Method and device for rapid cooling of packaged drinks

a beverage and packaging technology, applied in the direction of cooling fluid circulation, light and heating apparatus, food preservation, etc., can solve the problems of difficult use of ice for transferring cold quickly, inability to maintain a uniform temperature, and possible freezing, etc., to facilitate the rotation of the can

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

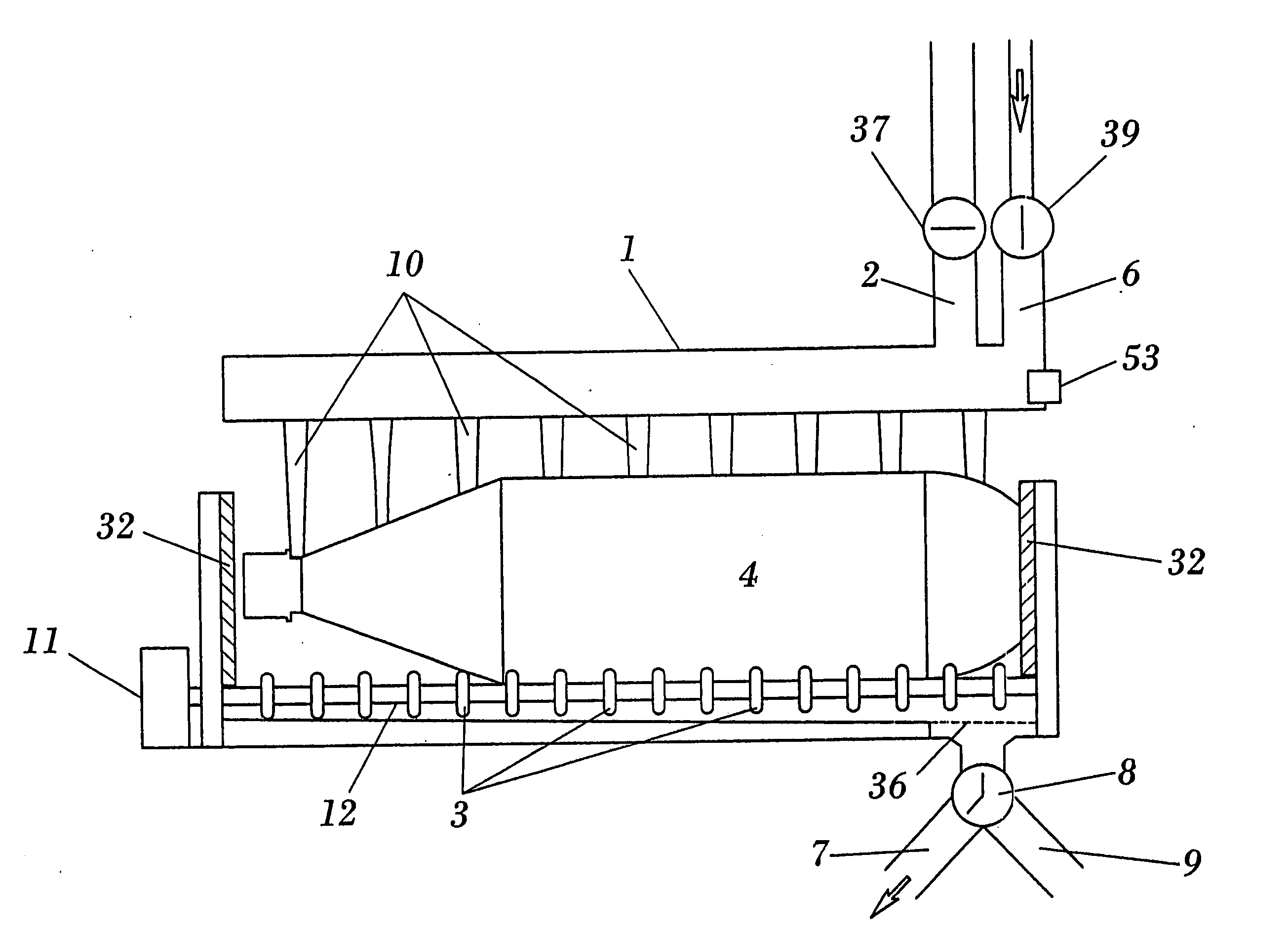

[0153]FIG. 10.—It shows a side view in detail of the interior of the apparatus for rapid cooling of packaged beverages in which its constituent elements are observed.

[0154]FIG. 11.—It shows a front view in detail of the interior of the first embodiment of the cooling apparatus.

[0155]FIG. 12.—It shows a front view of the first cooling apparatus embodiment in which are observed the control keyboard and the tray on which a bottle has been placed for its rapid cooling.

[0156]FIG. 13.—It shows a front view coincident with the preceding figure in which some cans are observed introduced for their rapid cooling.

second embodiment

[0157]FIG. 14.—It shows a side view in detail of the interior of the rapid cooling apparatus of packaged beverages in which its constituent elements are observed.

[0158]FIG. 15.—It shows a front view in detail of the interior of the second embodiment of the rapid cooling apparatus of packaged beverages in which its internal elements are observed.

[0159]FIG. 16.—It shows a front view of the second embodiment of the rapid cooling apparatus of packaged beverages in which are observed the control keyboard and the tray on which a bottle has been introduced for its rapid cooling.

[0160]FIG. 17.—It shows a front view of the second embodiment of the rapid cooling apparatus of packaged beverages in which it is observed that some cans have been introduced for their rapid cooling.

third embodiment

[0161]FIG. 18.—It shows a side view in detail of the interior of the cooling apparatus with top access to the containers.

[0162]FIG. 19.—It shows a front view of the third embodiment of the cooling apparatus in which a cover is observed which covers the containers to prevent splashing.

[0163]FIG. 20.—It shows the apparatus of the preceding figure with the top cover lifted.

[0164]FIG. 21.—It shows a rear view of the apparatus object of the third embodiment with an open cover.

[0165]FIG. 22.—It shows a block diagram in which the operating sequence of the cooling process is represented.

[0166]FIGS. 23 and 23 bis.—They show the cross-section of the auxiliary recipient with horizontal and vertical trays which support products to be frozen.

[0167]FIG. 24.—It shows a cross-section similar to that of preceding FIG. 23 during the freezing phase.

[0168]FIG. 25.—It shows an ice-cream maker mounted in the apparatus.

[0169]FIG. 26.—It shows different embodiments of projections: annular, worm and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com