Styrene exhaust gas treatment method

A technology for waste gas treatment and styrene, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as easy polymerization, large thermal effect of polymerization and adsorption heat effect, inability to regenerate, complex device configuration, etc., to eliminate environmental risks and safety hazards, reduce styrene emissions, and occupy a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

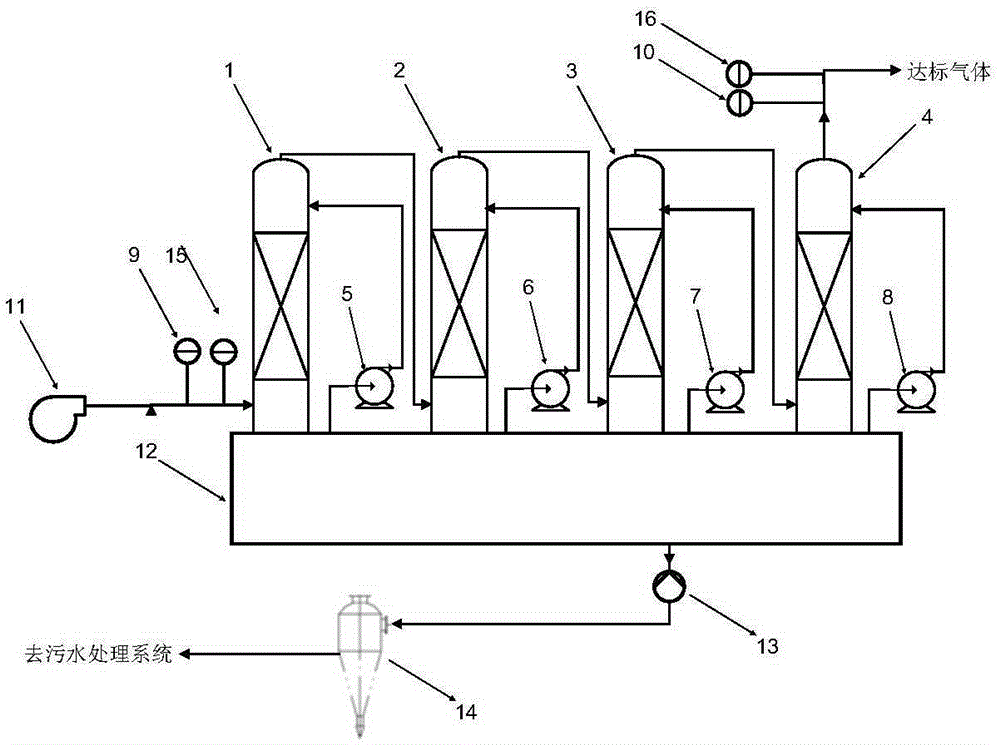

[0022] The invention provides a method for treating styrene waste gas. The method mainly includes the following steps: making countercurrent contact between styrene waste gas and an alkaline solution of potassium permanganate, and during the contact process, the alkaline solution of styrene and potassium permanganate Oxidation reaction occurs, C 6 h 5 CH=CH 2 +OH-+KMnO 4 =C 6 h 5 CH(O)CH 2 OH+MnO 2 +K 2 MnO 4 +H 2 O, after the reaction is completed, the waste gas that consumes styrene is discharged into the atmosphere.

[0023] Specifically, the styrene waste gas and the alkaline solution of potassium permanganate can be countercurrently contacted in the absorption tower, and the inside of the absorption tower is provided with a packing layer. Styrene waste gas enters the absorption tower from the bottom of the absorption tower, and the alkaline solution of potassium permanganate enters the absorption tower from the top of the absorption tower. In the packing layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com