Flue gas desulfurization system

A desulfurization system and flue gas technology, which are applied in gas treatment, separation methods, dispersed particle separation, etc., can solve the problems of low effective utilization rate of activated carbon sulfur and energy waste in the regeneration process, so as to improve the effective utilization rate and reduce the energy consumption of desulfurization. , the effect of reducing mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

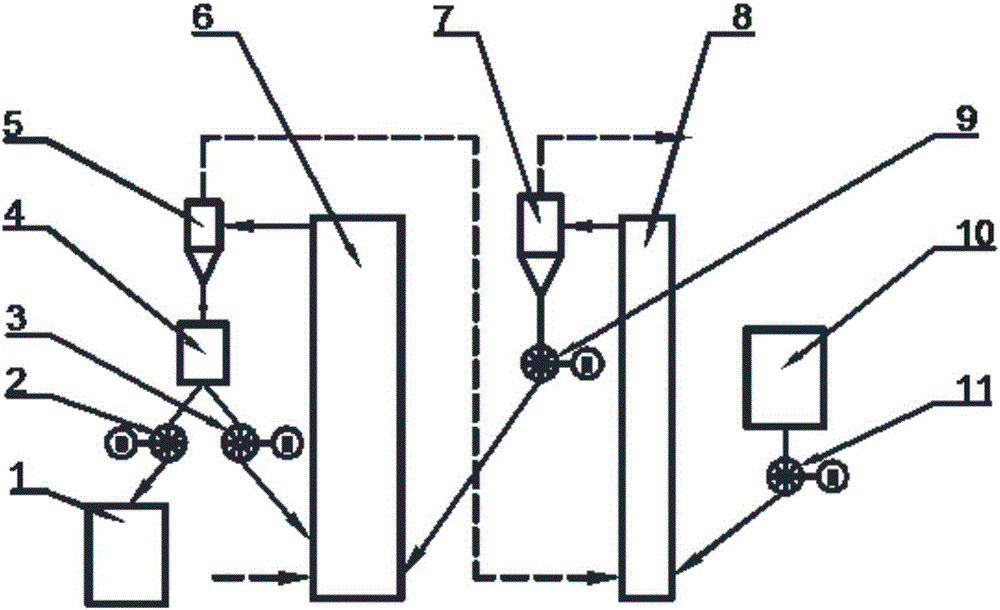

[0030] Such as figure 1 The flue gas desulfurization system shown includes exhausted carbon bin 1, exhausted carbon gas lock feeder 2, circulating carbon gas lock feeder 3, circulating carbon bin 4, cyclone separator 5, primary adsorption tower 6, bag dust removal Device 7, secondary adsorption tower 8, primary carbon gas lock feeder 9, fresh activated carbon bin 10, fresh activated carbon gas lock feeder 11.

[0031] The primary adsorption tower 6 is connected to the cyclone separator 5, and the cyclone separator 5 is connected to the circulating carbon bin 4 and the secondary adsorption tower 8, wherein the circulating carbon bin 4 is connected to the spent carbon gas-locking feeder 2 and the circulating carbon gas-locking feeder The machine 3 is connected, the circulating carbon-locked gas feeder 3 is connected with the primary adsorption tower 5, the carbon-spent gas-locked feeder 2 is connected with the carbon-spent bin 1, the secondary adsorption tower 8 is connected wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com