Collophanite dressing technology

A technology of collophosite and process, which is applied in the beneficiation process of middle and low-grade Shifang collophosphine, and in the field of collophosite beneficiation process, which can solve the problems of large area, waste of phosphate resources, and complicated beneficiation system, etc. Achieve the effects of avoiding waste, good development and utilization, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment relates to the treatment process of medium and low-grade phosphate rock, and selects Shifang Qingping County's medium and low grade (P 2 o 5 Grade 25%) phosphate rock, the specific steps include: setting up a beneficiation device to beneficiate the phosphate rock pulp, and concentrating the concentrate pulp and tailings pulp obtained from the beneficiation to obtain phosphorous concentrate and tailings.

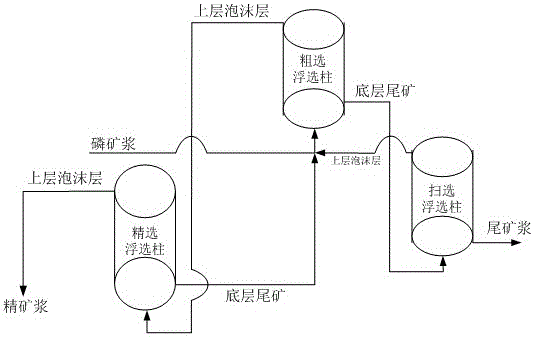

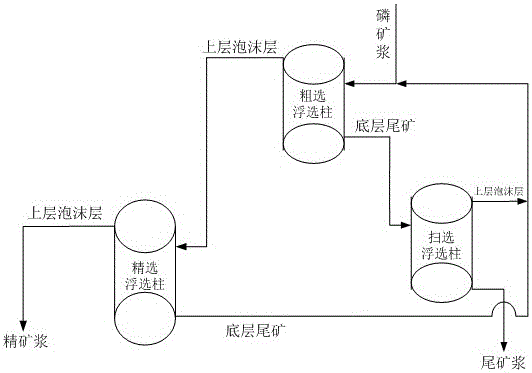

[0064] In this embodiment, the beneficiation device includes a roughing flotation column, a concentrating flotation column and a sweeping flotation column, and the described beneficiation steps are as follows:

[0065] A: Rough selection, the phosphate rock slurry is sent to the rougher flotation column for mineralization flotation, the upper foam layer is sent to the selection flotation column, and the operation of step B is completed, and the middle layer of pulp is sent to the rougher flotation column for mineralization flotation again. Chemical flo...

Embodiment 2

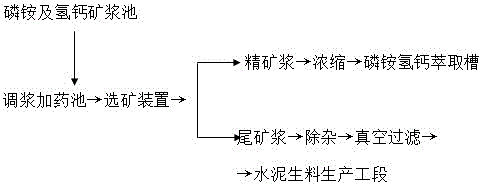

[0069] This embodiment is based on the ore dressing device in Example 1, and involves the treatment process of medium-grade phosphate rock in Shifang, Qingping, and Ping'an County. The treatment process is combined with the ammonium hydrogen calcium phosphate process. Calcium Hydrogen Slurry Pool, P 2 o 5 Phosphate pulp with a grade of 27% (the water content is about 30%, and the impurities MgO, Fe contained in it 2 o 3 and Al 2 o 3 The total amount is 15%) for mineral processing, and the concentrate slurry obtained from mineral processing is concentrated to produce phosphorus concentrate with a water content of 28-32% and sent to the ammonium hydrogen calcium phosphate extraction tank; the tailings slurry obtained from mineral processing is cleaned of impurities , concentrating, and filtering to obtain tailings and send them to the cement raw meal production section.

Embodiment 3

[0071] The difference between this embodiment and Embodiment 2 is that: between the ammonium phosphate and hydrogen calcium ore pulp pool and the ore dressing device involved in this embodiment, a slurry dosing pool is provided, and slurry mixing liquid and chemicals are added in the slurry dosing pool, according to Percentage meter, the P 2 o 5 Phosphate pulp with a grade of 27% contains: MgO, Fe 2 o 3 and Al 2 o 3 The total amount is 12%, and its water content is 58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com