Combined treatment process for cotton pulping black liquid and saponin wastewater

A combined treatment and black liquor technology, applied in the field of environmental protection and wastewater treatment, can solve the problems of difficult operation and management of sewage treatment process facilities, high investment and operation costs of sewage treatment, and substandard effluent quality, achieving outstanding promotion and application value , Saving sewage treatment costs, and the effect of high-efficiency solid-liquid separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with specific embodiments.

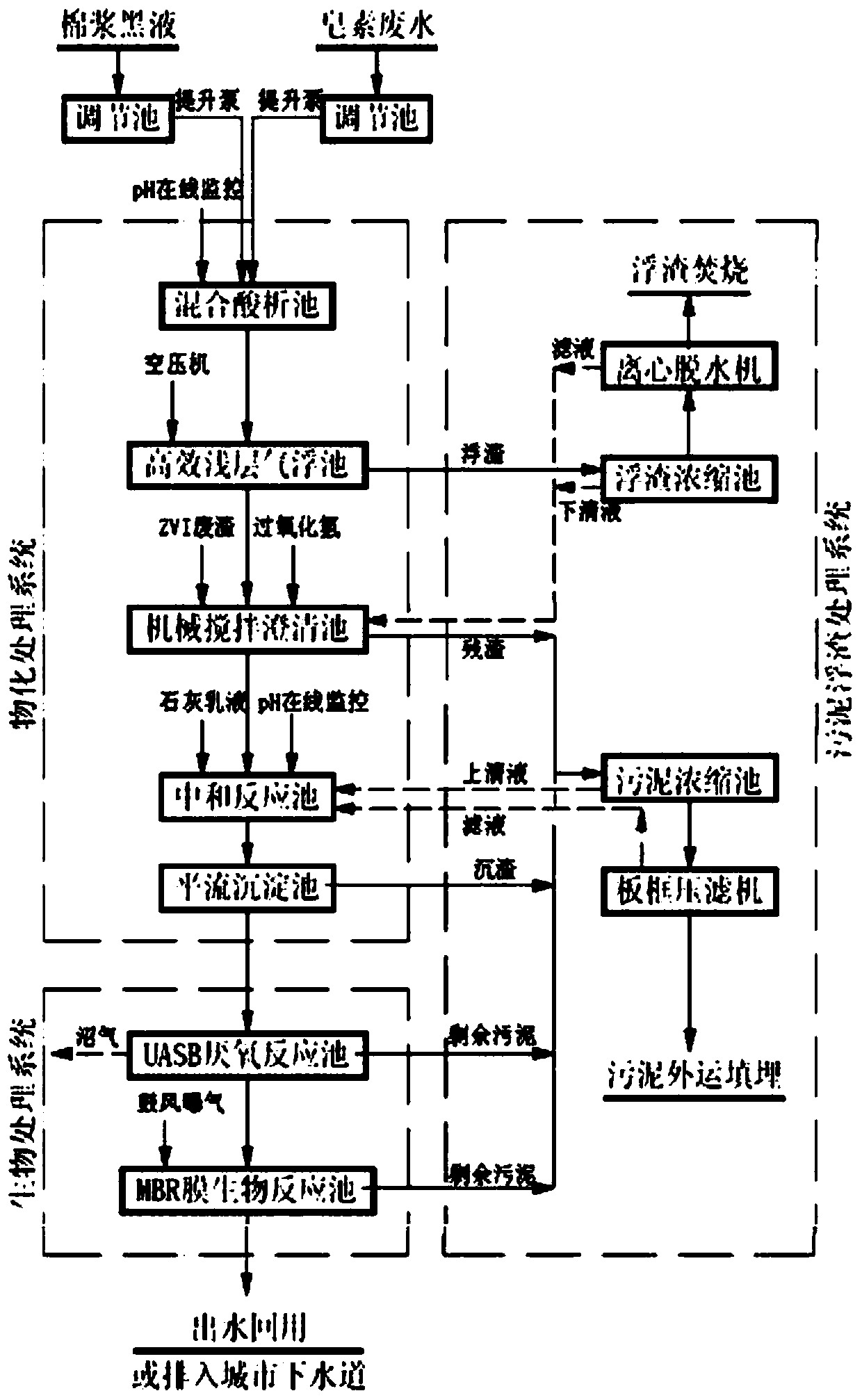

[0027] The flow chart of the joint treatment process of cotton pulp black liquor and saponin waste water provided by the present invention is as figure 1 As shown, in the actual operation of the factory, it is necessary to use various process treatment tanks for wastewater treatment.

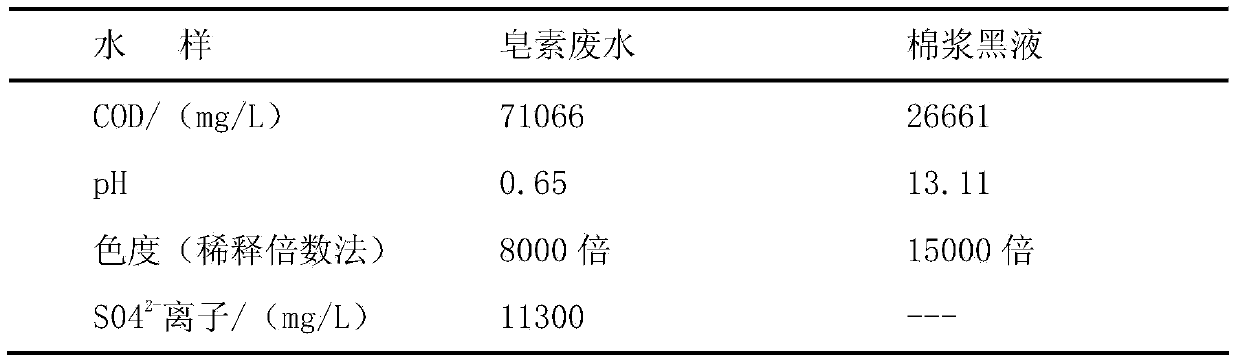

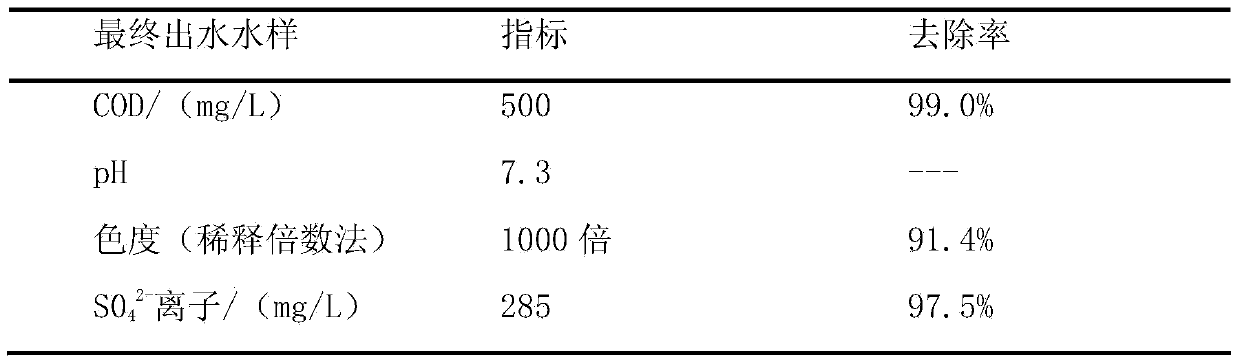

[0028] The water quality of the selected cotton pulp black liquor and saponin wastewater in the present embodiment is as follows after testing:

[0029]

[0030] Discharge the cotton pulp black liquor and saponin waste water into their respective adjustment tanks according to the volume ratio of 1.1:1, and then lift the cotton pulp black liquor and saponin waste water to the mixed acid analysis tank through the lift pump, and then the mixed acid analysis tank Set the pH online monitoring, and monitor the pH value in the mixed acid analysis tank to be about 2.5, and the mixed solution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com