Method used for preparing acetylpropionic acid based on catalysis of furan with acid catalyst

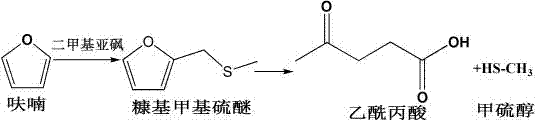

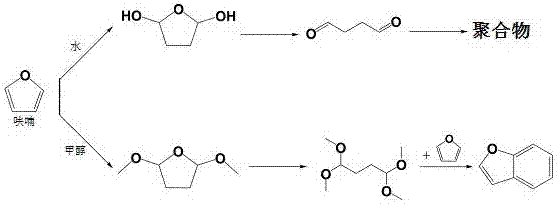

An acidic catalyst and levulinic acid technology, which is applied in the preparation of carboxylate, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of complicated levulinic acid process, low conversion rate, and difficult disposal of waste liquid to pollute the environment. , to achieve the effect of overcoming the complicated preparation process, low cost and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

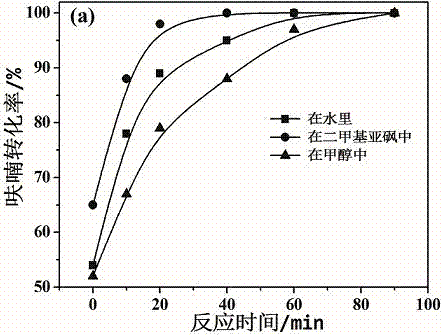

[0026] Embodiment 1, the present invention: the method for preparing levulinic acid by catalyzing furan with dimethyl sulfoxide as solvent, comprises the following steps:

[0027] (1) Uniform mixing: the acidic catalyst quality is 5g, the furan quality is 5g, and the volume of dimethyl sulfoxide solvent is 50mL and mixed in the reaction kettle, and the raw materials are uniformly mixed by stirring, the stirring speed is 400rpm, and the stirring time For 20min; the acidic catalyst is an acidic macroporous resin, the acidic macroporous resin is a Bronsted acid catalyst macroporous resin, and the particle diameter of the acidic macroporous resin is 0.121~0.989mm;

[0028] (2) Air exhaust: after the mixture was added to the reactor, high-purity nitrogen was used to get rid of the air in the autoclave;

[0029] (3) Heating: put the mixture obtained by stirring into an autoclave reactor to heat and react, the reaction temperature is 200°C, the heating rate is 20°C / min, and the heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com