Direct-driving circular loom magnetic suspension shuttle device

A circular loom, direct-drive technology, applied to circular looms, looms, textiles, etc., can solve problems such as lack of dynamic control means, affect work stability, and easy damage to parts, so as to reduce damage and improve efficiency , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further description will be made below in conjunction with the embodiments and accompanying drawings.

[0027] See attached picture.

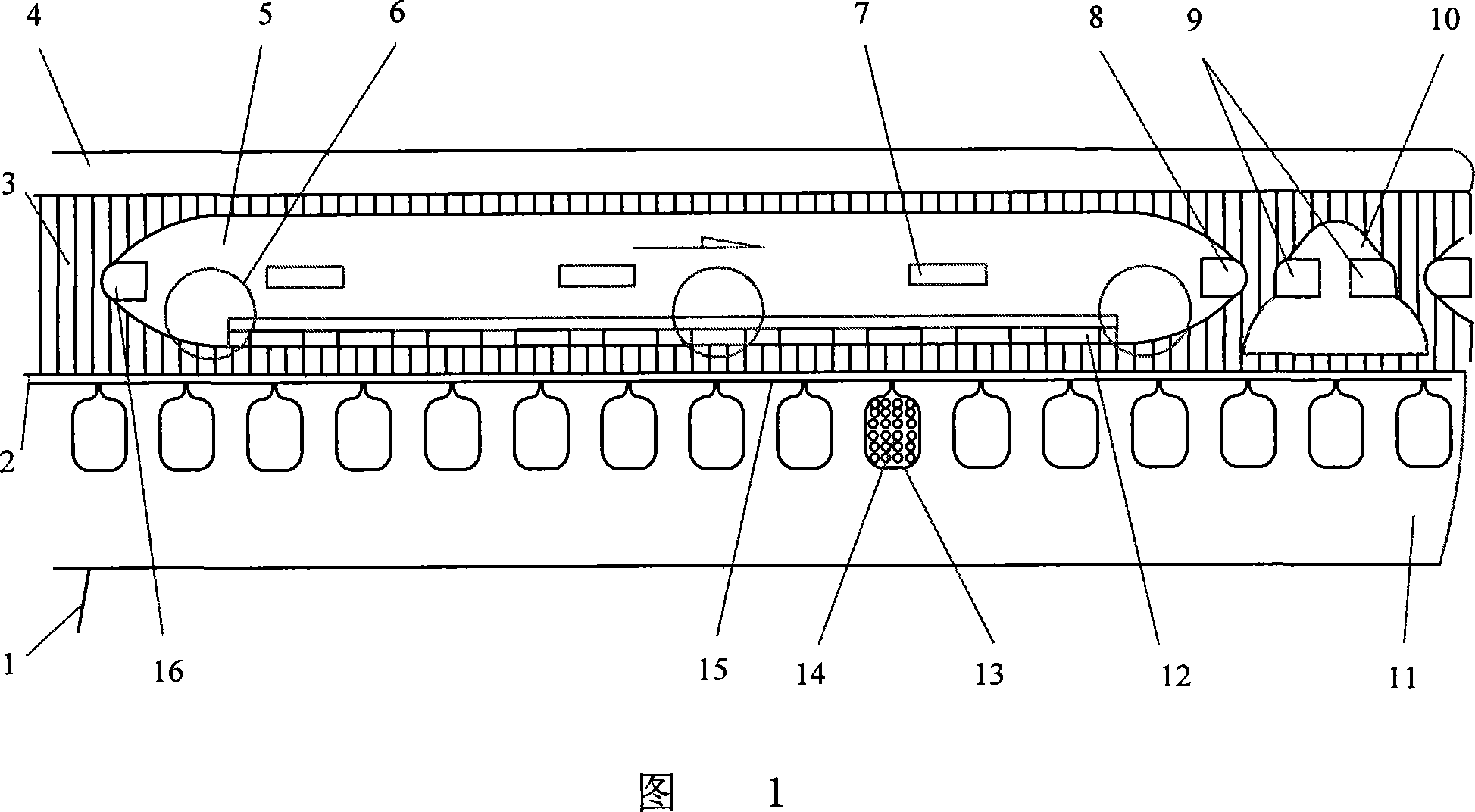

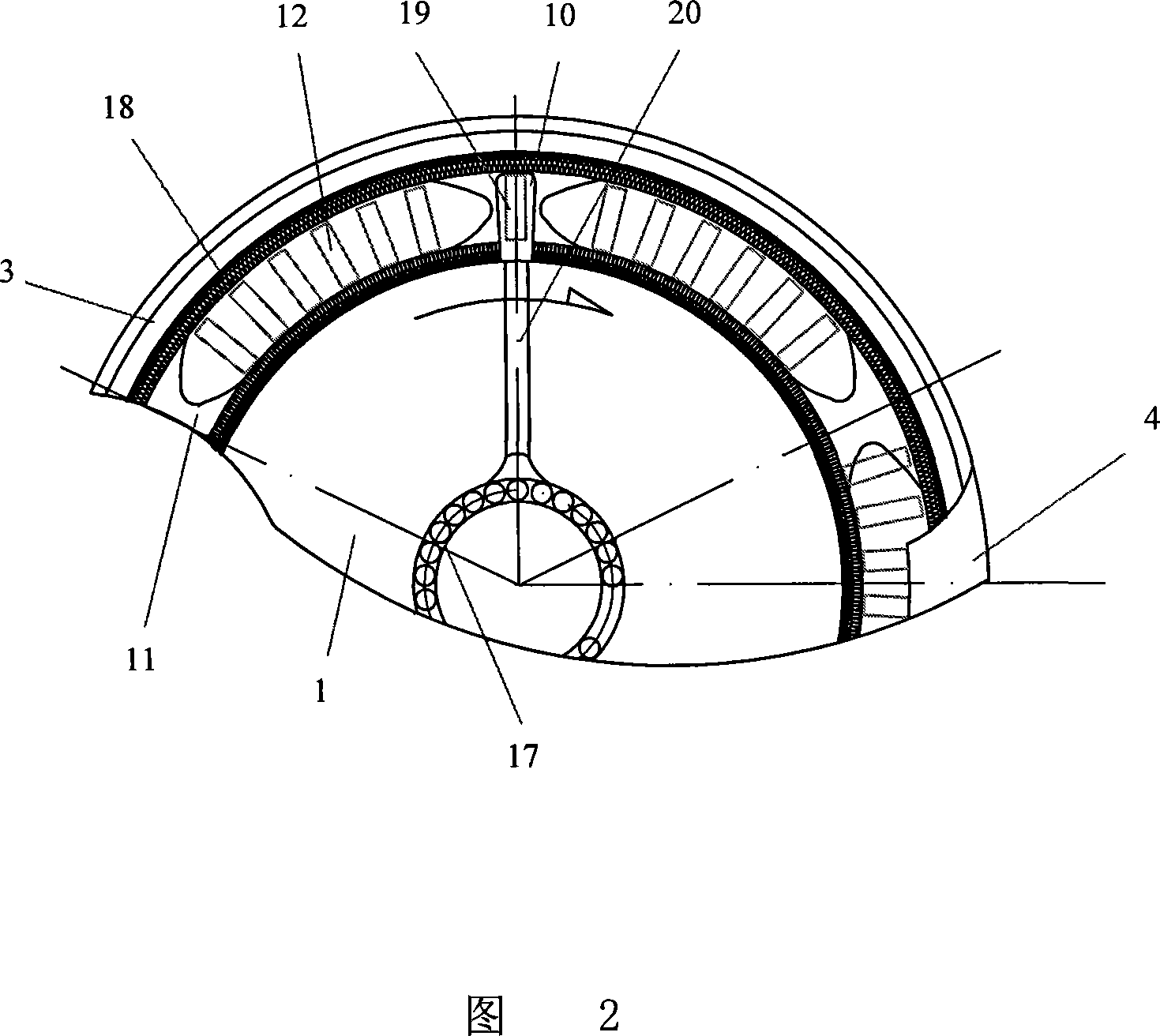

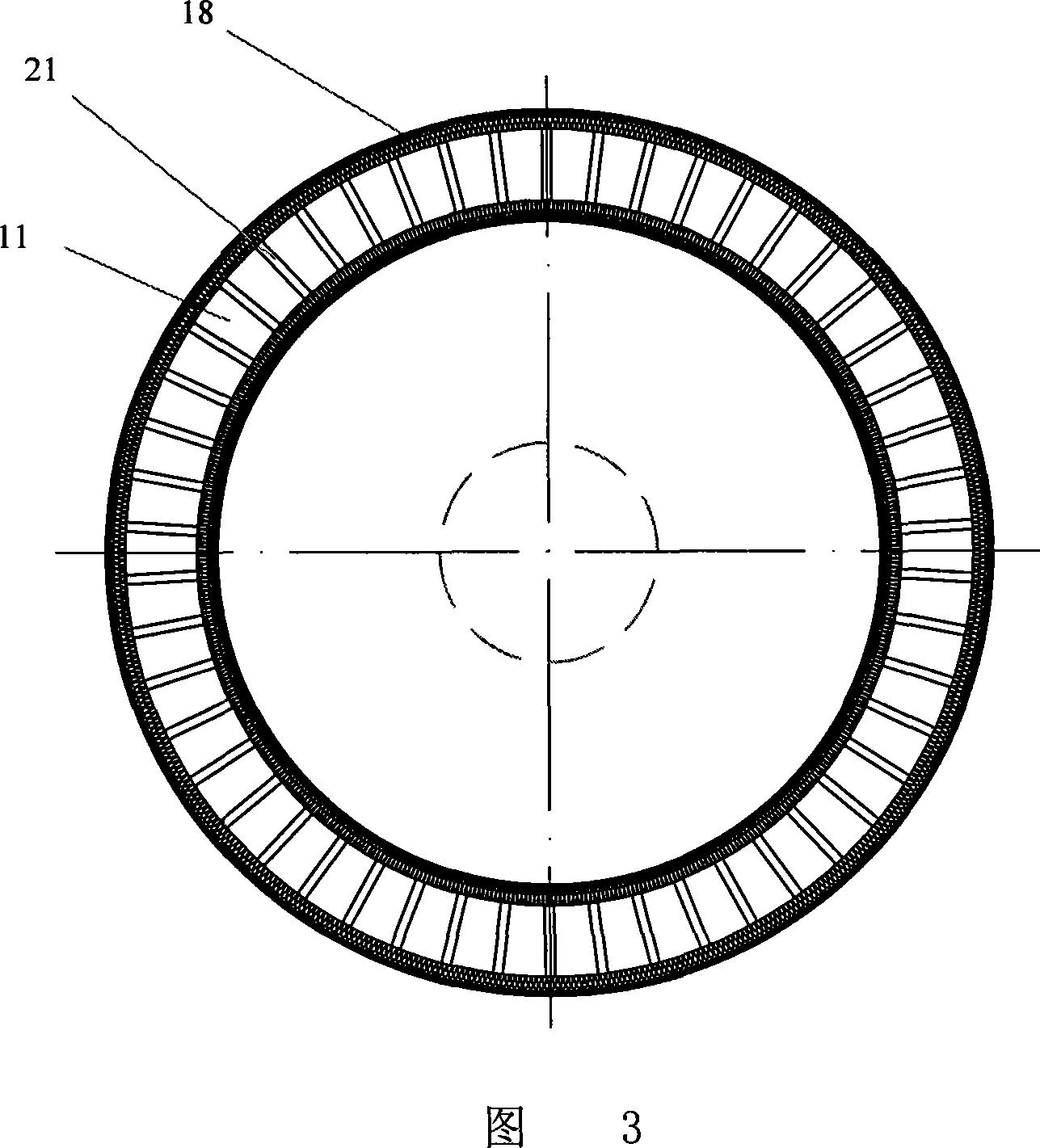

[0028] Fig. 1, 2 are the embodiments of the magnetic levitation shuttle device of this direct drive type circular loom. It includes frame 1, rail 2, gate rail ring 3, upper door ring 4, shuttle 5, shuttle bar 20, magnetic head 8, 16, magnetic block, guide wheel, motor and its electrical control device, wherein the motor adopts A permanent disk surface motor is provided, and its primary stator 11 is integrated with the frame 1, the gate rail ring 3, and the upper door ring 4; its permanent magnet secondary mover 12 is combined by a separated permanent magnet and pure iron (also can use Composite soft magnetic material) is arranged on the bottom surface of the shuttle 5, corresponding to the primary electromagnetic coil; the shuttle 5 is arranged on the inner side of the gate rail 3 and on the table track of the annular primary 11; There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com