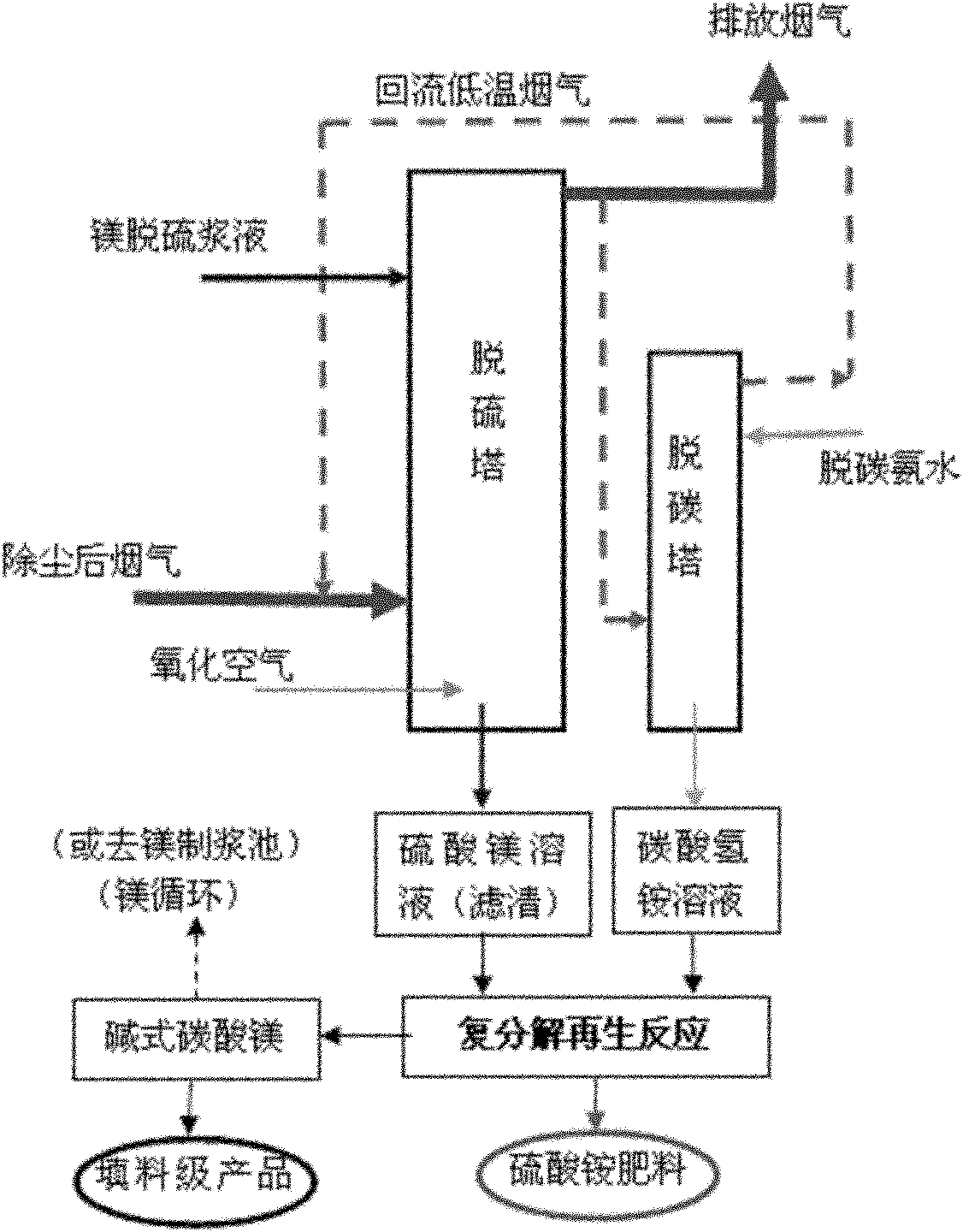

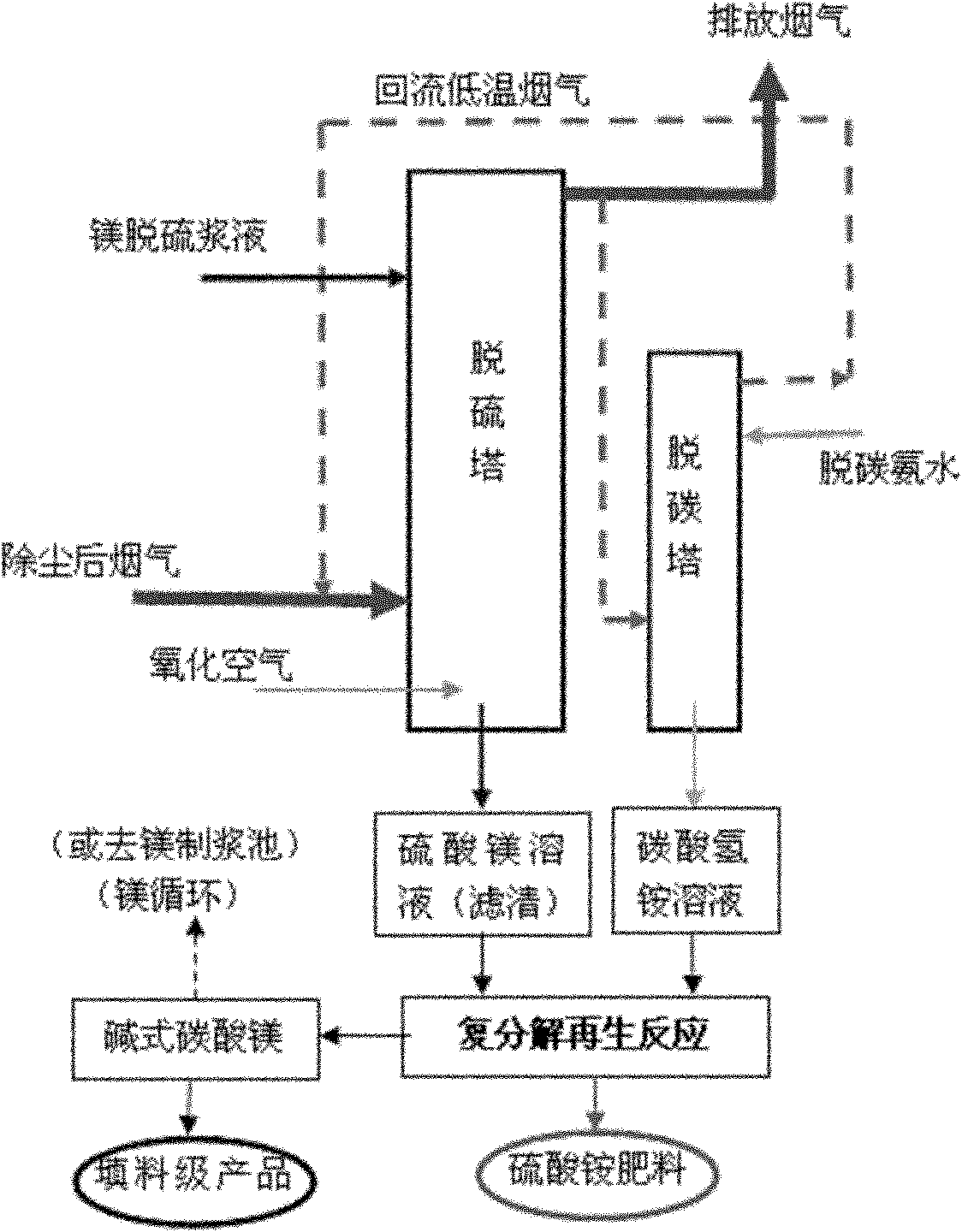

Method for implementing magnesium-ammonia combined flue gas desulfuration and decarbonization and by-product recovery

A technology for realizing methods and by-products, applied in separation methods, chemical instruments and methods, products, etc., can solve problems such as increased desulfurization costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the present embodiment, 262.0 g of magnesium sulfate heptahydrate solid (13.47% of magnesium element content) was weighed, dissolved in 1500 ml of water, and 1500 ml of solution containing magnesium sulfate 10% was configured, pH=7. At a temperature of 60°C, 232.0 g of ammonium bicarbonate solid was metered and added five times, and the reaction was carried out under closed stirring at a temperature of 60°C for 3 hours. Separate with a centrifuge to obtain about 280 g of basic magnesium carbonate solid (wet, about 80 g after drying at 120° C.) and 1300 ml of filtrate. The magnesium ion content in the filtrate is detected by the EDTA method (GB / T 15452-95), and it is determined through calculation that 80% of the magnesium ion is converted into basic magnesium carbonate precipitation in the regeneration reaction.

[0035] The present embodiment collects the filtrate 1500ml of above-mentioned reaction as solvent, adds 262.0g magnesium sulfate heptahydrate solid (magnes...

Embodiment 2

[0038]In the present embodiment, 262.0 g of magnesium sulfate heptahydrate solid (13.47% of magnesium element content) was weighed, dissolved in 1500 ml of water, and 1500 ml of solution containing magnesium sulfate 10% was configured, pH=7. At a temperature of 60° C., 0.5 g of polyvinyl alcohol was added, and 232.0 g of ammonium bicarbonate solid was metered in five times, and the reaction was carried out under closed stirring at a temperature of 60° C. for 3 hours. Separate with a centrifuge to obtain about 315 g of basic magnesium carbonate solid (wet, about 90 g after drying at 120° C.) and 1300 ml of filtrate. The content of magnesium ions in the filtrate was detected by the EDTA method (GB / T 15452-95), and it was determined through calculation that 90% of the magnesium ions were converted into basic magnesium carbonate precipitates in the regeneration reaction.

[0039] The present embodiment collects 1500ml of the filtrate of the above reaction as a solvent, adds 262.0g...

Embodiment 3

[0042] In this embodiment, 35Kg of industrial-grade light-burned magnesia (with a magnesia content of 95%) was weighed, and the solution was dissolved in 300 L of water to prepare a slurry containing 10% magnesia. Liquid to gas ratio 2.5L / m 3 , The diameter of the desulfurization tower is 480mm, and the height is 3000mm. The tower is equipped with a double-layer spray system and a single-layer swirl plate. The desulfurization slurry is sprayed down from the top of the tower, contacts with the flue gas in the reverse direction, and reacts in full gas-liquid phase contact on the swirl plate, and the desulfurization slurry absorbs the harmful gas of sulfur dioxide in the flue gas. The removal efficiency of sulfur dioxide in flue gas is 96%.

[0043] In this embodiment, the desulfurized and purified flue gas passes through the demister and is directly discharged into the atmosphere through the chimney, and part of the purified flue gas enters the decarbonization tower through a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com