Mineral processing method for recovering low-grade zinc oxide ore from flotation tailings of lead-zinc ore

A technology for flotation tailings and zinc oxide ore, applied in flotation, solid separation and other directions, can solve the problem of lead-zinc ore flotation tailings with large mud content, low concentrate grade and recovery rate, and sticky foam that is difficult to eliminate. problems such as bubbles, etc., to achieve the effect of ensuring enterprise efficiency and resource utilization, good sorting effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

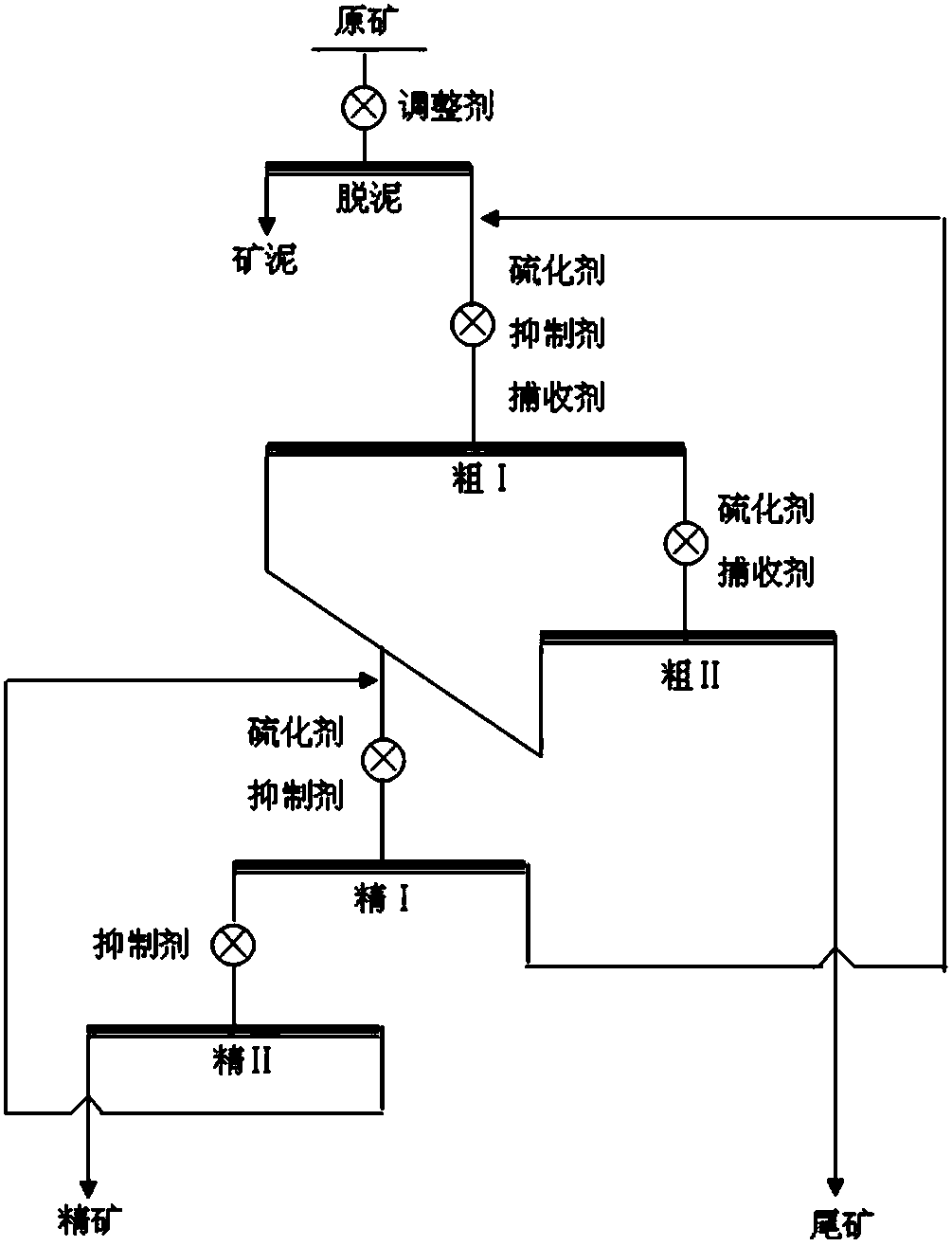

[0030] Example: such as figure 1 As shown, a beneficiation method for recovering low-grade zinc oxide ore from lead-zinc ore flotation tailings includes the following steps and conditions:

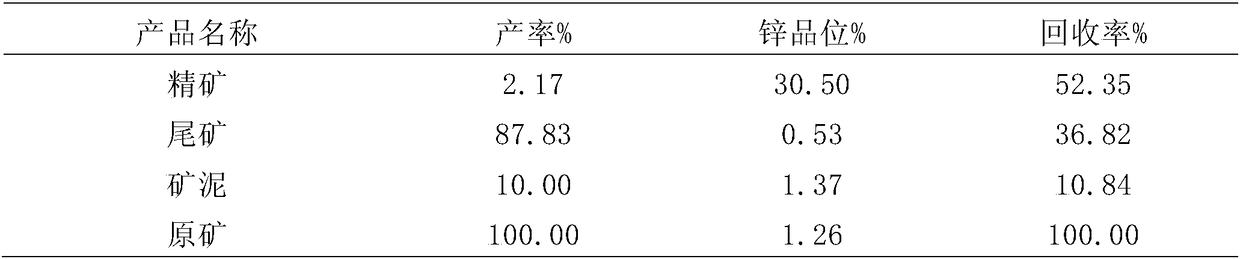

[0031] (1) Desliming: Taking the flotation tailings of a lead-zinc mine in Xinjiang as the raw ore, containing 1.26% of Zn, the oxidation rate of zinc is 75%, the fineness is -0.074mm 79.82%, and the regulator sodium carbonate 1250g / t is added. , Stir, and enter the desliming hopper after mixing, and the desliming yield is 10%;

[0032] (2) Flotation: firstly add 3400g / t of vulcanizing agent sodium sulfide, 400g / t of inhibitor water glass and 10g / t of collector etheramine to the pulp after the treatment in step (1), stir, and enter after mixing The crude I cyclone-static microbubble flotation column is used for the first rough separation to obtain crude I tailings and crude I concentrate. In the crude I tailings, 300g / t of sodium sulfide sulfide and 10g of collector etheramine are added. / t, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com