Reclamation and comprehensive treatment method for paper-making waste water

A papermaking wastewater and comprehensive treatment technology, which is applied in the direction of processing wastewater treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of poor biodegradability, use, high salt content, etc., and solve the problem of water consumption big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

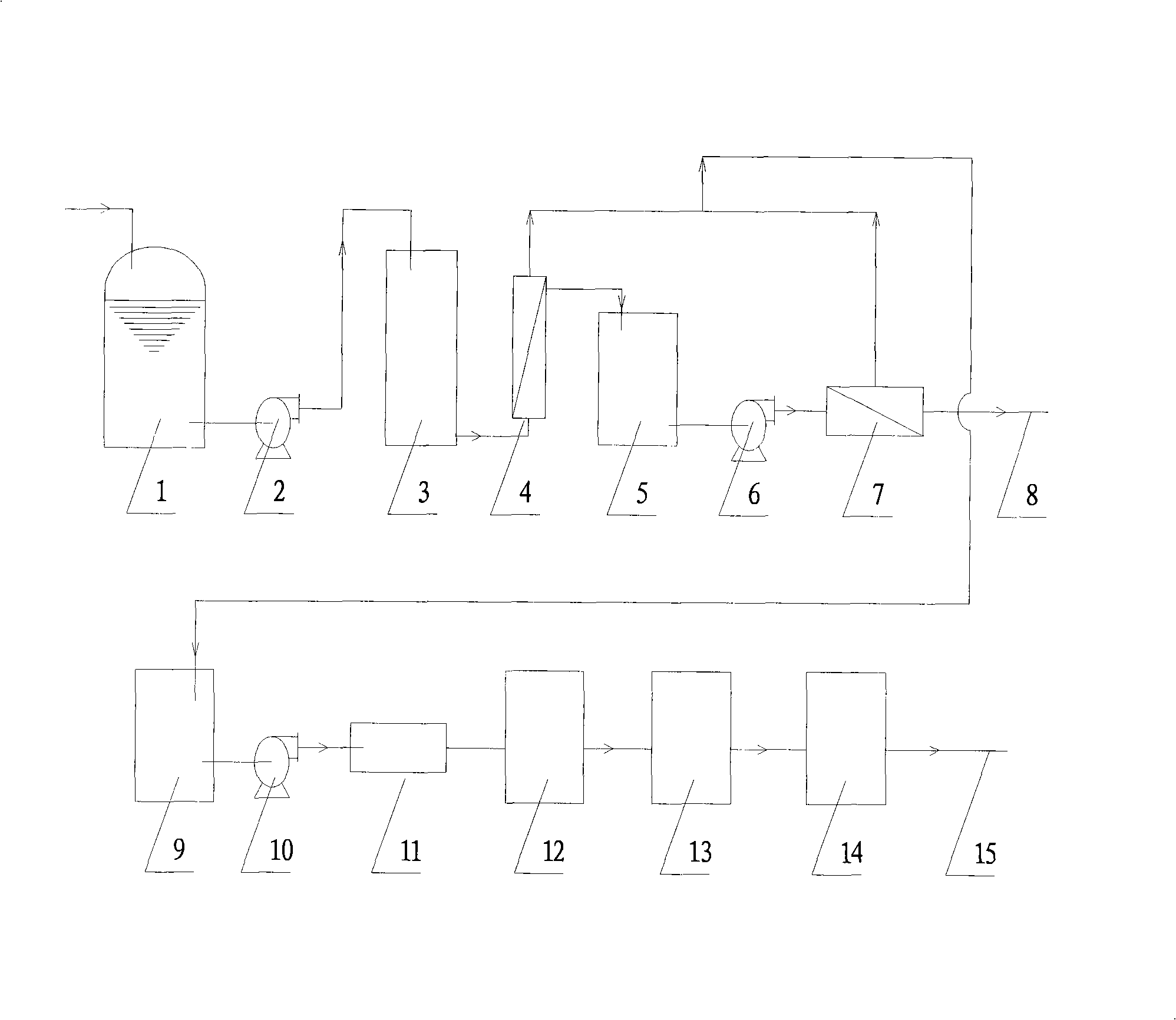

[0011] As shown in the attached figure, the comprehensive treatment system for papermaking wastewater reuse includes discharge well 1, booster pump 2, membrane pretreatment system 3, ultrafiltration equipment 4, ultrafiltration water production pool 5, booster system 6, reverse osmosis or nanofiltration Equipment 7, Permeate Outlet 8, Concentrated Wastewater Pool 9, Booster Pump 10, Dosing Mixing Reaction System 11, Microwave Equipment 12, Sedimentation Tank 13, Filter Tank 14, Wastewater Outlet 15. The release well 1 is sequentially connected with the booster pump 2, the membrane pretreatment system 3, the ultrafiltration equipment 4, the ultrafiltration water production tank 5, the booster system 6, the reverse osmosis or nanofiltration equipment 7, and the permeate outlet 8; The concentrated wastewater outlet of equipment 4 and the concentrated wastewater outlet of reverse osmosis or nanofiltration equipment 7 are sequentially connected with concentrated water tank 9, booste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com