Complete plant for treating and recovering printing light polluted waste liquid

A technology for wastewater treatment and complete sets of equipment, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. The problem of high operating cost can increase the residence time, increase the gas-liquid contact area, and reduce the investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

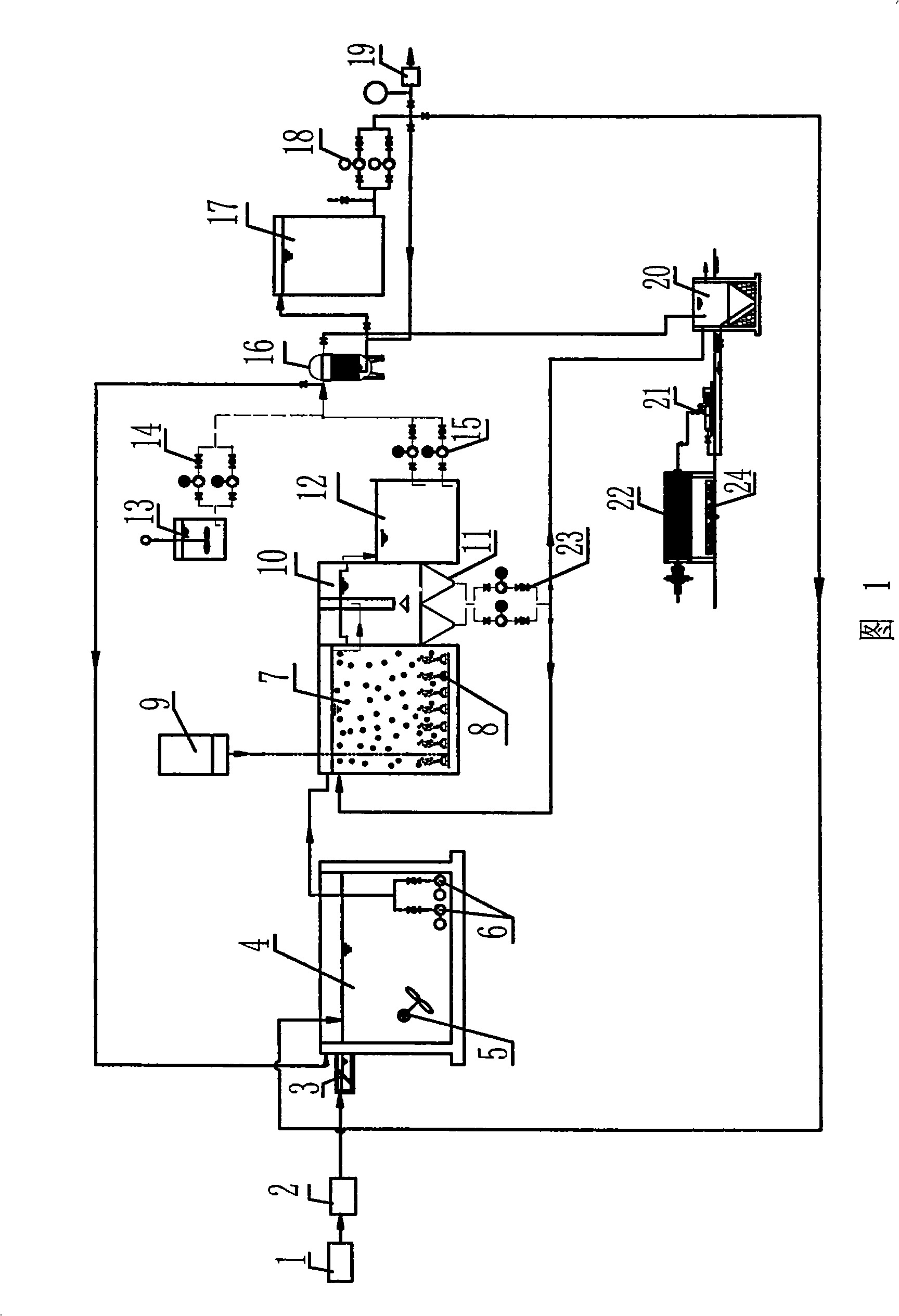

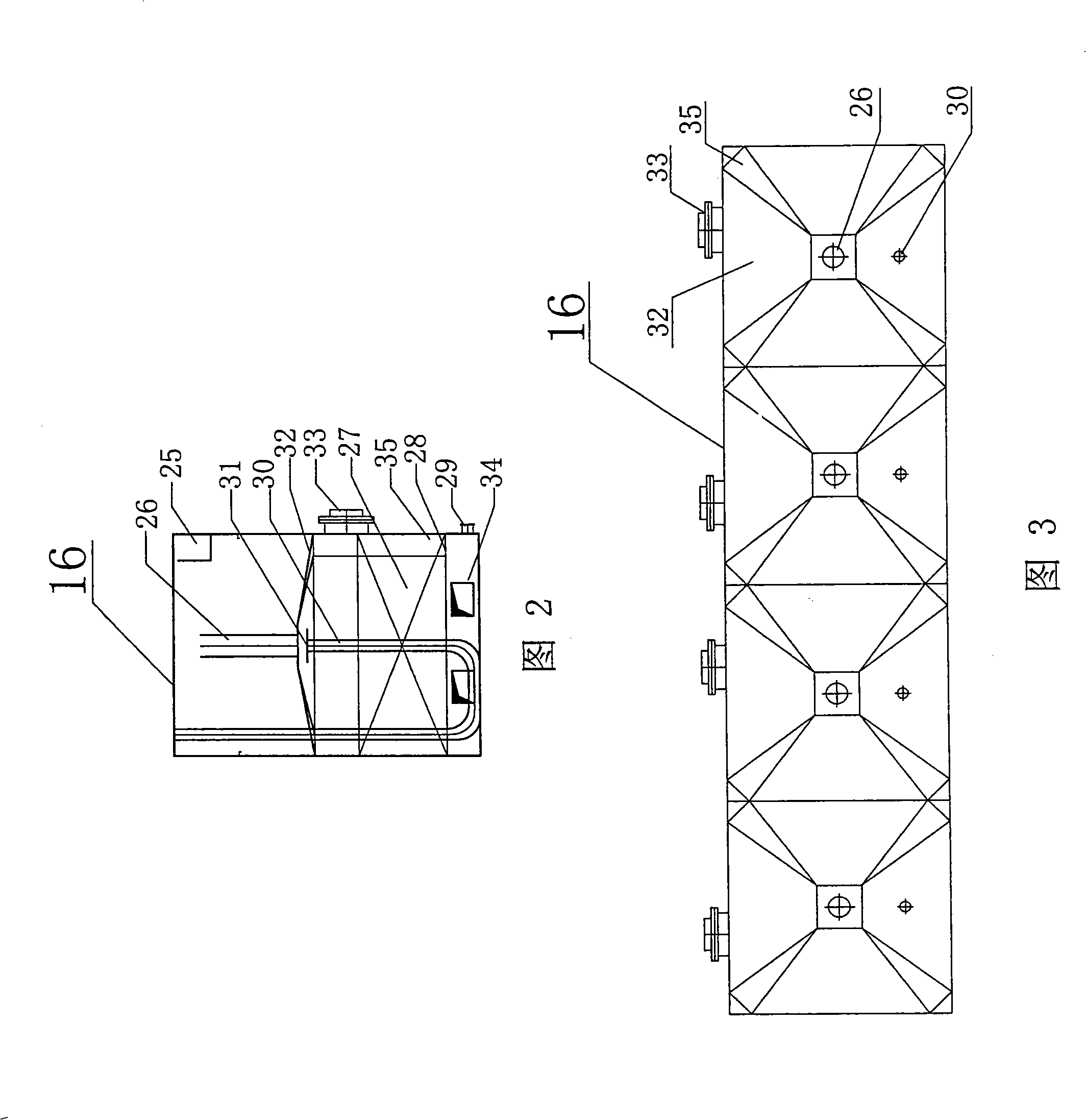

[0031] The present invention is mainly composed of workshop waste water collection pool 1 connected in sequence, automatic diversion pipeline 2, screen 3, regulating pool 4 with submersible mixer 5 and lift pump 6 inside, moving bed bioreactor 7, bottom with mud discharge bucket 11 Sedimentation and separation tank 10, intermediate pool 12, secondary lift pump 15, backwash self-cleaning filter 16, reuse pool 17, reuse lift pump 18, automatic reuse system 19, etc. A dosing pump 14 with a dosing device 13 is also provided between the secondary lift pump 15 and the backwash self-cleaning filter 16 .

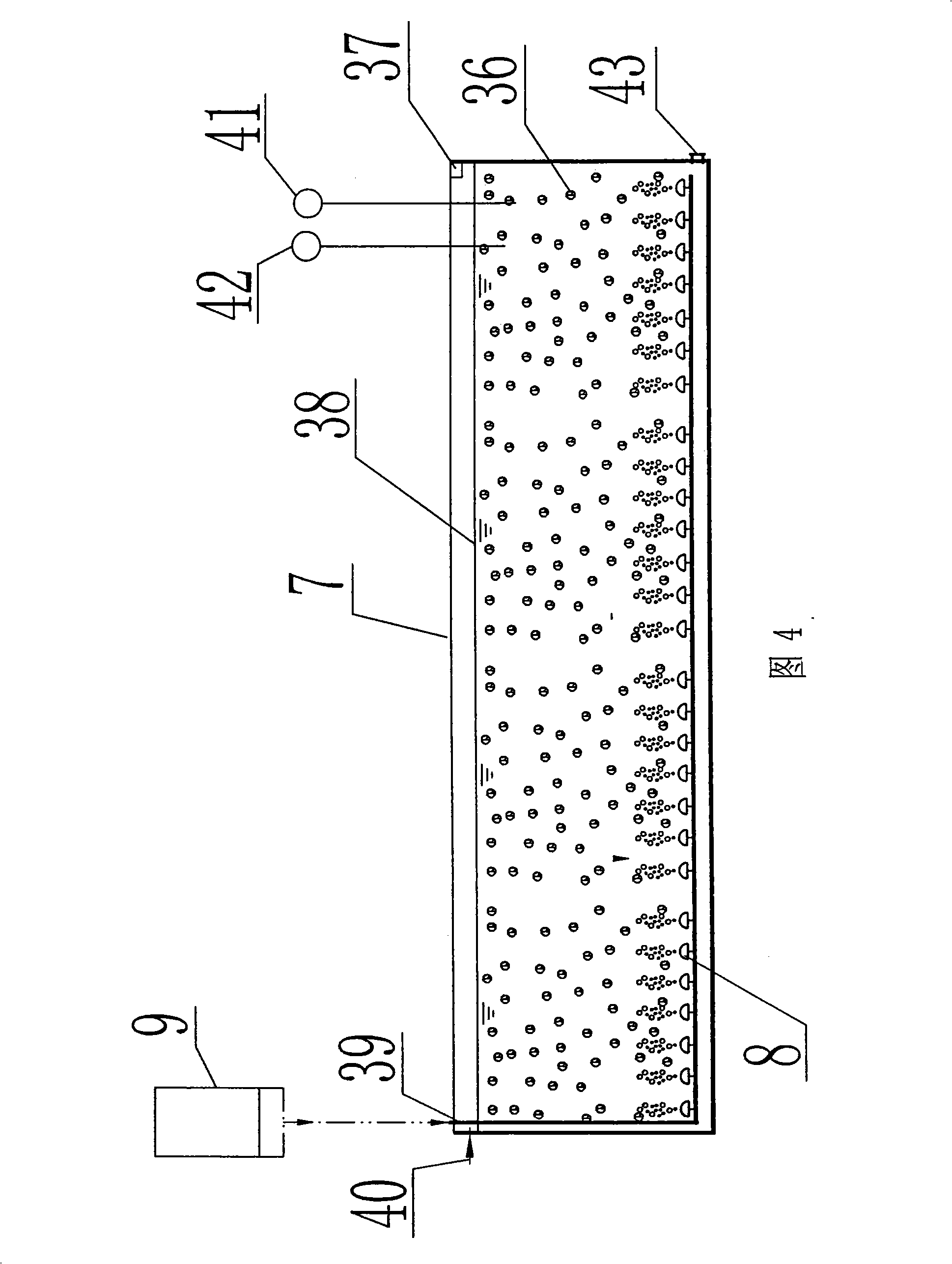

[0032]The moving bed bioreactor 7 is provided with a packing layer 36, the upper part is provided with a water inlet 40 and a porous water outlet weir box 37, and the bottom is provided with a microporous aerator 8 and a mud discharge port 43 for emergency or maintenance. The packing layer 36 Covered with an intercepting net 38 to block the overflow of the filler, the microporous ae...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com