Efficient desliming method for low-grade argillaceous zinc oxide ores

A zinc oxide ore, low-grade technology, applied in solid separation, flotation, etc., can solve the problems of low desliming efficiency and poor selectivity, and achieve high desliming efficiency, less zinc metal loss, and efficient mineralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

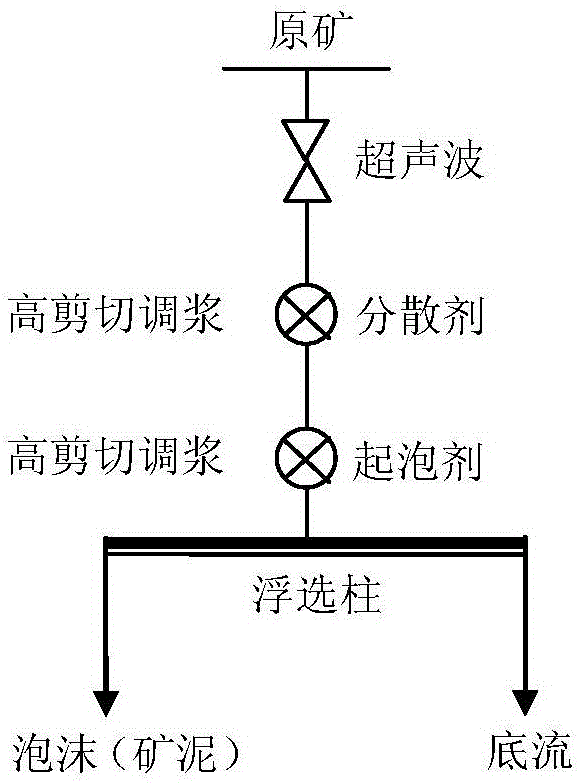

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the ore pulp solid mass concentration of raw ore is 30%,-0.074mm content 83%; Ultrasonic generation probe is inserted into ore pulp, carries out ultrasonic pretreatment, and ultrasonic frequency is 20kHz, and power is 60W; Add in the ore pulp after ultrasonic treatment 1200g / t sodium carbonate, stir for 5min, then add 20g / t terpineol oil, stir for 5min, the stirring speed is 1000r / min; send the evenly mixed pulp into the cyclone-static micro-bubble flotation column for flotation desliming , the foam in the flotation column is the detached slime, and the bottom flow of the flotation column is used for subsequent zinc oxide ore separation operations; the slime and bottom flow are filtered, dried and tested respectively.

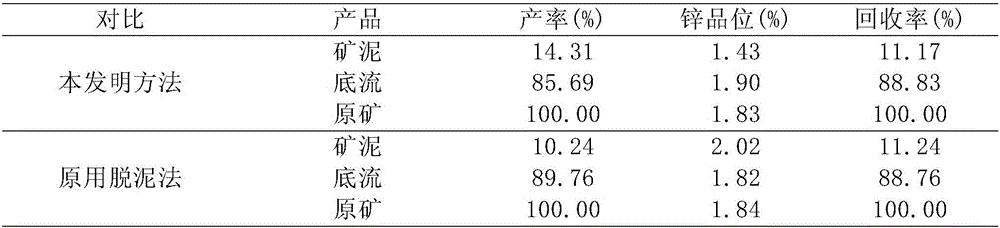

[0027] Table 1 Desliming test results

[0028]

[0029] As can be seen from Table 1, under the close situation of loss of zinc metal recovery rate, the desliming rate of the new method of the present invention is 4.07% higher than the or...

Embodiment 2

[0030] Embodiment 2: The ore pulp solid mass concentration of raw ore is 33%,-0.074mm content 85%; Ultrasonic generation probe is inserted into ore pulp, carries out ultrasonic pretreatment, and ultrasonic frequency is 30kHz, and power is 120W; Add in the ore pulp after ultrasonic treatment 1400g / t sodium carbonate, stir for 5min, then add 30g / t terpineol oil, stir for 5min, the stirring speed is 1000r / min; send the evenly mixed pulp into the cyclone-static micro-bubble flotation column for flotation desliming , the foam in the flotation column is the detached slime, and the underflow of the flotation column is used for subsequent zinc oxide ore separation operations; the foam and underflow are filtered, dried and tested respectively, and the final results are shown in Table 2.

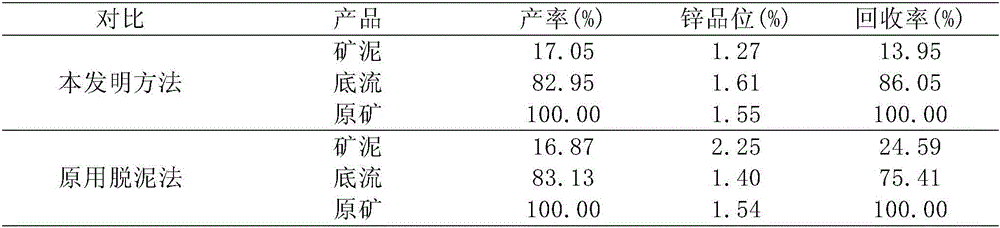

[0031] Table 2 Desliming test results

[0032]

[0033] As can be seen from Table 2, under the similar situation of desliming rate, the zinc grade of the deslimed by the new method of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com