Method for deeply treating antibiotic pharmaceutical wastewater based on magnetic Fenton-like resin

A technology for advanced treatment of pharmaceutical wastewater, applied in natural water treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

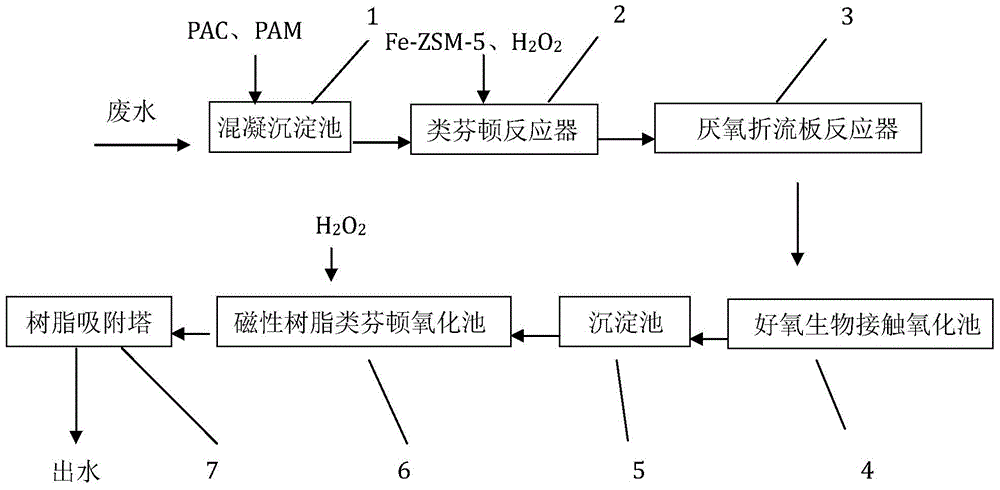

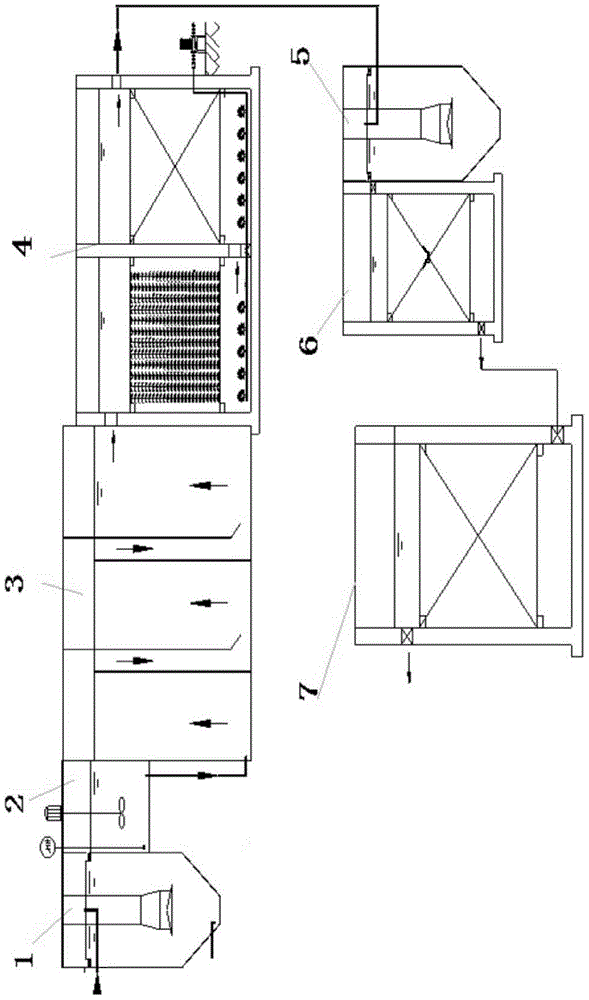

[0032] Such as figure 1 , 2As shown, a device based on magnetic Fenton resin for advanced treatment of antibiotic pharmaceutical wastewater is a coagulation sedimentation tank 1, Fenton-like reactor 2, anaerobic baffle reactor 3, aerobic biological Contact oxidation tank 4, sedimentation tank 5, magnetic resin Fenton oxidation tank 6, resin adsorption tower 7; wherein the coagulation sedimentation tank 1 and the sedimentation tank adopt a vertical flow structure; the Fenton-like reactor 2 is equipped with agitator and pH meter; the anaerobic baffle reactor 3 is provided with four vertically installed baffles, which are the first lower baffle, the first upper baffle, the second lower baffle, and the second upper baffle Flow plate, four baffle plates divide the anaerobic baffle reactor 3 into a first upflow chamber, a first downflow chamber, a second upflow chamber, a second downflow chamber, a third upflow chamber, the first upflow chamber and the second upflow chamber The tw...

Embodiment 2

[0044] Embodiment 2: basically the same as embodiment 1, the difference is: in the step (1), the coagulant dosage is controlled at 50g / m 3 , hydraulic retention time is controlled at 3.5h; In step (2), the dosage of Fe-ZSM-5 is 0.5g / L, H 2 o 2 The dosage is 5ml / L, the reaction pH value is controlled between 4-5, and the hydraulic retention time is controlled at 1h; the hydraulic retention time is controlled at 10h in step (3); the dissolved oxygen DO value is controlled at 4mg / L, hydraulic retention time is controlled at 7h; In step (5), hydraulic retention time is 3h; In step (6), H 2 o 2 The dosage is 0.5ml / L, the hydraulic retention time is controlled at 1h, and the hydraulic retention time is controlled at 5h in step (7).

Embodiment 3

[0045] Embodiment 3: basically the same as Embodiment 1, the difference is: in step (1), the dosage of coagulant is controlled at 100g / m 3 , hydraulic retention time is controlled at 3h; In step (2), the dosage of Fe-ZSM-5 is 0.8g / L, H 2 o 2 The dosage is 0.5ml / L, the reaction pH value is controlled between 5-6, and the hydraulic retention time is controlled at 0.5h; the hydraulic retention time is controlled at 6h in step (3); the DO value of dissolved oxygen in step (4) Control at 5mg / L, hydraulic retention time is controlled at 8h; In step (5), hydraulic retention time is 2.5h; In step (6), H 2 o 2 The dosage is 1ml / L, the hydraulic retention time is controlled at 1h, and the hydraulic retention time is controlled at 3h in step (7).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com