Wet desulfurization tower based flue gas desulphurization method capable of enhancing adaptability to low load

A technology for wet desulfurization and desulfurization tower, applied in the field of flue gas desulfurization, can solve the problems of unmaintainable mist removal efficiency of mist eliminators, sedimentation of fly ash and droplets at the entrance and exit of towers, and reduced desulfurization efficiency, so as to enhance low-load adaptation. High performance, operation safety and reliability, ensuring the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

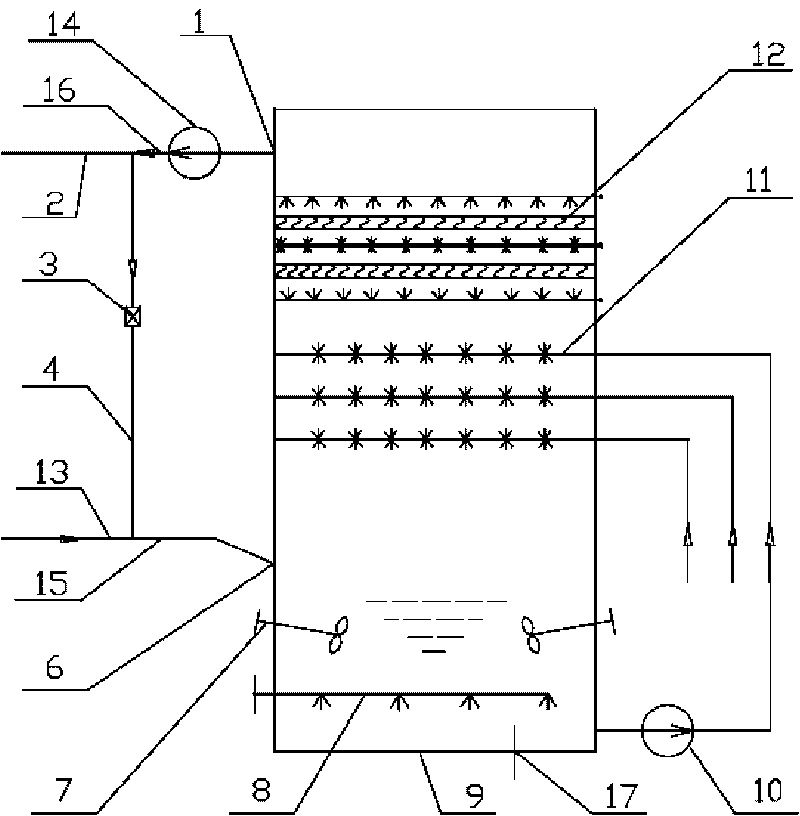

[0012] Specific implementation mode one: as figure 1 and figure 2 As shown, the flue gas desulfurization method based on the wet desulfurization tower with enhanced low-load adaptability described in this embodiment is carried out using a wet desulfurization tower, and the flue gas desulfurization method is implemented according to the following steps: Step 1. Calcium-based slurry is added to the desulfurization tower body 9, which contains 5-8% (mass) gypsum seed crystals, and an air pipe 8 is set in the bottom of the desulfurization tower to provide CaSO 3 Oxygen required for oxidation (CaSO 3 from the SO in the flue gas 2 with CaCO in calcium-based slurry 3 or Ca(OH) 2 generated by the reaction), an agitator 7 is set on the side wall of the desulfurization tower body 9 to stir the calcium-based slurry;

[0013] Step 2: Send the flue gas to be treated into the cavity between the calcium-based slurry liquid level in the desulfurization tower body 9 and the spray layer 1...

specific Embodiment approach 2

[0015] Specific implementation mode two: as figure 1 As shown, the present embodiment uses the negative pressure at the entrance of the desulfurization tower body 9 produced by the induced draft fan 14 to automatically draw back part of the flue gas at the outlet of the induced draft fan 14 in step three of the specific implementation mode, and the flue gas from the flue gas inlet pipe 13 The flue gas to be treated is mixed to form mixed flue gas and flows into the desulfurization tower body 9 together; the desulfurized flue gas in the upper part of the desulfurization tower body 9 is extracted; An induced draft fan 14 is installed on the main pipe 16, so that part of the desulfurized flue gas is discharged from the flue gas discharge pipe 2, and another part flows into the desulfurization tower body 9 from the circulating flue gas pipe 4 through the desulfurization tower inlet 6. Other steps are the same as in the first embodiment.

[0016] Such as figure 1 , when the load ...

specific Embodiment approach 3

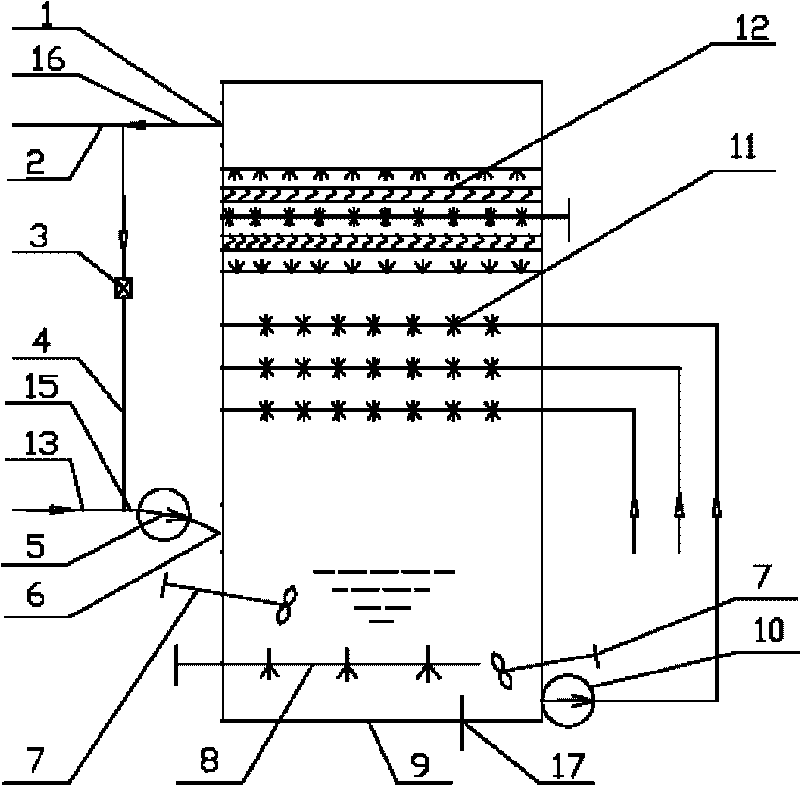

[0017] Specific implementation mode three: as figure 2 As shown, in this embodiment, in the third step of the specific embodiment, the desulfurization booster fan 5 is used to blow the mixed flue gas into the desulfurization tower body 9; A desulfurization booster blower 5 is installed on the main inlet pipe 15 so that the flue gas to be treated and the desulfurized flue gas are blown into the desulfurization tower body 9 through the desulfurization booster fan 5 . Other steps are the same as in the first embodiment.

[0018] Such as figure 2 , when the load of the desulfurization system is greater than 30% of the rated load, the load in the desulfurization tower meets the adaptability requirements at this time, and the original flue gas from the outlet of the desulfurization booster fan 5 enters the desulfurization tower 9, and is pumped by the circulating slurry pump 10 to the spray layer 11 The atomized desulfurization slurry is in countercurrent contact, and the net fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com