Wolframine beneficiation wastewater treatment process

A technology for scheelite beneficiation and wastewater treatment, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as high cost, high energy consumption, and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

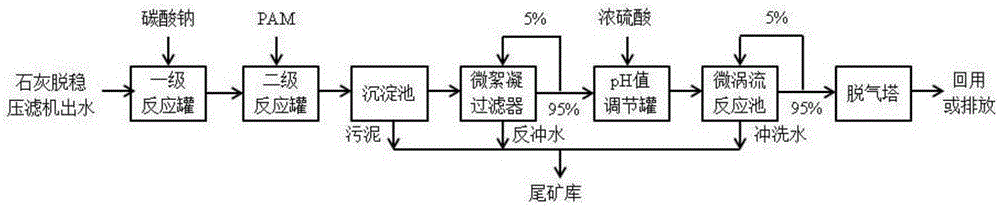

[0041] A kind of scheelite beneficiation wastewater treatment process, combined with figure 1 , the steps are:

[0042] A. Add lime to the scheelite beneficiation wastewater, and adjust the pH value to 11-12; adding lime milk can not only destroy the colloidal stability of the wastewater, but also precipitate and remove heavy metal ions in the wastewater at the same time; however, adding a large amount of lime Milk will cause the pH value to exceed the standard (pH value is about 12), and direct discharge may form a large amount of calcium-containing minerals in the river; the treated wastewater is used in scheelite beneficiation, and high pH value will also inhibit scheelite. In the flotation process of ore, the excess calcium ions contained will adsorb and activate gangue minerals, resulting in the consumption of a large amount of collectors in the flotation process. Adjusting the pH value will lead to the precipitation of silicic acid sol, and white flocculent sediments wi...

Embodiment 2

[0053] The wastewater from the tailings pond of a scheelite beneficiation enterprise is apparently clear, because the lime treatment is alkaline, and the pH value is 11-12. If it is directly discharged into the water body, a light yellow sedimentary pollution zone will quickly form downstream of the discharge outlet; if the current When the acid is added to adjust the pH value to 8-9, a large amount of flocculent floating matter will be formed tens of meters downstream of the discharge outlet; in order to reduce sewage discharge and improve the reuse rate of wastewater, the company reuses part of the tailings pond wastewater , but has a negative impact on the recovery rate of scheelite.

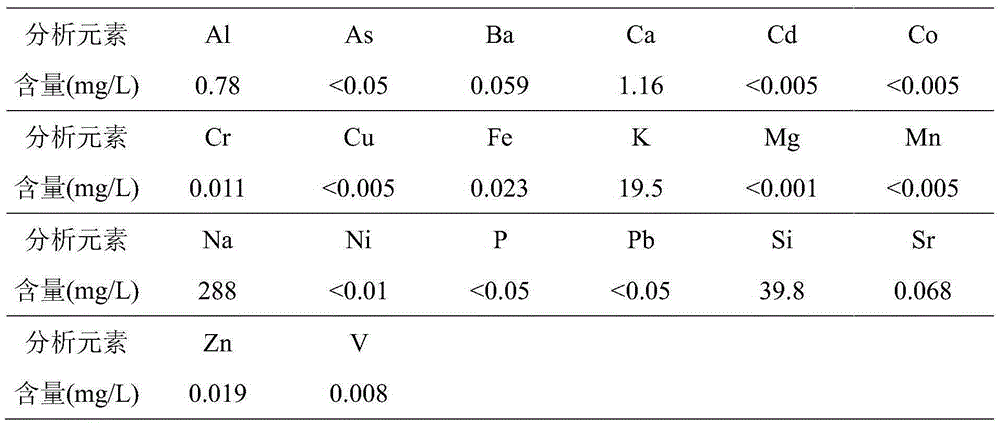

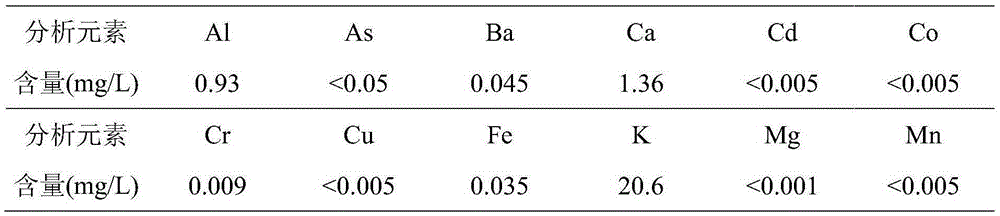

[0054] The discharge water samples were taken for detection and analysis, and the following results were obtained:

[0055] 1) The volatile organic compound VSS content of the flocs downstream of the discharge outlet is about 20%, indicating that the flocs are not formed by substances charact...

Embodiment 3

[0060] After the scheelite beneficiation wastewater has been treated with lime, coagulation sedimentation and plate and frame filtration, the main indicators have reached the discharge standard, but there will still be existing environmental impact problems. In view of the water quality characteristics of the effluent from the existing treatment process of scheelite beneficiation wastewater and the requirements for tail water reuse and discharge after treatment, the micro-flocculation filtration and micro-vortex reaction of special fillers for chemical precipitation are selected in combination with the technology of blowing off free carbon dioxide by wind to realize the removal of residual carbon dioxide. Removal of harmful mineral impurities.

[0061] The basic principles of the present invention are chemical precipitation, micro-flocculation filtration, micro-vortex reaction and wind blowing off: use sodium carbonate and PAM to chemically react with residual harmful mineral i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com