Ceramic thin film cast iron piston ring and manufacturing method thereof

A ceramic film, cast iron piston technology, applied in the field of piston rings, can solve the problems of poor wear resistance, large wear power loss, and large attack of the cylinder body, and achieves strong anti-sintering ability, stable performance and small wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

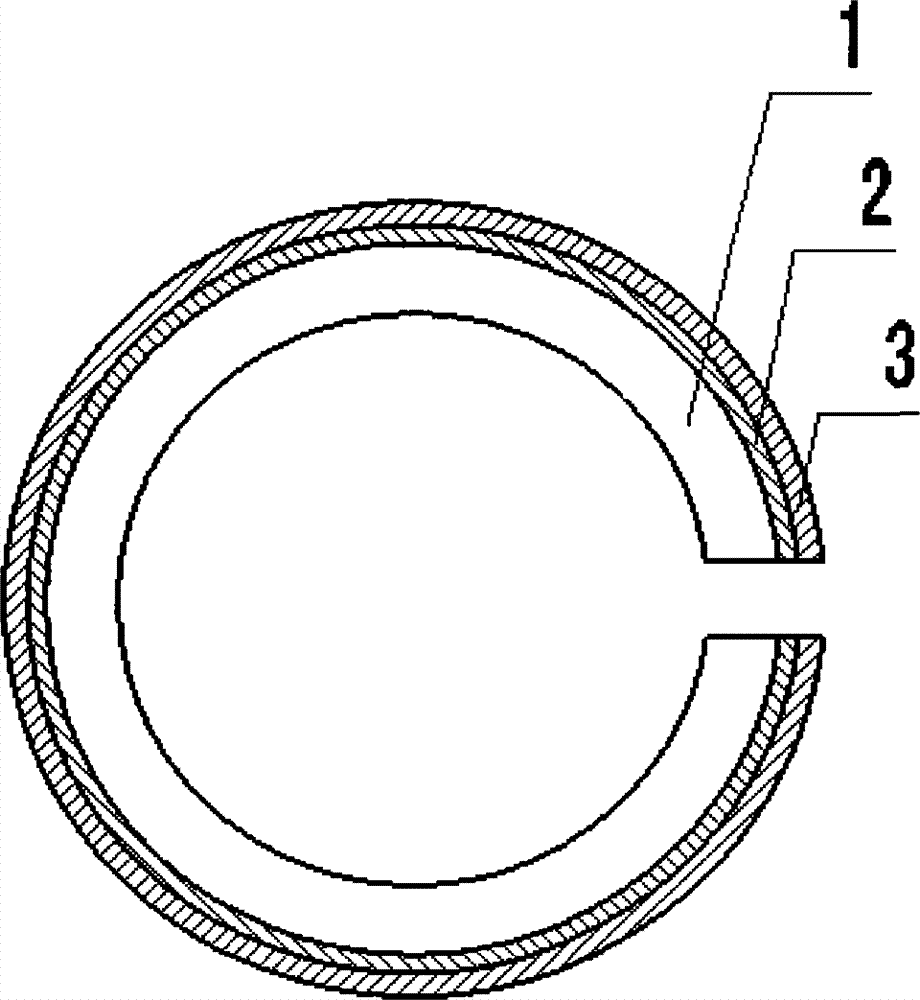

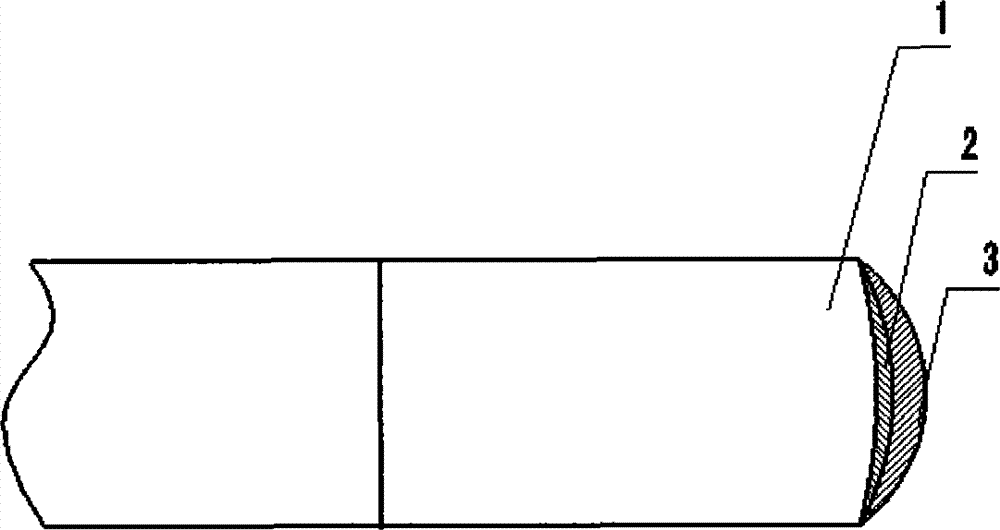

[0035] see figure 1 , figure 2 , the wear-resistant cast iron piston ring of the present invention comprises a piston ring ring body 1, a transitional thin chromium plating layer 2 on the outer circumference of the ring, and a ceramic film 3 coated on the outer circumference of the thin chromium layer 2. The formation principle of the ceramic thin film 3 is: using Ti or Cr metal as the evaporation source, through arc discharge, and N 2 , O 2 React, and solidify on the nitrided layer of the target source of the piston ring to form TiN, CrN, CrN[O] ceramic thin films. The metal vaporization ion rate is high, and the deposition effect is good. The specific embodiment of the present invention is as follows:

Embodiment approach 1

[0037] Step 1. Conventional preliminary processing of piston rings such as casting, cutting, copying, and inner circle turning;

[0038] Step 2, processing the outer circular surface and the upper and lower sides of the piston ring through a grinding process;

[0039] Step 3. Use ultrasonic waves to clean and degrease the surface of the piston ring;

[0040] Step 4: Use the clamping cylinder to clamp the piston ring and polish the outer surface;

[0041] Step 5, chrome plating treatment on the outer circle, the treatment time is 0.5 hours, and the temperature of the electroplating bath is 60°C;

[0042] Step 6, sandblasting the inner and outer surfaces;

[0043] Step 7. Piston ring degreasing and cleaning;

[0044] Step 8: Loading into PVD furnace, PVD treatment, treatment process time: 15-20 hours, treatment temperature: 400-500°C.

[0045] Step 9, honing and finishing of the outer circular surface;

[0046] Step 10. Grinding and finishing the upper and lower sides.

Embodiment approach 2

[0048] Step 1. Conventional preliminary processing of piston rings such as casting, cutting, copying, and inner circle turning;

[0049] Step 2, processing the outer circular surface and the upper and lower sides of the piston ring through a grinding process;

[0050] Step 3. Use ultrasonic waves to clean and degrease the surface of the piston ring;

[0051] Step 4. Use the clamping cylinder to clamp the piston ring and polish the outer surface:

[0052] Step five, sandblasting the inner and outer surfaces;

[0053] Step 6. Degreasing and cleaning the piston ring;

[0054] Step 7: Loading into a PVD furnace for PVD treatment. Processing time: 17-22 hours, processing temperature: 400-500°C. If the ceramic film is CrN or CrN[O], just install the chromium block target, use Cr metal as the evaporation source, discharge through the arc, and set the PVD furnace program, and do not feed N within 2 hours at the beginning of the discharge. 2 , O 2 , only metal chromium ions are d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com