Method for treating N-(phosphonomethyl)iminodiacetic acid wastewater

A treatment method and technology of glyphosate, applied in natural water treatment, heating water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of waste of resources, poor biochemical treatment effect, high salt content, and reduce COD. and salt content, harmless treatment, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A pesticide factory in Shandong produces 5 tons of glyphosate wastewater per hour, which is treated and recycled using the technology provided by the invention. The process is as follows:

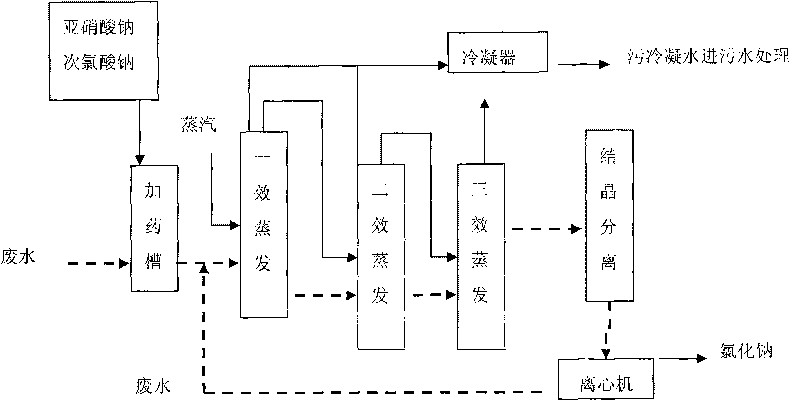

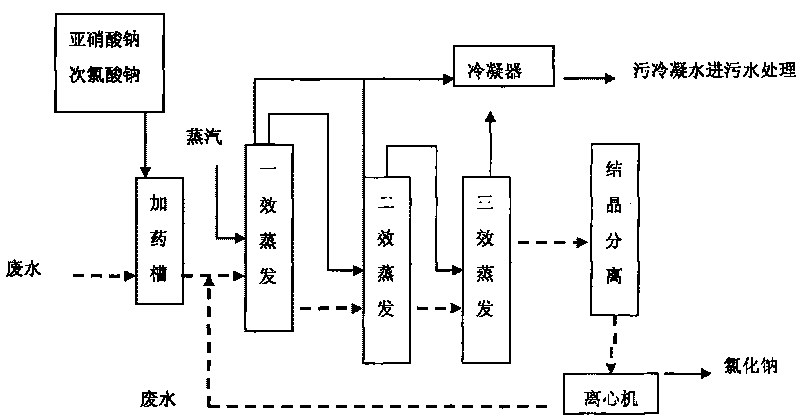

[0017] Diglyphosate mother liquor COD is 100000mg / L, first filtered, introduced into the dosing tank through a lift pump, added to the dosing tank at the rate of 37.5kg sodium nitrite per hour and 72.5kg sodium chlorate per hour, and stirred for 30min. Control the water inflow at 5 tons / hour, pour water into the multi-effect evaporator, control the temperature in the primary evaporator at about 70°C, and the vacuum degree at about -0.09Mpa, continuously feed water during the evaporation process, and the first-stage residence time is about After 20 minutes, it enters the second stage evaporation, the temperature is controlled at about 90°C, the vacuum degree is about -0.05Mpa, and the temperature is raised to further catalyze the oxidation. Further increase the temperature, and the re...

Embodiment 2

[0020] A pesticide factory in Shandong produces 15 tons of glyphosate wastewater per hour, which is treated and recycled using the technology provided by the invention. The process is as follows:

[0021] Diglyphosate mother liquor COD is 100000mg / L. Firstly, it is filtered and then introduced into the dosing tank through a lifting pump. The dosage of 160kg sodium nitrite per hour and 200kg sodium chlorate per hour is added to the dosing tank, stirred for 50min, and controlled. The water volume is 15 tons / hour, and the water is poured into the multi-effect evaporator. The temperature in the first-stage evaporator is controlled at about 65°C, and the vacuum degree is about -0.08Mpa. Water is continuously fed during the evaporation process, and the first-stage residence time is about 25 minutes. , enter the secondary evaporation, the temperature is controlled at about 95°C, the vacuum degree is about -0.05Mpa, the temperature is raised to further catalyze the oxidation, and the r...

Embodiment 3

[0024] A pesticide factory in Jiangsu produces 8 tons of glyphosate wastewater per hour, which is treated and recycled using the technology provided by the invention. The process is as follows:

[0025] Diglyphosate mother liquor COD is 120000mg / L. First, after filtering, it is introduced into the dosing tank through a lift pump, and is added to the dosing tank at the dosage of 42kg sodium nitrite per hour and 102kg sodium chlorate per hour, and stirred for 60min to control the feeding time. The water volume is 8 tons per hour, and then the water is poured into the multi-effect evaporator. The temperature in the first-stage evaporator is controlled at about 75°C, the vacuum degree is about -0.09Mpa, water is continuously fed during the evaporation process, and the first-stage residence time is about 25 Minutes, enter the secondary evaporation, the temperature is controlled at about 100 ° C, the vacuum is about -0.05Mpa, the temperature is raised to further catalyze the oxidatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com