Device for portioned delivery of milk, particularly for cappuccino machines

a technology of cappuccino machine and milk delivery, which is applied in the field of cappuccino machine, can solve problems such as affecting storage, and achieve the effect of preventing the heating of milk in the connection line inside the refrigerator, reliable and efficient rinsing of this connection line, and ensuring storag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

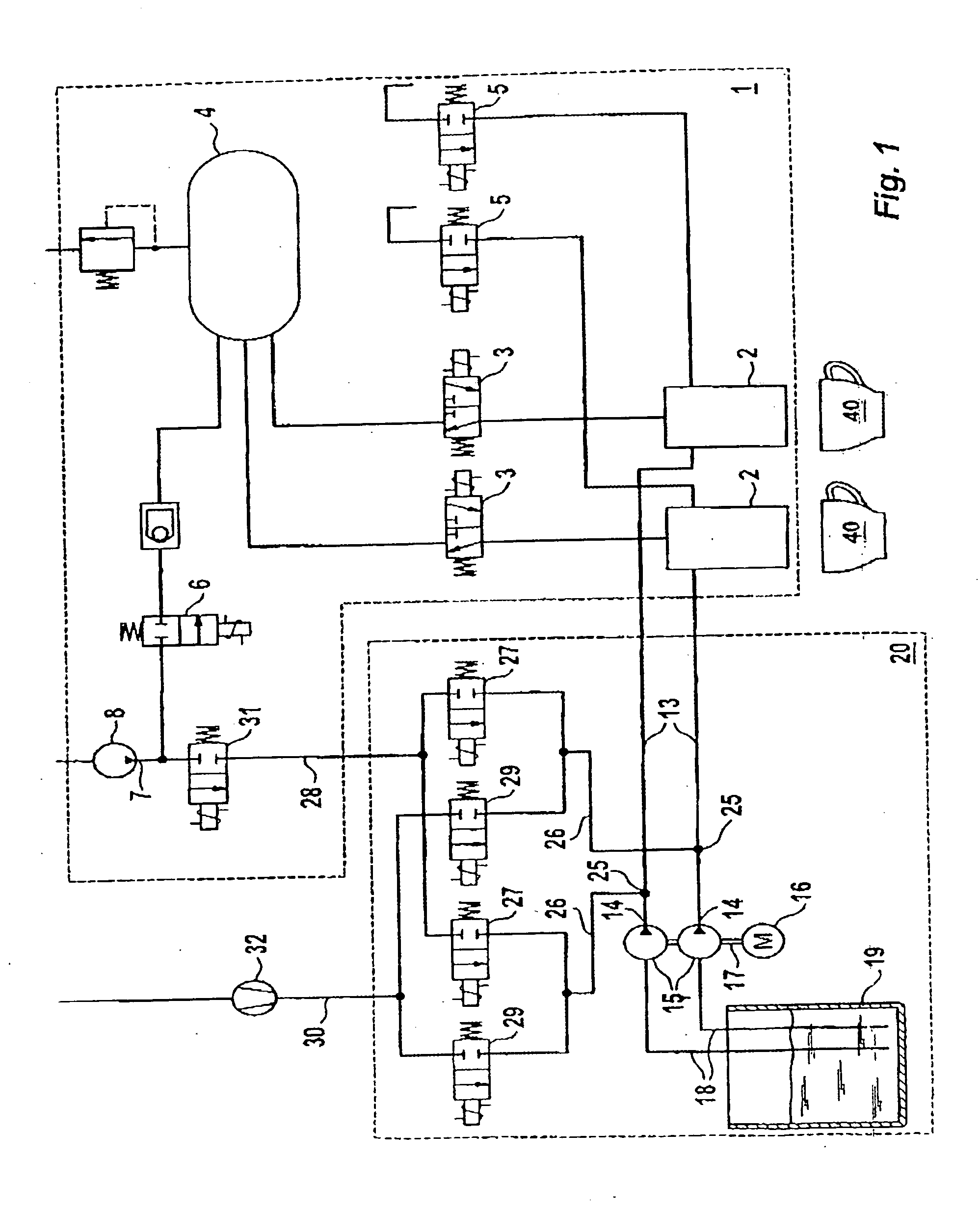

[0013] In the following, an exemplary embodiment of the present invention is described on the basis of the drawing. The single FIGURE shows a circuit diagram of a milk foaming device for cappuccino machines.

[0014] Two foamer heads 2 are positioned in a coffee machine 1. Each head 2 is connected via an on-off valve 3 to a steam boiler 4 and via a second on-off valve 5 to the atmosphere. A level switch (not shown) in the boiler 4 regulates the fresh water supply to the boiler 4 from the outlet 7 of a water pump 8 via a further on-off valve 6.

[0015] Each foamer head 2 is also connected via a connection line 13 to the outlet 14 of a volumetric milk pump 15. The two pumps 15 are driven by a shared motor 16, whose driven shaft 17 rotates around a predetermined angle of rotation to deliver a milk portion. The lines 18 to the suction side of the pumps 15 are dipped into a milk container 19. The container 19, the pumps 15, the lines 18, and a part of the lines 13 are installed in a refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com