Comprehensive treatment method for high-salt high-COD wastewater

A comprehensive treatment and waste water technology, applied in water/sewage treatment, biological water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as impact stability, poor impact load resistance, inhibition of microbial growth, etc., to eliminate impact , maintain the activity of the enzyme, promote the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

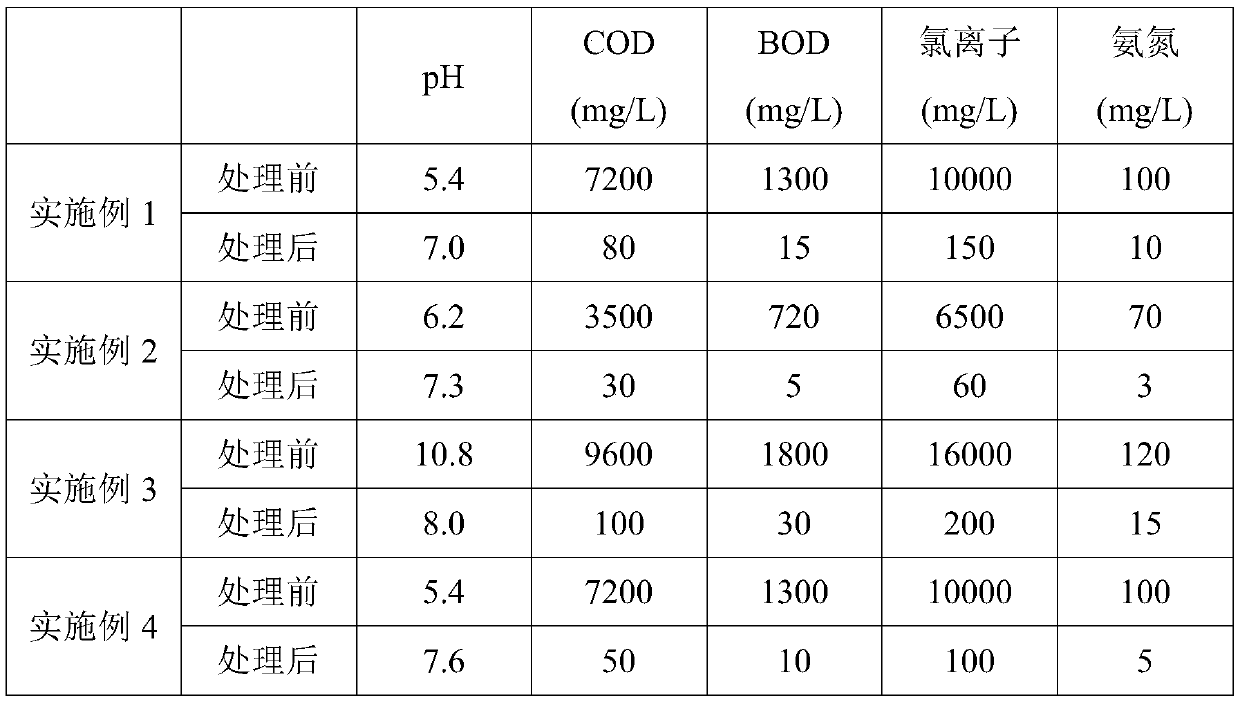

Examples

Embodiment 1

[0030] A comprehensive treatment method for high-salt and high-COD wastewater, comprising the following steps:

[0031] (1) The waste water enters the regulating pool through the grid, and the water quantity and water quality are adjusted and homogenized in the regulating pond to ensure the stability of the subsequent treatment; 10% sodium hydroxide solution is used to adjust the pH to 8.5;

[0032] (2) The effluent from the adjustment tank enters the coagulation sedimentation tank, and the flocculant polyaluminum chloride and anionic polyacrylamide are added for mixed sedimentation treatment. The dosage of polyaluminum chloride is 200mg / L, and the dosage of anionic polyacrylamide is 5mg / L , the reaction time is 30min;

[0033] (3) The effluent of the coagulation sedimentation tank enters the ultrasonic electrocatalytic oxidation device for treatment, the ultrasonic frequency is 20kHz, and the current density is 400A / m 2 , electrode spacing D=30mm, voltage 4.0V, reaction time...

Embodiment 2

[0041] A comprehensive treatment method for high-salt and high-COD wastewater, comprising the following steps:

[0042] (1) The waste water enters the regulating pool through the grid, and the water quantity and water quality are adjusted and homogenized in the regulating pond to ensure the stability of the subsequent treatment; the pH is adjusted to 9.0 by using 5% calcium hydroxide solution;

[0043] (2) The effluent from the adjustment tank enters the coagulation sedimentation tank, and the flocculant ferrous sulfate and cationic polyacrylamide are added for mixed sedimentation treatment. The dosage of ferrous sulfate is 500mg / L, and the dosage of cationic polyacrylamide is 6mg / L. Time 25min;

[0044] (3) The effluent of the coagulation sedimentation tank enters the ultrasonic electrocatalytic oxidation device for treatment, the ultrasonic frequency is 25kHz, and the current density is 300A / m 2 , electrode spacing D = 40mm, voltage 5.0V, reaction time 1.5h;

[0045] (4) U...

Embodiment 3

[0052] A comprehensive treatment method for high-salt and high-COD wastewater, comprising the following steps:

[0053] (1) The waste water enters the regulating pool through the grid, and the water quantity and water quality are adjusted and homogenized in the regulating pond to ensure the stability of the subsequent treatment; 5% sulfuric acid solution is used to adjust the pH to 9.5;

[0054] (2) The effluent from the adjustment tank enters the coagulation sedimentation tank, and the flocculant polyaluminum ferric sulfate and non-ionic polyacrylamide are added for coagulation treatment. The dosage of polyaluminum ferric sulfate is 600mg / L, and the dosage of non-ionic polyacrylamide is 7mg / L, the reaction time is 40min;

[0055] (3) The effluent of the coagulation sedimentation tank enters the ultrasonic electrocatalytic oxidation device for treatment, the ultrasonic frequency is 28kHz, and the current density is 500A / m 2 , electrode spacing D = 25mm, voltage 6.0V, reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com