Method for recovering low-concentration calcite type fluorite tailing containing mica

A technology of fluorite tailings and calcite type, which is applied in the direction of solid separation and flotation, can solve the problems of low utilization rate of tailings pond, pollution of flocculation backwater, poor sorting efficiency, etc., to solve the problem of difficult concentration and reduce inventory Stress, Adaptive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

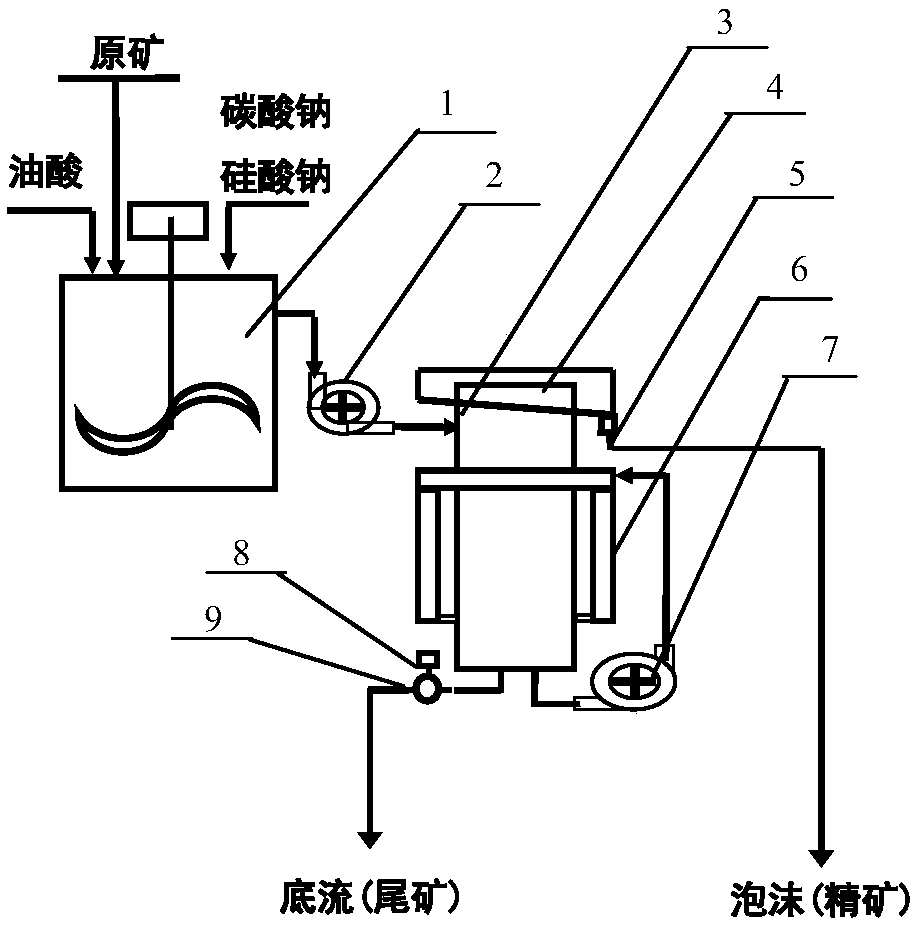

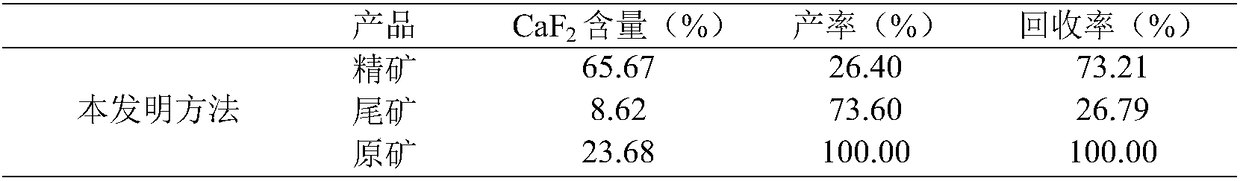

[0020] Example 1: Fluorite tailings slurry with solid mass concentration C of 7%, fineness of -0.045mm and mica-containing fluorite tailings with a content of 85%, is fed into the feed pump for stirring by the feed pump 2 of model LSB-40 Barrel 1, through the Φ1000×1000mm mixing barrel 1, perform high-speed shear and stirring pretreatment on the pulp, the stirring speed is 1000r / min; add 500g / t sodium carbonate to the pretreated pulp according to the mass ratio, stir for 5min, and then add 400g / t sodium silicate, stir for 5 minutes, then add 50g / t oleic acid, stir for 5 minutes, the stirring speed is 1000r / min; send the evenly mixed pulp into FCSMCΦ400×4000mm swirl-static micro-bubble flotation column, using the model It is a 50LZ-275 circulation pump 7 for sorting, and the foam product of the flotation column is the concentrate product. The underflow of the flotation column is the tailings product; the foam and underflow were filtered, dried and tested respectively, and the ...

example 2

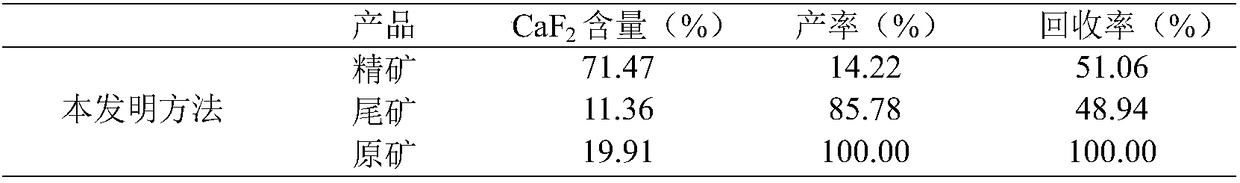

[0024] Example 2: The ore pulp solid mass concentration C of the raw ore is 5%, the fineness is -0.045mm, and the content accounts for 87% of mica-containing fluorite tailings. The pulp is subjected to high-speed shear pretreatment through the mixing tank 1, and the stirring speed is 1000r / min; Add 700g / t sodium carbonate to the pretreated pulp according to the mass ratio, stir for 5min, then add 400g / t sodium silicate, stir for 5min, then add 40g / t oleic acid, stir for 5min, the stirring speed is 1000r / min ; The evenly mixed pulp is sent to the cyclone-static micro-bubble flotation column for separation, and the foam product of the flotation column is the concentrate product. The underflow of the flotation column is the tailings product; the foam and underflow were filtered, dried and tested respectively, and the final results are shown in Table 2.

[0025] Table 2 sorting test results

[0026]

[0027] As can be seen from Table 2, it can be seen from Table 1 that the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com