Photocatalyst and preparation method and application thereof

A technology of photocatalyst and ion exchange method, applied in the field of photocatalyst and its preparation, can solve the problems such as inability to utilize sunlight well, low utilization rate of sunlight, limitation, etc., and achieve remarkable effect and application value, high-efficiency decolorization , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

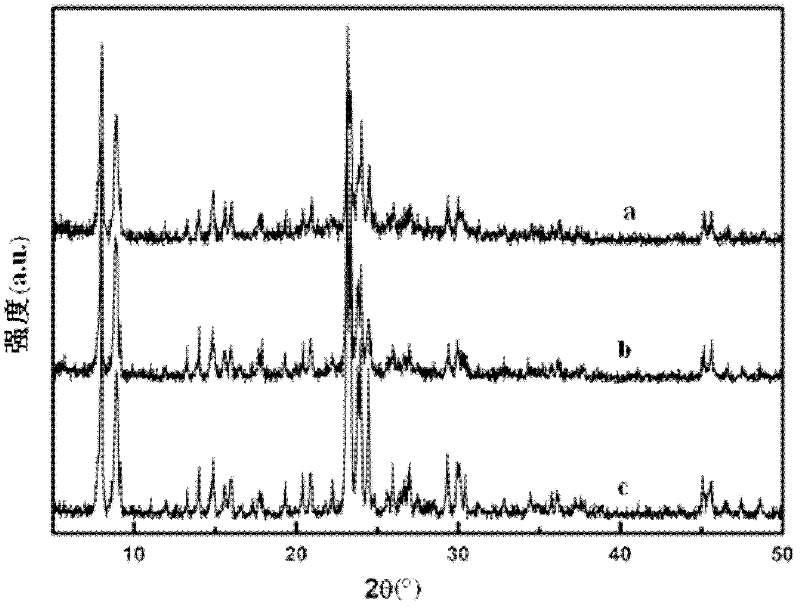

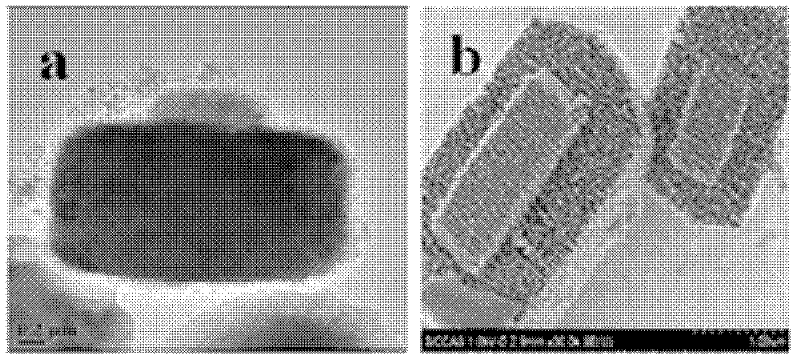

[0037] 1. Preparation of mesoporous zeolite material: MZ (Si / Al=50)

[0038] 0.031moL of tetrapropylammonium hydroxide (TPAOH) and 0.001moL of triisopropoxyaluminum (Al( i PrO) 3 ) and 0.05moL of tetraethyl orthosilicate (TEOS) were added to 90mL of water, stirred for 2 hours below 15°C, aged at 10°C for 24h, and then the mixed aqueous solution was added to the surface of 60mL with a concentration of 0.047moL / L Active agent cetyltrimethylammonium bromide (CTAB) aqueous solution, stirred vigorously at 10°C for 3 hours, then aged at room temperature for 4 hours, then put the formed gel into polytetrafluoroethylene hydrothermal In the still, conduct hydrothermal crystallization reaction at 150°C for 24 hours, centrifuge, wash the sample, dry at 100°C overnight, and finally roast at 550°C for 8 hours to obtain the mesoporous zeolite material MZ (Si / Al=50).

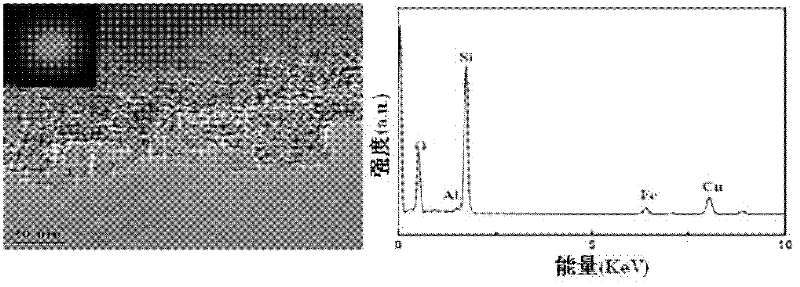

[0039] 2. Preparation of mesoporous zeolite material loaded with iron ions by ion exchange method: Fe-MZ (Si / Al=50)

[00...

Embodiment 2

[0067] Preparation of mesoporous zeolite material loaded with iron ions by in-situ doping method: Fe-MZ(Si / Al=50)

[0068] 0.1moL of ferric nitrate (Fe(NO 3 ) 3 9H 2 O) and 0.001moL of aluminum triisopropoxide (Al( i PrO) 3) and 0.05moL of tetraethyl ammonium hydroxide (TEOS) were added to 60mL of water to prepare a mixed aqueous solution; then 30mL of tetrapropylammonium hydroxide (TPAOH) aqueous solution with a concentration of 1.03moL / L was added and stirred at 5°C for 2 hours , and aged at 5°C for 24h; then added to 60mL of an aqueous solution of surfactant cetyltrimethylammonium bromide (CTAB) with a concentration of 0.047moL / L, vigorously stirred at 5°C for 3 hours, and then Aging at room temperature for 4 hours, then put the formed gel into a polytetrafluoroethylene hydrothermal kettle, carry out hydrothermal crystallization reaction at 160°C for 20h, centrifuge, wash the sample, dry at 100°C overnight, and finally dry it at 600°C Calcined for 8 hours, the mesoporo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com