High-fluidity ultra-high molecular weight polyethylene wear-resistant plate and preparation method thereof

An ultra-high molecular weight, high-fluidity technology, applied in the field of high-fluidity ultra-high molecular weight polyethylene wear-resistant sheet and its preparation, can solve the problems of poor processability and wear resistance, and achieve improved processability and wear resistance. Performance, high impact strength, high flow effect

Inactive Publication Date: 2021-04-09

常州利尔德通新材料科技有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to overcome the defects of poor processability and wear resistance of recycled ultra-high molecular weight polyethylene diaphragm plates without adding oily substances, the application provides a high-fluidity ultra-high molecular weight polyethylene wear-resistant plate and its preparation method. Adopt the following technical solutions:

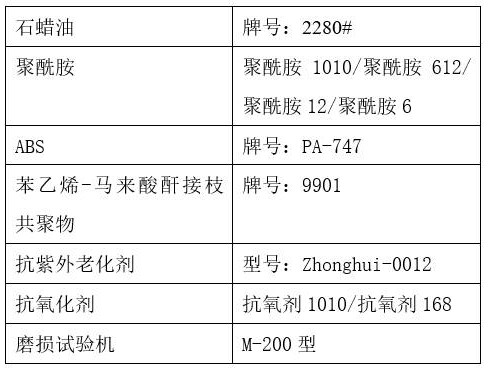

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example 1

[0035] Take 50g of antioxidant 1010 and 2g of antioxidant 168 and add them to 120g of anti-ultraviolet aging agent to prepare functional additive 1.

preparation example 2

[0037] Add 55g of antioxidant 1010 and 2.5g of antioxidant 168 to 130g of anti-ultraviolet aging agent to prepare functional additive 2.

preparation example 3

[0039] Add 60g of antioxidant 1010 and 3.0g of antioxidant 168 to 140g of anti-ultraviolet aging agent to prepare functional additive 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Login to View More

Abstract

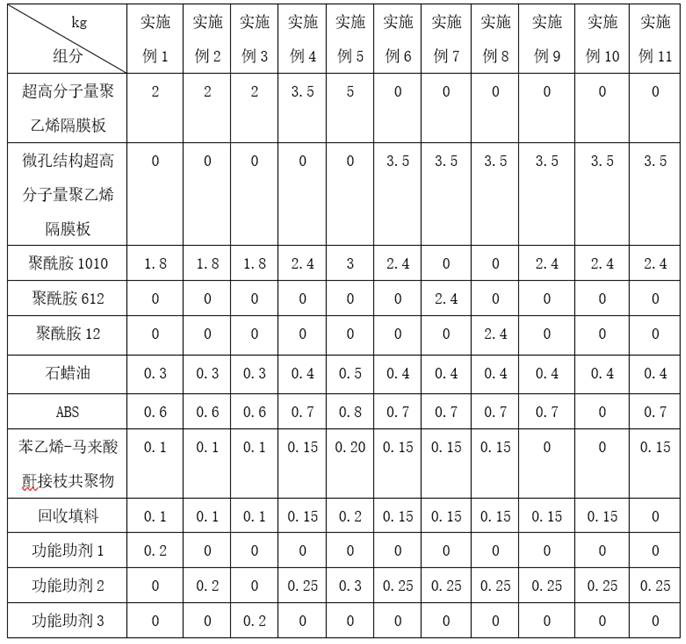

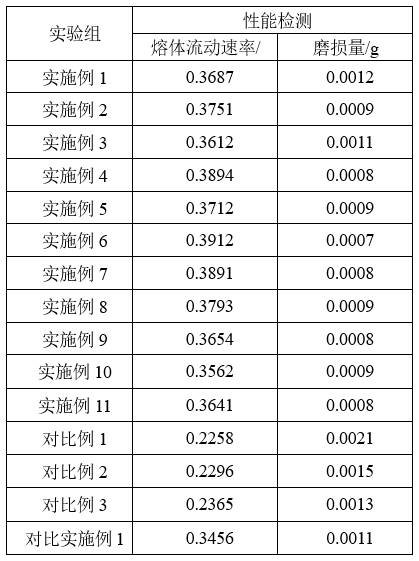

The invention relates to the field of high polymer materials, and particularly discloses a high-fluidity ultra-high molecular weight polyethylene wear-resistant plate and a preparation method thereof. The high-fluidity ultra-high molecular weight polyethylene wear-resistant plate comprises the following substances in parts by weight: 20-50 parts of an ultra-high molecular weight polyethylene diaphragm plate, 18-30 parts of polyamide, 3-5 parts of paraffin oil and 2-3 parts of a functional additive. After the ultra-high molecular weight polyethylene diaphragm plate is recycled, polyamide is adopted to replace an oily material adopted in a traditional diaphragm plate, so that on one hand, the flowing property of the ultra-high molecular weight polyethylene material is effectively improved, and the ultra-high molecular weight polyethylene material is convenient to process and extrude; on the other hand, due to the good crystallization property and wear resistance of polyethylene, polyethylene is added into the ultra-high molecular weight polyethylene material, so that the wear resistance of the composite material can be improved, and the defects of poor processability and wear resistance of the recycled ultra-high molecular weight polyethylene diaphragm plate after no oily substance is added are effectively overcome.

Description

technical field [0001] The application relates to the field of polymer materials, more specifically, it relates to a high-fluidity ultra-high molecular weight polyethylene wear-resistant plate and a preparation method thereof. Background technique [0002] The molecular weight of ultra-high molecular weight polyethylene is generally large, and its relative molecular mass is generally greater than 1.5 million. It is precisely because of the extremely high relative molecular mass of ultra-high molecular weight polyethylene that UHMWPE has many advantages that ordinary polyethylene does not have. It is one of the most comprehensive properties among all engineering plastics. However, ultra-high molecular weight polyethylene also has shortcomings. The main disadvantage is that the processing fluidity is extremely poor. Therefore, improving the flow properties of ultra-high molecular weight polyethylene materials is the key to its practical adjustment. [0003] In the existing pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/06C08L77/06C08L91/06C08L55/02C08L51/00C08L77/02C08K7/14

CPCC08L23/06C08L2205/035C08L2205/03C08L2207/068C08L77/06C08L91/06C08L55/02C08L51/003C08K7/14C08L77/02

Inventor 厉军方道成汤月屏

Owner 常州利尔德通新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com