Process for treating industrial waste water containing hydroxybenzene and ammine by double-tower stripping

A coal chemical wastewater and stripping technology, which is applied in ammonia preparation/separation, heating water/sewage treatment, degassed water/sewage treatment, etc., can solve the problem of increasing the load of ammonia refining section, large circulation volume, and deacidification process Unreasonable problems, to achieve the effect of reducing energy consumption and purification load, reducing the degree of scaling and crystallization, and improving equipment operating efficiency

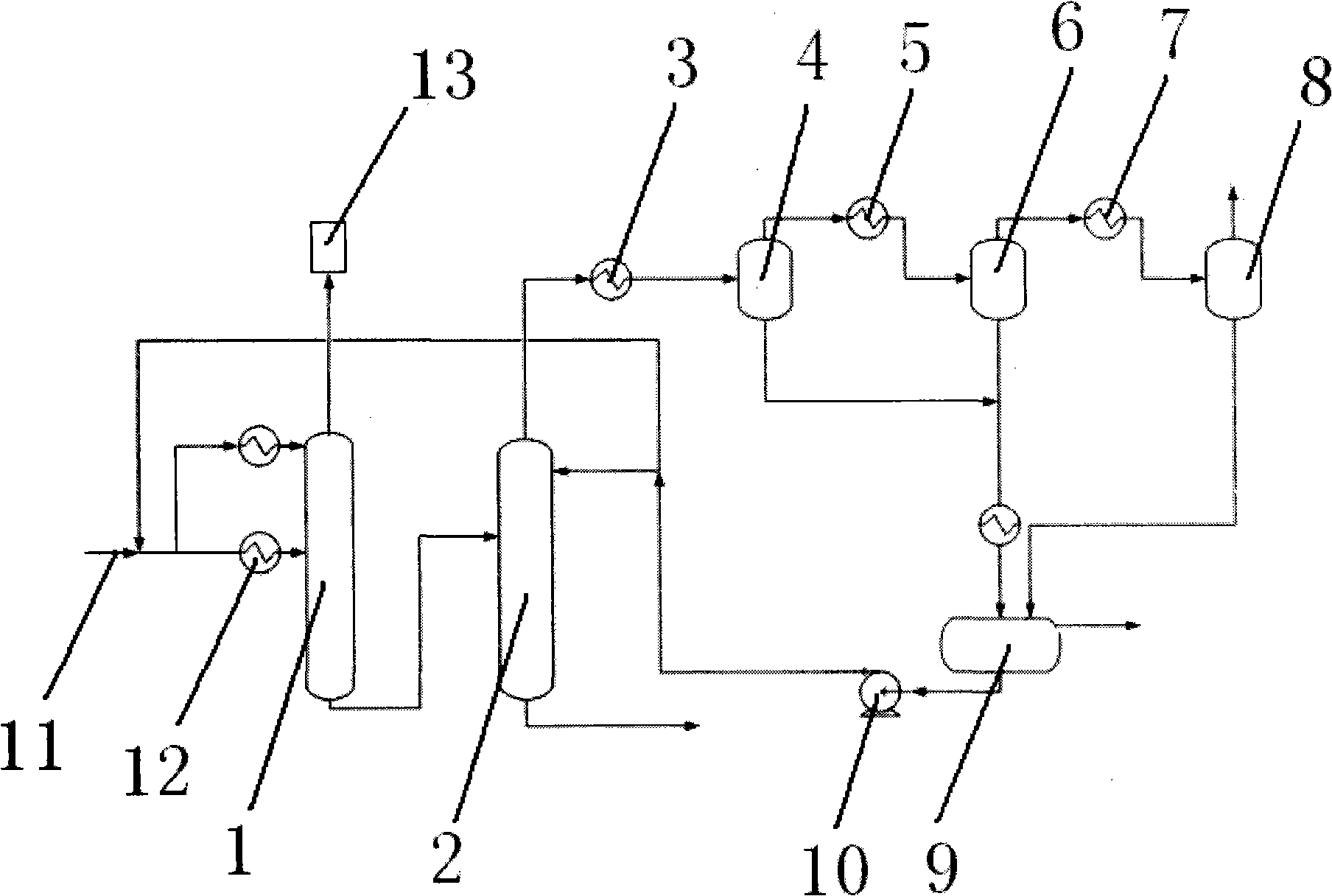

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Let the phenolic and ammonia-containing coal chemical wastewater enter into the tower from the upper part and middle upper part of the deacidification tower drawn out from the side line in two streams, cold and hot, so that the pressure at the top of the tower is 0.2 MPa (a), the temperature is 40 ° C, and the bottom of the tower is The pressure is 0.255Mpa(a), and the temperature is 120°C. The acid gas is stripped from the top of the tower, and according to the composition, it can enter the sulfur recovery unit, be incinerated by torch or be vented directly, and the still liquid is extracted from the bottom of the tower;

[0016] (2) The waste water from the removal of acid gas enters the deamination tower from the middle and upper part, the pressure at the top of the tower is 0.2-Mpa(a), the temperature is 40°C, the pressure at the bottom of the tower is 0.25Mpa(a), and the temperature is 120°C. Ammonia-water vapor containing 5% ammonia is stripped from the top of...

Embodiment 2

[0021] (1) Let the phenolic and ammonia-containing coal chemical wastewater enter into the tower from the upper part and middle upper part of the deacidification tower drawn out from the side line in two streams, cold and hot, so that the pressure at the top of the tower is 0.7MPa (a), the temperature is 80 °C, and the bottom of the tower is The pressure is 0.75Mpa(a), and the temperature is 170°C. The acid gas is stripped from the top of the tower, and depending on the composition, it can enter the sulfur recovery unit, be flared or directly vented. Extract the still liquid from the bottom of the tower;

[0022] (2) The waste water from the removal of acid gas enters the deamination tower from the middle and upper part, the pressure at the top of the tower is 0.7Mpa(a), the temperature is 80°C, the pressure at the bottom of the tower is 0.75Mpa(a), and the temperature is 170°C. Ammonia-water vapor containing 10% ammonia is stripped from the top of the tower. Extract the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com