Composite humidifying process suitable for circulating fluid bed semi-drying method flue gas desulfurization

A circulating fluidized bed, semi-dry technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of desulfurization ash sticking to the wall, poor continuous operation stability, high Ca/S ratio, etc. The effect of running stability and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

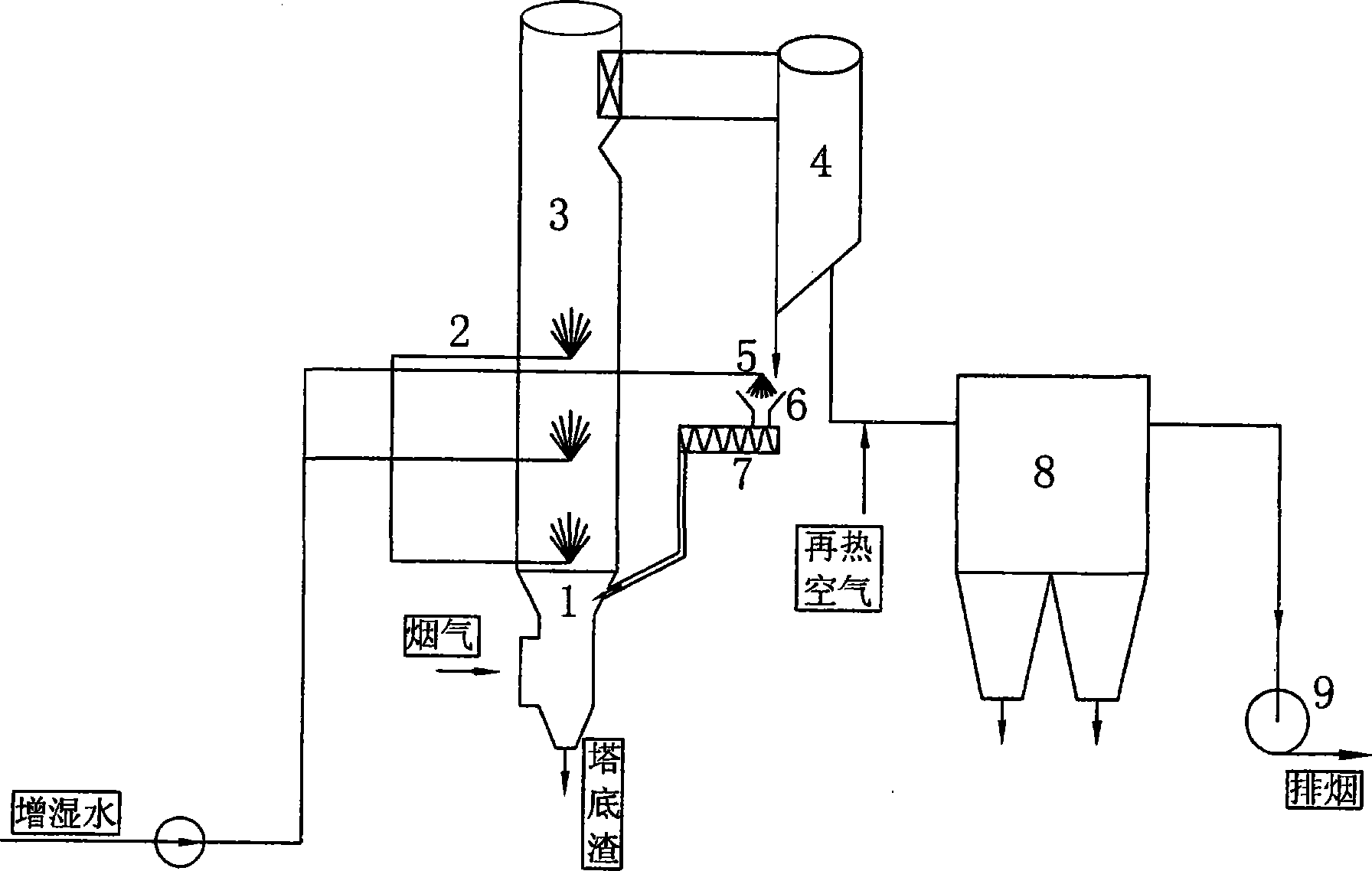

[0012] A best embodiment of the present invention is given below in conjunction with accompanying drawing 1.

[0013] The flue gas enters from the bottom of the desulfurization tower 3, and in the gradual expansion section 1, it contacts the circulating ash that has been humidified by the external humidification system 5. At this time, due to the large amount of external humidification ash, the total evaporation area is also large, and the surface The rapid evaporation of water can create better conditions for the desulfurization reaction, and because the ash and water are evenly mixed, it is conducive to the rapid progress of the desulfurization reaction. At the same time, it also reduces the temperature of the smoke and increases the relative humidity, providing more favorable conditions for the subsequent desulfurization reaction. After the flue gas reaches the position of the water spray humidification system 2 in the tower, the temperature of the flue gas is lowered in adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com