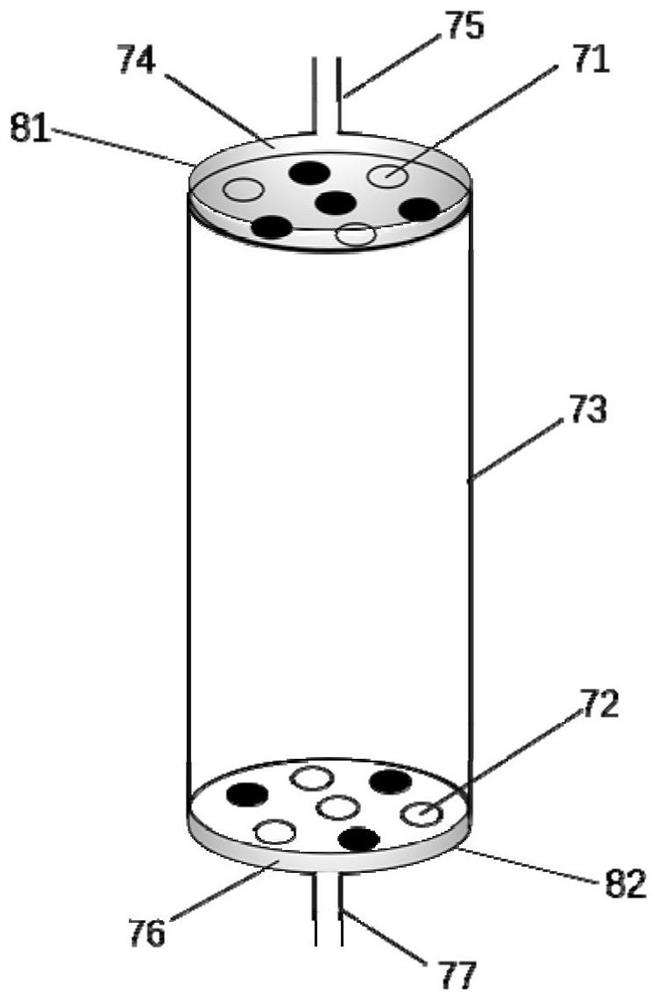

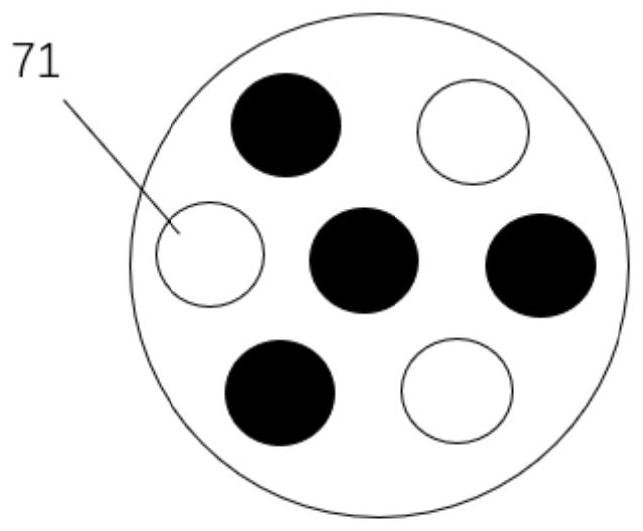

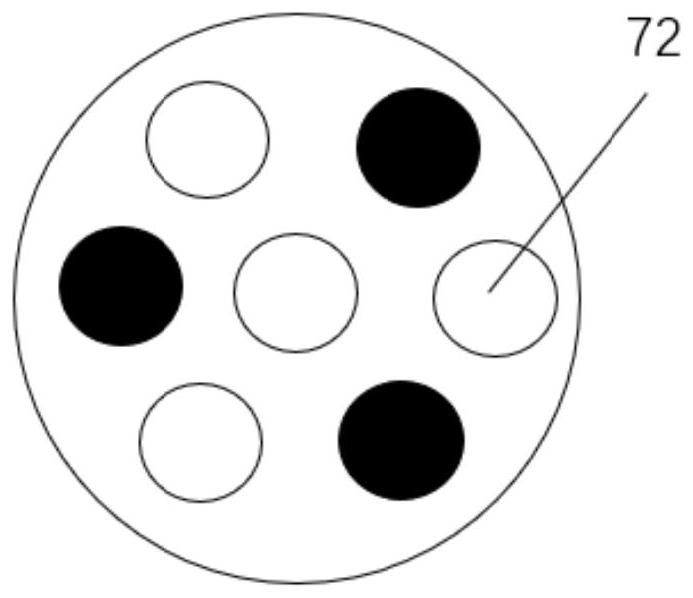

Electrocatalysis-ozone-membrane filtration three-in-one wastewater treatment device

ActiveCN113023966ASimple structureImprove the water effectWater treatment parameter controlWater treatment compoundsSewage treatmentCeramic membrane

The invention relates to the field of organic wastewater degradation, in particular to an electrocatalysis-ozone-membrane filtration three-in-one wastewater treatment device and process. The invention relates to an electrocatalysis-ozone-membrane filtration three-in-one cathode membrane assembly. The cathode membrane assembly comprises a microporous multichannel tubular conductive ceramic membrane, and an upper end cavity and a lower end cavity which are formed by a sealing material; the number of channels is more than or equal to 2, at least one channel with a sealed upper end and one channel with a sealed lower end are arranged, and the channel with the sealed upper end and the channel with the sealed lower end are adjacently arranged; a water outlet is formed in the upper end cavity; and an air inlet is formed in the lower end cavity. According to the membrane assembly, deep oxidation of ozone can be limited near the cathode, and the concentration of OH near the cathode is higher through ozonation reaction with H2O2 generated by electric reduction of O2, so that the sewage treatment effect is better, and the ozone utilization rate is higher.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

A selective flocculation-column flotation recovery method and system for fine-grained molybdenum beneficiation tailings

InactiveCN104984835BFine particle sizePoor floatabilityDifferential sedimentationFlotationFlocculationRecovery method

The invention discloses a selective flocculation-column flotation recovery method and system for fine-grained molybdenum concentrating tailings. The method is as follows: adding a dispersant and a collector to carry out the first stirring and pulping, so that the ore particles are fully dispersed And improve the hydrophobicity of the surface of the target ore particles; add flocculants and foaming agents for the second stirring and slurrying, so that the target ore particles are selectively flocculated; use the cyclone-static micro-bubble flotation column to carry out copper-molybdenum mixed flotation, using a Coarse-finish-sweeping flotation process to obtain copper-molybdenum mixed flotation concentrate and tailings; in copper-molybdenum mixed flotation concentrate, add inhibitors for third stirring and pulping; use cyclone-static micro-bubble flotation column Separation of copper and molybdenum is carried out, and a rough-fine flotation process is adopted to obtain molybdenum concentrate and copper concentrate. The present invention effectively combines two fine particle separation methods of selective flocculation and column flotation, recycles molybdenum and copper in molybdenum concentrate tailings, improves the comprehensive utilization rate of mineral resources, and has good economic benefits and social benefits.

Owner:CHINA UNIV OF MINING & TECH

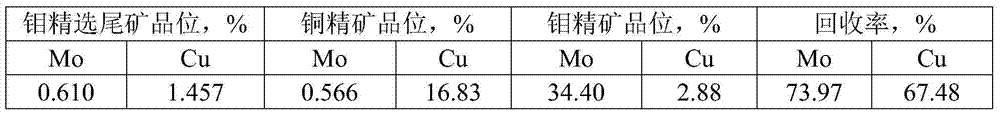

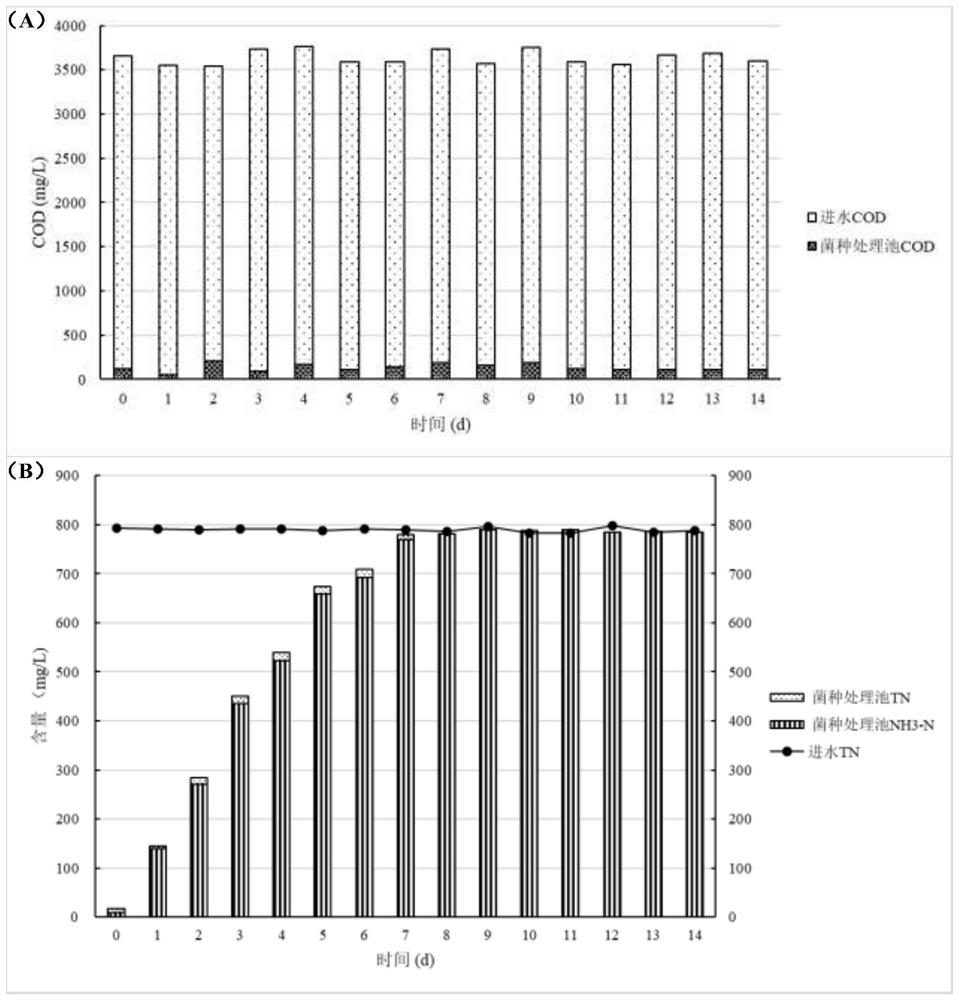

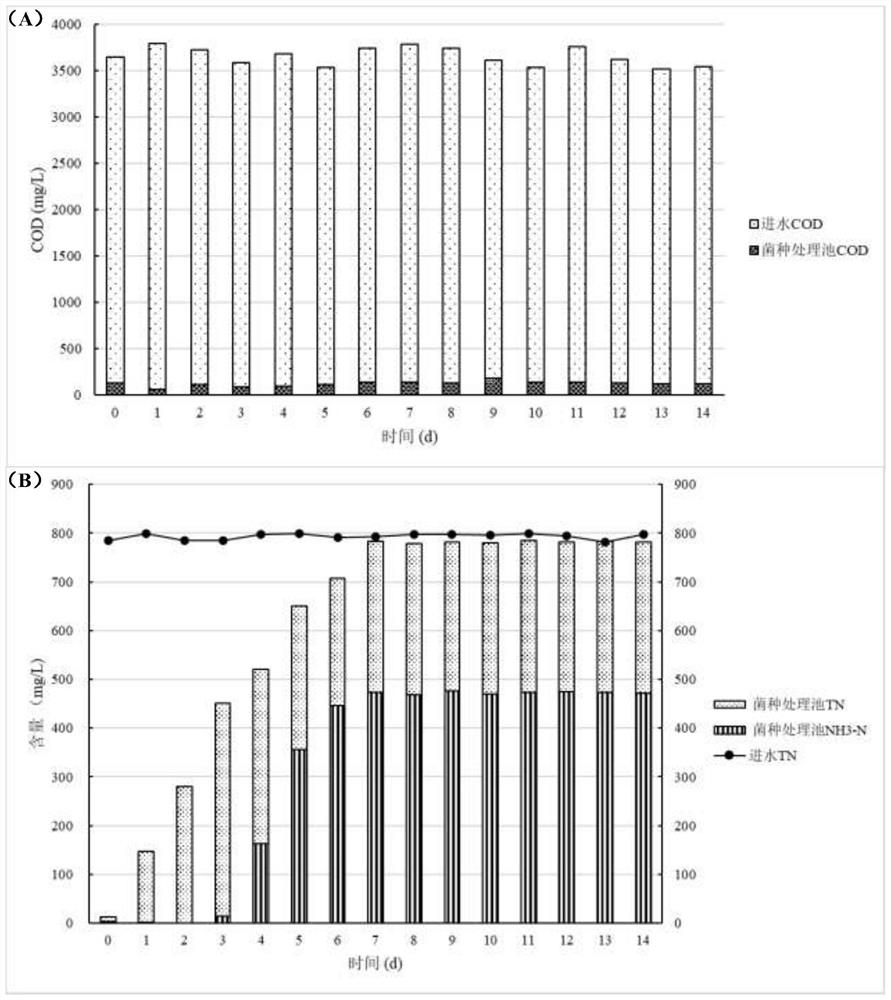

Paracoccus thiooxidans capable of efficiently degrading DMF (Dimethyl Formamide) and application of Paracoccus thiooxidans in treatment of DMF-containing wastewater

PendingCN114456974AImprove toleranceEfficient mineralizationBacteriaWater contaminantsEnvironmental engineeringNitrogen source

The invention relates to the technical field of DMF (Dimethyl Formamide) degradation, and provides paracoccus thiooxidans capable of efficiently degrading DMF and application of the paracoccus thiooxidans in treatment of DMF-containing wastewater. The paracoccus thiooxidans is named as 175A1-1, has been preserved in the China General Microbiological Culture Collection Center on October 25, 2021, the preservation number of the paracoccus thiooxidans is CGMCC NO.23659, and the classification of the microorganisms is named as paracoccus thiooxidans. The paracoccus thiooxidans 175A1-1 disclosed by the invention has relatively high DMF (Dimethyl Formamide) tolerance and can be used for converting DMF into NH3-N by taking DMF as a unique carbon source and a unique nitrogen source, so that efficient ammonification and mineralization of DMF are realized; in addition, the strain can be efficiently and stably applied to field engineering.

Owner:浙江台州秀川科技有限公司

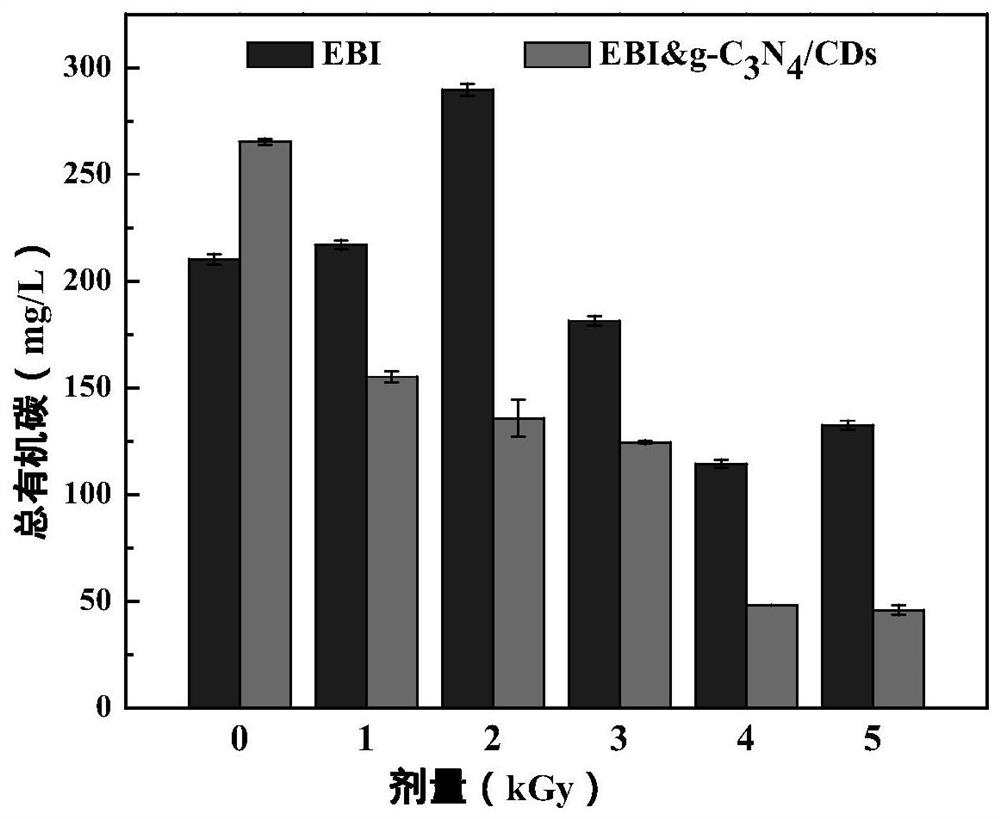

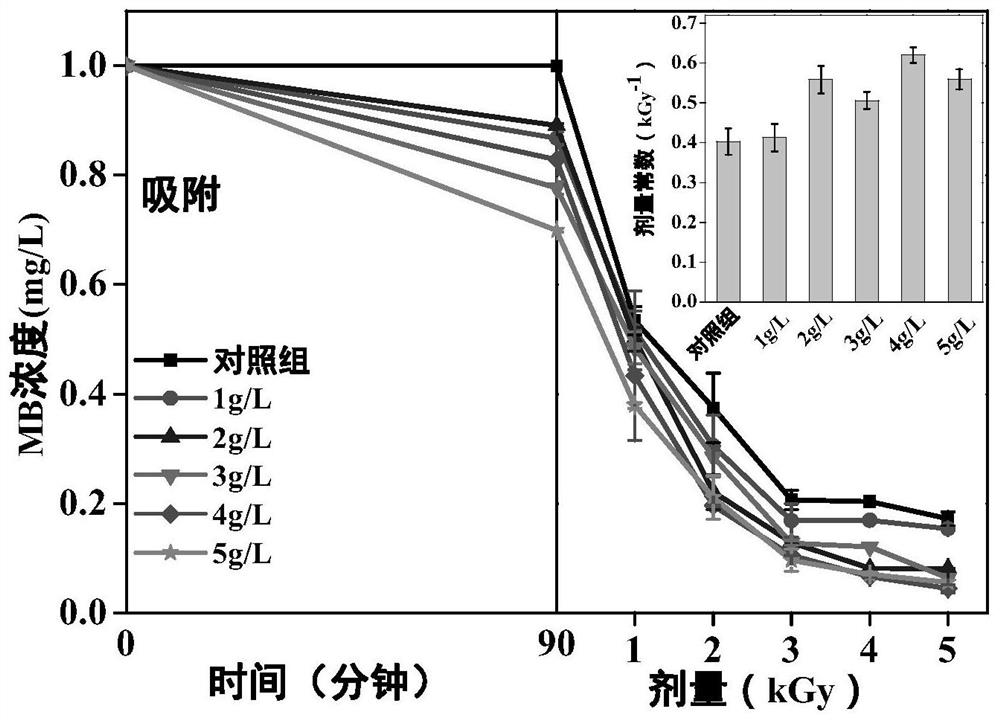

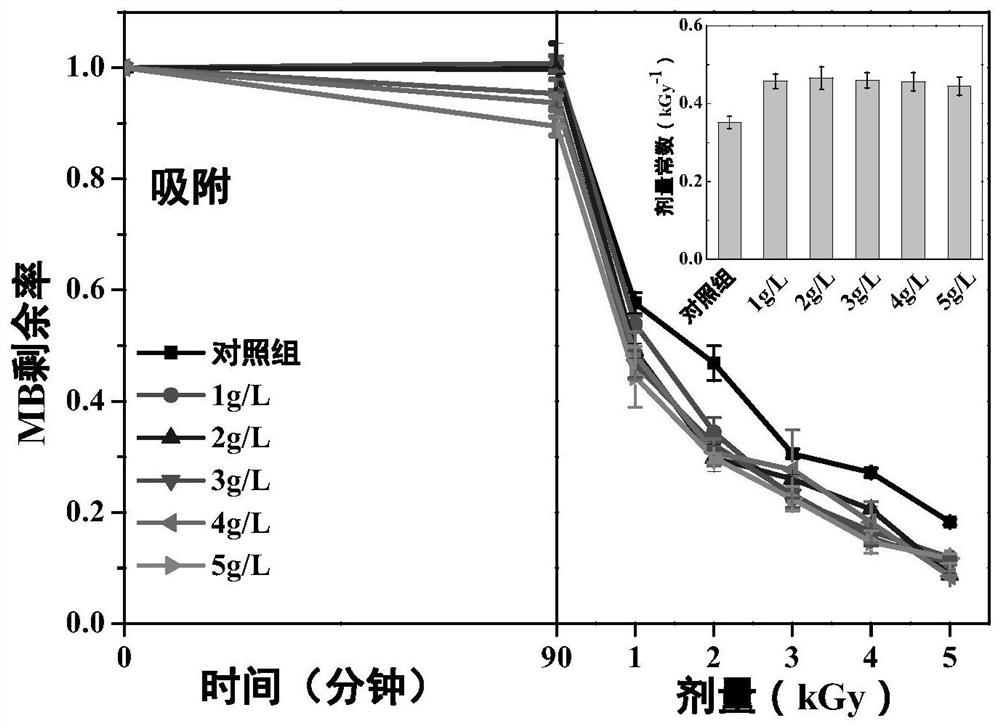

Method for degrading organic pollutants in water through cooperation of catalyst and ionization irradiation

PendingCN113603182AEasy to prepareImprove adsorption capacityPhysical/chemical process catalystsWater/sewage treatment by irradiationPtru catalystCarbon nitride

The invention discloses a method for degrading organic pollutants in water by using a catalyst in cooperation with ionization irradiation. The method comprises the following steps: adding a catalyst into wastewater containing organic pollutants, and uniformly mixing; and performing ionization irradiation treatment to degrade the organic pollutants in water, wherein the catalyst comprises a carbon nanodot / carbon nitride binary composite material, or a carbon nanodot / carbon nitride / metal ternary composite material, or a carbon nanodot / carbon nitride / metal oxide ternary composite material. According to the method, organic wastewater is utilized, a carbon nanodot / carbon nitride binary composite material or a carbon nanodot / carbon nitride / metal ternary composite material or a carbon nanodot / carbon nitride / metal oxide ternary composite material is irradiated through ionization, a degradation technology is combined, and the additive amount of the catalyst is changed to research the possibility of the technology; and research shows that the technology can be applied to the aspect of degrading high-concentration organic pollutants.

Owner:WUHAN UNIV OF TECH

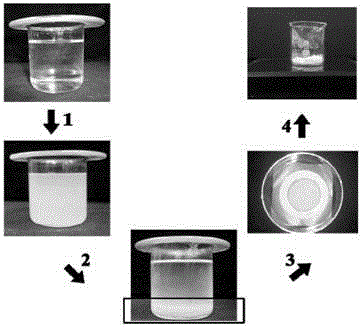

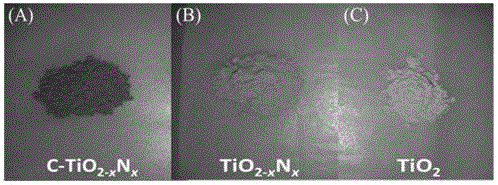

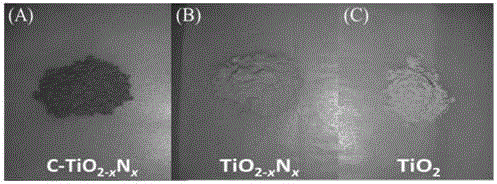

Method for preparing high activity TiO2 nano-single crystal from waste electrolyte solution

ActiveCN103603041AEffective resource recyclingSimple methodCellsPolycrystalline material growthHazardous substanceLow voltage

The invention discloses a method for preparing a high activity TiO2 nano-single crystal from a waste electrolyte solution. The method is characterized by including the steps of: subjecting a titanium sheet to a ''high voltage-low voltage-constant voltage'' interactive anodic oxidation process to obtain the waste electrolyte solution; carrying out concentration, microfiltration, purification and extraction on the waste electrolyte solution to obtain white powder; calcining the white powder at 300-800DEG C for 1-10h to obtain an initial TiO2 nano-single crystal; and cleaning and drying the initial TiO2 nano-single crystal, thus obtaining the high activity TiO2 nano-single crystal. The method provided by the invention takes the waste electrolyte solution generated by the anodic oxidation technology as a raw material, and prepares the anatase type high activity TiO2 nano-single crystal containing {001} crystal planes through one-step synthesis. The method is simple, and performs effective resource recycling on the toxic and harmful substances generated by the anodic oxidation technology, thus having significant economic and environmental benefits.

Owner:UNIV OF SCI & TECH OF CHINA

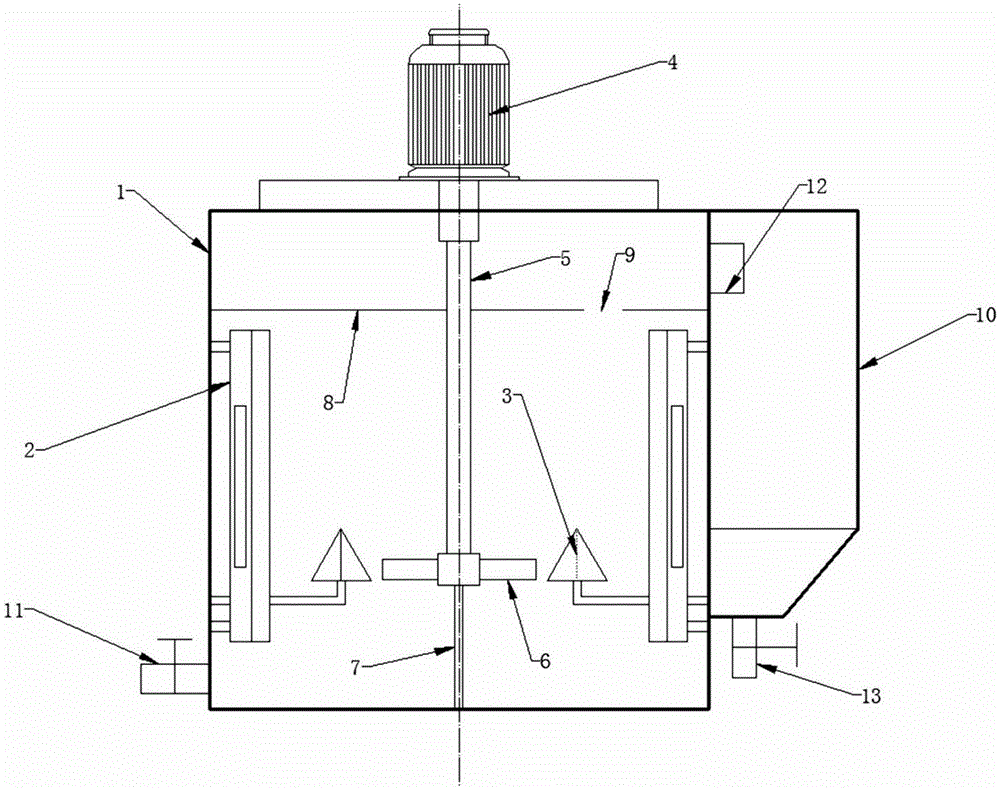

Slurry mixing and stirring tank for fine-grain mineral flotation

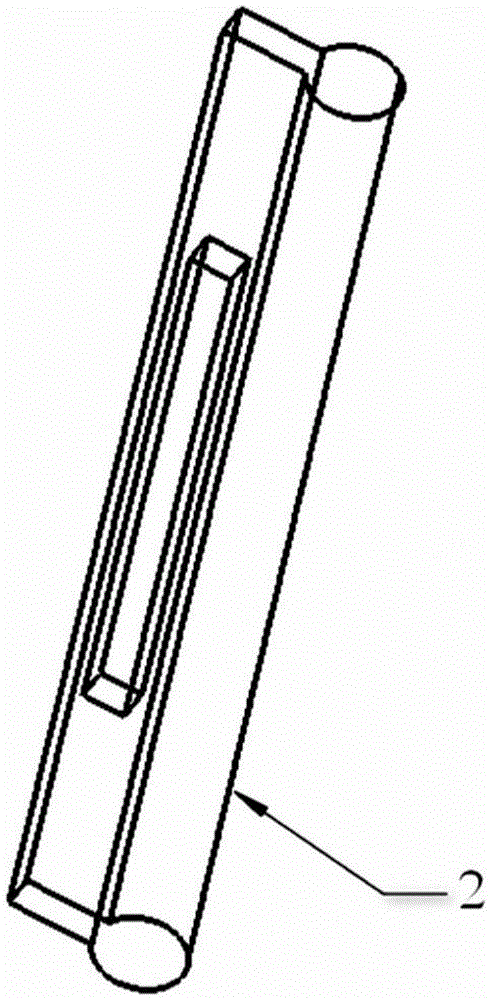

The invention discloses a slurry mixing and stirring tank for fine-grain mineral flotation. The slurry mixing and stirring tank comprises a stirring tank body (1), baffle plates (2), a frequency adjusting motor (4) and a stirring shaft (5); the baffle plates are uniformly distributed on the inner wall of the stirring tank body; the frequency adjusting motor is mounted at the top of the stirring tank body; an output shaft of the frequency adjusting motor is connected with the stirring shaft; a mixing impeller (6) is mounted at the bottom end of the stirring shaft; a feed pipe (11) is arranged on the lower side wall of one side of the stirring tank body; an overflow pipe (12) is arranged on the upper side wall of the other side of the stirring tank body; one ends, near the stirring shaft, of the baffle plates are cylindrical; the other ends, near the side walls of the stirring tank body, of the baffle plates are straight plate-shaped; rectangular gaps are formed in the straight plates of the baffle plates; and a plurality of turbine generators (3) are uniformly distributed between the stirring shaft and the baffle plates. The slurry mixing and stirring tank intensifies the effects of the baffle plates by improving accessories of the baffle plates, and the turbine generators are used to generate streamwise vortexes by using a flow pattern in the stirring tank, so that the reinforcement of shearing strength in the stirring tank and the enhancement of the turbulent effect are achieved, and the high-efficiency mineralization is realized.

Owner:CHINA UNIV OF MINING & TECH

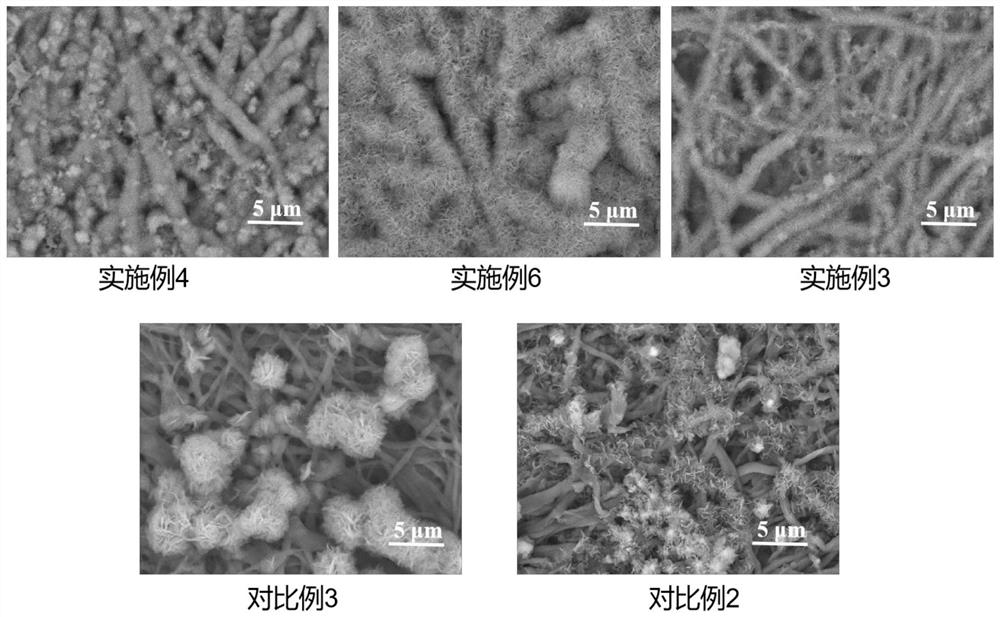

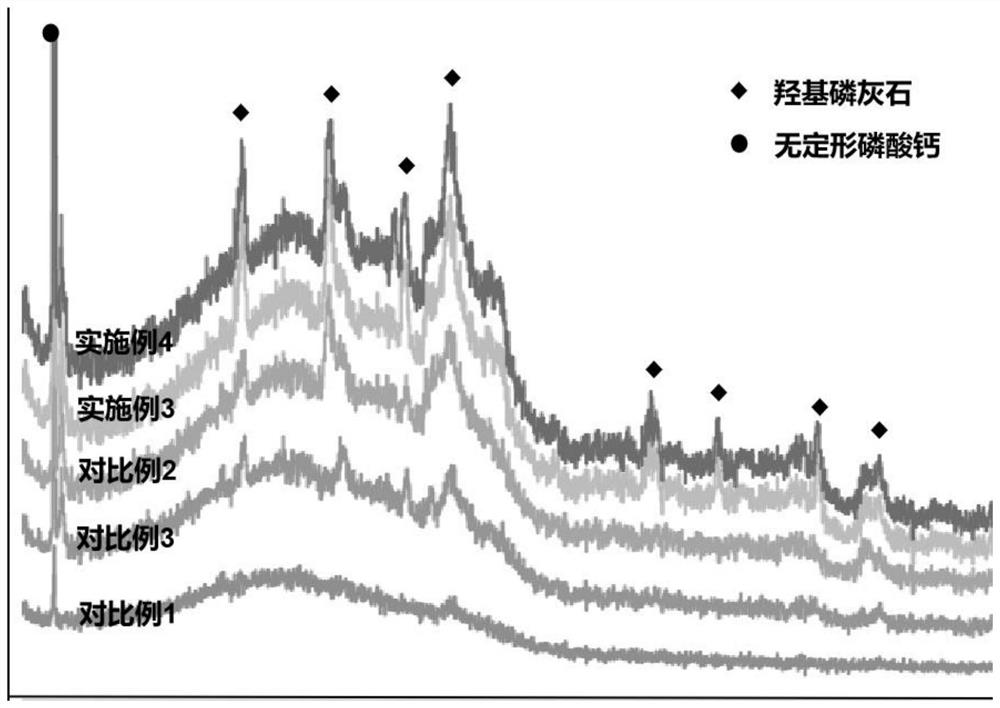

A biomimetic mineralization membrane prepared based on layered eggshell membrane and protein induction, preparation method and application

ActiveCN111330078BIrregular fiber network structureUniform fiber network structureTissue regenerationProsthesisHydrolysateBone tissue

The invention belongs to the technical field of medical biomimetic materials, and particularly relates to a biomimetic mineralized membrane prepared based on layered eggshell membrane and protein induction, a preparation method and application. The preparation method comprises the following steps of: S1, material preparation, including three parts of preparing an eggshell membrane, preparing enzymatic hydrolysate and preparing protein mineralized liquid, wherein the enzymatic hydrolysate is prepared by dissolving protease and a reducing agent in deionized water and adjusting the pH to 6-9, andthe protein mineralized liquid is prepared by dissolving water-soluble protein in mineralized liquid; and S2, preparation of the biomimetic mineralized membrane, namely soaking the inner eggshell membrane and / or the outer eggshell membrane in the enzymatic hydrolysate to obtain a modified eggshell membrane; and placing the modified eggshell membrane in the protein mineralized liquid for treatmentto obtain the biomimetic mineralized membrane prepared based on layered eggshell membrane and protein induction. The biomimetic mineralized membrane can be used as a bone tissue repair material, andthe preparation process has the characteristics of high mineralization efficiency, short preparation cycle time and good mineralization effect.

Owner:HUAZHONG AGRI UNIV

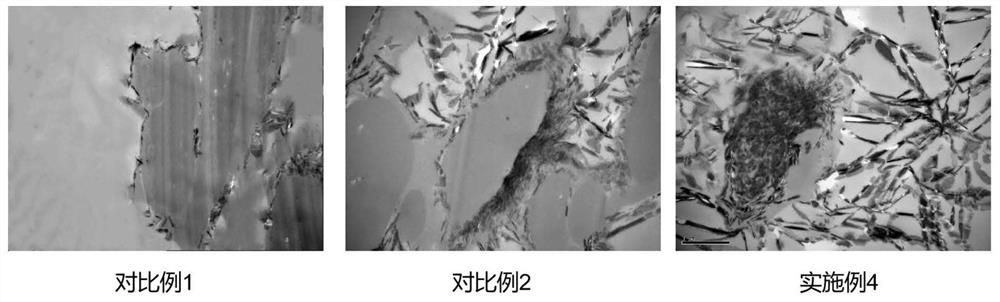

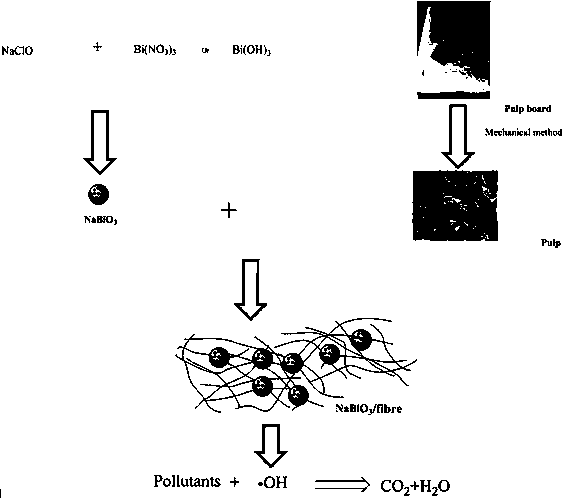

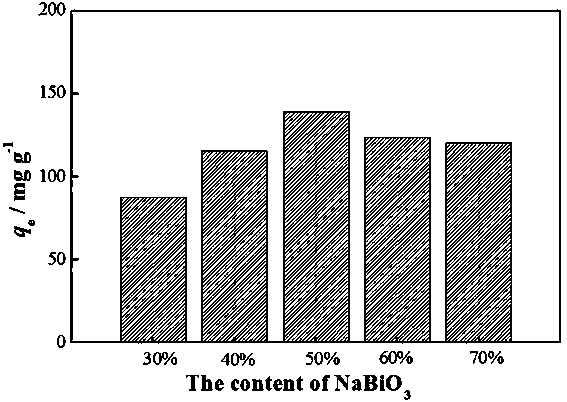

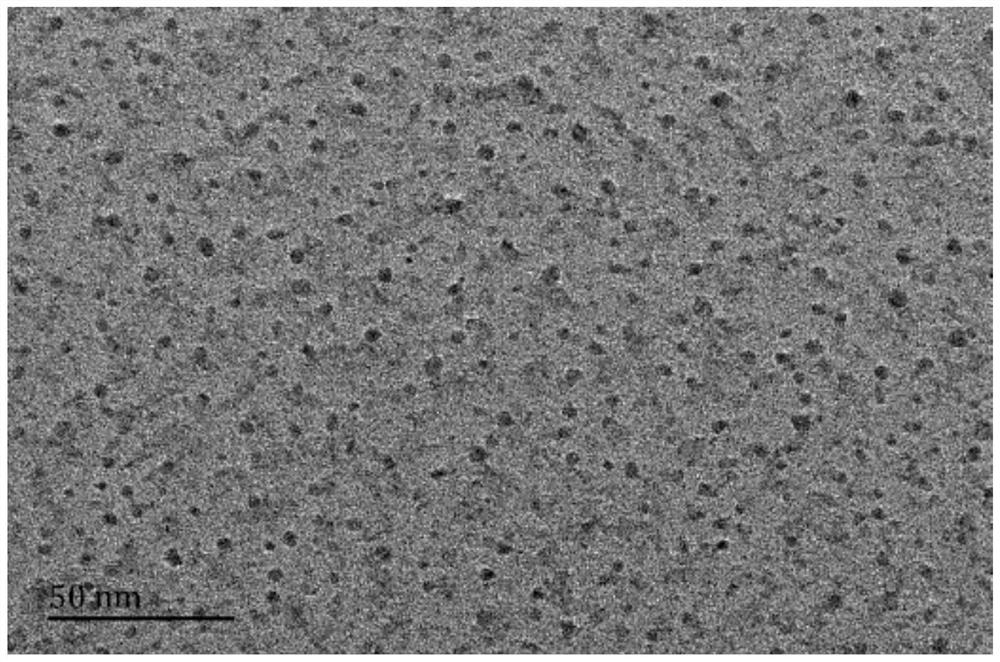

A preparation method of sodium bismuthate-based visible light catalytic paper material

InactiveCN107744835BAvoid reunionGuaranteed adsorption effectWater/sewage treatment by irradiationWater treatment compoundsFiberFiber suspension

Owner:HUBEI UNIV OF TECH

A nanometer zero-valent iron-carbon material and its preparation method and application

ActiveCN112607832BEffective size controlSmall sizeWater contaminantsWater/sewage treatment using germicide/oligodynamic-processCarbon layerPhysical chemistry

The invention relates to the field of nanometer materials, in particular to a nanometer zero-valent iron-carbon material and its preparation method and application. The material includes a carbon layer and ultra-fine nano-zero-valent iron uniformly distributed in the carbon layer, wherein the iron content is as high as 92-97%, and the particle size of the nano-zero-valent iron is between 3-8nm. Further, the nano-zero The element composition of the valent iron-carbon material also includes at least one of oxygen and nitrogen, wherein there is a coordination bond between the iron and nitrogen, and the nanometer zero-valent iron-carbon material is a porous material with a specific surface area of 120-140m 2 / g, the pore volume is 0.3‑0.4cm 3 / g, the pore size is 2-3nm. The nanometer zero-valent iron-carbon material provided by the invention has better activity of degrading organic pollutants, and can be used in the treatment of sewage polluted by organic matter.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Ceramic products possessing antisepsis and water mineralization and activation functions, and its preparation method and uses

InactiveCN100390098CSustainable accessSustainably obtain highly effective antibacterialWater/sewage treatment by substance additionActivation functionMontmorillonite

Ceramic products possessing antisepsis and water mineralization and activation functions, and its preparation method and uses, wherein the ceramic product is prepared from the following ingredients (by weight ratio): montmorillonite 25-60 parts, diatomite 10-30 parts, aluminum oxide 5-20 parts, silicon oxide 3-15 parts, calcium carbonate 15-45 parts, multifunctional health ceramic material 5-20 parts, adhesive 9-15 parts through proportioning, disintegrating, mixing, blank making and sintering.

Owner:淄博博纳科技发展有限公司

A method for degrading organic pollutants in water by ionizing radiation

ActiveCN111115745BEfficient degradation abilityEfficient mineralizationWater/sewage treatment by irradiationRadiation applicationsIndustrial waste waterIonizing irradiation

The invention belongs to the technical field of sewage treatment, and in particular relates to a method for removing refractory organic pollutants in water by intensified ionizing radiation, comprising: uniformly mixing waste water containing organic pollutants with a certain amount of MOF or its derivative materials, and performing ionization Irradiation treatment. The method has high irradiation efficiency and can be carried out at normal temperature. The MOF material can be reused, and can be applied to the treatment of refractory industrial wastewater such as effluent from urban sewage plants, pharmaceutical wastewater, and dye wastewater.

Owner:TSINGHUA UNIV

A method for preparing highly active tio2 nanometer single crystals by using waste electrolyte

ActiveCN103603041BEffective resource recyclingSimple methodCellsPolycrystalline material growthLow voltageHazardous substance

The invention discloses a method for preparing a high activity TiO2 nano-single crystal from a waste electrolyte solution. The method is characterized by including the steps of: subjecting a titanium sheet to a ''high voltage-low voltage-constant voltage'' interactive anodic oxidation process to obtain the waste electrolyte solution; carrying out concentration, microfiltration, purification and extraction on the waste electrolyte solution to obtain white powder; calcining the white powder at 300-800DEG C for 1-10h to obtain an initial TiO2 nano-single crystal; and cleaning and drying the initial TiO2 nano-single crystal, thus obtaining the high activity TiO2 nano-single crystal. The method provided by the invention takes the waste electrolyte solution generated by the anodic oxidation technology as a raw material, and prepares the anatase type high activity TiO2 nano-single crystal containing {001} crystal planes through one-step synthesis. The method is simple, and performs effective resource recycling on the toxic and harmful substances generated by the anodic oxidation technology, thus having significant economic and environmental benefits.

Owner:UNIV OF SCI & TECH OF CHINA

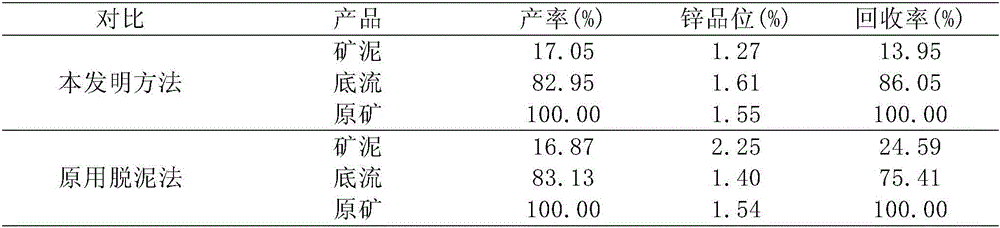

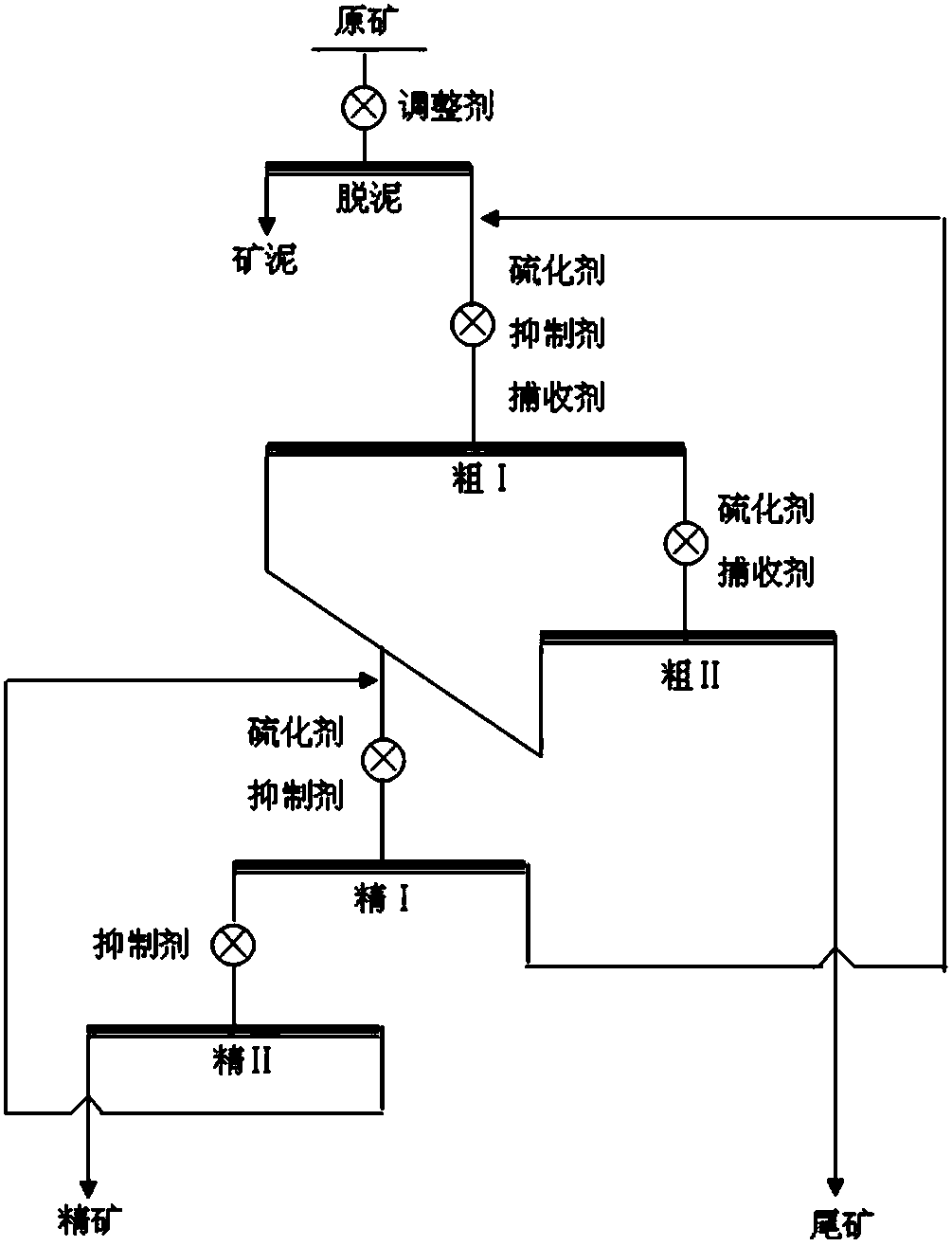

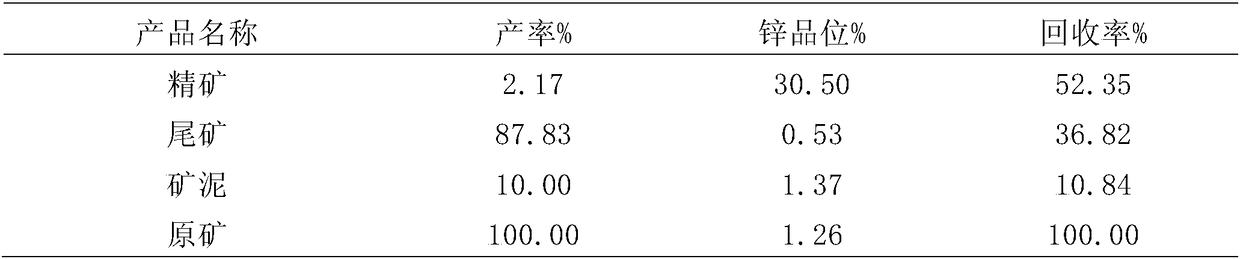

Mineral processing method for recovering low-grade zinc oxide ore from flotation tailings of lead-zinc ore

The invention discloses a beneficiation method for recovering low-grade zinc oxide ore from lead-zinc ore flotation tailings and belongs to beneficiation methods for zinc oxide ore. The method includes the steps that the lead-zinc ore flotation tailings are used as raw ore, and desliming is carried out after a regulator is added and stirred for pulp conditioning; and a vulcanizing agent, an inhibitor and a collecting agent are added into ore pulp obtained after desliming and stirred for pulp conditioning, the zinc oxide ore is recovered through a flotation column, and after two times of closed roughing flotation and two times of closed cleaner flotation, zinc oxide concentrate is obtained. According to the method, the agent selectivity is improved firstly, so that the problems that bubbles are sticky and hard to remove are solved; then the sorting effect of equipment on micro-fine particles is improved, so that the concentrate grade and the recovery rate are increased; and finally the technological process is simplified, production cost is lowered, and enterprise benefits and the resource utilization rate are guaranteed. The method has the advantages that the sorting effect is good, the technological process is short, production cost is low, and the method is friendly to environment; efficient sorting of the low-grade zinc oxide ore in the lead-zinc ore flotation tailings is achieved, the comprehensive utilization rate of mineral resources is increased, and high economic and social benefits are achieved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com