Out tower oxidizing lime/acetylene sludge-gypsum process desulphurization technology and equipment

A technology of desulfurization process and desulfurization device, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve problems such as poor economy, reduce investment and operating costs, ensure desulfurization efficiency, and achieve high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

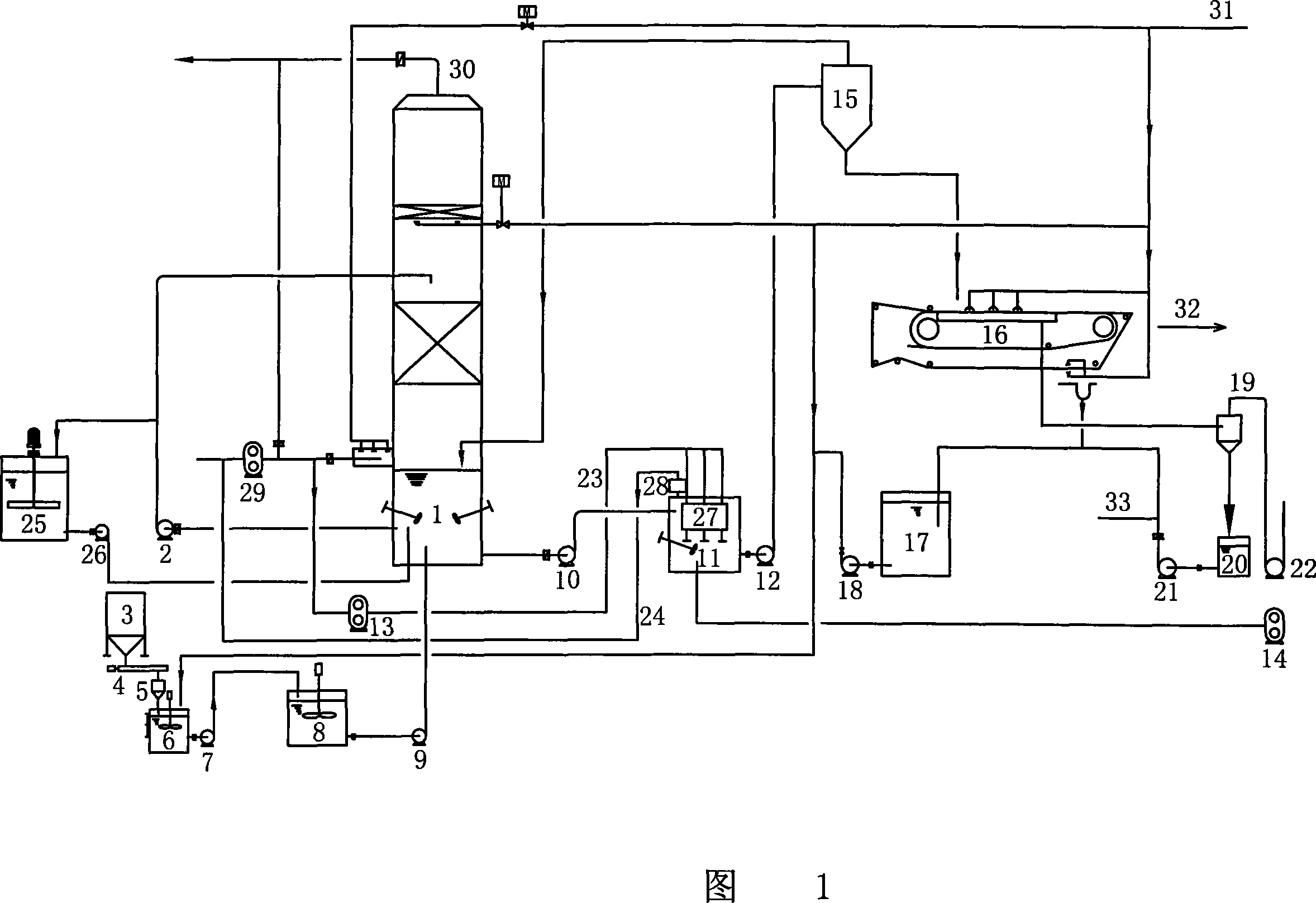

[0041] As shown in Figure 1, the process flow of the present invention is that the flue gas from the boiler enters the main fan 29 after dedusting, and the flue gas (initial flue gas) at the outlet of the main fan 29 is divided into two paths, most of which enter the desulfurization tower 1, the Part of the flue gas reacts with the lime / carbide slag slurry in the desulfurization tower 1, and is discharged from the chimney 30 on the upper part of the desulfurization tower 1 after purification. Packed tower, Venturi, spray tower, etc., the lime / carbide slag slurry in the desulfurization tower 1 is circulated through the circulation pump 2.

[0042] The absorbent lime or calcium carbide slag is stored in the lime storage bin 3, and enters the alimerator 6 through the screw conveyor 4 and the weighing tank 5, and then the ash pump 7 is introduced into the lime slurry tank 8, and the lime / calcium carbide in the lime slurry tank 8 The slag slurry is transported to the desulfurizatio...

Embodiment 2

[0051] Flue gas is treated according to the process flow of Example 1. A 130t / h pulverized coal furnace in a thermal power plant uses calcium carbide slag for desulfurization, and the flue gas volume is 240,000m 3 / h, the concentration of sulfur dioxide at the inlet of the desulfurization tower is 4000mg / Nm 3 , design liquid-gas ratio 5L / m 3 , the pH value in the desulfurization tower is 8.0, the pH value in the oxidation tank is 5.0, the amount of flue gas passing into the oxidation tank accounts for 20% of the total flue gas volume, the desulfurization efficiency is 96.2%, the moisture content of desulfurization gypsum is less than 9%, and the purity is 91%. The particle size is 60-90 microns, and the residual calcium hydroxide content is 0.009%.

Embodiment 3

[0053] Flue gas is treated according to the process flow of Example 1. The 170t / h pulverized coal furnace of a thermal power plant adopts lime desulfurization, and the flue gas volume is 280000m 3 / h, the concentration of sulfur dioxide at the inlet of the desulfurization tower is 2100mg / Nm 3 , design liquid-gas ratio 3L / m 3 , the pH value in the desulfurization tower is 6.0, the pH value in the oxidation tank is 4.0, the amount of flue gas passing into the oxidation tank accounts for 10% of the total flue gas volume, the desulfurization efficiency is 92.6%, the moisture content of desulfurization gypsum is less than 8%, and the purity is 92%. The particle size is 70-100 microns, and the residual amount of calcium hydroxide is 0.005%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com