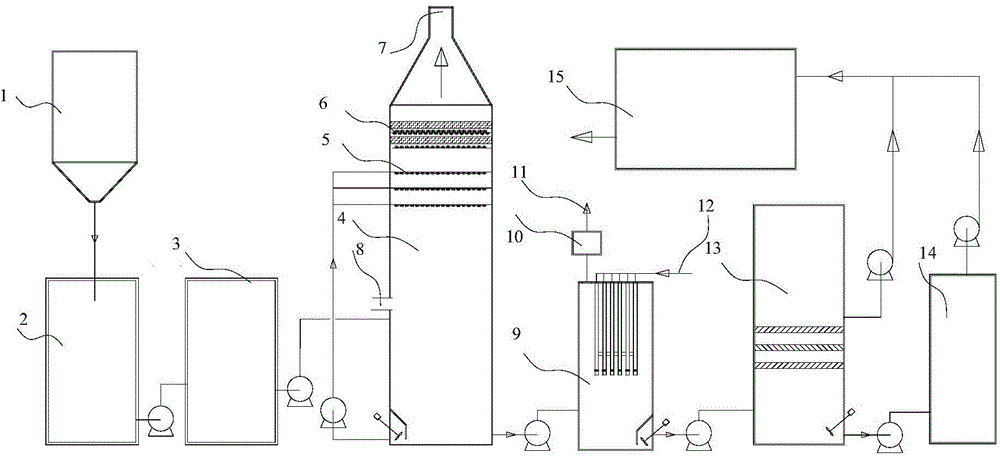

Device and method for redesulfuration with desulfurization ash

A desulfurization ash and absorption device technology, which is applied in chemical instruments and methods, separation methods, and solid waste removal, etc., can solve the problems of simplicity, insufficient utilization, and complex pulping systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

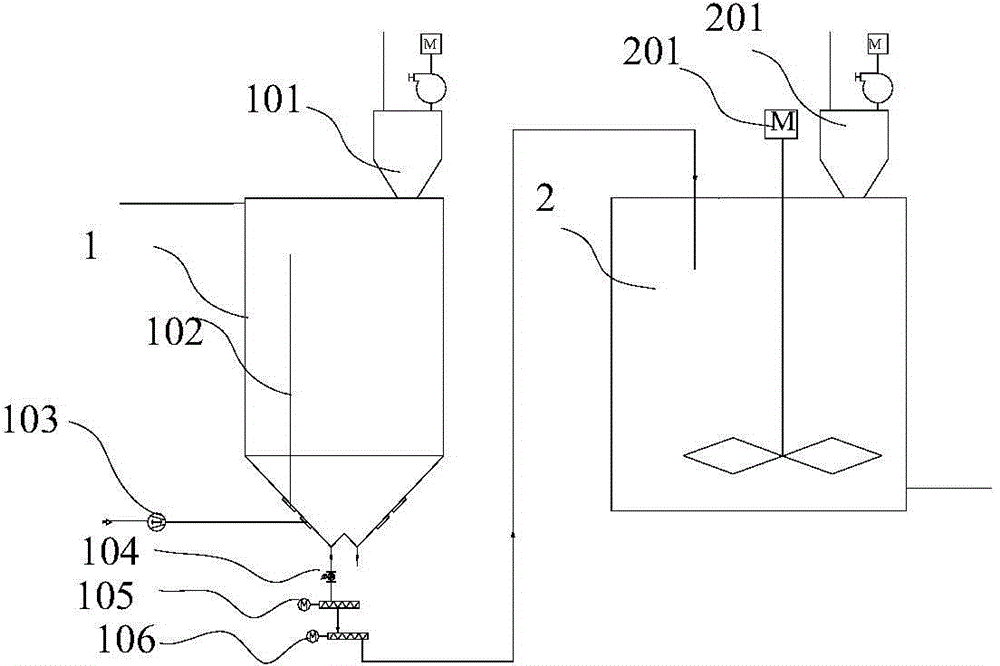

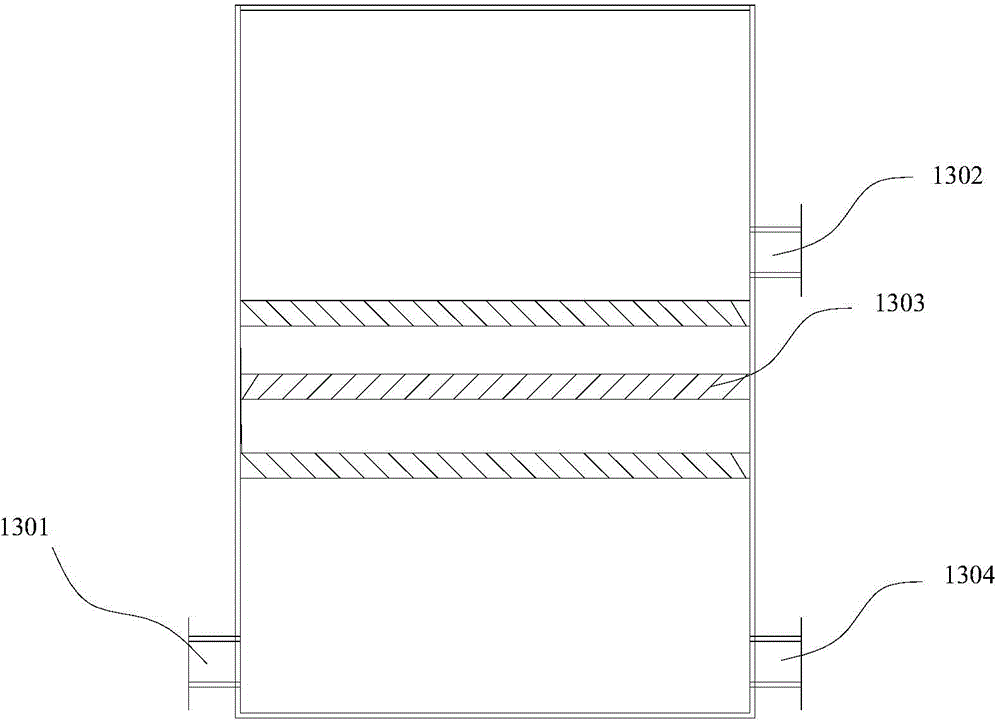

Method used

Image

Examples

Embodiment 1

[0079] A power plant, 2×300MW unit flue gas desulfurization project, uses semi-dry desulfurization ash as desulfurization agent, the effective calcium content in the desulfurization ash is 26.1%, the ash content is 18%, and the concentration of the desulfurization ash slurry in the slurry tank is 32%. Using desulfurization ash slurry as desulfurization absorbent to adjust SO 2 The pH value in the absorption device is 5.6, the solid content of the slurry is 20%, when the sulfur dioxide concentration in the imported flue gas is 1970mg / m 3 , the wet base standard flue gas flow rate is 1.286 million Nm 3 / h, the concentration of sulfur dioxide at the outlet is 34mg / m 3 Below, the desulfurization efficiency reaches over 98.3%; adjust the pH value in the oxidation device to 4.8, and the oxidation rate of calcium sulfite reaches 97%; after passing through the ash separation device, the purity of gypsum reaches over 95%. The entire desulfurization system operates stably, and the con...

Embodiment 2

[0081] A power plant with semi-dry desulfurization process, 2×410t / h unit flue gas desulfurization project, using internal semi-dry desulfurization ash as desulfurization agent, desulfurization ash with effective calcium content of 30.7%, ash content of 15%, slurry The concentration of desulfurization ash slurry in the pond is 28%. Using desulfurization ash slurry as desulfurization absorbent to adjust SO 2 The pH value in the absorption device is 5.5, the solid content of the slurry is 20%, when the sulfur dioxide concentration in the imported flue gas is 1495mg / m 3 , the wet base standard flue gas flow rate is 986,000 Nm 3 / h, the concentration of sulfur dioxide at the outlet is 17mg / m 3 Below, the desulfurization efficiency is above 98.9%; adjust the pH value in the oxidation device to 4.8, and the oxidation rate of calcium sulfite reaches 99%; after passing through the ash separation device, the purity of gypsum reaches above 97.8%. The entire desulfurization system ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com