Electrocatalysis-ozone-membrane filtration three-in-one wastewater treatment device

A three-in-one, membrane filtration technology, applied in the direction of oxidized water/sewage treatment, special compound water treatment, water/sewage treatment, etc., can solve the problems of low utilization rate of oxygen and ozone, achieve good water effluent effect, efficient degradation, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

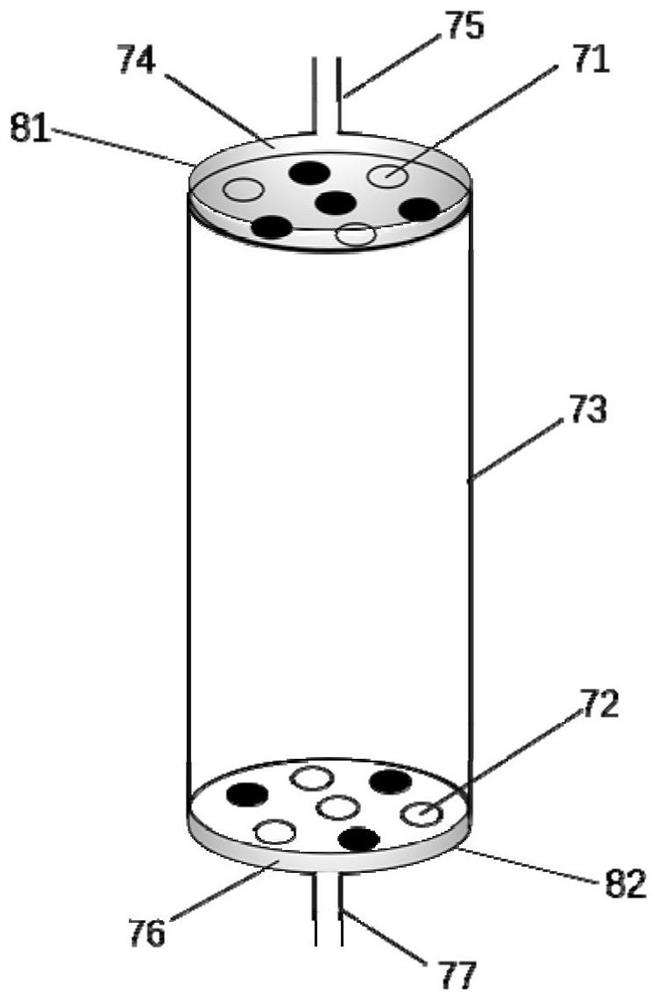

[0061] An electrocatalysis-ozone-membrane filtration trinity wastewater treatment device includes a reaction tank 1, a water inlet system, a power supply 5, an anode 6, a cathode membrane assembly, an ozone generation system, a water outlet system and a catch tank 32.

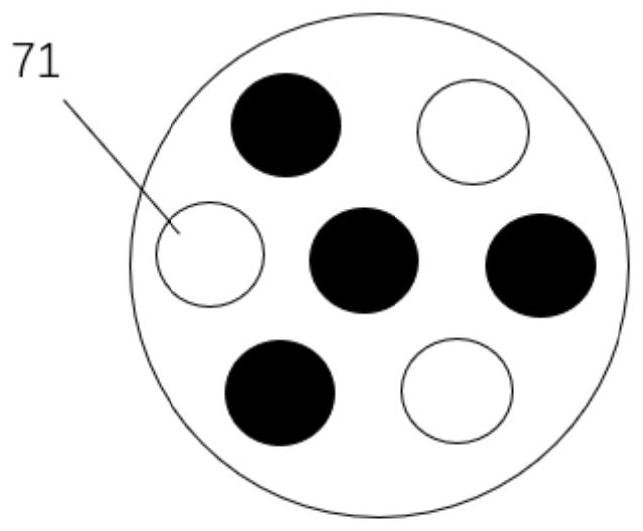

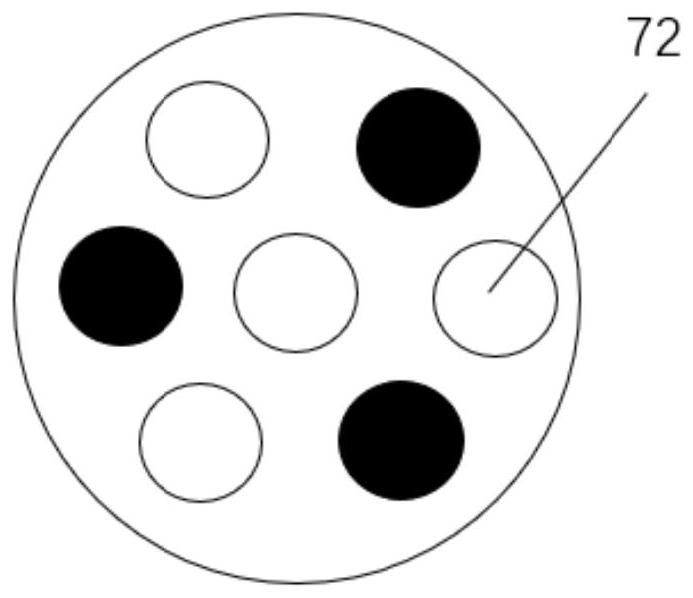

[0062] The cathode membrane assembly includes a microporous multi-channel tubular conductive ceramic membrane 7, a first cover 81 and a second cover 82, and the upper and lower ends of the microporous multi-channel tubular conductive ceramic membrane 7 are connected to the first cover 81 respectively. , the upper cavity 74 and the lower cavity 76 formed by the second cover 82, the first cover 81 is provided with a water outlet 25; the second cover 82 is provided with an air inlet 77; the micropore The multi-channel tubular conductive ceramic membrane 7 has a pore size of 20 μm, and the number of channels is 7, of which there are 4 channels sealed at the upper end and 3 channels sealed at the lower end, and the c...

Embodiment 2

[0073] The difference from Example 1 is that the microporous multi-channel tubular conductive ceramic membrane 7 is prepared by the following method.

[0074] Soak the multi-channel tubular ceramic membrane 7 with a pore size of 20 μm (the base material is SiC) in saturated NaOH-ethanol solution and ultrapure water for cleaning, take it out and wash it, place it in a glucose solution for suspension and stirring for 24 hours, and then place it in the Vacuum drying was carried out at 160° C., and carbonization was carried out at 650° C. for 2 hours under the protection of a nitrogen atmosphere, so as to prepare a carbon-deposited multi-channel tubular conductive ceramic film 7 .

[0075] The specific mode of operation of the device of the present invention is

[0076] Concrete mode of operation 1-use the device of embodiment 2 of the present invention

[0077] S1: The organic wastewater enters the reaction pool 1 through the water inlet system, and the power supply 5 is powered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com