Ammonia-process desulfurization optimum control method based on multi-variable constraint zone predicting control

An ammonia desulfurization and predictive control technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as few closed-loop control, and achieve the effect of reducing requirements, overcoming large delays, and reducing actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

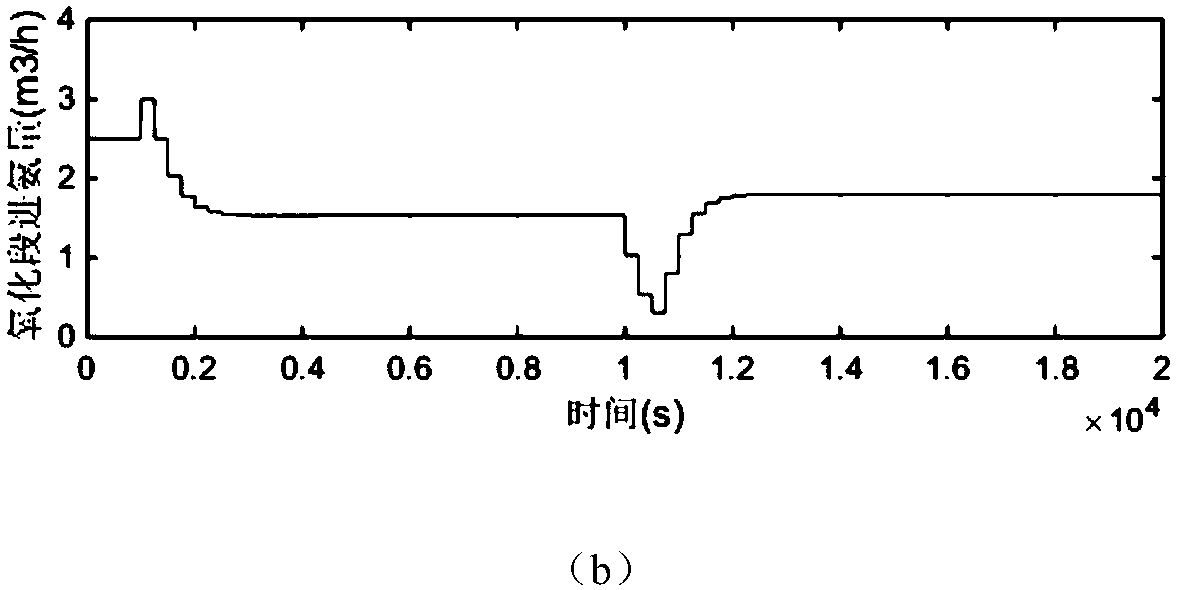

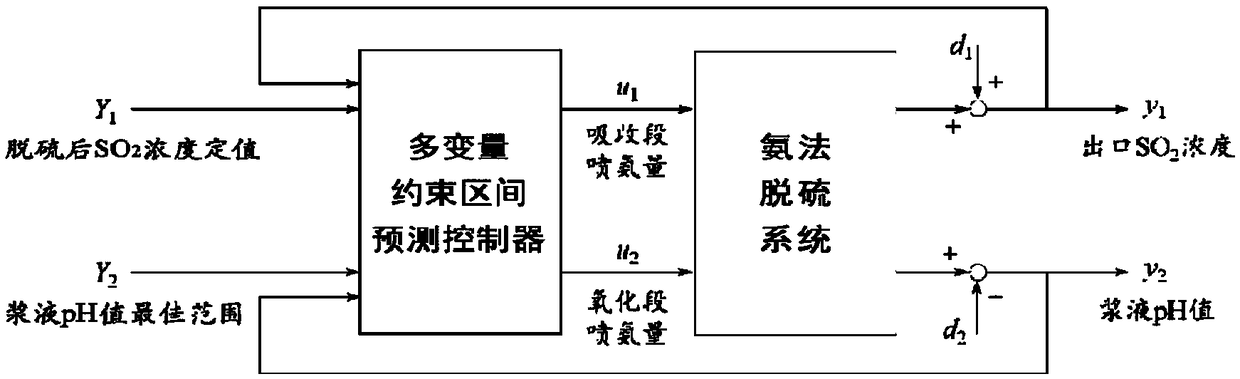

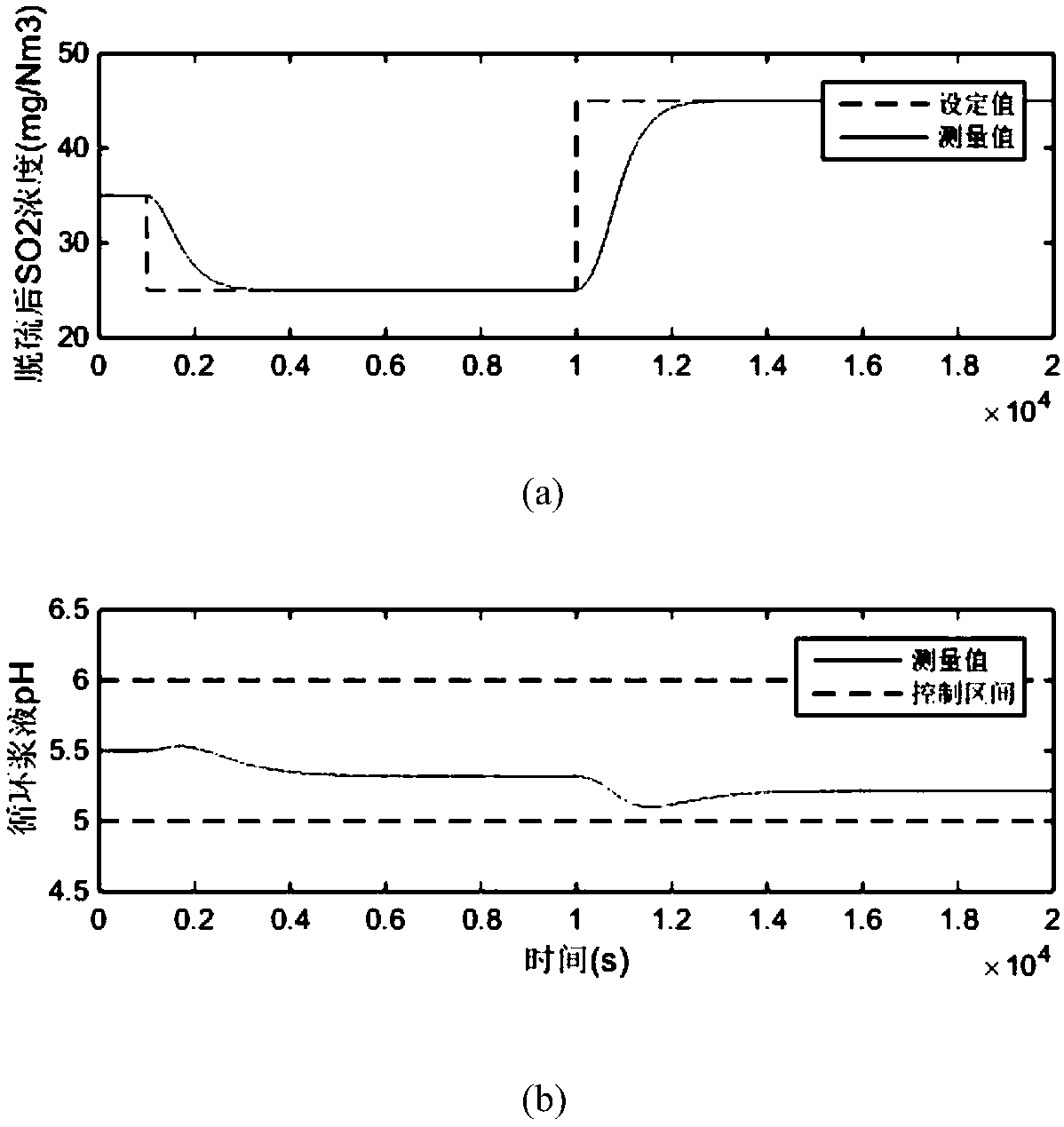

[0058] The optimal control method for ammonia desulfurization based on multivariable constrained interval predictive control obtained in Example 1 has SO 2 The control effect when the concentration is disturbed by the set value is as follows: figure 2 , image 3 shown. It can be seen from the figure that the ammonia desulfurization optimization control method of the present invention can quickly and reasonably adjust the ammonia water flow rate in the absorption section and the oxidation section when the set value disturbance occurs in the system, so as to ensure that the pH of the circulating slurry is within the control range, and at the same time Maintain SO after desulfurization 2 The concentration quickly and stably follows the change of the set value, which reduces the ammonia consumption and the ammonia escape rate.

[0059] The control effect of the ammonia desulfurization optimization control method based on multivariable constraint interval predictive control obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com