Treatment method of printing ink wastewater generated in circuit board production

A technology for ink wastewater and treatment methods, which is applied in water/sewage treatment, illuminated water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of membrane pollution, poor effect, difficult treatment, etc., and achieve reduction of membrane pollution and efficiency High, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

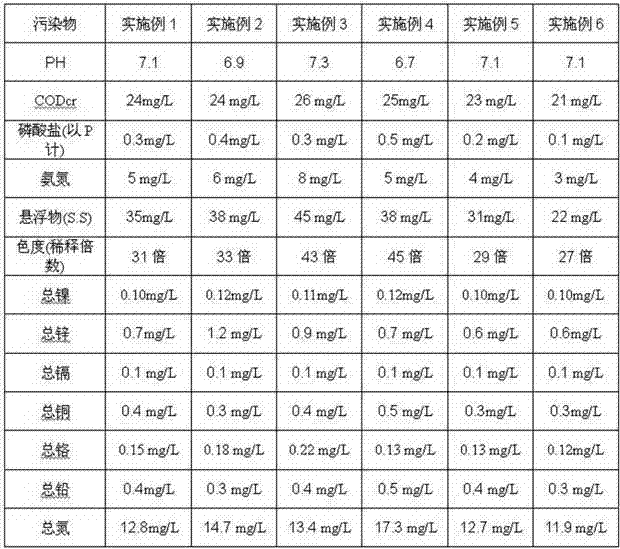

[0024] A method for treating ink wastewater produced by circuit boards, comprising the steps of:

[0025] S1. Raw water collection pool: firstly, import the raw water of circuit board production ink wastewater into the raw water collection pool for water quality balance, and then pump it into S2, reaction pool;

[0026] S2. Reaction tank: The wastewater after the water quality balance in the raw water collection tank is adjusted in the reaction tank to make the pH value of the wastewater 3.0. At the same time, a coagulant is added to the reaction tank. The amount of the coagulant added is 3mg / L; the coagulant is powdered activated carbon particles, the fineness of the powdered activated carbon particles is 130-200 mesh, stirred and mixed to form a mud-water mixture of flocs;

[0027] S3, filter press: use a pump to send the mud-water mixture in the reaction tank into the plate-and-frame filter press, perform solid-liquid separation on the mud-water mixture, transport the filt...

Embodiment 2

[0037] A method for treating ink wastewater produced by circuit boards, comprising the steps of:

[0038] S1. Raw water collection pool: firstly, import the raw water of circuit board production ink wastewater into the raw water collection pool for water quality balance, and then pump it into S2, reaction pool;

[0039] S2. Reaction tank: The wastewater after the water quality balance in the raw water collection tank is adjusted in the reaction tank to make the pH value of the wastewater 2.6. At the same time, a coagulant is added to the reaction tank. The amount of the coagulant added is 4mg / L; the coagulant is a mixture of powdered activated carbon particles, aluminum sulfate, and ferrous sulfate, and the mass ratio of each component is powdered activated carbon particles: aluminum sulfate: ferrous sulfate=1:1:1, the powdery The fineness of activated carbon particles is 130-200 mesh, stirring and mixing to form a mud-water mixture of flocs;

[0040] S3, filter press: use a...

Embodiment 3

[0050] A method for treating ink wastewater produced by circuit boards, comprising the steps of:

[0051] S1. Raw water collection pool: firstly, import the raw water of circuit board production ink wastewater into the raw water collection pool for water quality balance, and then pump it into S2, reaction pool;

[0052] S2. Reaction tank: The wastewater after the water quality balance in the raw water collection tank is adjusted in the reaction tank to make the pH value of the wastewater 2.9. At the same time, a coagulant is added to the reaction tank. The amount of the coagulant added is 5mg / L; the coagulant is formed by mixing powdered activated carbon particles and ferric chloride at a mass ratio of 1:1, the fineness of the powdered activated carbon particles is 130-200 mesh, stirred and mixed to form a mud-water mixture of flocs ;

[0053] S3, filter press: use a pump to send the mud-water mixture in the reaction tank into the plate-and-frame filter press, perform solid-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com