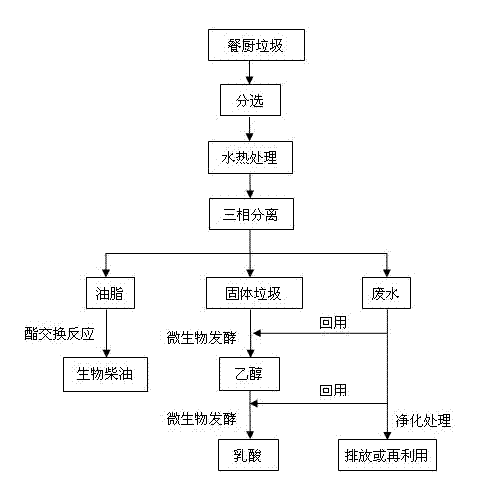

Method adopting hydro-thermal treatment to facilitate producing ethyl alcohol and lactic acid through kitchen waste

A technology for kitchen waste and hydrothermal treatment, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of complex composition of biological bacteria liquid and mixed enzyme preparations, difficult to obtain bacteria species, and complicated configuration methods. , to achieve the effect of good application value, low production cost and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Preliminarily sort the collected food waste, remove the debris that is not easy to ferment, put it into the hydrothermal reactor hydrothermal chamber, add 2 times the volume of water, and conduct hydrothermal treatment at 130°C for 60 minutes; turn on the motor and stir for 10 minutes closure.

[0038] 2. After the hydrothermal treatment is completed, the kitchen waste is sprayed to the three-phase separator, and after standing still, the grease and water-containing solid kitchen waste are separated.

[0039]3. Send the separated water-containing solid food waste to the fermenter, add the stored three-phase separated food waste water to make the solid-liquid volume ratio 1:10, and then add 20% of the weight of the solid food waste mixed bacteria Groups were fermented at 35°C for 96 hours. The ratio of each strain in the mixed flora is Pichia pastoris: Zymomonas mobilis: Aspergillus niger: Rhizopus tokyo: Saccharomyces cerevisiae: Trichoderma reesei=1:1:1:1:1:1. Aft...

Embodiment 2

[0043] The main steps of this embodiment are the same as in Example 1, except that in step 1, when the food waste contains a lot of water, after removing the impurities that are not easy to ferment, it is directly hydrothermally treated at 200°C for 10 minutes, and the stirring motor is not turned on at the same time. After the hydrothermal treatment, the pressure is released. When the pressure of the hydrothermal reactor is released to 1.5atm, the kitchen waste is sprayed into the three-phase separator, and after standing still, the oil and the water exceeding the range of solid-liquid ratio required for ethanol fermentation are separated. , so that the solid-liquid ratio reaches 1:15. The remaining solids and water were sent to the fermenter, and 40% of the solid weight of the mixed flora was added to ferment at 42°C for 120 hours.

Embodiment 3

[0045] The main steps of this embodiment are the same as in Example 1, the difference is that in step 1, 10 times the volume of solid food waste is added; in step 3, water is no longer added, and 40% of the solid weight of the mixed flora is directly added, 38 220 hours of fermentation at ℃. Among them, the ratio of each strain in the mixed flora is Pichia pastoris: Zymomonas mobilis: Aspergillus niger: Rhizopus Tokyo: Saccharomyces cerevisiae: Trichoderma reesei=3:6:4:3:6:6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com