Slurry mixing and stirring tank for fine-grain mineral flotation

A mineral flotation and agitation tank technology, applied in flotation, solid separation and other directions, can solve the problems of time lag of chemical action, poor slurry mixing effect, low separation recovery rate, etc., to promote full mixing and enhance turbulence. As well as the shearing mechanism, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

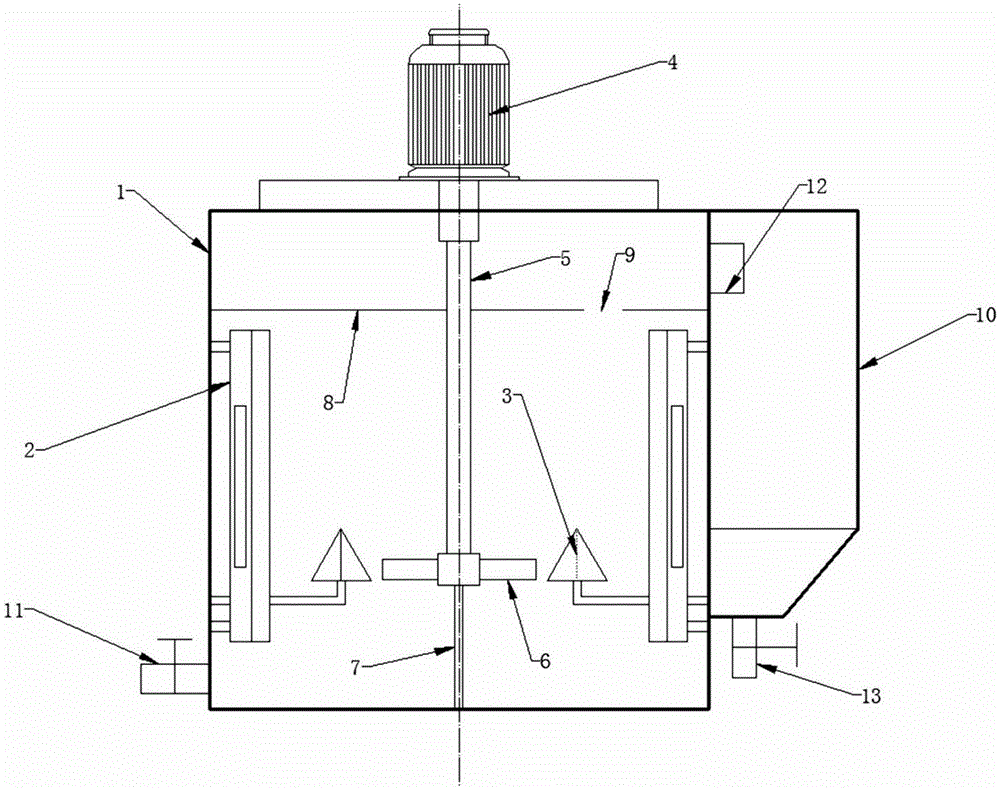

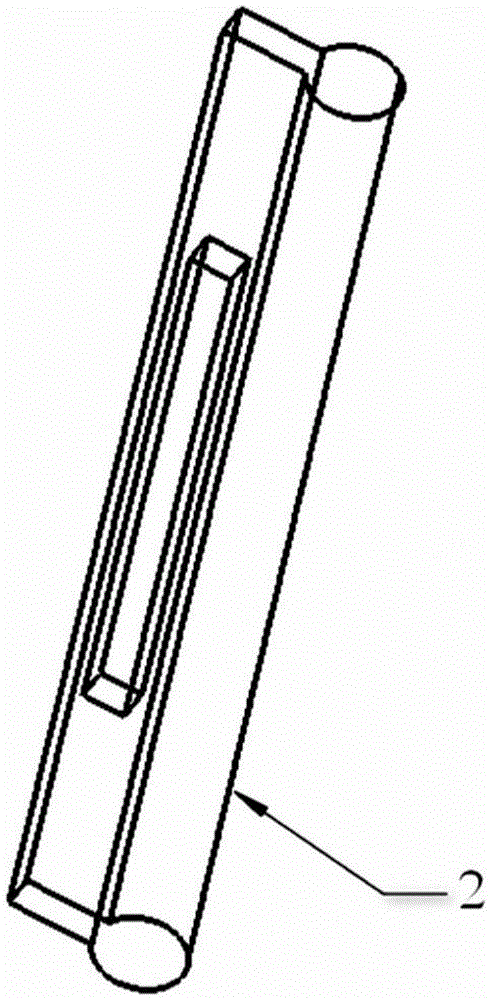

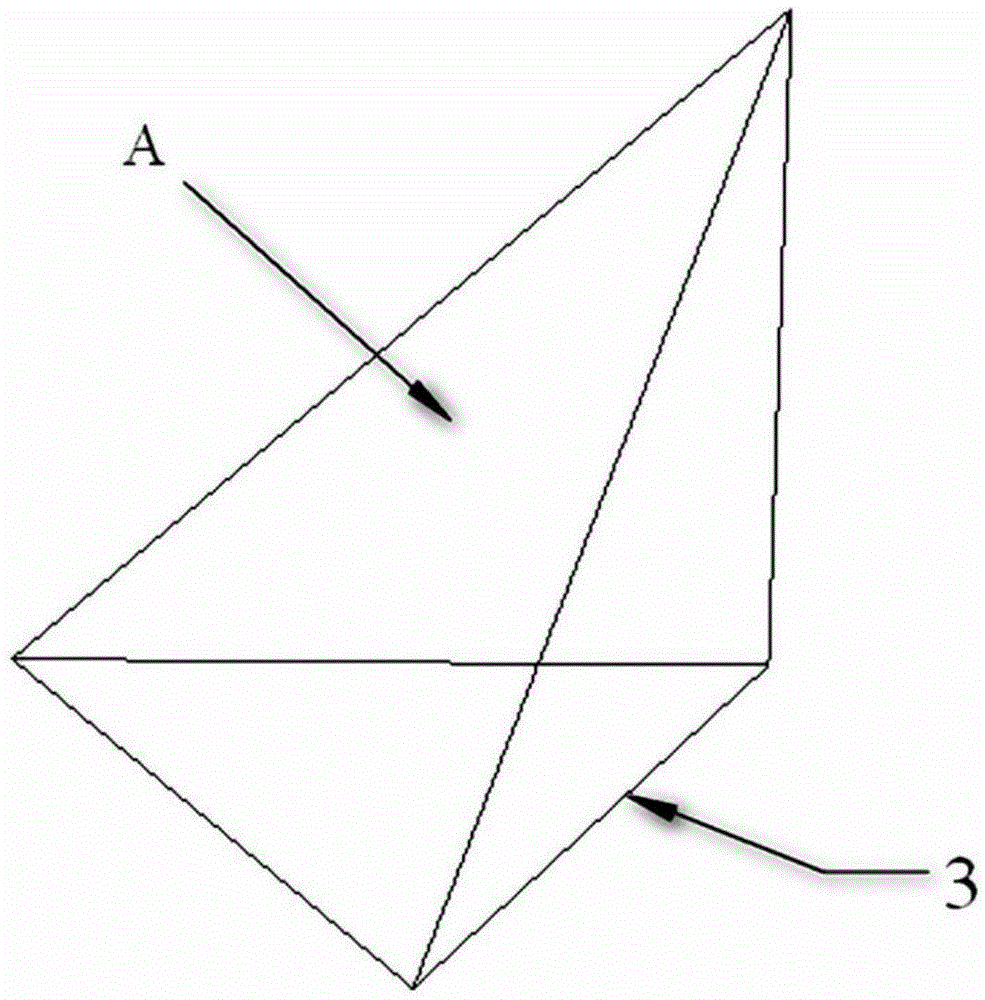

[0023] Such as figure 1 and Figure 4 As shown, a slurry mixing tank for fine-grained mineral flotation includes a stirring tank body 1, a baffle plate 2, a frequency modulation motor 4 and a stirring shaft 5, and the baffle plate 2 is evenly distributed on the inner wall of the stirring tank body 1, The frequency modulation motor 4 is installed on the top of the stirring tank 1, its output shaft is connected with the stirring shaft 5, the bottom of the stirring shaft 5 is equipped with a stirring impeller 6, and the lower side wall of one side of the stirring tank 1 is provided with a feed pipe 11. The upper side wall on the other side is provided with an overflow pipe 12, which is characterized in that the end of the baffle plate 2 close to the stirring shaft 5 is cylindrical, and the end close to the side wall of the stirring tank body 1 is straight. There are rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com