Electrocatalysis coupled advanced oxidation system and application thereof

An advanced oxidation and electrocatalysis technology, applied in chemical instruments and methods, contaminated groundwater/leachate treatment, water pollutants, etc., can solve the problems that chloride ions are not deeply affected, and chloride ions are not mentioned and studied , to achieve the effects of good catalytic effect, easy recycling and cheap materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

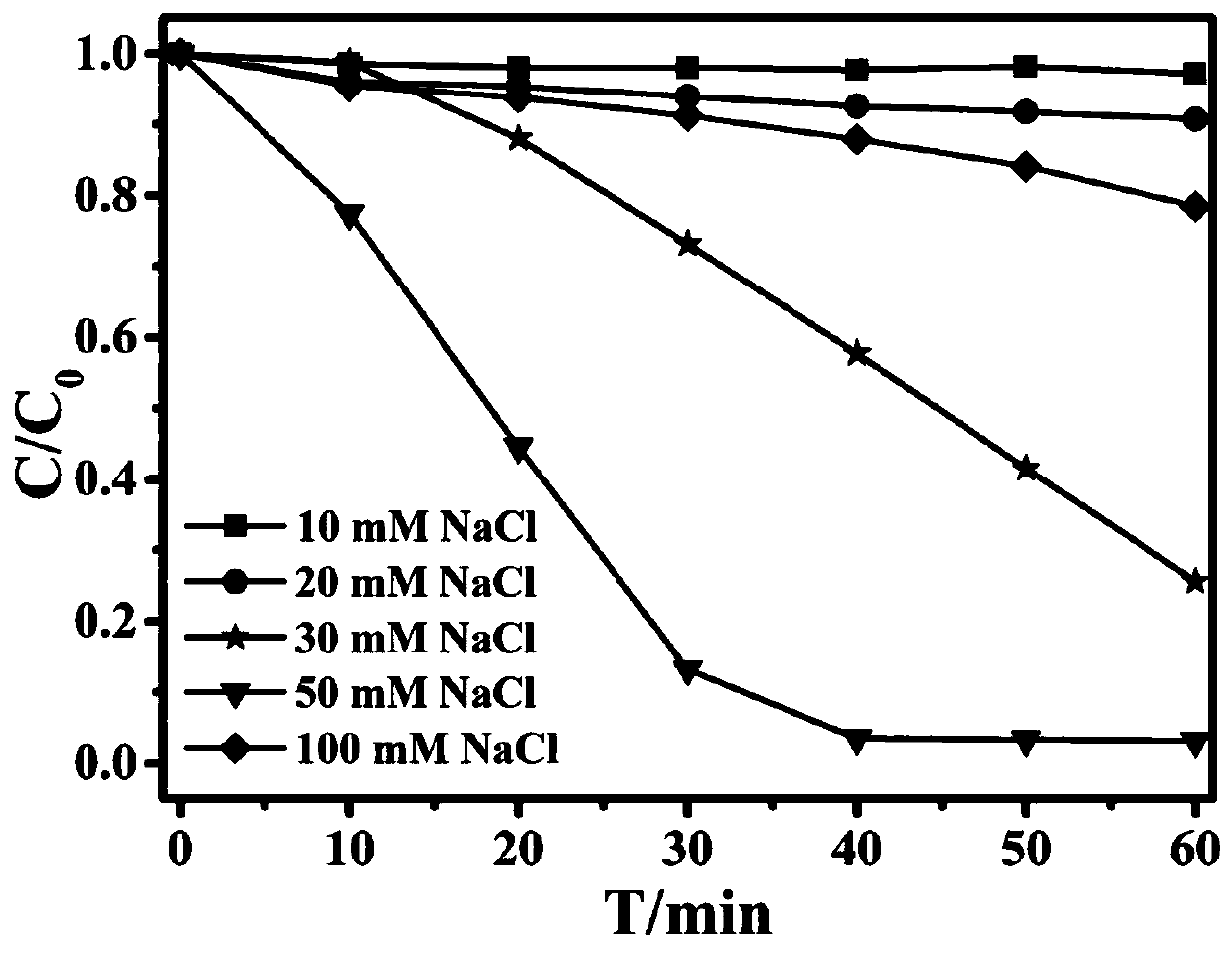

[0077] Study on the Effect of Different Concentrations of NaCl in Anolyte on the Degradation Rate of p-Nitrophenol

[0078] As a three-dimensional hexagonal star Co 3 o 4 As the anode material, the three-dimensional hexagonal star-shaped Co 3 o 4 Attached to the conductive glass as the anode, the platinum sheet as the cathode, and Ag / AgCl as the reference electrode; add 70mL of anolyte to the series of anode cells, and the concentration of sodium chloride in the anolyte is 10, 20, 30, 50 and 100mmol / L, the concentration of potassium persulfate is 0.01mmol / L, and the concentration of p-nitrophenol is 10mg / L; 70mL of sodium chloride solution with a concentration of 50mmol / L is added to the cathode cell, and the Degradation; Applied bias voltage is 2.5V vs Ag / AgCl;

[0079] The anode is attached with a three-dimensional six-pointed star-shaped Co 3 o 4 The conductive glass is prepared by the following steps:

[0080] Dissolve 2mmol of cobalt nitrate hexahydrate in 40mL of ...

Embodiment 2

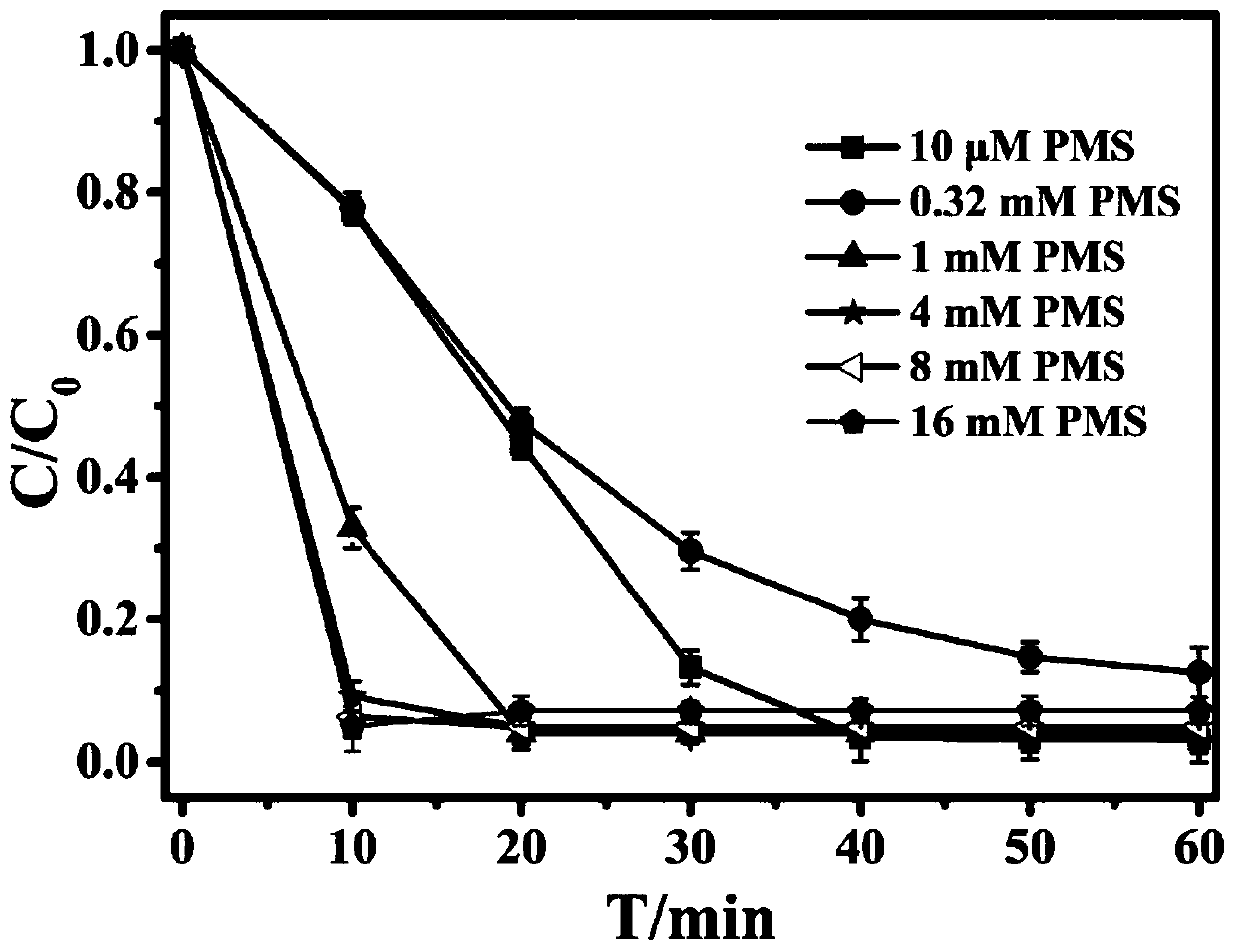

[0083] The effect of different concentrations of potassium hydrogen persulfate in the anolyte on the degradation rate of p-nitrophenol was studied using three-dimensional hexagonal star-shaped Co 3 o 4 As the anode material, the three-dimensional hexagonal star-shaped Co 3 o 4 Attached to the conductive glass as the anode, the platinum sheet as the cathode, and Ag / AgCl as the reference electrode; add 70mL of anolyte to the series of anode cells, and the concentration of sodium chloride in the anolyte is 50mmol / L. The concentration of potassium bisulfate is 0.01, 0.32, 1, 4, 8 and 16mmol / L respectively, and the concentration of p-nitrophenol is 10mg / L; add 70mL of sodium chloride solution with a concentration of 50mmol / L in the cathode pool as the cathode Electrolyte, energized for degradation; applied bias voltage is 2.5V vs Ag / AgCl;

[0084] The preparation method of the anode is the same as that of Example 1.

[0085] figure 2 It is the degradation diagram of p-nitroph...

Embodiment 3

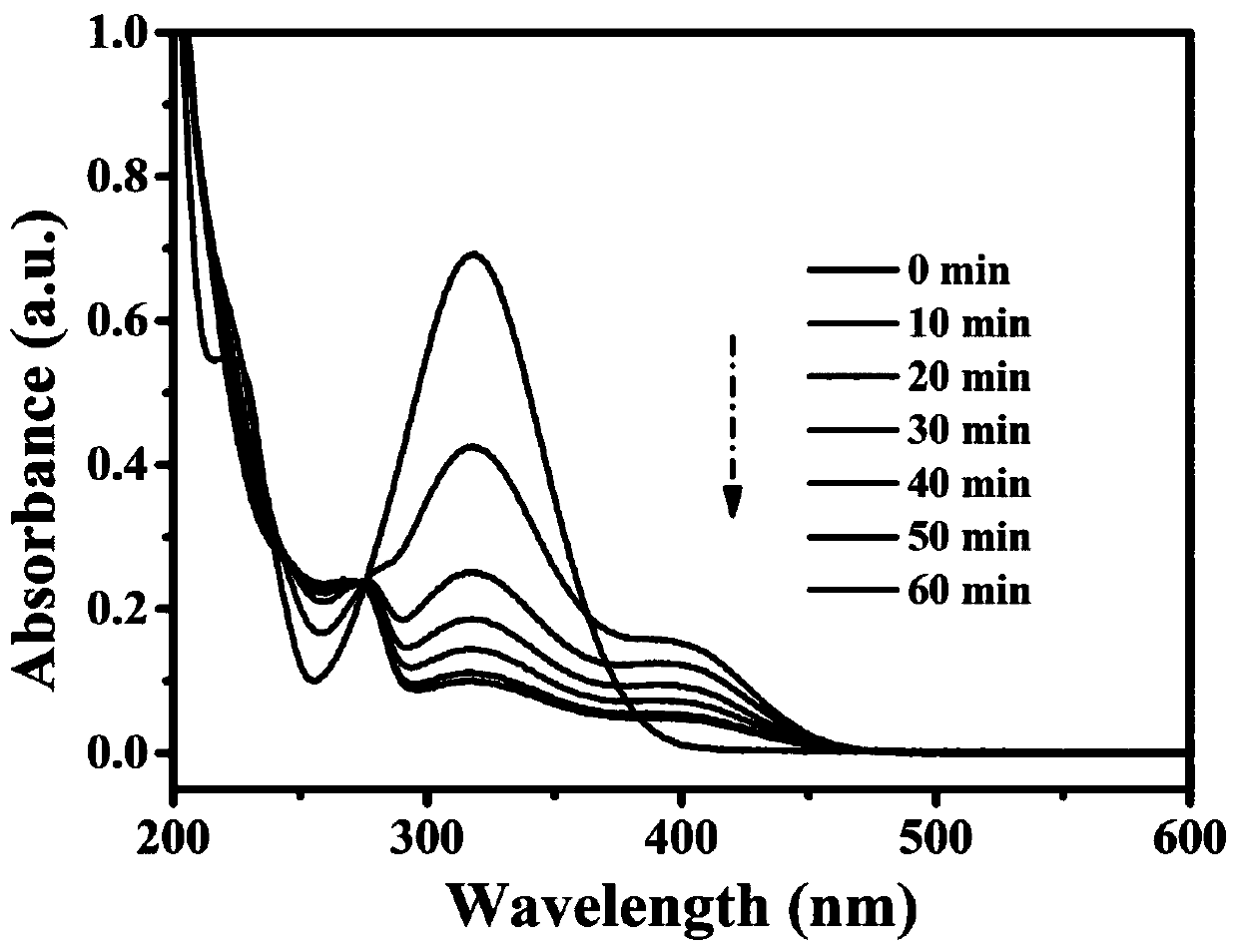

[0088] As a three-dimensional hexagonal star Co 3 o 4 As the anode material, the three-dimensional hexagonal star-shaped Co 3 o 4 Attached to the conductive glass as the anode, the platinum sheet as the cathode, and Ag / AgCl as the reference electrode; add 70mL of anolyte to the anode cell, the concentration of sodium chloride in the anolyte is 50mmol / L, persulfuric acid The concentration of potassium hydrogen is 0.01mmol / L, and the concentration of p-nitrophenol is 10mg / L; 70mL of sodium chloride solution with a concentration of 50mmol / L is added to the cathode cell, and power is applied for degradation for 1h; the applied bias voltage is 2.5V vs Ag / AgCl;

[0089] The preparation method of the anode is the same as that of Example 1.

[0090] image 3 The ultraviolet-visible full-band diagram of the electrocatalytic coupled advanced oxidation system degrading p-nitrophenol for 1 h is provided for this example. From image 3 It can be seen that when the applied bias volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com