Regeneration method for urban sewage by continuous flow

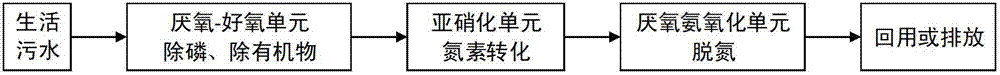

A technology for urban domestic sewage and water inflow, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Loss of nitrosation effect and other problems, to achieve the effect of high phosphorus removal efficiency and power cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The water used for the test was effluent from a septic tank in a community in Beijing. The water temperature was 20-22°C. The raw water COD was 290.0-313.0mg / L, the ammonia nitrogen was 54.5-64.2mg / L, the total nitrogen was 59-72mg / L, and the nitrite nitrogen And nitrate nitrogen is less than 0.2mg / L, TP is 5.92-7.81mg / L.

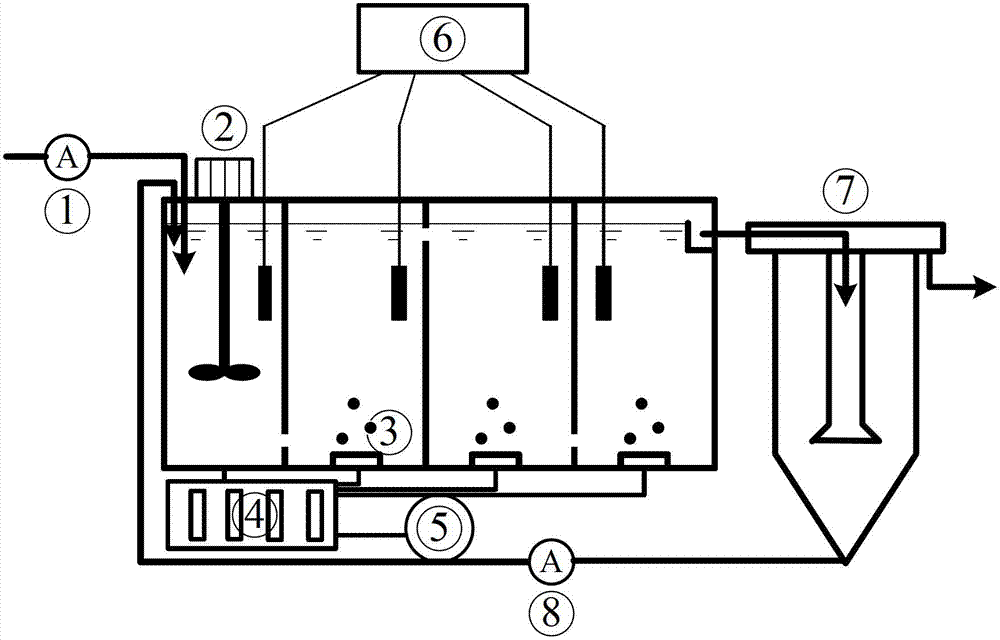

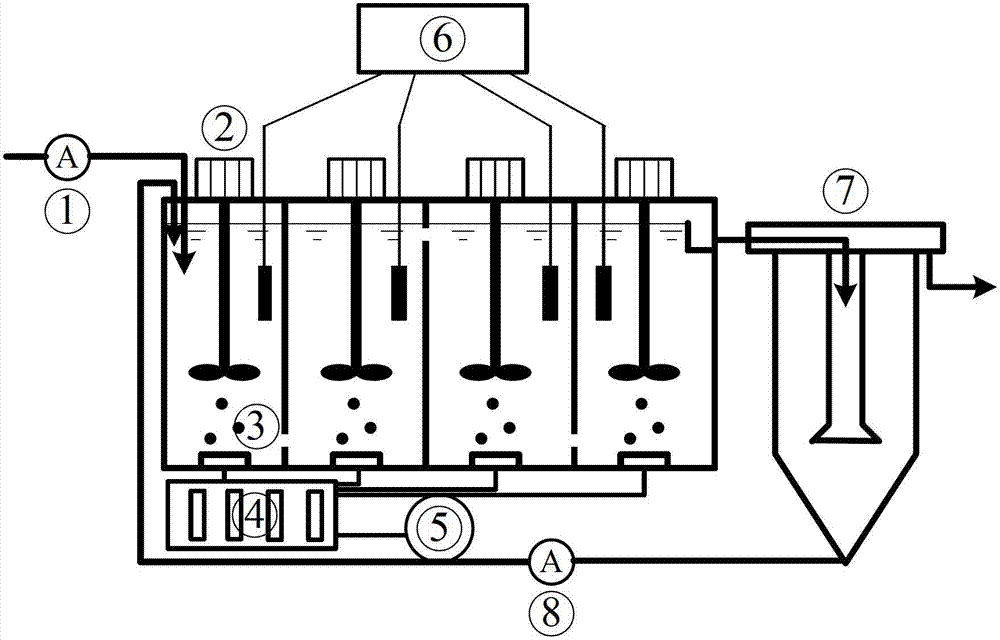

[0039] The length × width × height of the anaerobic-aerobic process reactor is 2m × 0.6m × 1m, and the effective volume is 1.08m 3 , divided into anaerobic zone and aerobic zone, which are separated by a perforated baffle, and the volume ratio is 1:3.5. The anaerobic zone is equipped with a mixer 2, and the aerobic zone is divided into three sections, and the aeration plate 3 is used for aeration. The air compressor 5 supplies air, the gas flow meter 4 adjusts the aeration rate, the online dissolved oxygen meter 6 measures the dissolved oxygen, the sedimentation tank 7 is a vertical flow type, the diameter is 0.5m, the central tube height is 0.95m, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com