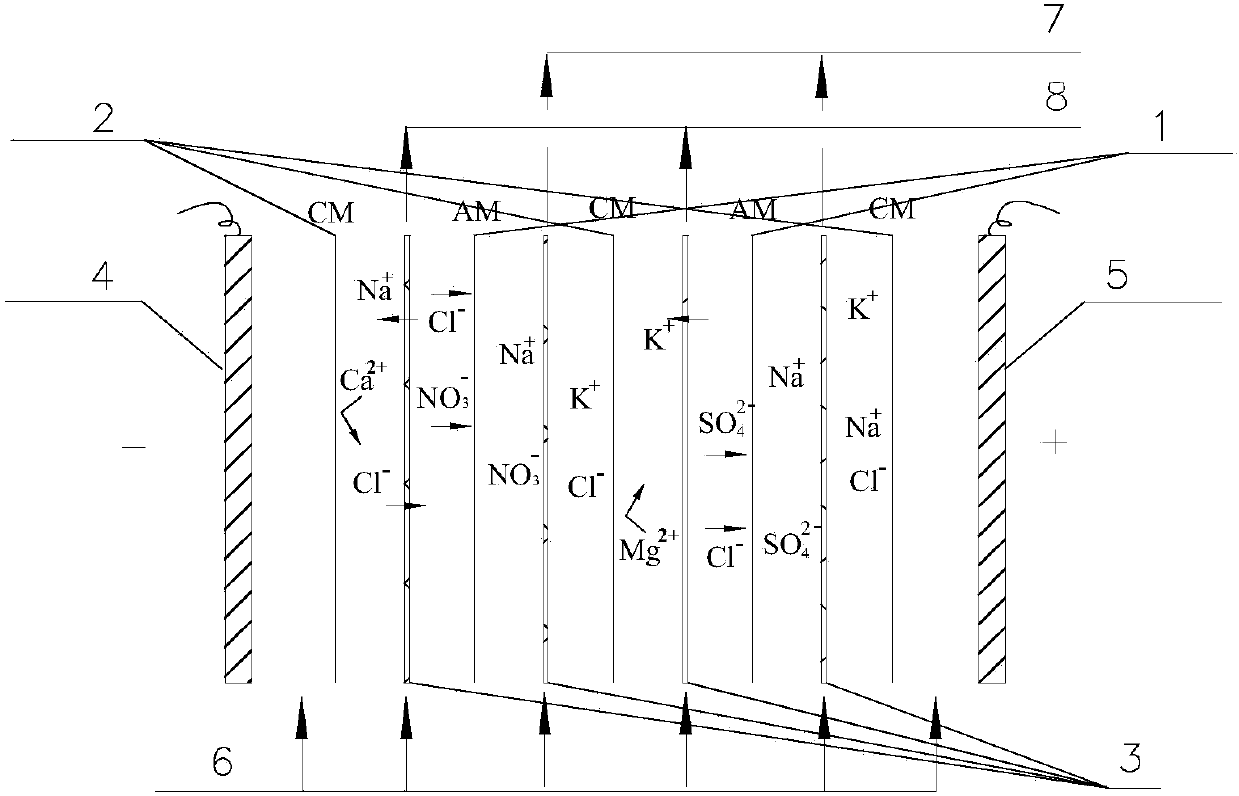

Electrodialyzer and near-zero-release industrial wastewater recycling technique

A technology of electrodialyzer and industrial wastewater, which is applied in electrodialysis, general water supply saving, chemical instruments and methods, etc., and can solve the problems of high treatment cost and low recovery rate of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0056] The wastewater of a power plant is the mixed sewage of circulating water discharge sewage, standard sewage and RO concentrated water. The total hardness of mixed sewage is 2009mg / L (CaCO 3 meter), the total alkalinity is 444mg / L (CaCO 3 Meter), the conductivity is 2790uS / cm, the turbidity is 1.51NTU, SiO 2 The content is 16.8mg / L. Due to the high hardness, turbidity, and salt content of the mixed sewage, it is difficult to process it and reuse it in the plant's circulating water system while ensuring a high water recovery rate.

[0057] By analyzing the water quality of mixed sewage, the near-zero discharge industrial wastewater reuse process provided by the present invention is adopted, that is, the integrated device is firstly used to conduct comprehensive functions such as electrocoagulation, air flotation, high-efficiency sedimentation and multi-media filtration on the sewage, effectively Reduce hardness, turbidity and other indicators in water.

[0058] The ele...

Embodiment 2

[0063] The TDS of fracturing wastewater in an oilfield is 7012mg / L, the TSS is 482mg / L, and the turbidity is 280NTU. Part of the produced water is required to be reused, and the TDS of the recycled water is <350mg / L; the other part is reinjected, and the TDS of the reinjected water is <2100mg / L. The concentrated water produced requires a salt content of more than 100,000 mg / L and is sent to the evaporation plant for treatment.

[0064] By analyzing the water quality of mixed sewage, the near-zero discharge industrial wastewater reuse process provided by the present invention is adopted, that is, the integrated device is firstly used to conduct comprehensive functions such as electrocoagulation, air flotation, high-efficiency sedimentation and multi-media filtration on the sewage, effectively Reduce suspended solids and turbidity indicators in water.

[0065] The present invention uses reverse osmosis equipment to desalinate part of the integrated water produced. The fresh wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com