Method for preparing magnesium oxychloride doped aluminosilicate cement from waste incineration fly ash and aluminum ash

A technology for waste incineration fly ash and aluminosilicate cement, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of few products, harmless disposal and resource utilization technology Immature, restricting the application of aluminum ash, etc., to achieve the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

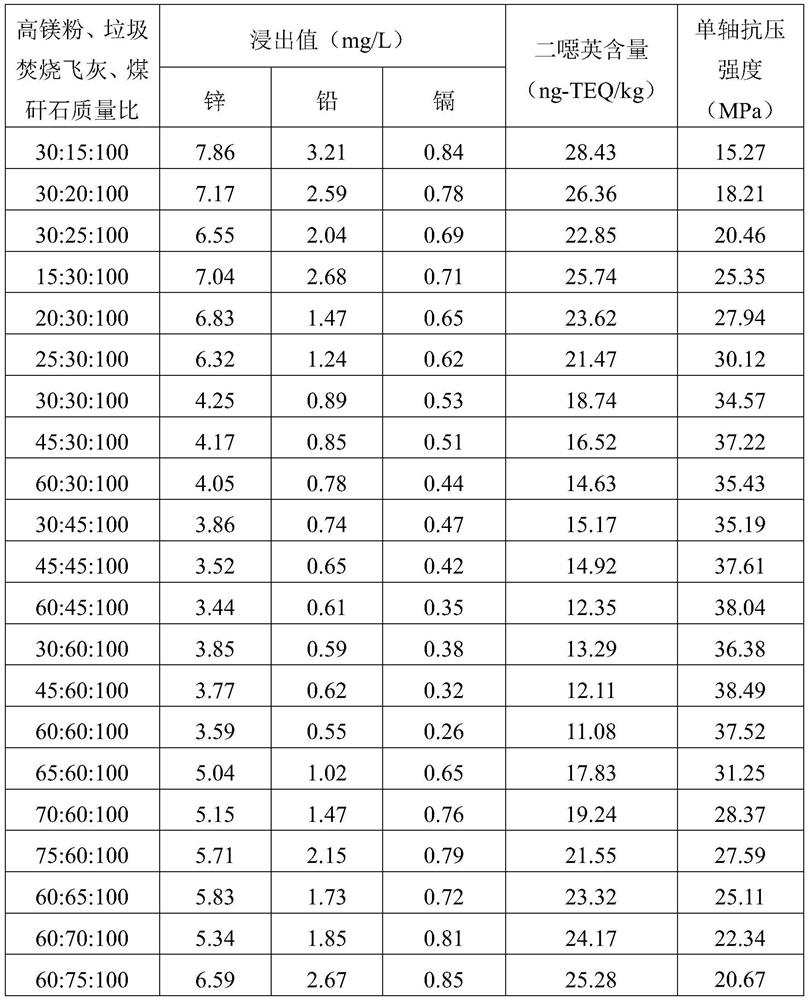

[0020] Effects of mass ratio of high magnesium powder, waste incineration fly ash and coal gangue on the properties of prepared magnesium oxychloride mixed aluminosilicate cement

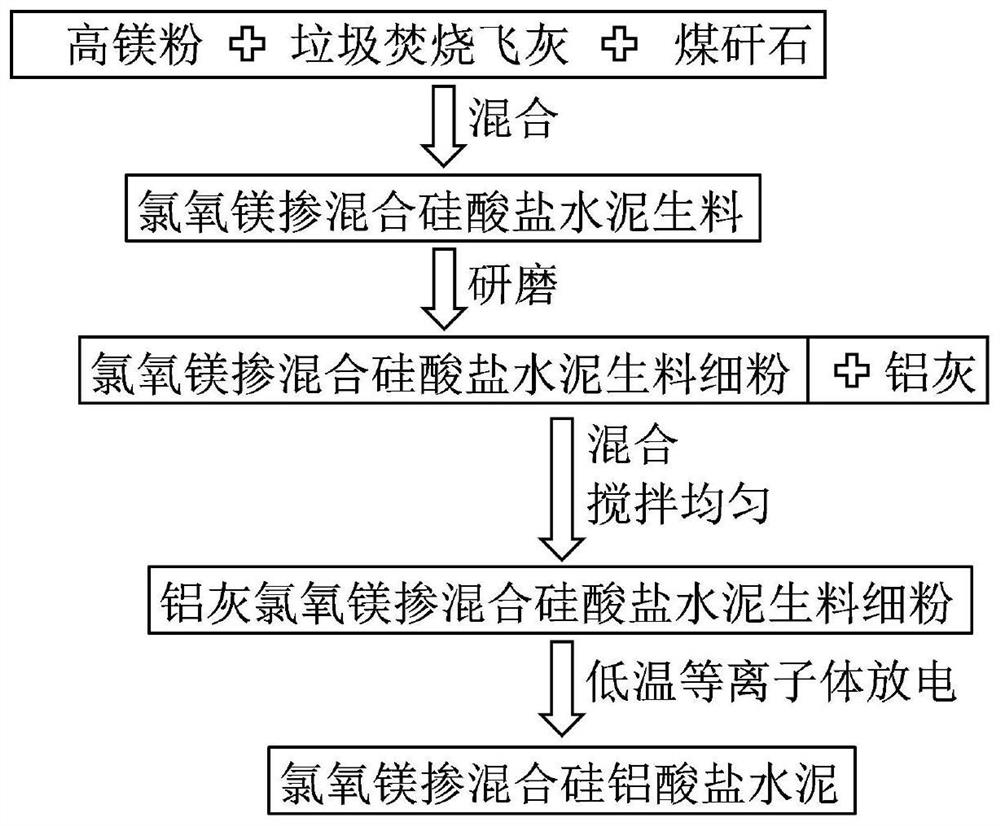

[0021] Preparation of magnesium oxychloride mixed with aluminosilicate cement: such as figure 1 As shown, according to the mass ratios 30:15:100, 30:20:100, 30:25:100, 15:30:100, 20:30:100, 25:30:100, 30:30:100, 45: 30:100, 60:30:100, 30:45:100, 45:45:100, 60:45:100, 30:60:100, 45:60:100, 60:60:100, 65:60: 100, 70:60:100, 75:60:100, 60:65:100, 60:70:100, 60:75:100 respectively weigh high magnesium powder, waste incineration fly ash and coal gangue, and mix them to obtain chlorine Magnesium oxychloride mixed with Portland cement raw meal, and ground for 3 hours to obtain fine powder of magnesium oxychloride mixed with Portland cement raw meal; weigh aluminum ash and magnesium oxychloride mixed with Portland cement in a mass ratio of 5:100 Raw meal fine powder, mix and stir evenly to obtain aluminum...

Embodiment 2

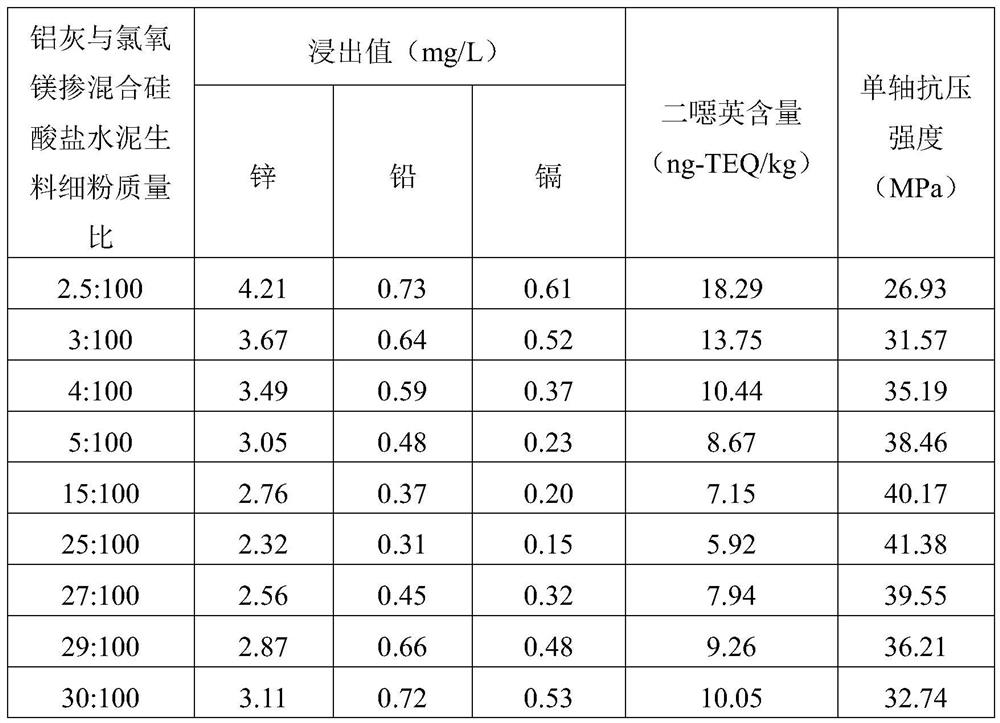

[0030] Effect of mass ratio of aluminum ash and magnesium oxychloride blended with Portland cement raw meal fine powder on the properties of prepared magnesium oxychloride blended with aluminosilicate cement

[0031] Preparation of magnesium oxychloride mixed with aluminosilicate cement: Weigh high magnesium powder, waste incineration fly ash and coal gangue according to the mass ratio of 60:60:100, and mix them to obtain magnesium oxychloride mixed with Portland cement raw meal, Grind for 7.5 hours to obtain magnesium oxychloride mixed with Portland cement raw meal fine powder; At 29:100 and 30:100, respectively weigh aluminum ash and magnesium oxychloride mixed with Portland cement raw meal fine powder, mix and stir evenly to obtain aluminum ash magnesium oxychloride mixed with Portland cement raw meal fine powder; Aluminum ash magnesium oxychloride mixed with Portland cement raw meal fine powder was blown into the low-temperature plasma discharge channel for 5.25 hours to o...

Embodiment 3

[0037] Effect of low temperature plasma discharge voltage on properties of prepared magnesium oxychloride mixed aluminosilicate cement

[0038] Preparation of magnesium oxychloride mixed with aluminosilicate cement: Weigh high magnesium powder, waste incineration fly ash and coal gangue according to the mass ratio of 60:60:100, and mix them to obtain magnesium oxychloride mixed with Portland cement raw meal, Grind for 12 hours to obtain magnesium oxychloride mixed with Portland cement raw meal fine powder; weigh aluminum ash and magnesium oxychloride mixed with Portland cement raw meal fine powder in a mass ratio of 25:100, mix and stir evenly to obtain Aluminium ash magnesium oxychloride mixed with Portland cement raw meal fine powder; the aluminum ash magnesium oxychloride mixed with Portland cement raw meal fine powder was blown into the low temperature plasma discharge channel for 1.25 hours to obtain magnesium oxychloride mixed Aluminosilicate cement, wherein the low temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com