Advanced treatment process for fermentation antibiotic wastewater

A technology for the advanced treatment of antibiotic wastewater, which is applied in biological water/sewage treatment, water/sewage treatment, natural water treatment, etc., and can solve problems such as difficulties in practical application, technical stagnation of advanced treatment of fermented antibiotic wastewater, and failure to discharge wastewater up to standard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

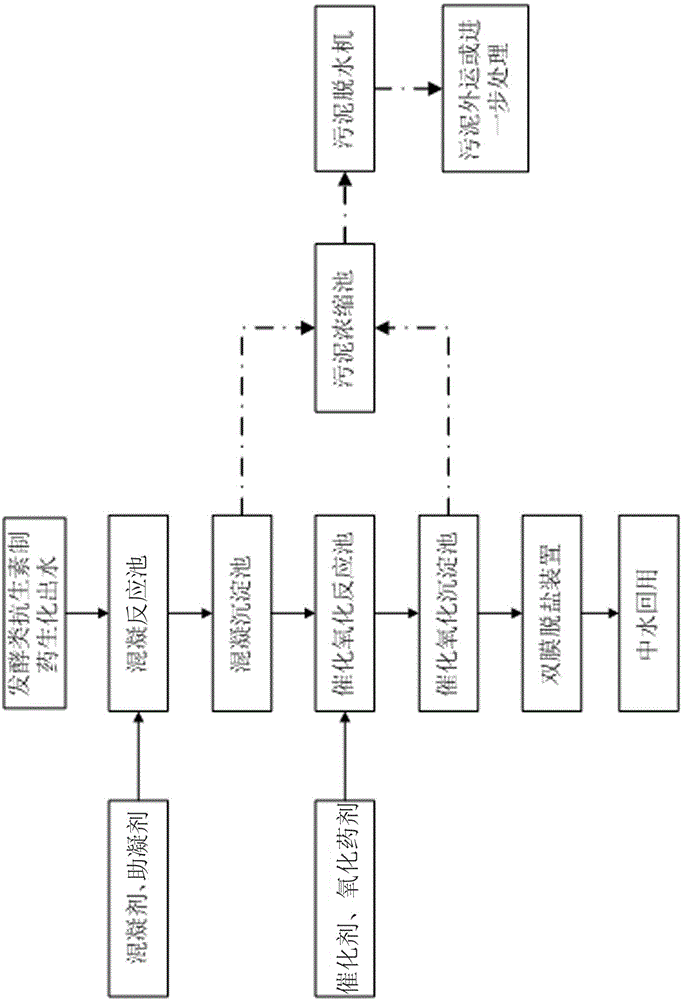

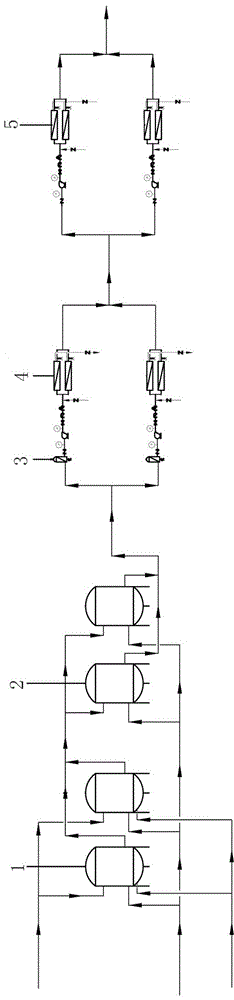

[0018] Embodiment 1: a kind of advanced treatment technology of fermented class antibiotic waste water, as figure 1 , figure 2 As shown, firstly, the fermentation antibiotic wastewater is biochemically treated: three steps: hydrolytic acidification, anaerobic reaction and aerobic reaction. The conditions for hydrolytic acidification are that the pH of the wastewater is between 5-9, and the temperature of the wastewater is 20-40°C. A large number of microorganisms are required to participate in the reaction in the hydrolytic acidification tank, and the main purpose is to improve the biodegradability of wastewater; the conditions for anaerobic reaction are that the pH of the influent is between 6.8-7.6, and the temperature of the wastewater is optimal at 30-36°C, which requires a large amount of anaerobic reaction. Microbes participate in the reaction, including methanogenic bacteria, acetogenic bacteria, etc. The conditions for aerobic reaction are that the pH of the wastewate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com