L-shaped piston ring of internal combustion engine

A technology for piston rings and internal combustion engines, applied to piston rings, mechanical equipment, engine components, etc., can solve problems such as increased emissions, pollution, harmful spaces, and unfavorable combustion, and achieve the effects of improving emissions and reducing mechanical losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

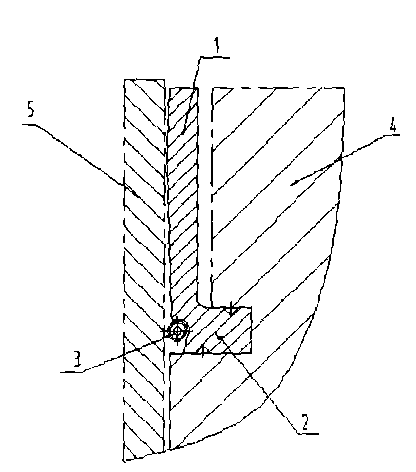

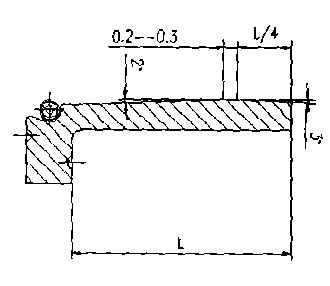

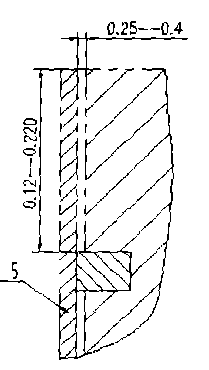

[0017] like figure 1 As shown, the L-shaped internal combustion engine piston ring is composed of a long arm (1) and a short arm (2). The long arm (1) and the short arm (2) form 90° each other. , the top of its long arm (1) is flush with the top of the piston (4). The L-shaped internal combustion engine piston ring has a split structure, which is divided into three or four sections in the circumferential direction, and is locked into a combined ring by the coil spring (3) located outside the short arm (2). The L-shaped internal combustion engine piston ring has a gap between the inner surface of the long arm (1) and the piston (4), and communicates with the cylinder. The pressure in the cylinder can act on the inner surface of the long arm (1). After the inner surface of the long arm (1) is stressed, each section will deflect around the coil spring, and the outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com