Method for preparing high activity TiO2 nano-single crystal from waste electrolyte solution

A technology of waste electrolyte and nano-single crystal, applied in the electrolysis process, electrolysis components, single crystal growth and other directions, can solve the problems of high precursor requirements, complicated preparation process, unfavorable experimental promotion, etc., and achieves low price, physical and chemical The effect of stable nature and optimized performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

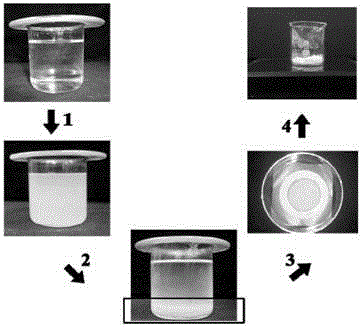

[0043] This example uses waste electrolyte to prepare highly active TiO 2 The nano-single crystal method is carried out as follows:

[0044] a. Obtain waste electrolyte by anodic oxidation of titanium sheet:

[0045] a1. Soak the titanium sheet in anhydrous acetone, absolute ethanol and deionized water for 90 minutes in order to remove organic pollutants and residual oil stains on the surface of the titanium sheet to obtain spare titanium sheets;

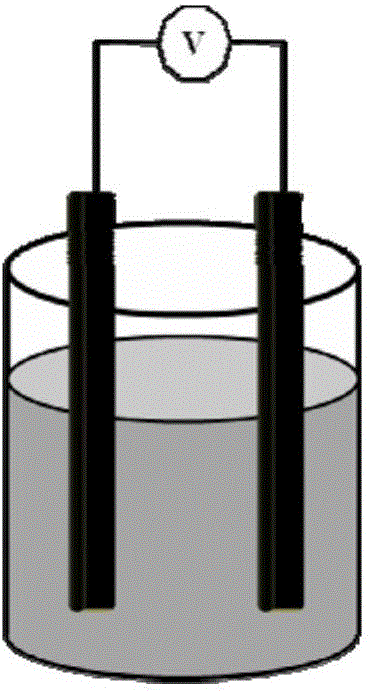

[0046] a2, take 7.0g NH 4 F. 10.0ml deionized water and 70.0ml ethylene glycol are used as the anodized electrolyte, and the DC power supply is boosted from the open voltage to 110V at a boost rate of 5V / min at room temperature, and the pressure is maintained under constant voltage conditions. The spare titanium sheet is anodized for 6 minutes; then the voltage is reduced to 50V, and the spare titanium sheet is anodized for 4 hours under constant voltage conditions to obtain TiO 2 Nanotubes and waste electrolyte.

[0047] b. Concentrate, mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com