Method for degrading organic pollutants in water by ionization irradiation

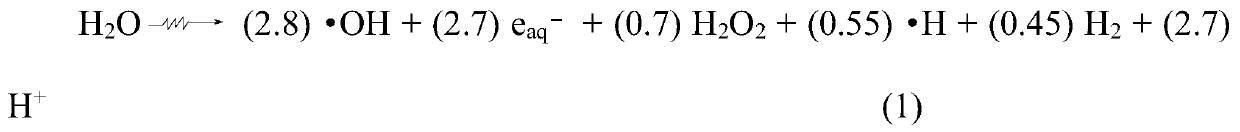

A technology of organic pollutants and ionizing radiation, applied in water pollutants, light water/sewage treatment, water/sewage treatment, etc., can solve the problems of high radiation absorbed dose, low removal effect, affecting economical application, etc. To achieve the effect of wide application, broad application prospects, efficient degradation and mineralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] MIL-88B(Fe) was prepared by one-step solvothermal method. The reaction raw material is FeCl 3 ·6H 2 O, terephthalic acid (H 2 BDC), N,N-dimethylformamide (DMF) and NaOH, reacted at 100°C for 12h, cooled naturally, washed, and dried in vacuum at 50°C for 12h.

[0042] Dissolve a certain amount of cephalosporin C sodium salt in groundwater to prepare a cephalosporin C solution with an initial concentration of 0.18mM and a pH value of 5.4. Then add 0.5g / L MIL-88B(Fe) and mix well. The mixed solution of described cephalosporin C and MIL-88B (Fe) is put into the irradiation container, adopts Co60 Gamma rays (radiation activity 3.6×1014Bq) were irradiated at a dose rate of about 30Gy / min. The absorbed dose was controlled at 0.2, 0.4, 0.6, 1.0 and 2.0kGy by adjusting the irradiation time. After the irradiation, the solution was centrifuged and precipitated to recover MIL-88B(Fe), and the supernatant was filtered through a 0.45 μm filter membrane to detect the concentratio...

Embodiment 2

[0046] Preparation of iron-based MOF-derived materials:

[0047] Firstly, MIL-100(Fe) was synthesized by one-step solvothermal method. The reaction raw materials are Fe powder, trimesic acid (H 3 BTC), HNO3 and HF, etc., reacted at 150°C for 24h, cooled naturally, washed, and dried in vacuum at 70°C for 12h. Calcination and carbonization are then carried out at a temperature of 780°C for 2 hours of reaction. Programmed temperature, argon protection.

[0048] A certain amount of cephalosporin C sodium salt was dissolved in deionized water to prepare a cephalosporin C solution with an initial concentration of 20 mg / L and a pH value of 6.1. Then add 0.5 g / L of iron-based MOF derivative material and mix well. Put the mixture of the cephalosporin C solution and the iron-based MOF derivative material into the irradiation container, and use Co 60 Gamma rays (radiation activity 3.6×1014Bq) were irradiated at a dose rate of about 30Gy / min. The absorbed dose was controlled at 0.1,...

Embodiment 3

[0052] The preparation method of the iron-based MOF derived material is the same as in Example 2.

[0053] Dissolve a certain amount of sulfamethazine in deionized water to prepare a sulfamethazine solution with an initial concentration of 20 mg / L and a pH of 5.7. Then add 0.5 g / L of iron-based MOF derivative material and mix well. Put the mixture of the sulfamethazine solution and the iron-based MOF derivative material into an irradiation container, and use Co60γ rays (radiation activity 3.6×10 14 Bq) was irradiated at a dose rate of about 30Gy / min. The absorbed dose was controlled at 0.1, 0.2, 0.4, 0.6 and 1.0kGy by adjusting the irradiation time. After the irradiation, the solution was centrifuged and precipitated to recover the iron-based MOF derivative material. After the supernatant was filtered through a 0.45 μm filter membrane, the concentrations of sulfamethazine and TOC were detected. Sulfamethazine solutions without iron-based MOF-derived materials were simultane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com