Method for circularly processing hot boiler flue gas and desulfurization wastewater

A technology for desulfurization wastewater and recycling treatment, applied in chemical instruments and methods, separation methods, water/sewage treatment, etc., can solve the problems of water environment impact, inability to remove desulfurization wastewater salt, dust absorption, etc., to save water and improve wastewater. The effect of treatment and reuse, reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

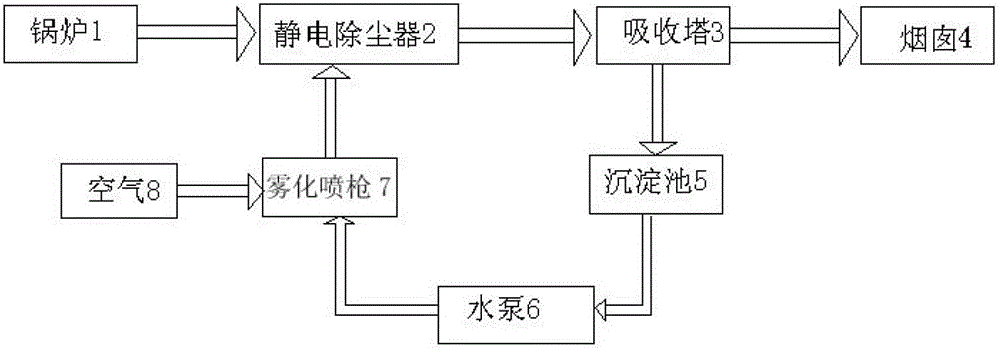

[0027] A method for circularly treating boiler hot flue gas and desulfurization wastewater, characterized in that: utilizing boiler hot flue gas to evaporate desulfurization wastewater, and using desulfurization wastewater boiler hot flue gas to cool down and remove dust, so as to reduce waste water and waste gas emissions, specifically comprising the following steps :

[0028] 1) storing the waste water produced by wet flue gas desulfurization in the sedimentation tank 5;

[0029] 2) Pass the hot flue gas discharged from the coal-fired boiler 1 into the electrostatic precipitator 2; introduce the desulfurization wastewater in the sedimentation tank 5 into the atomizing spray gun 7 at the entrance of the electrostatic precipitator 2 through the water pump 6;

[0030] 3) The air inlet of the atomizing spray gun 7 is connected with the air, and the air is introduced into the atomizing spray gun 7 by using the flow pressure generated when the desulfurization wastewater flows, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com