Patents

Literature

31results about How to "Appropriate connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

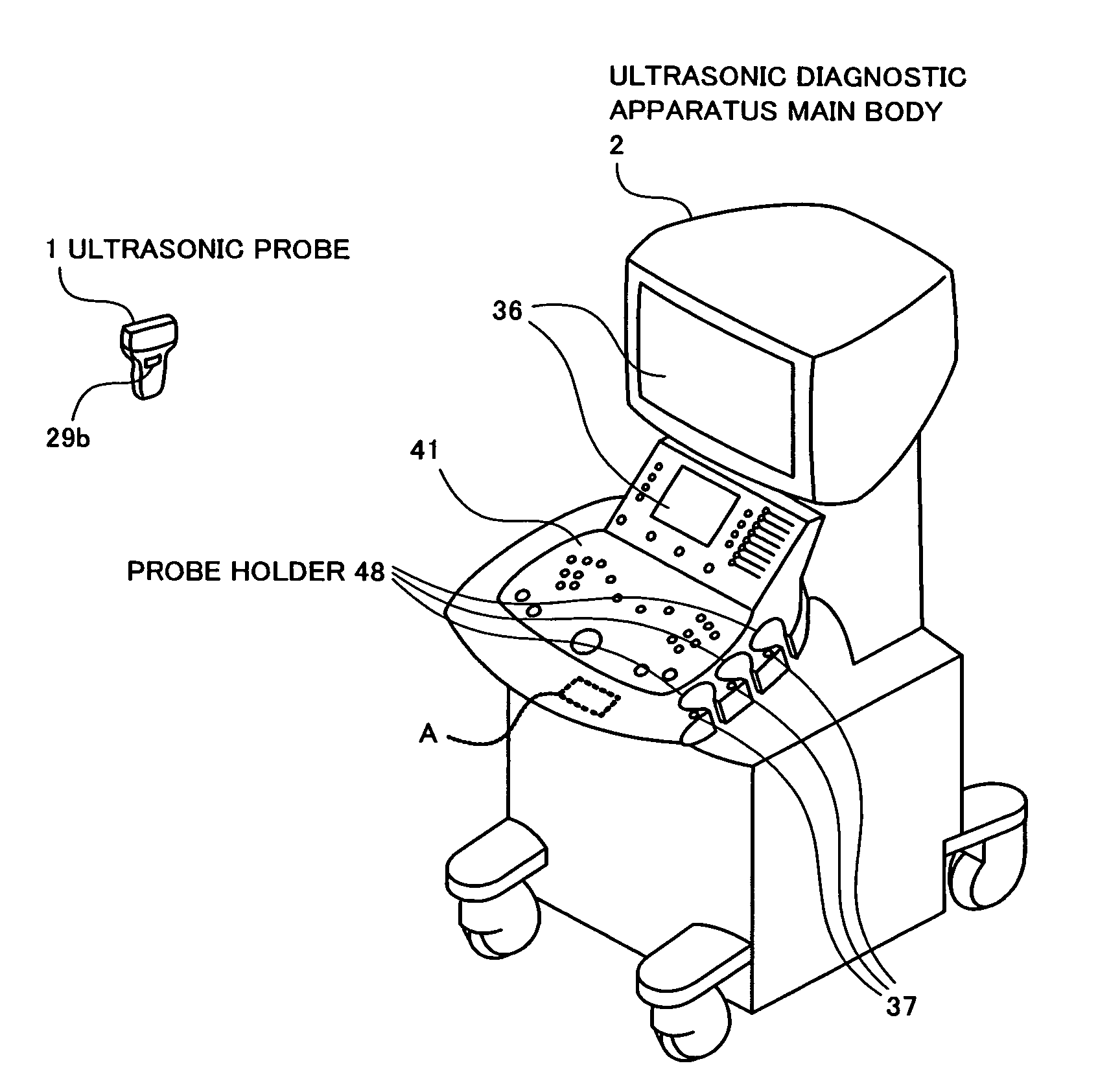

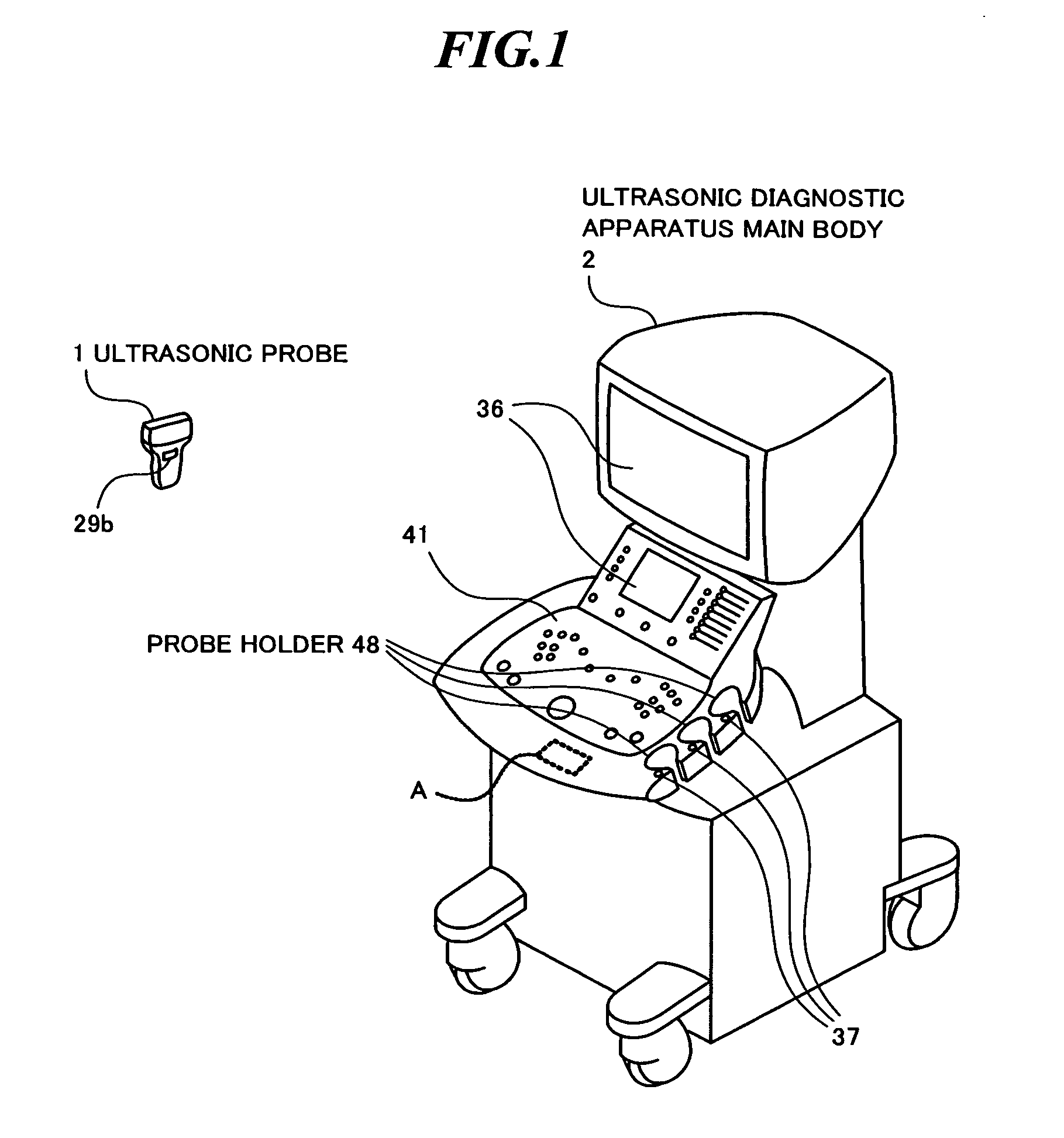

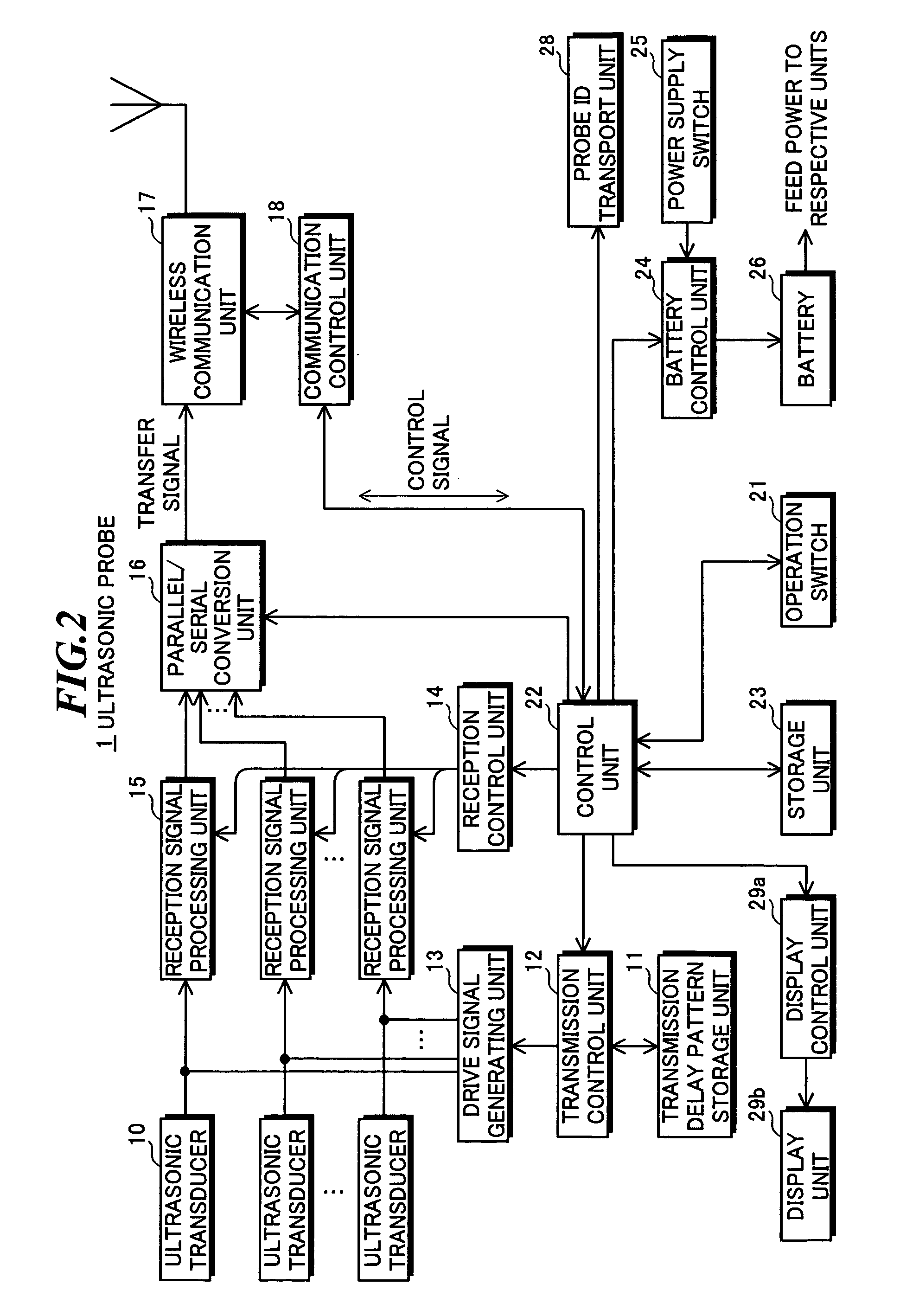

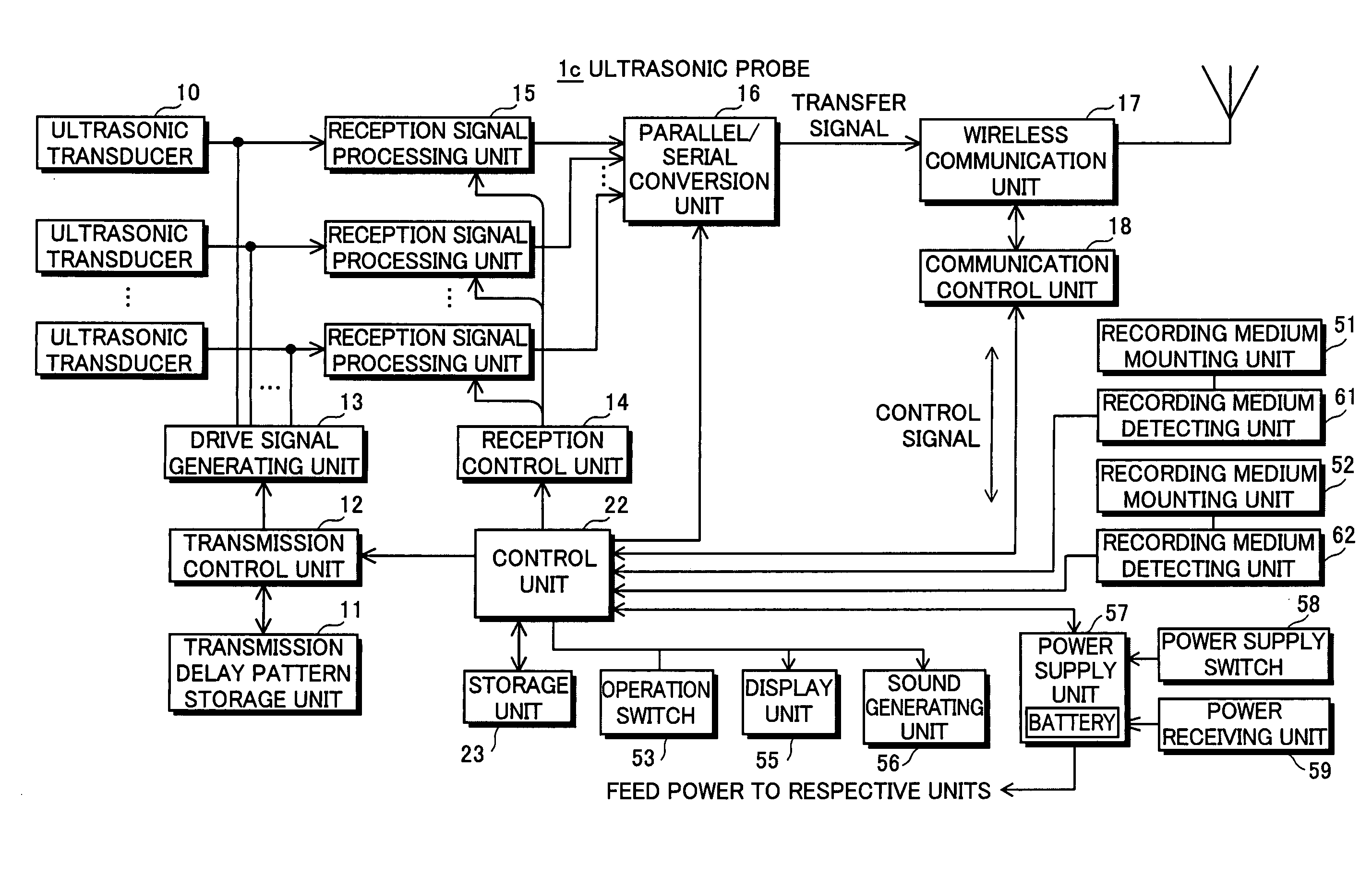

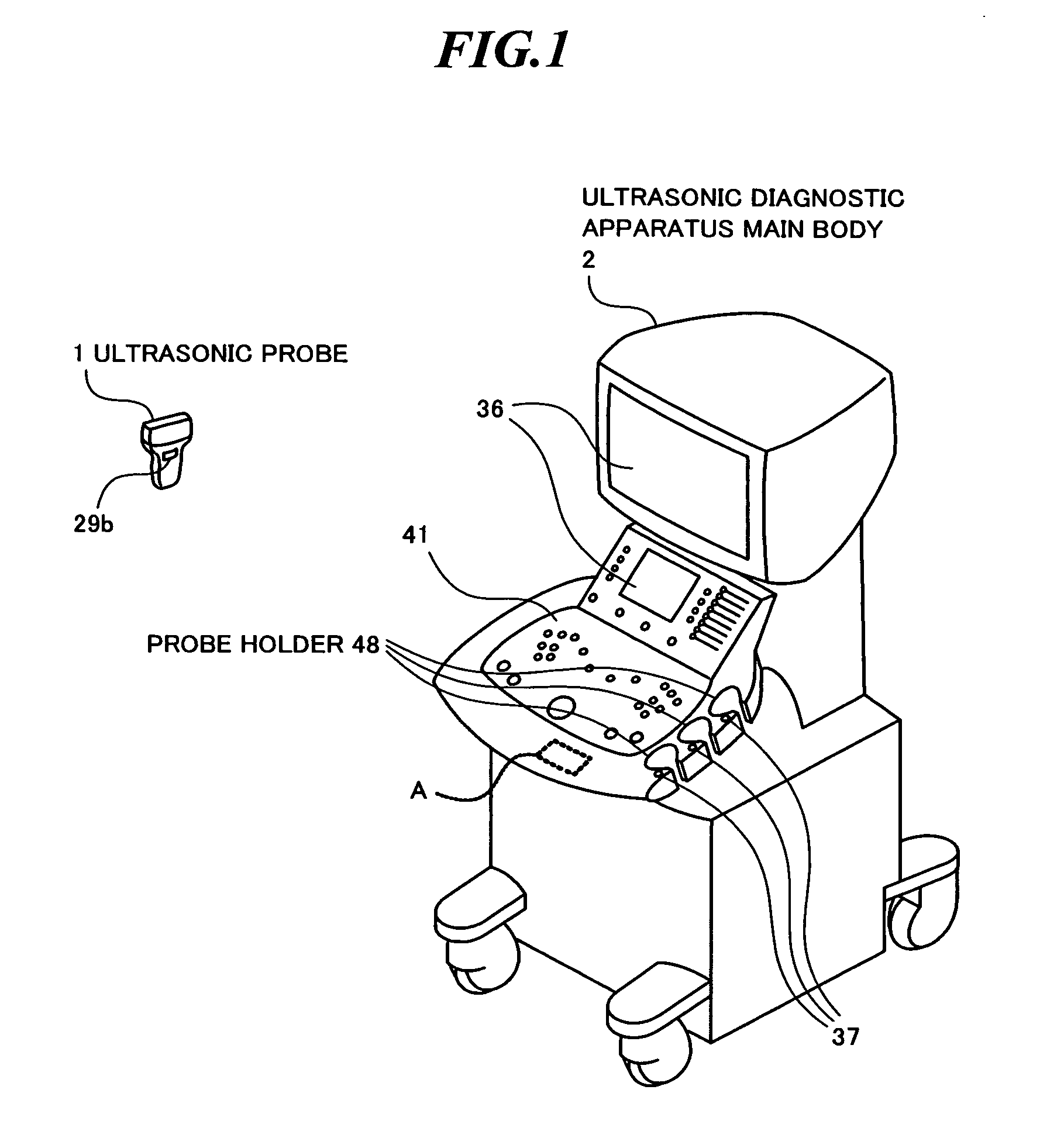

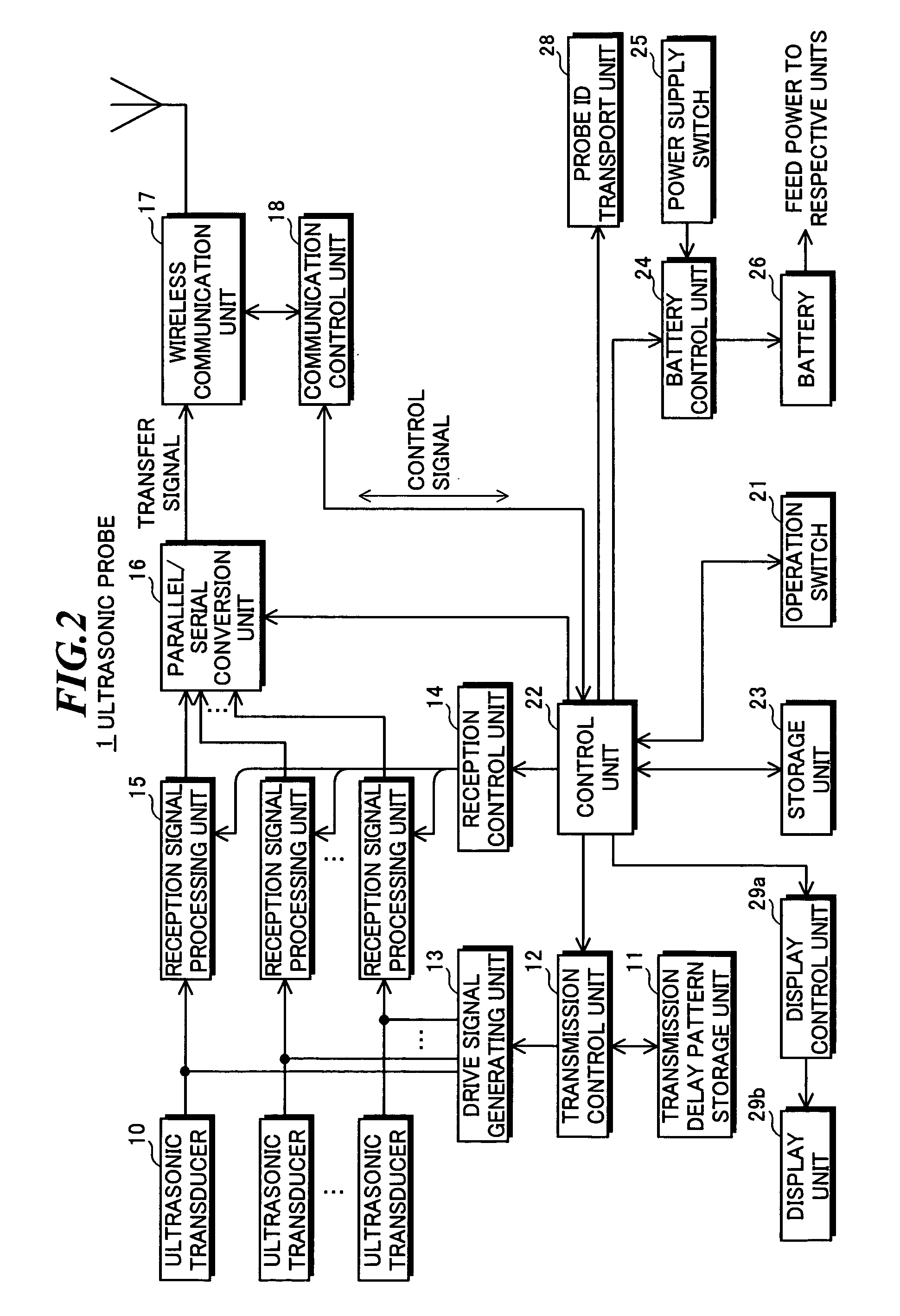

Ultrasonic diagnostic apparatus and ultrasonic probe

ActiveUS20100191121A1Wireless connectionReduce misidentificationDiagnostic recording/measuringInfrasonic diagnosticsCommunication unitFalse recognition

When a transfer signal according to ultrasonic echoes is wirelessly transmitted from an ultrasonic probe to an ultrasonic diagnostic apparatus main body, the main body and the probe are reliably connected without false recognition. An ultrasonic diagnostic apparatus includes an ultrasonic probe and an ultrasonic diagnostic apparatus main body, and the ultrasonic probe includes a probe ID transport unit having a transport distance shorter than that of a first wireless communication unit for transporting a probe ID for identification of itself in contact or noncontact to an outside, the ultrasonic diagnostic apparatus main body includes a probe ID acquiring unit for acquiring the probe ID transported from the probe ID transport unit, and a second wireless communication unit receives the transfer signal from the ultrasonic probe having the probe ID acquired by the probe ID acquiring unit.

Owner:FUJIFILM CORP

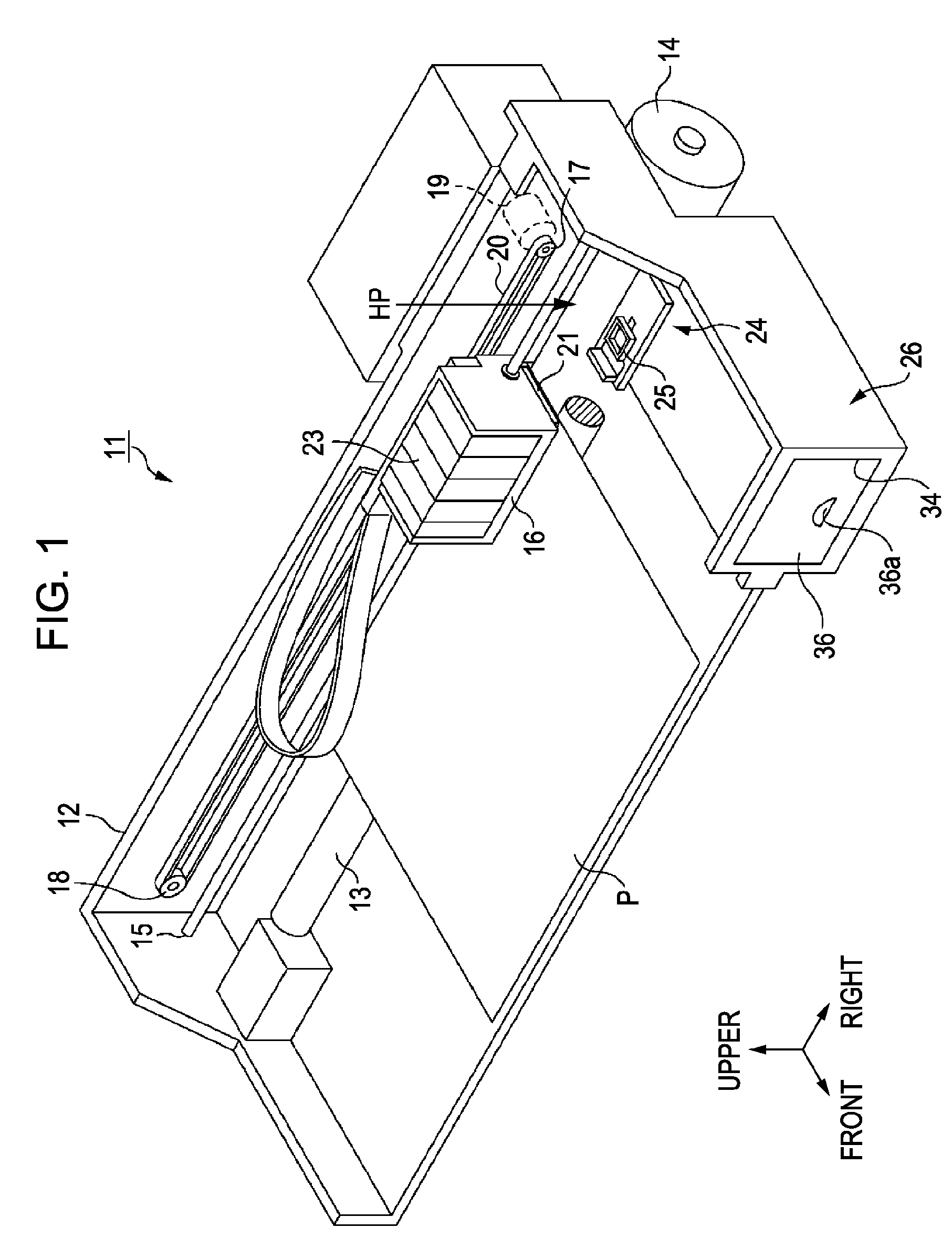

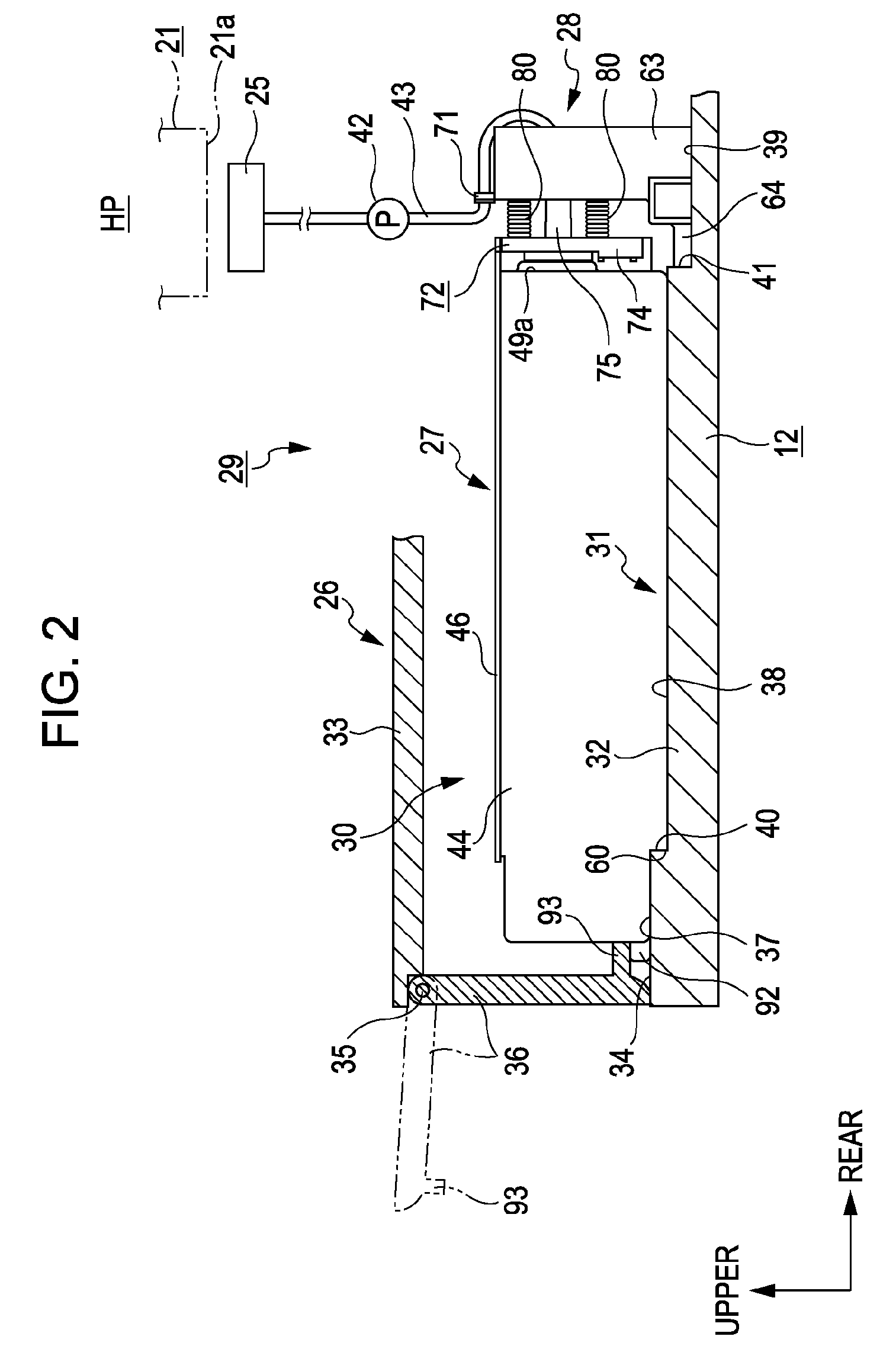

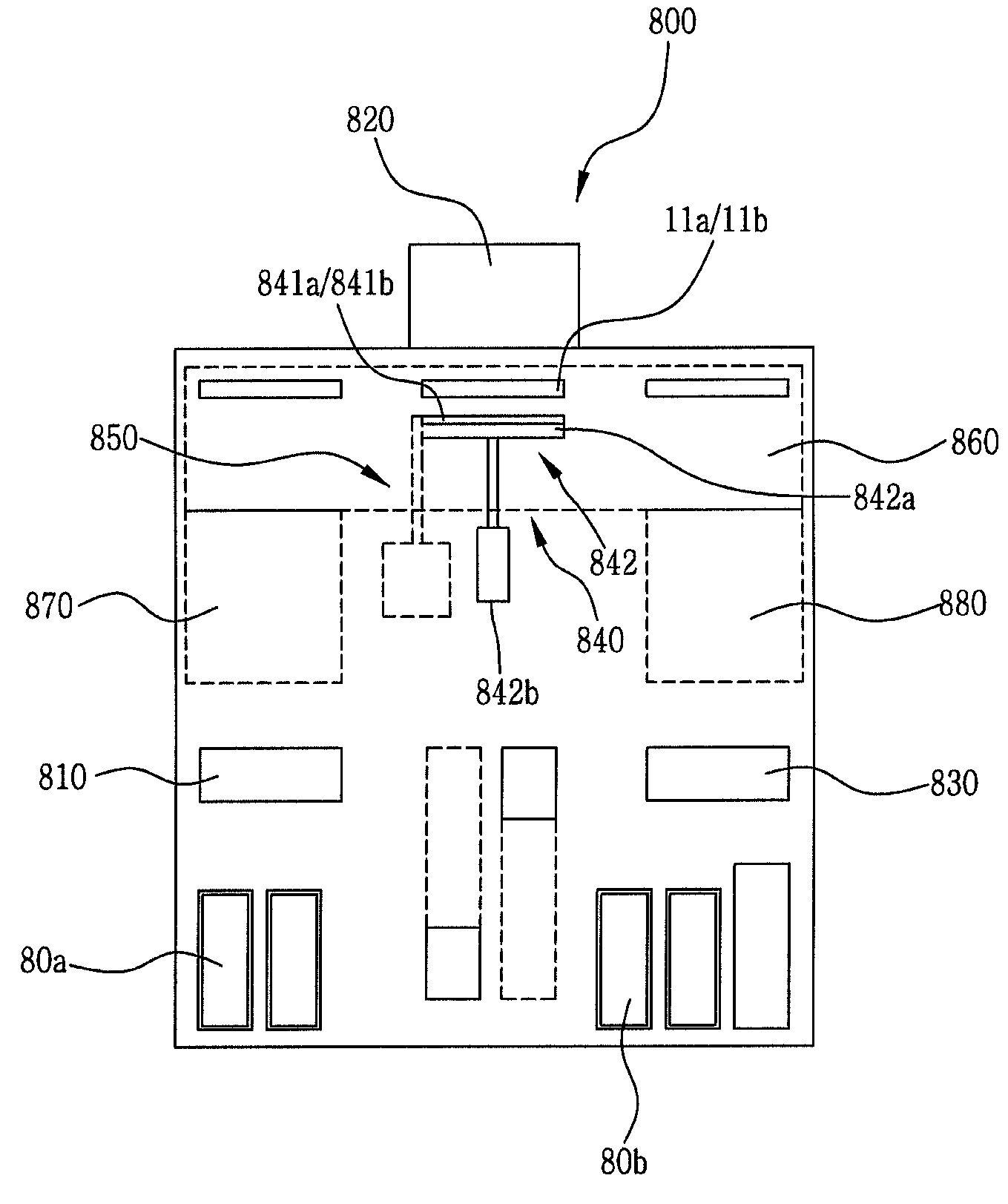

Waste liquid collector

A waste liquid collector is detachably mounted on a device including a discharge unit discharging a waste liquid and stores the waste liquid discharged from the discharge unit when the waste liquid collector is mounted on the device. The waste liquid collector includes: an opening through which the discharge unit is inserted or extracted at the time of mounting or detaching the waste liquid collector on or from the device; a collector-side connection terminal which comes in contact with a device-side connection terminal included in the device when the discharge unit of the device is inserted into the opening; and a positioning unit which positions the collector-side connection terminal to come in contact with the device-side connection terminal when the waste liquid collector is mounted on the device.

Owner:SEIKO EPSON CORP

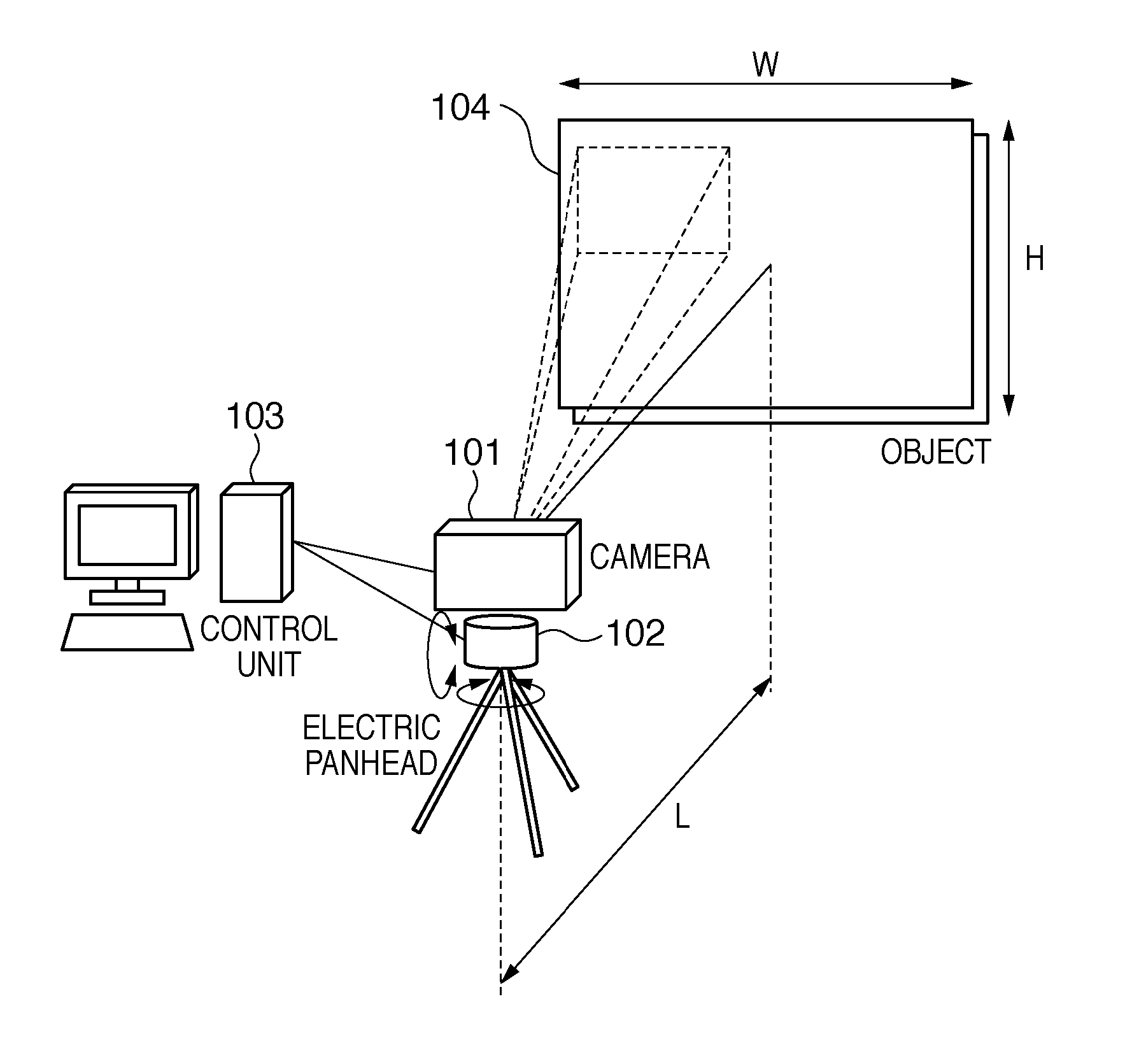

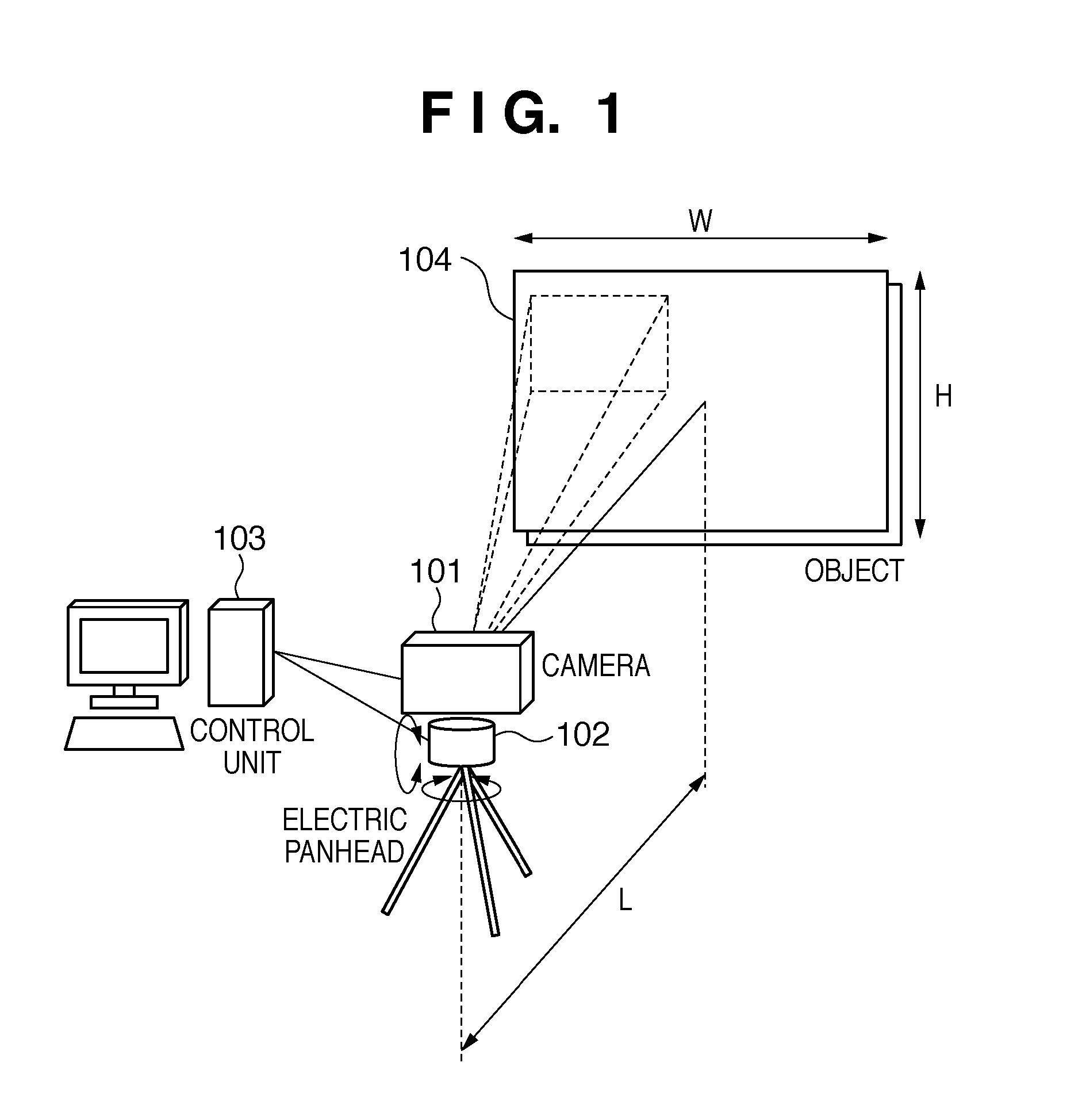

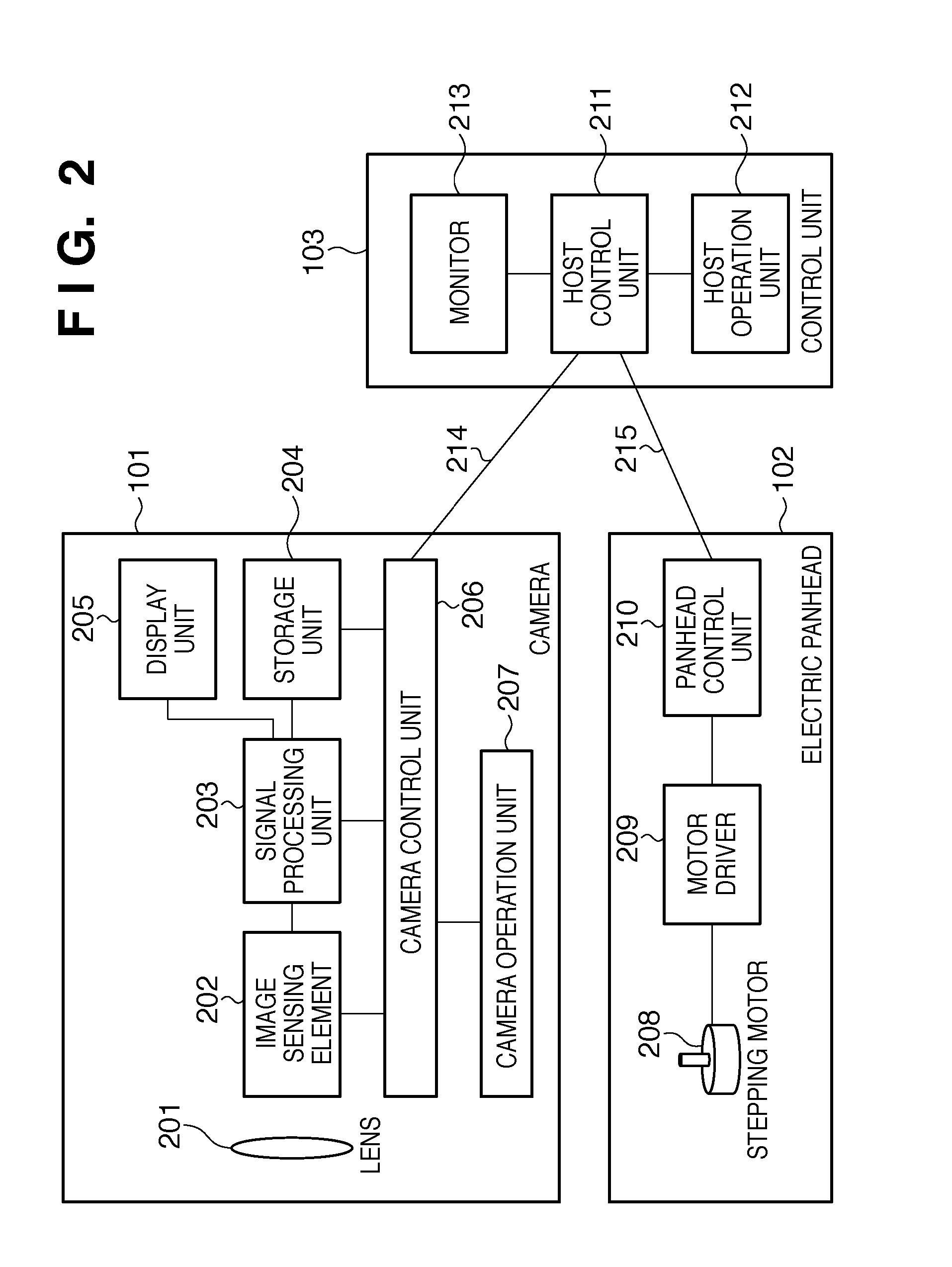

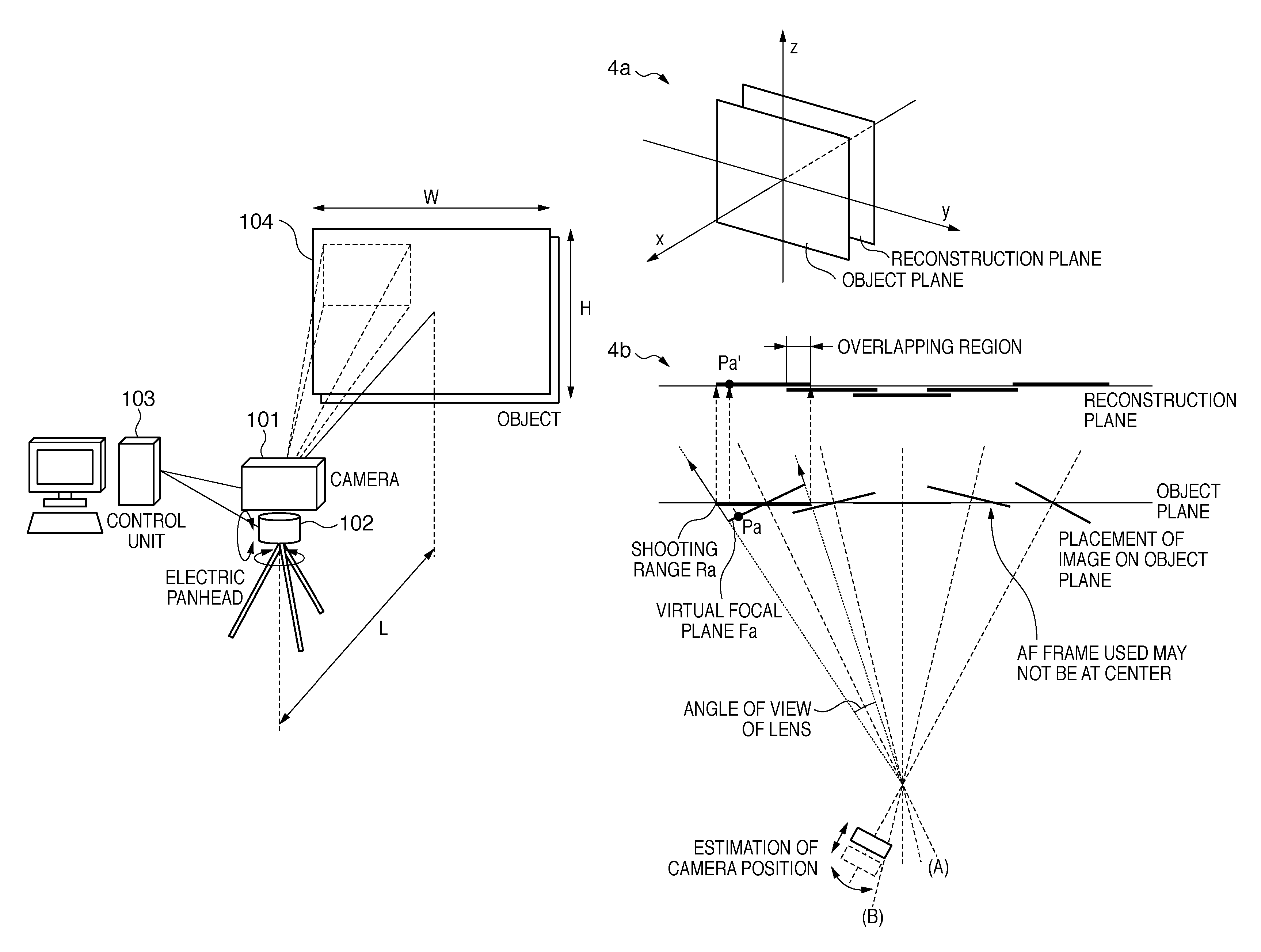

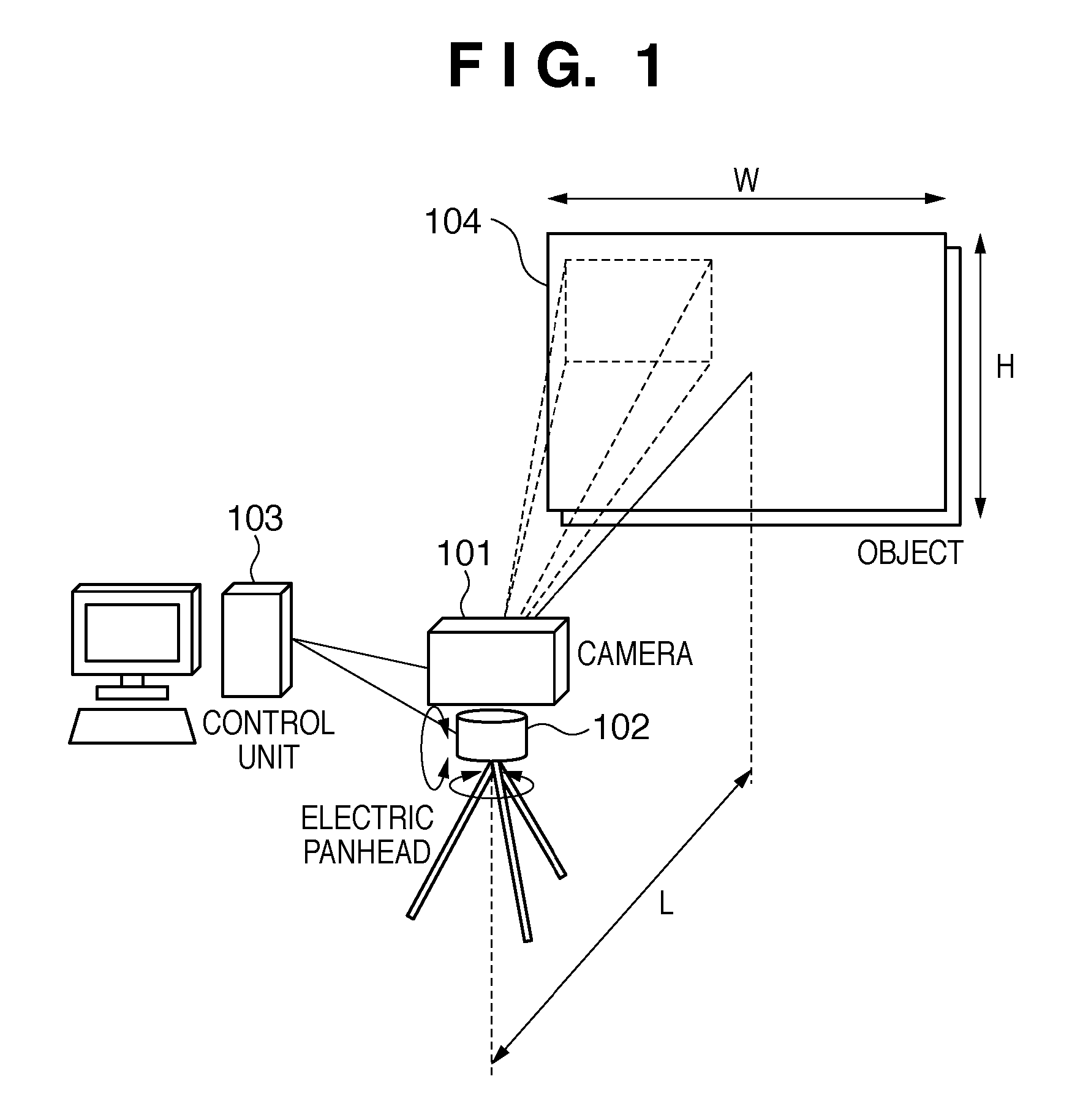

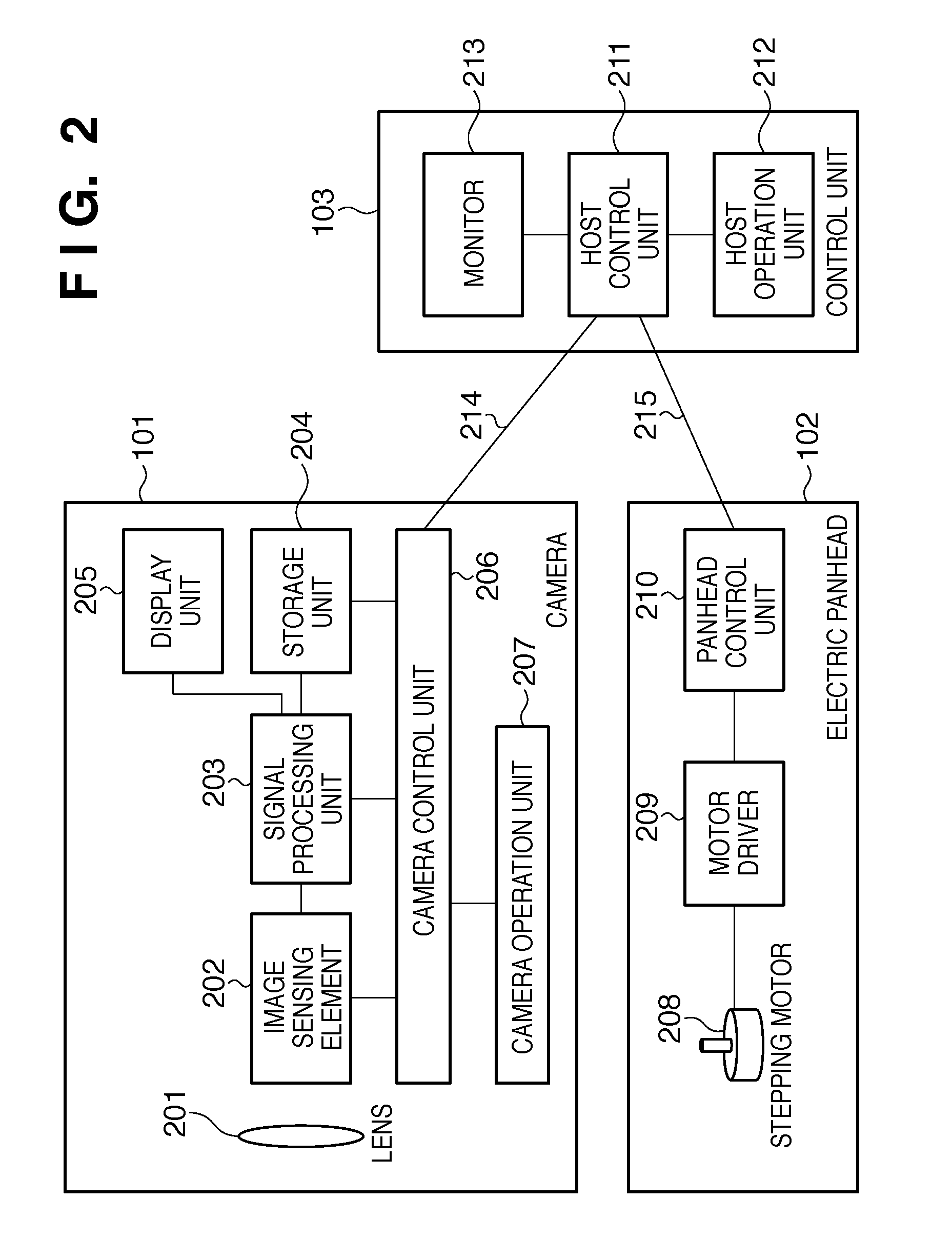

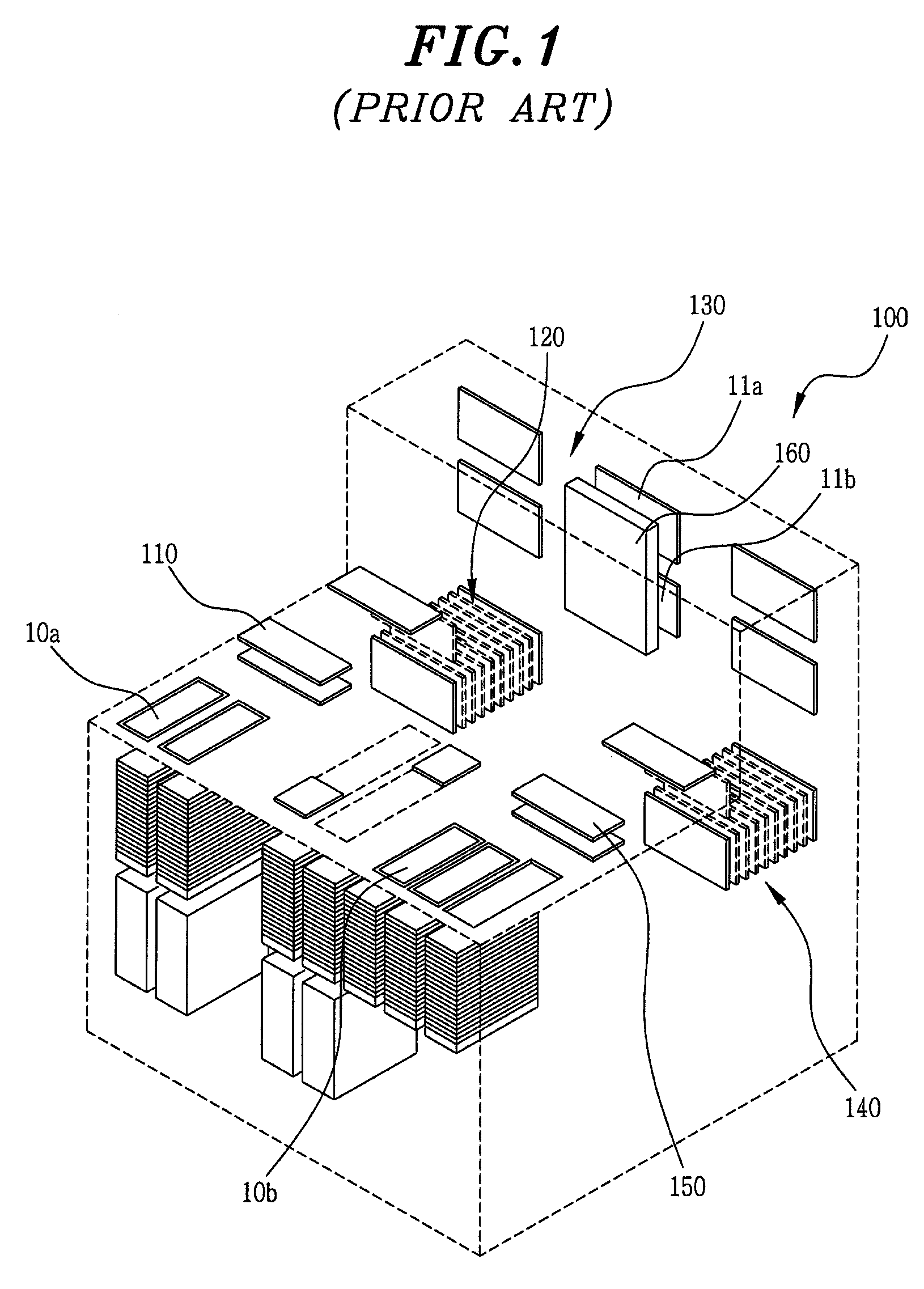

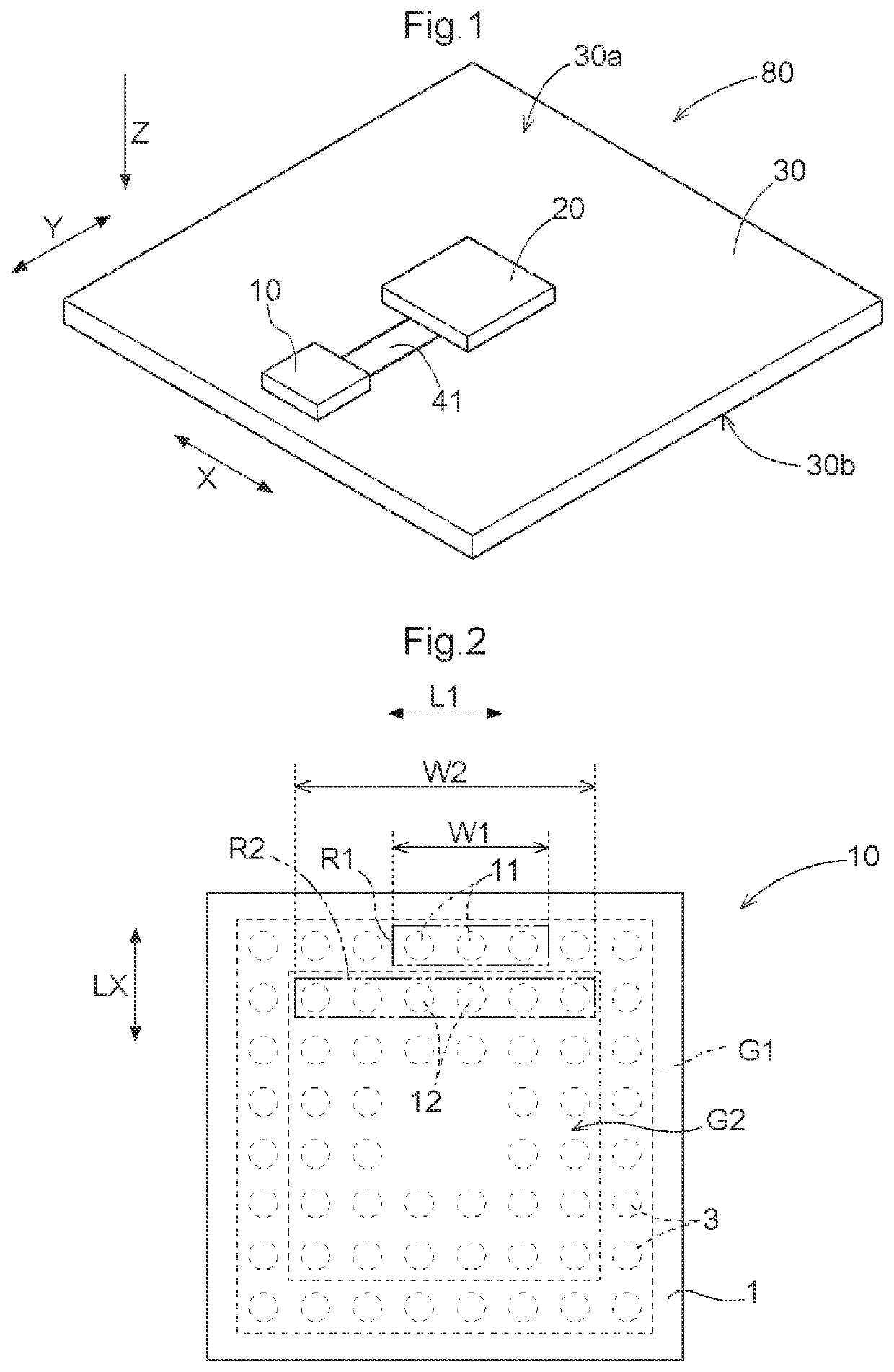

Image processing apparatus, image processing method, and storage medium

ActiveUS20110157396A1Appropriate connectionTelevision system detailsColor television detailsImaging processingImage differencing

The invention provides an image processing apparatus comprising: an acquisition unit configured to acquire a plurality of captured images captured by an image capturing apparatus; a determination unit configured to determine position information of the image capturing apparatus for each of the plurality of captured images so that an evaluation value becomes smaller; and a connecting unit configured to connect the plurality of captured images projected onto a reconstruction plane using the determined position information of the image capturing apparatus, wherein the determination unit comprises a calculation unit configured to project each of the plurality of captured images onto the reconstruction plane based on the set position information and to calculate, as the evaluation value, an image difference between the projected images in a overlapping region between the projected images.

Owner:CANON KK

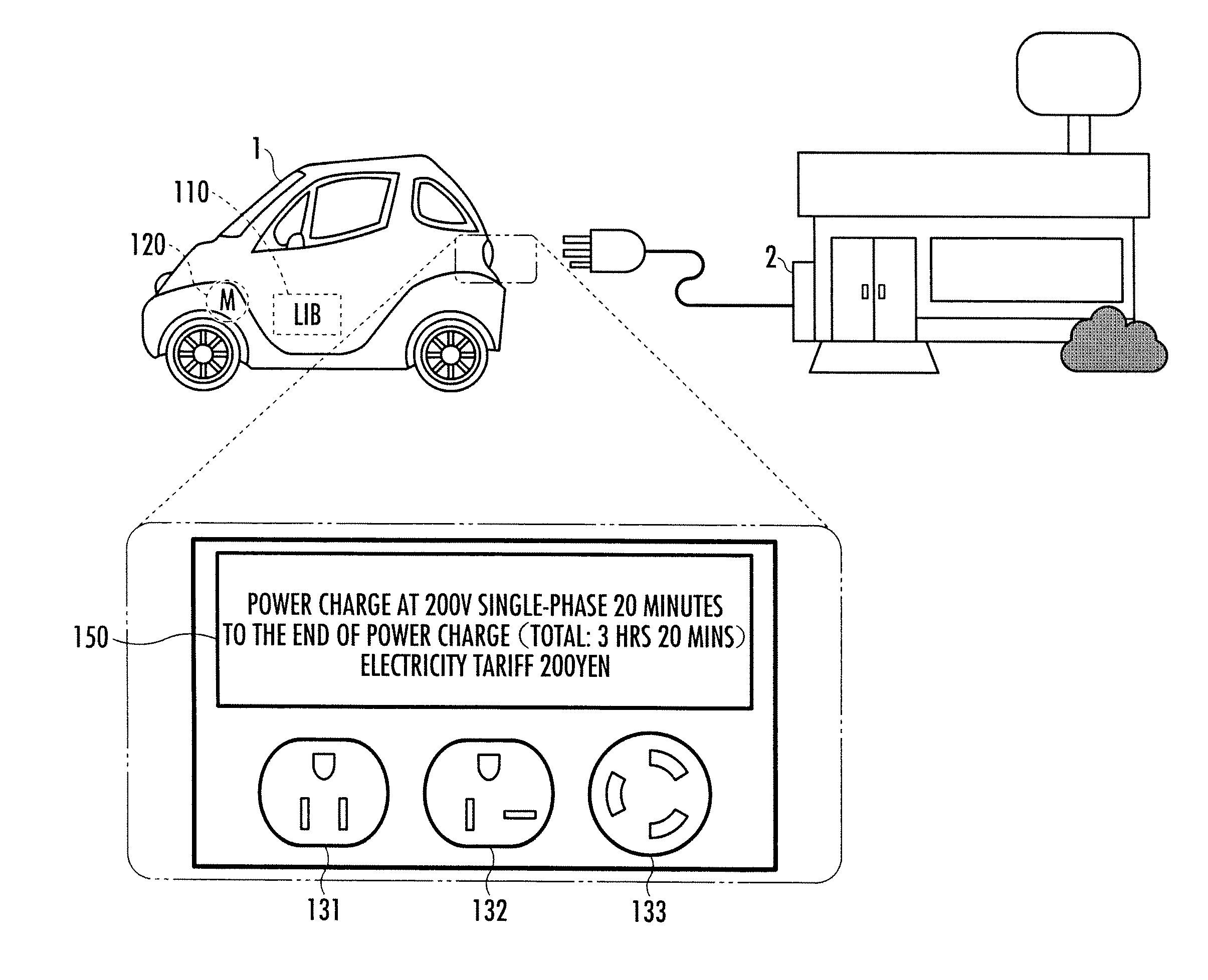

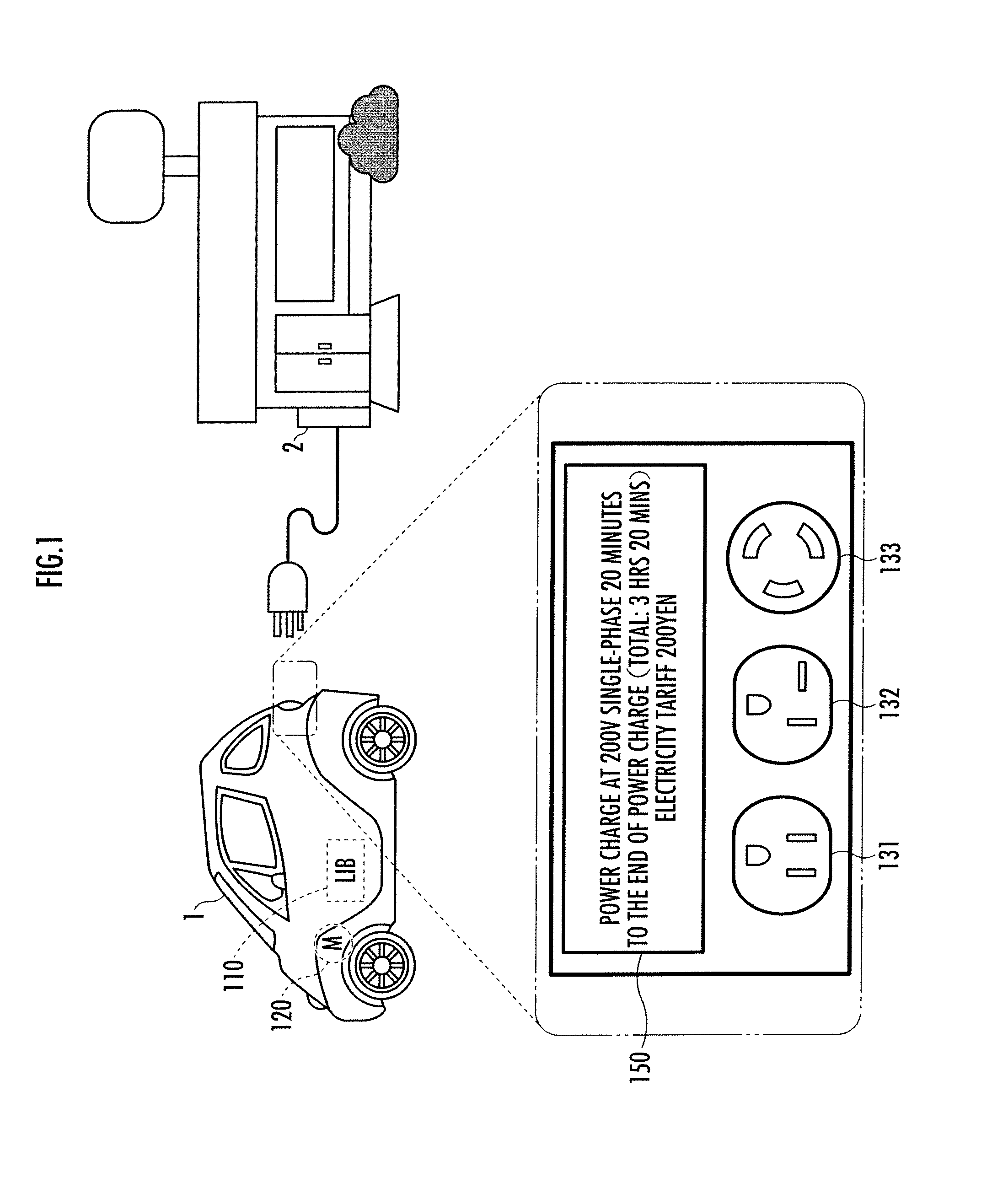

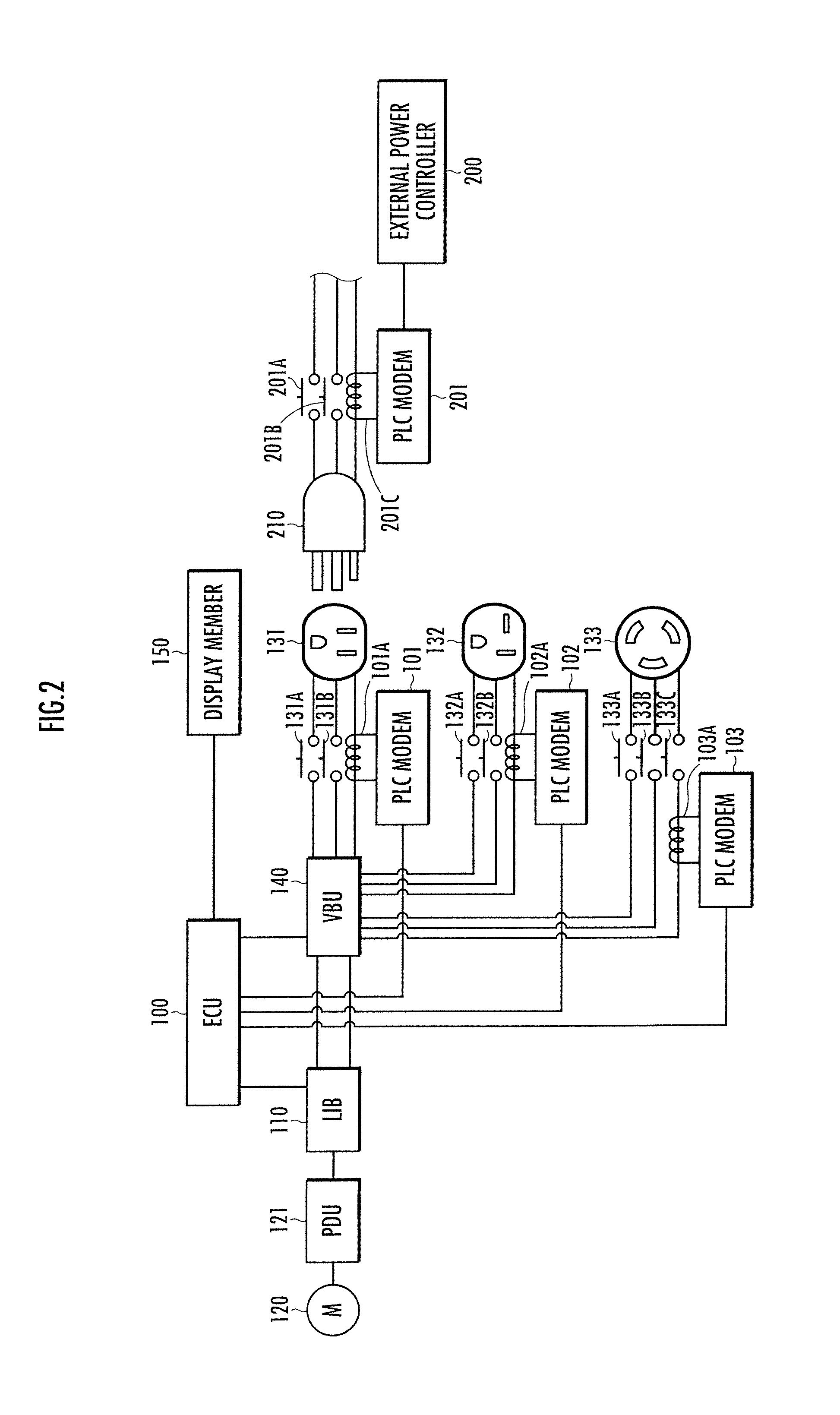

Power system

InactiveUS20110156642A1Inappropriate chargingAppropriate connectionBatteries circuit arrangementsCharging stationsElectric power systemElectric power

Provided is a power system capable of assisting an appropriate connection to an external power and preventing inappropriate power charge from being carried out. The power system mounted in a vehicle (1) is provided with a secondary battery (110), an electric motor (120) connected to the secondary battery (110) for driving the vehicle (1), a plurality of external power connecting members (131, 132 and 133) connected respectively by plural types of power supplying connectors for supplying electric power from an external power to the secondary battery (110), and movable insulation plates (171, 172 and 173) configured to block a further connection of a power supplying connector to the other external power connecting members when either one of the external power connecting members (131, 132 and 133) is detected by the connection detecting member to have a connection to a corresponding power supplying connector.

Owner:HONDA MOTOR CO LTD

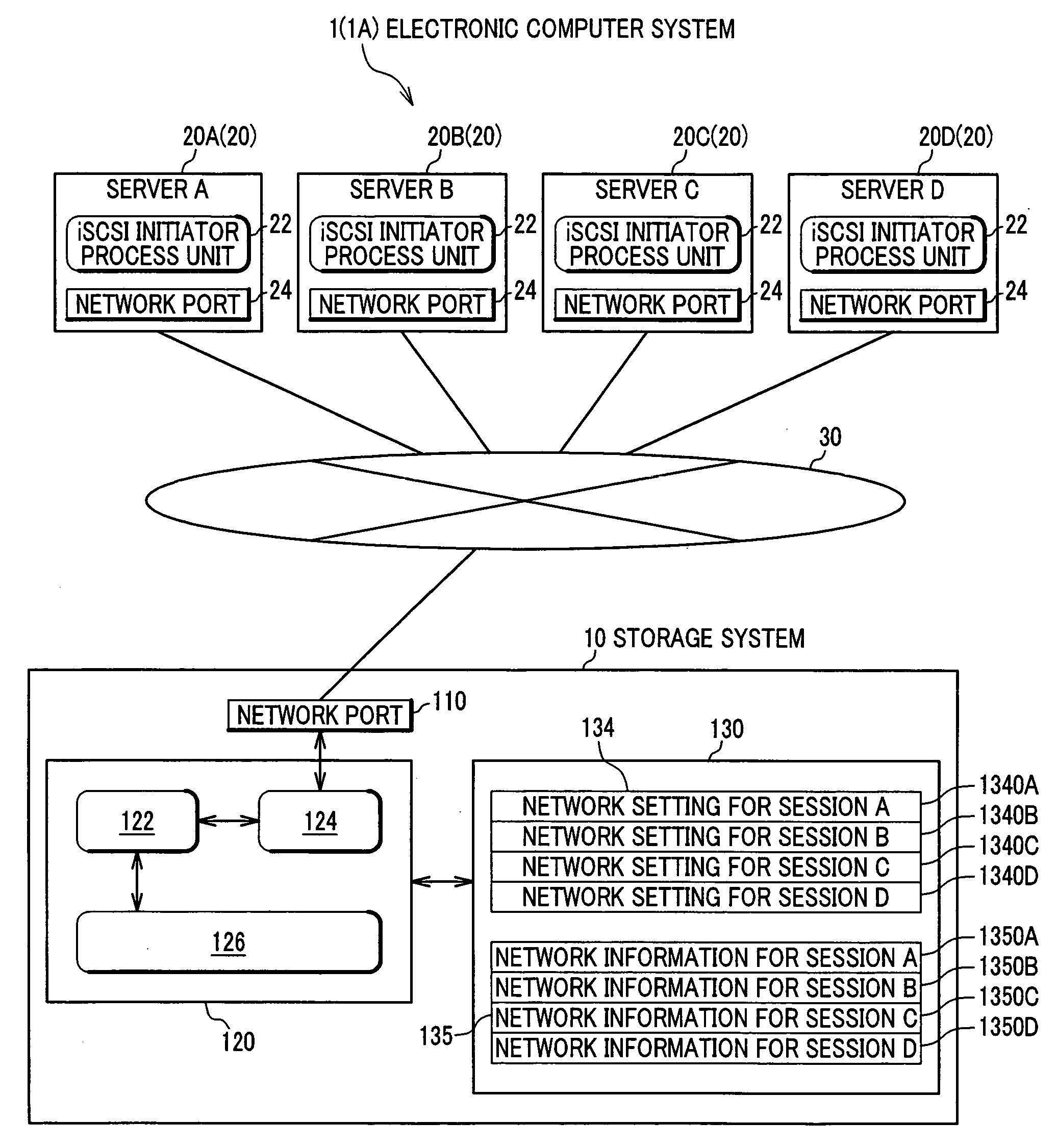

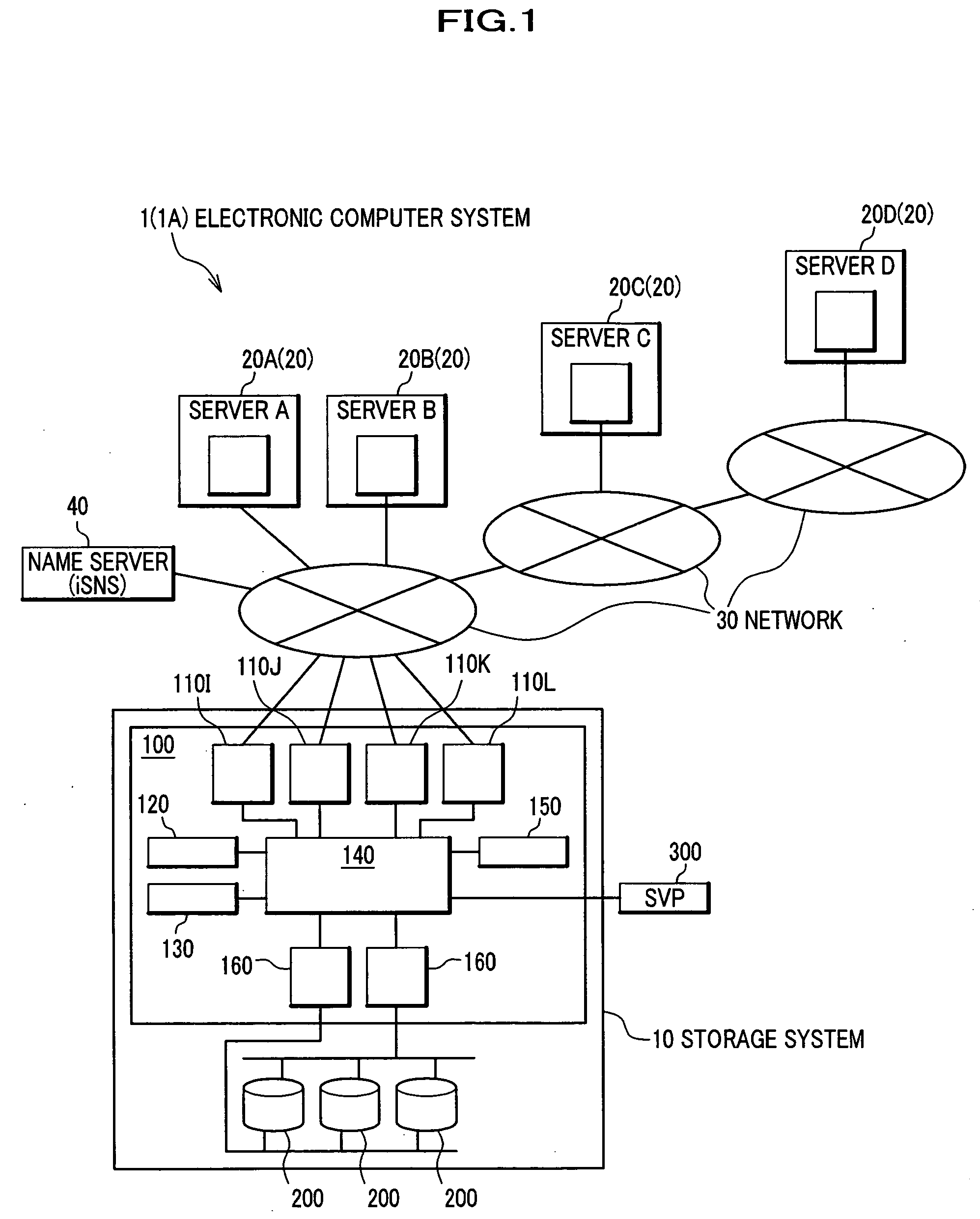

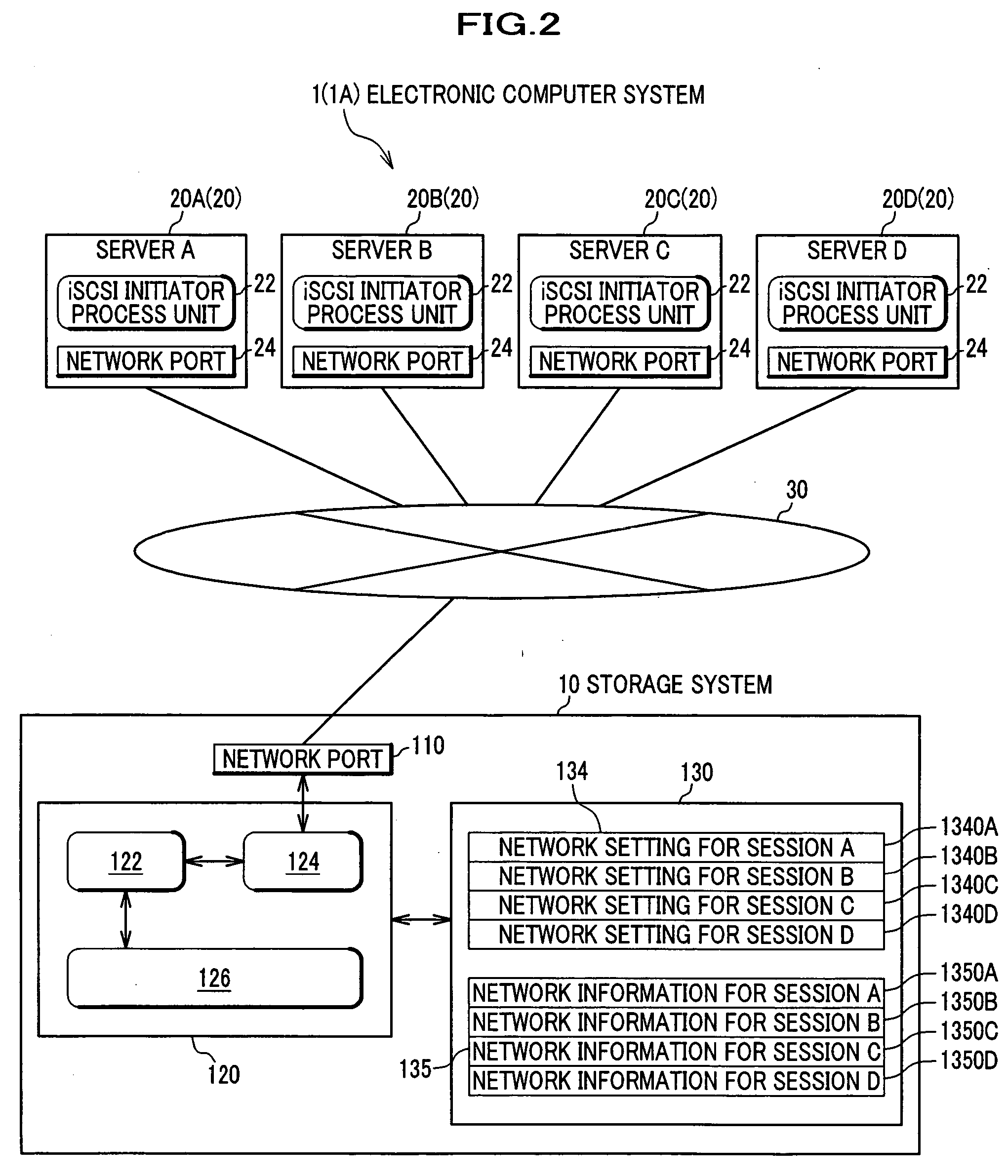

Method, device and program storage medium for controlling communication

InactiveUS20060215656A1Appropriate connectionData switching by path configurationControl communicationsNetwork connection

Disclosed is a communication control method which enables a single device to be connected appropriately to multiple hosts under various conditions. The method, which is executed by a storage system composed of a processing unit, a storage unit and a connecting unit for a network, includes the steps of receiving a request for a communication from the network by the connecting unit, determining at least one characteristic of the communication by the processing unit, storing the determined characteristic and a threshold of the characteristic in the storage unit, conducting an analysis of the characteristic by the processing unit, while referring to the threshold, specifying at least one parameter of a communication protocol based on a result of the analysis by the processing unit, and performing the communication in accordance with the specified parameter by the connecting unit.

Owner:HITACHI LTD

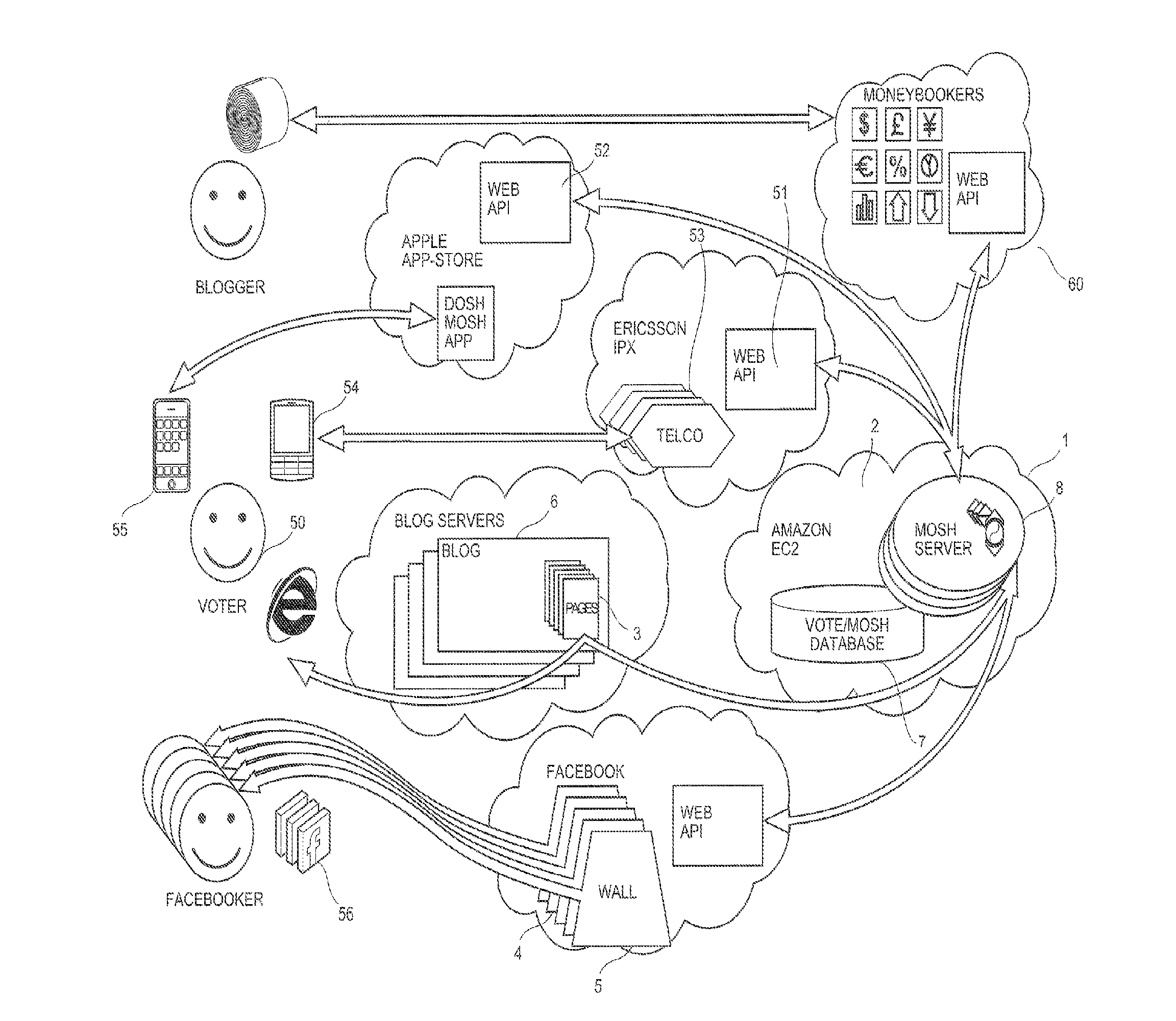

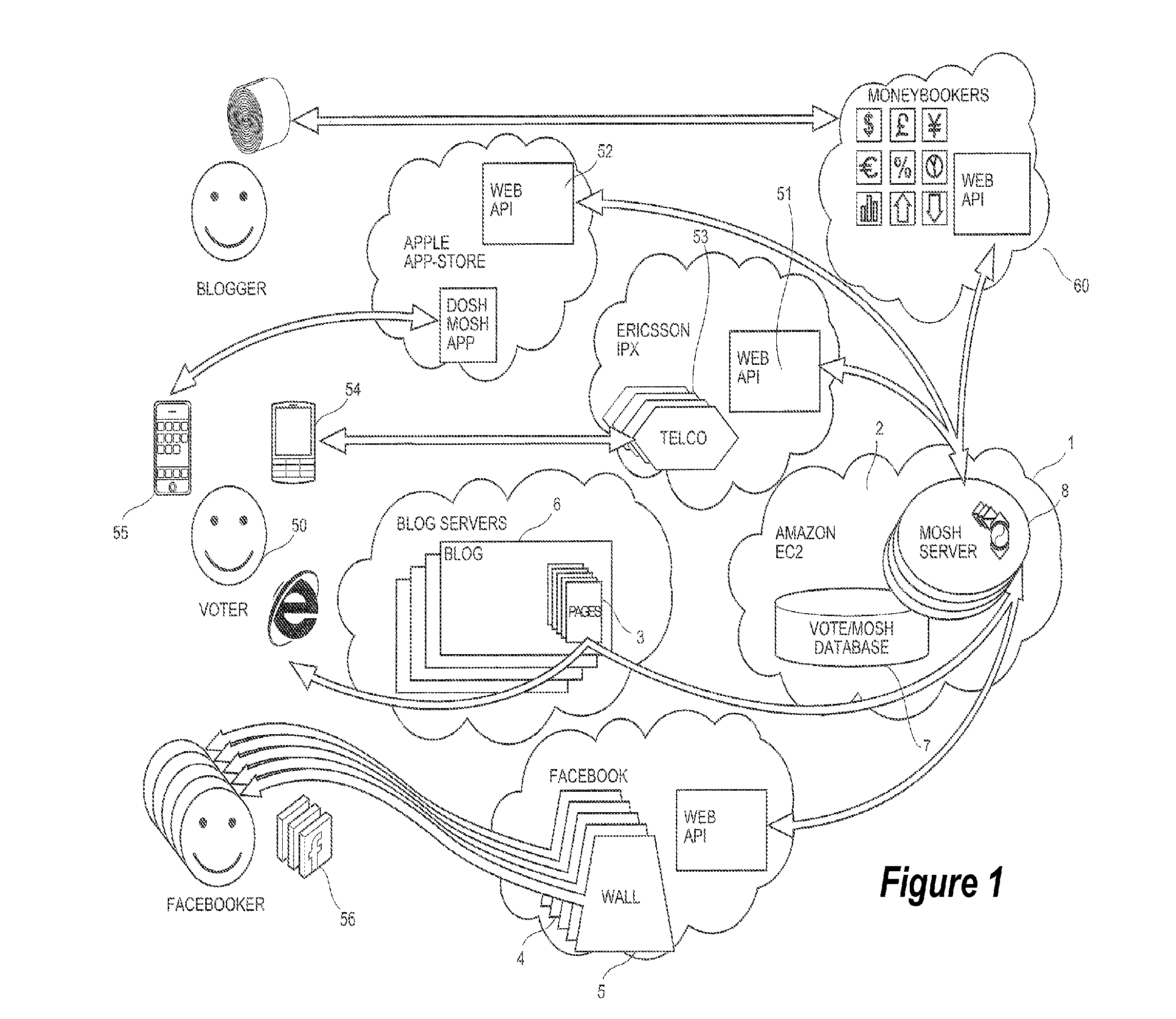

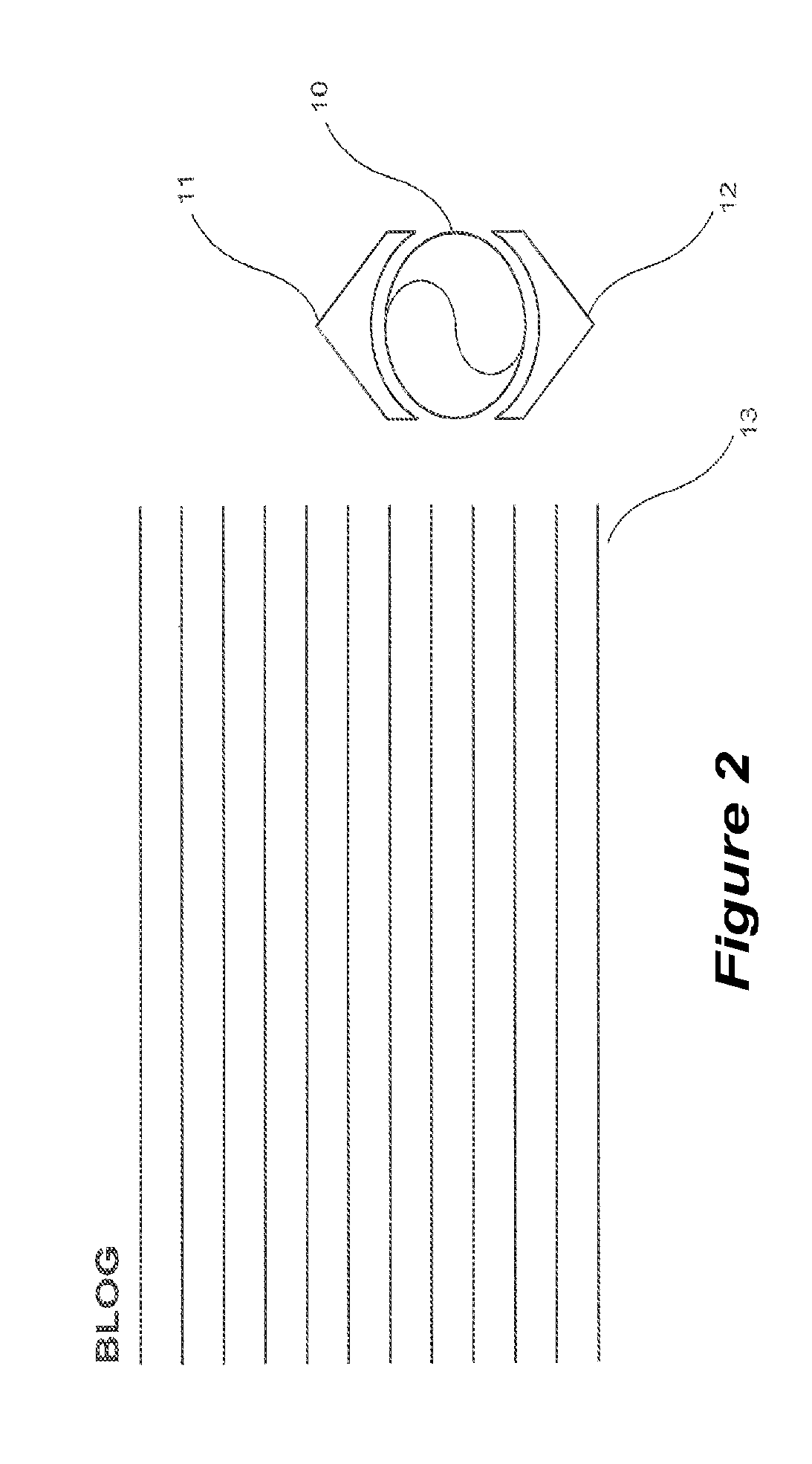

Computer based ballot system and process

InactiveUS20140351026A1Easy to operateAppropriate connectionVoting apparatusError detection/correctionUser inputThe Internet

The present invention relates to a computer based ballot system and apparatus enabling polling to be implemented by Wide Area Networks, such as the Internet. A user is able to cast a vote utilising a voting device in the form of a computing process, via a voting interface, which may be a distributed computing element, distributed by webpages. Persons may be able to place votes relating to the content of various webpages. Ballots are generated as a plurality of linked ballots, and when a vote is placed on one ballot the vote may propagate through the other ballots that are linked to it. The structure of the linkage between the ballots may be determined based on user input.

Owner:DOSHMOSH

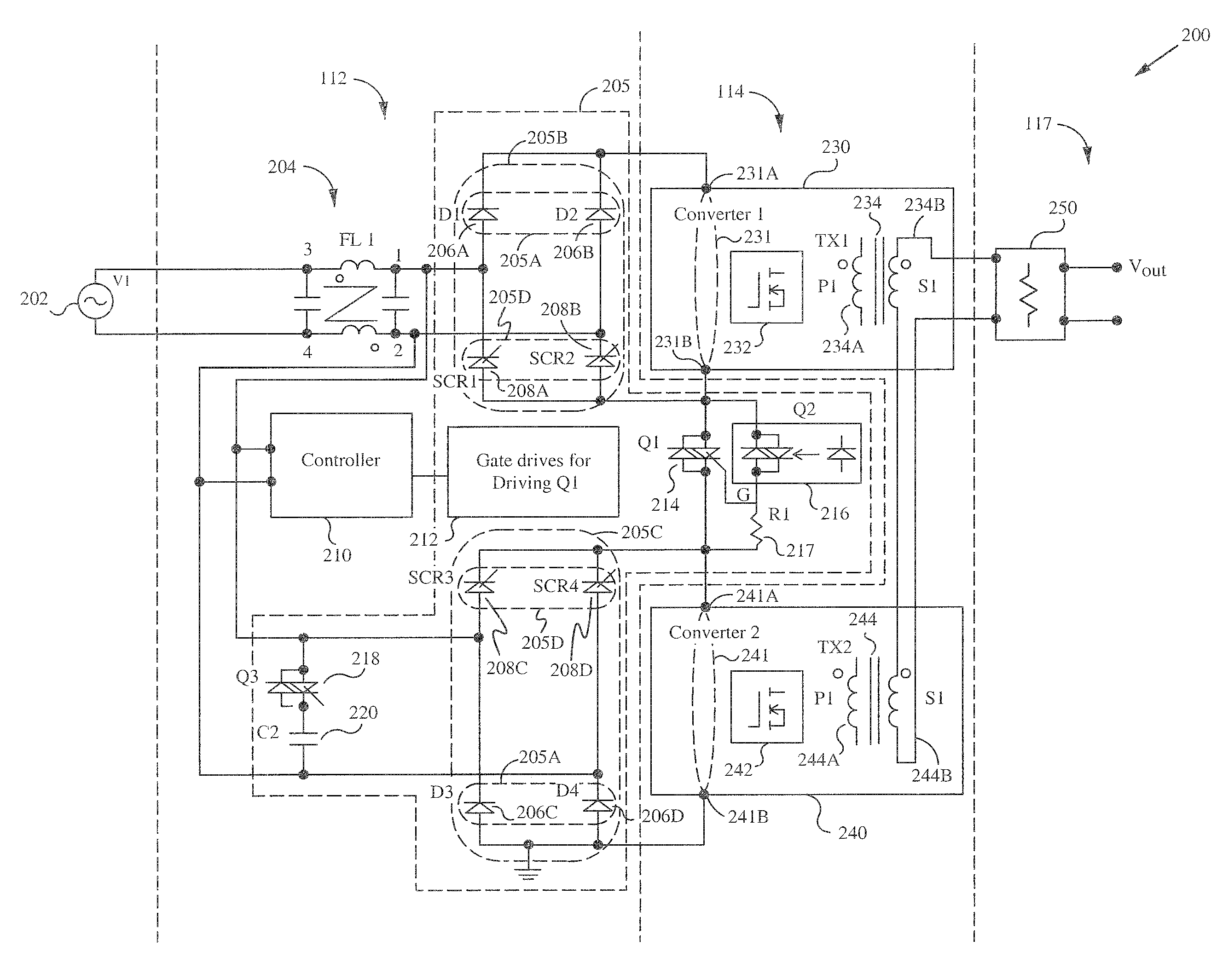

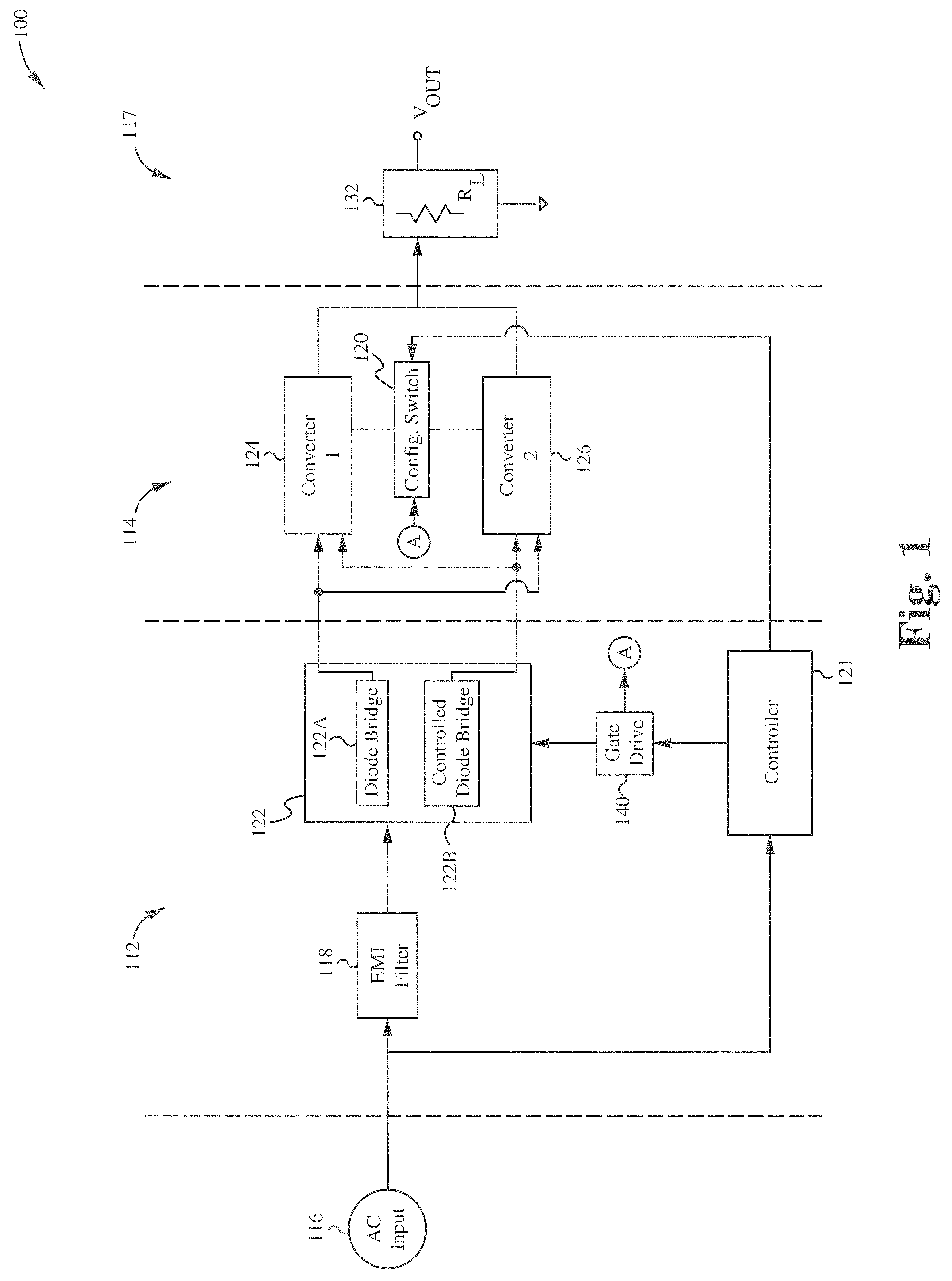

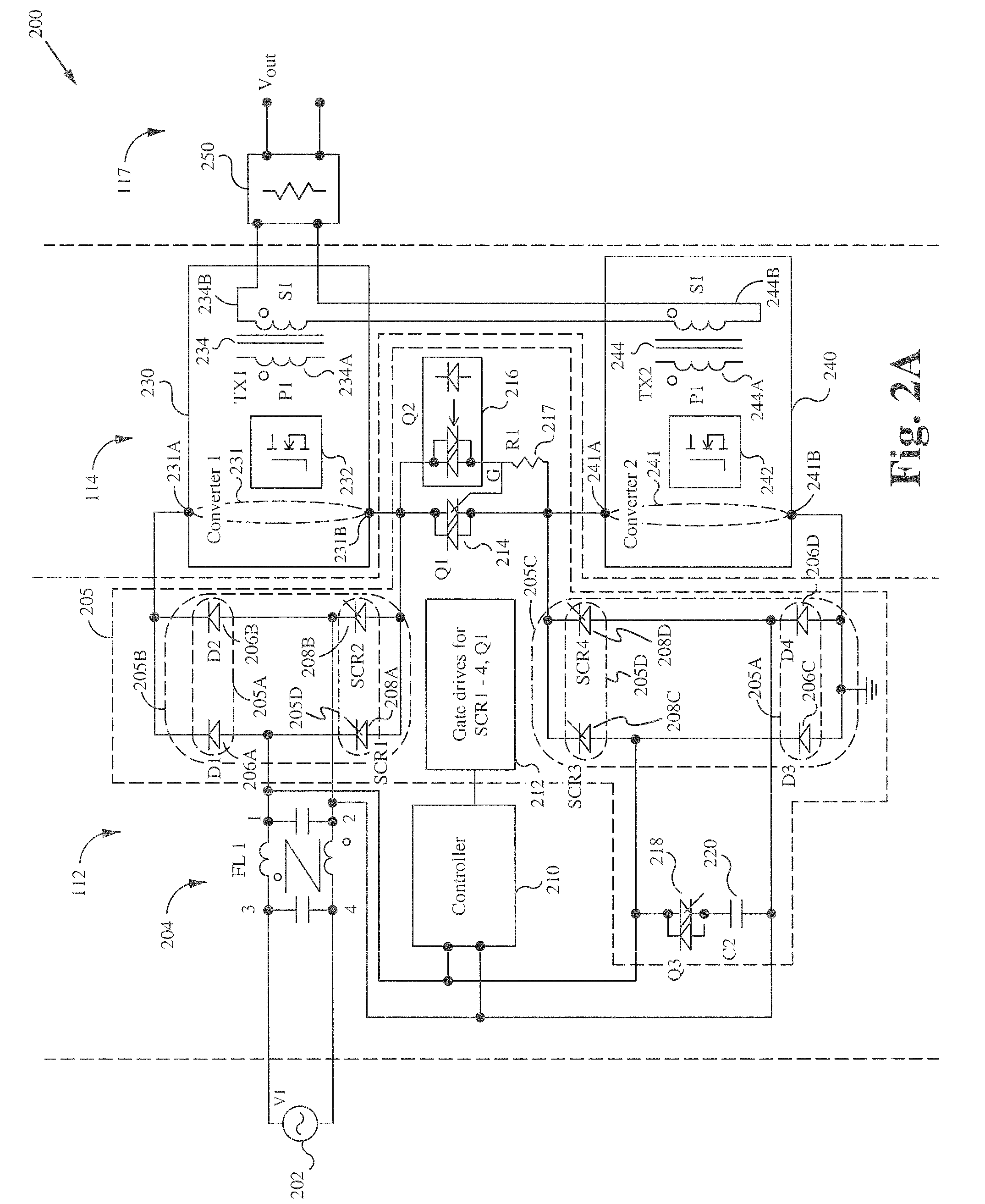

Line switcher for power converters

ActiveUS8289741B2Appropriate connectionAc-dc conversion without reversalDc source parallel operationTransformerControl switch

A regulated power supply apparatus and method are provided. The apparatus includes a converter circuit for generating a regulated voltage signal. The converter circuit includes a first switching circuit and a second switching circuit both coupled with an output circuit. A first and a second transformer include a first and a second secondary, which are coupled with each other in series or alternatively, coupled with each other in parallel. An input rectifier circuit is coupled with the first and the second switching circuit. The input rectifier circuit is configured for receiving an AC input voltage and for generating a rectified voltage. The input rectifier circuit includes controlled switches and a first and second configuration of a bridge rectifier that couples the first and second switching circuits in series or parallel depending if the AC input power signal is “high-line” or “low-line.” A controller circuit is provided for enabling either the first configuration or the second configuration. A configuration switch is controlled by the controller circuit for coupling the first and second switching circuits together.

Owner:FLEXTRONICS AP LLC

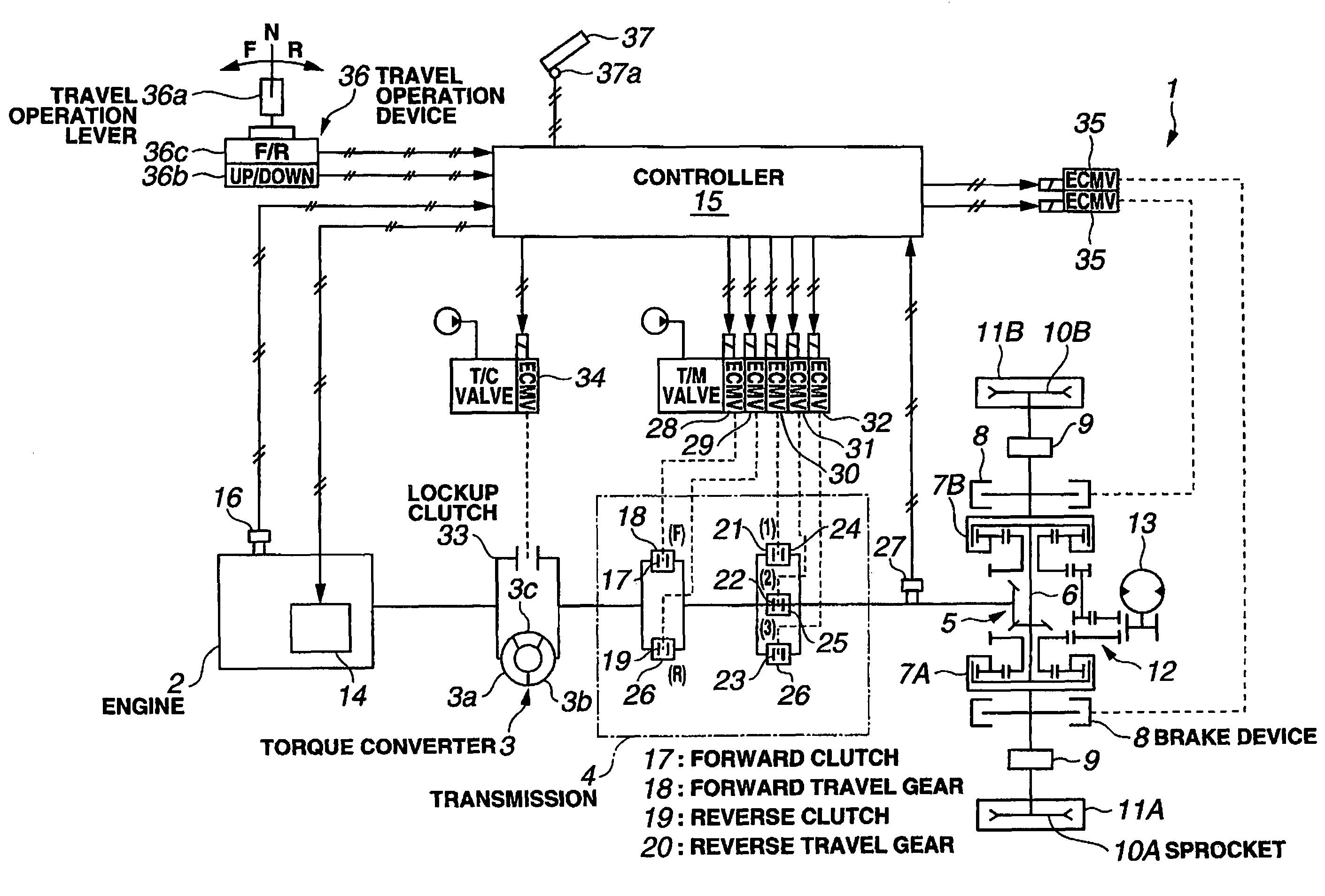

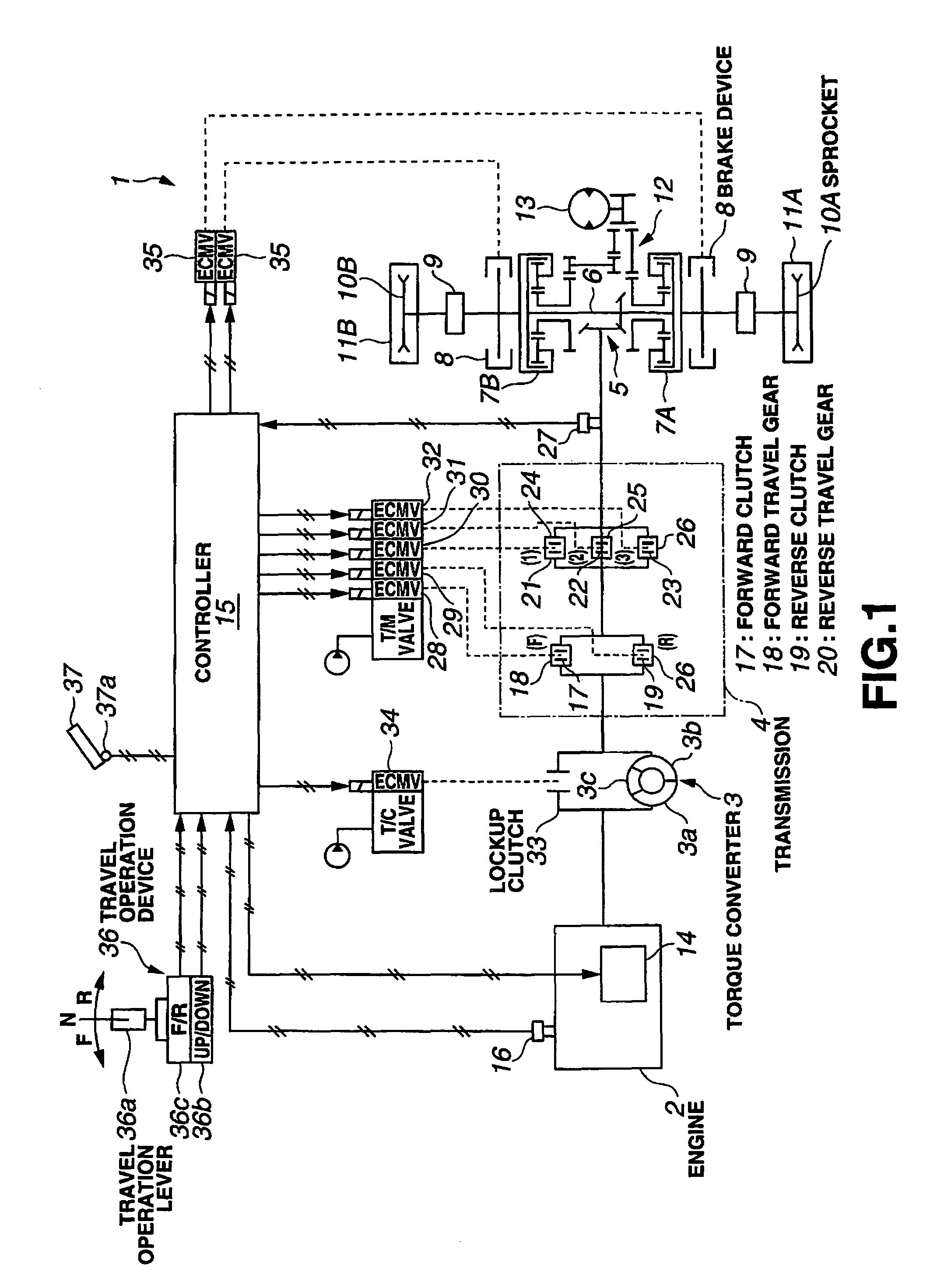

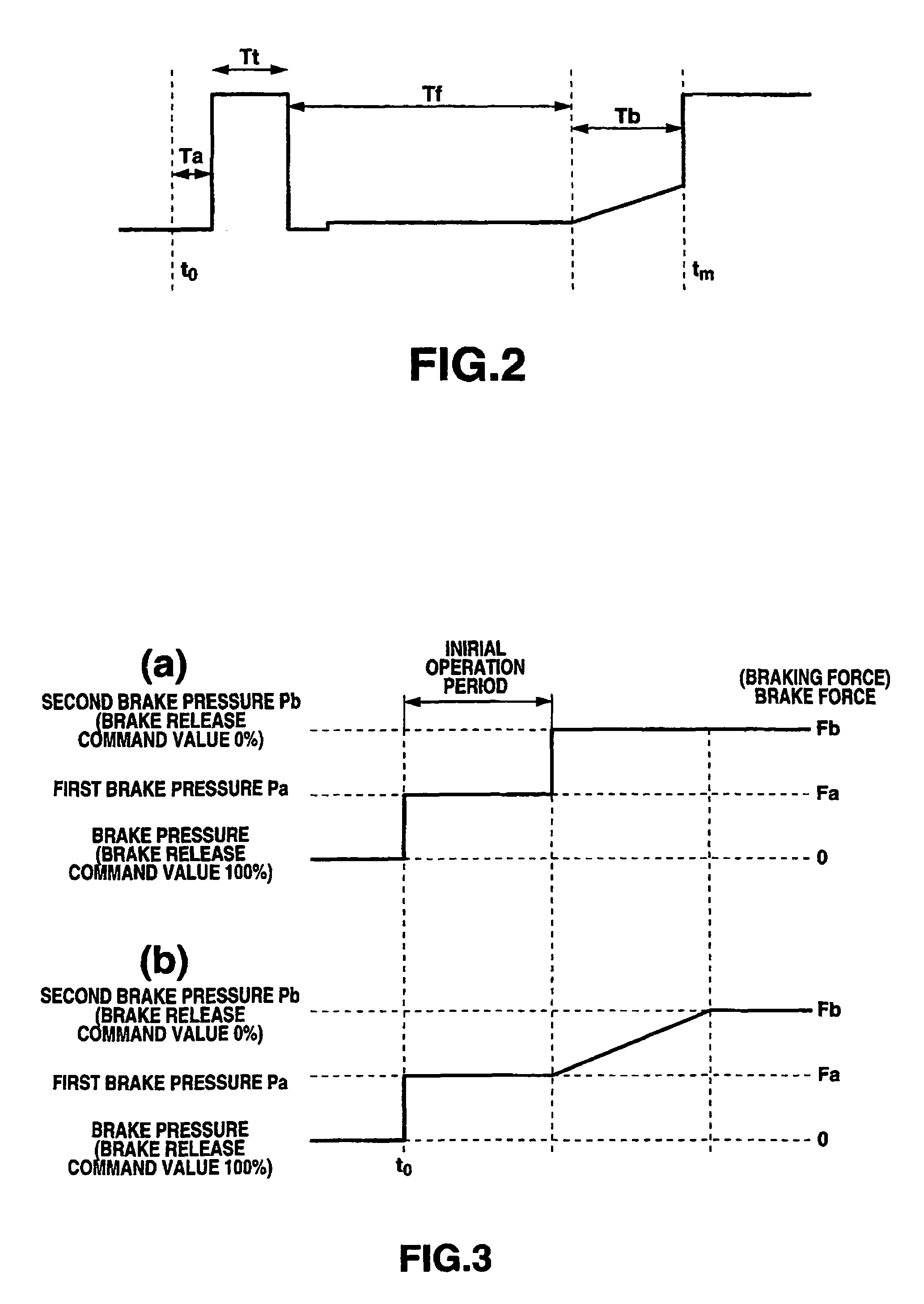

Work vehicle controller

ActiveUS7946404B2Reduced life-timeAppropriate connectionClutchesAutomatic initiationsDirection flagOil pressure

A device for a work vehicle eliminates uncomfortable operation feeling, improves the working efficiency, and reduces thermal load on a clutch and transmission shock. It is determined whether the current travel direction of the vehicle body is a forward travel direction F or a reverse travel direction R based clutch oil pressure of the forward clutch or reverse clutch. Braking force of a brake device is controlled such that the brake device is activated on the conditions that the travel direction position selected by the travel operation lever and the travel direction determined by a travel direction flag are opposite to each other, and the detected vehicle body speed is equal to or greater than a predetermined threshold value.

Owner:KOMATSU LTD

Image processing apparatus, image processing method, and storage medium

ActiveUS8279297B2Appropriate connectionTelevision system detailsColor television detailsImaging processingImage differencing

Owner:CANON KK

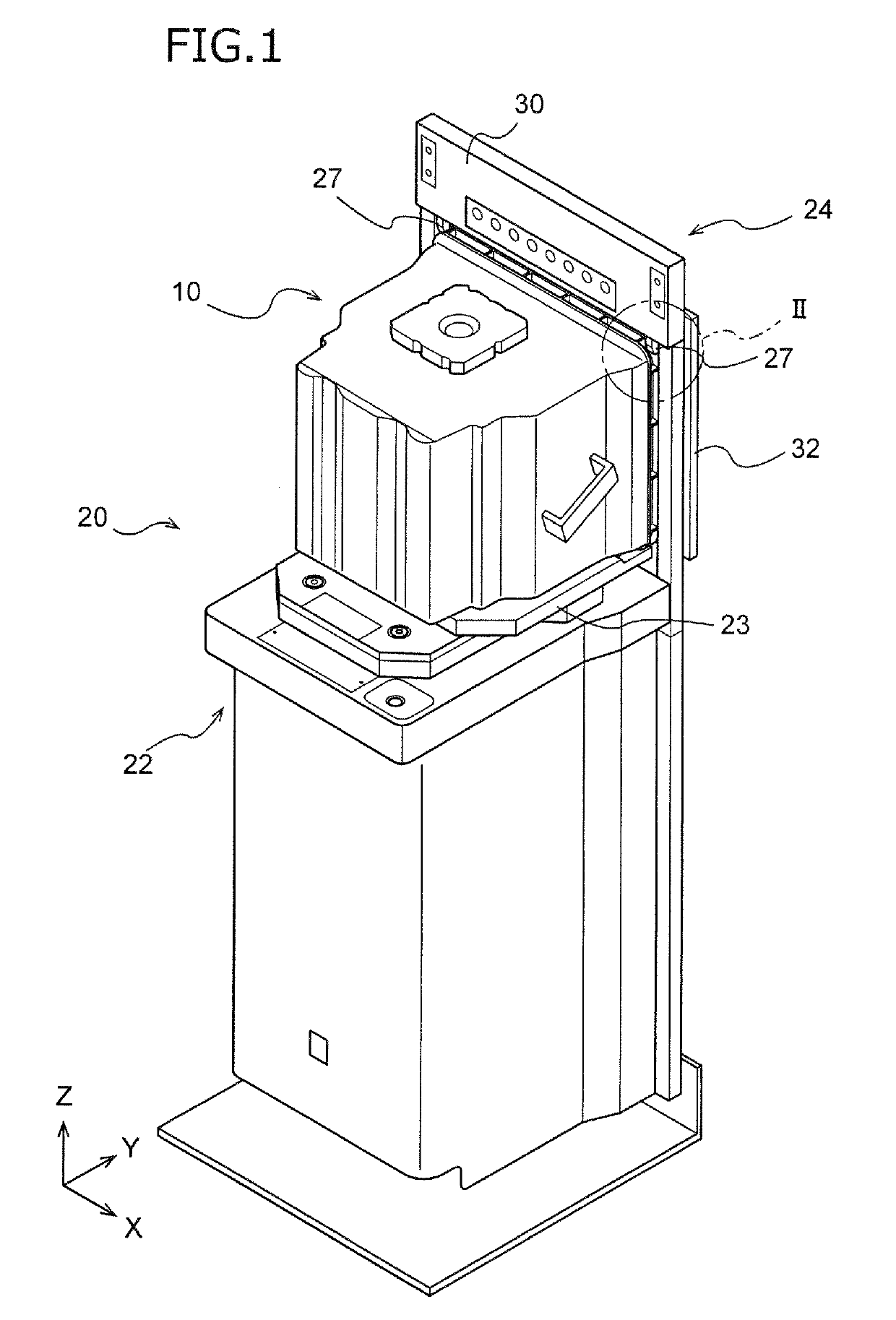

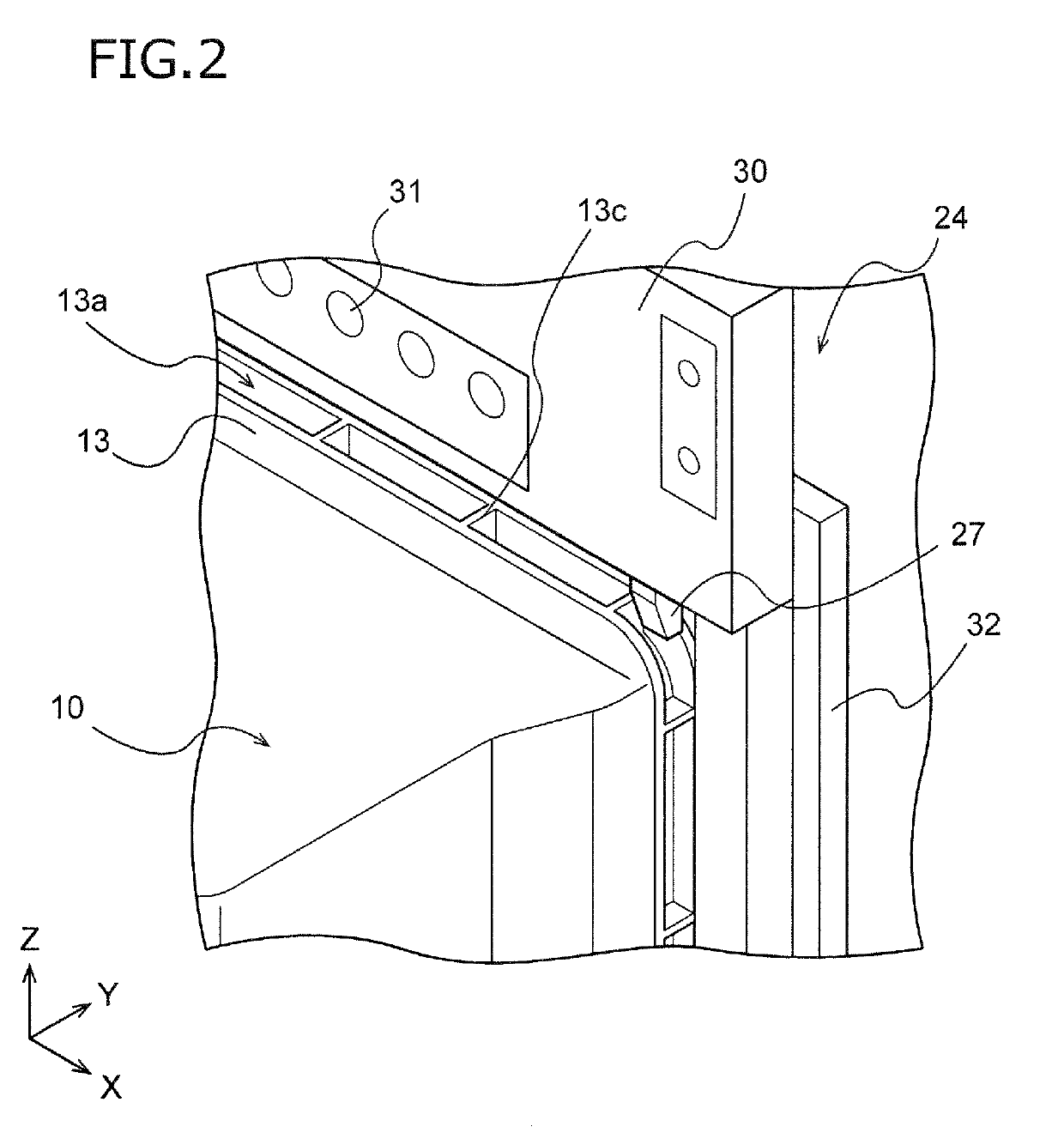

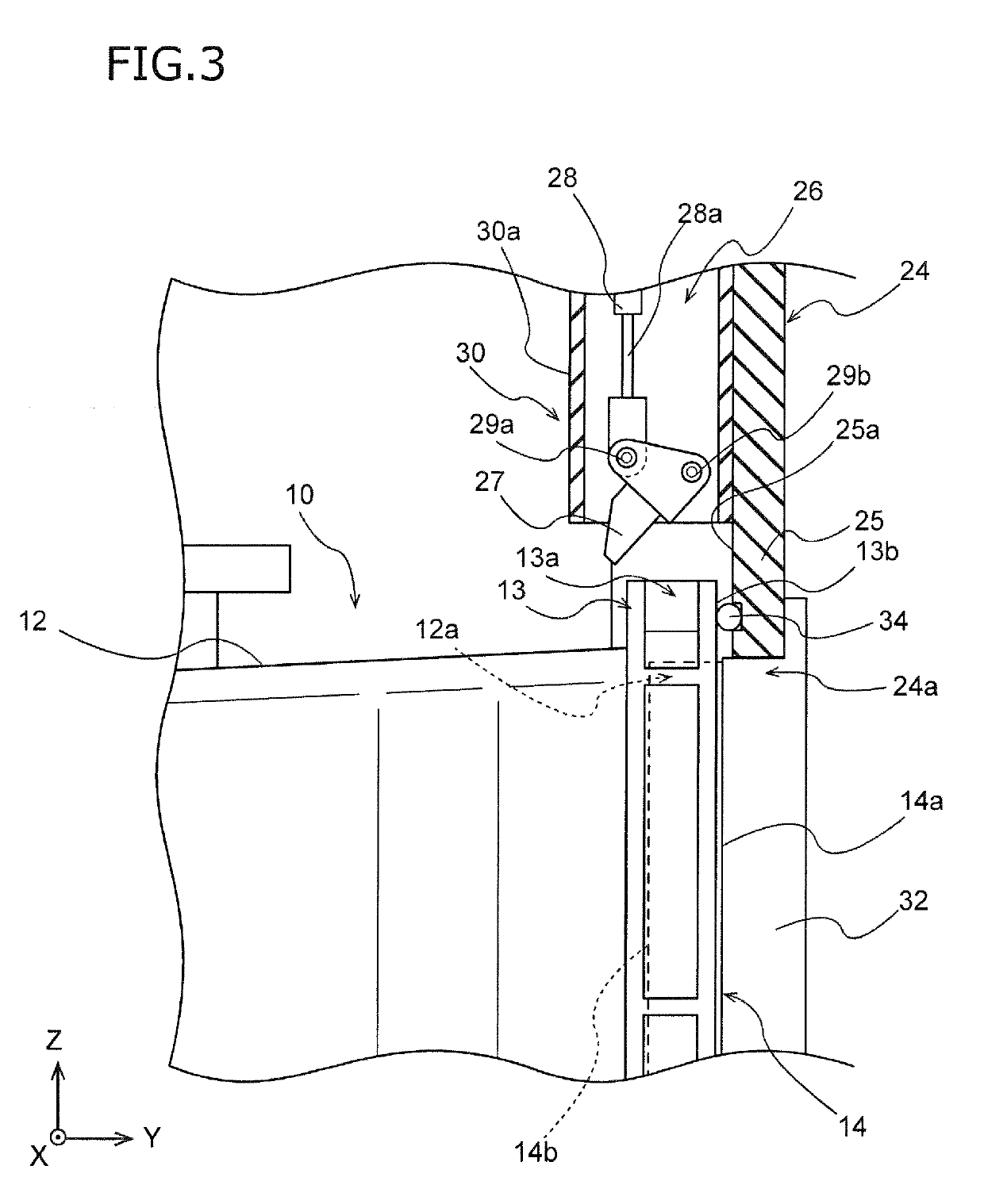

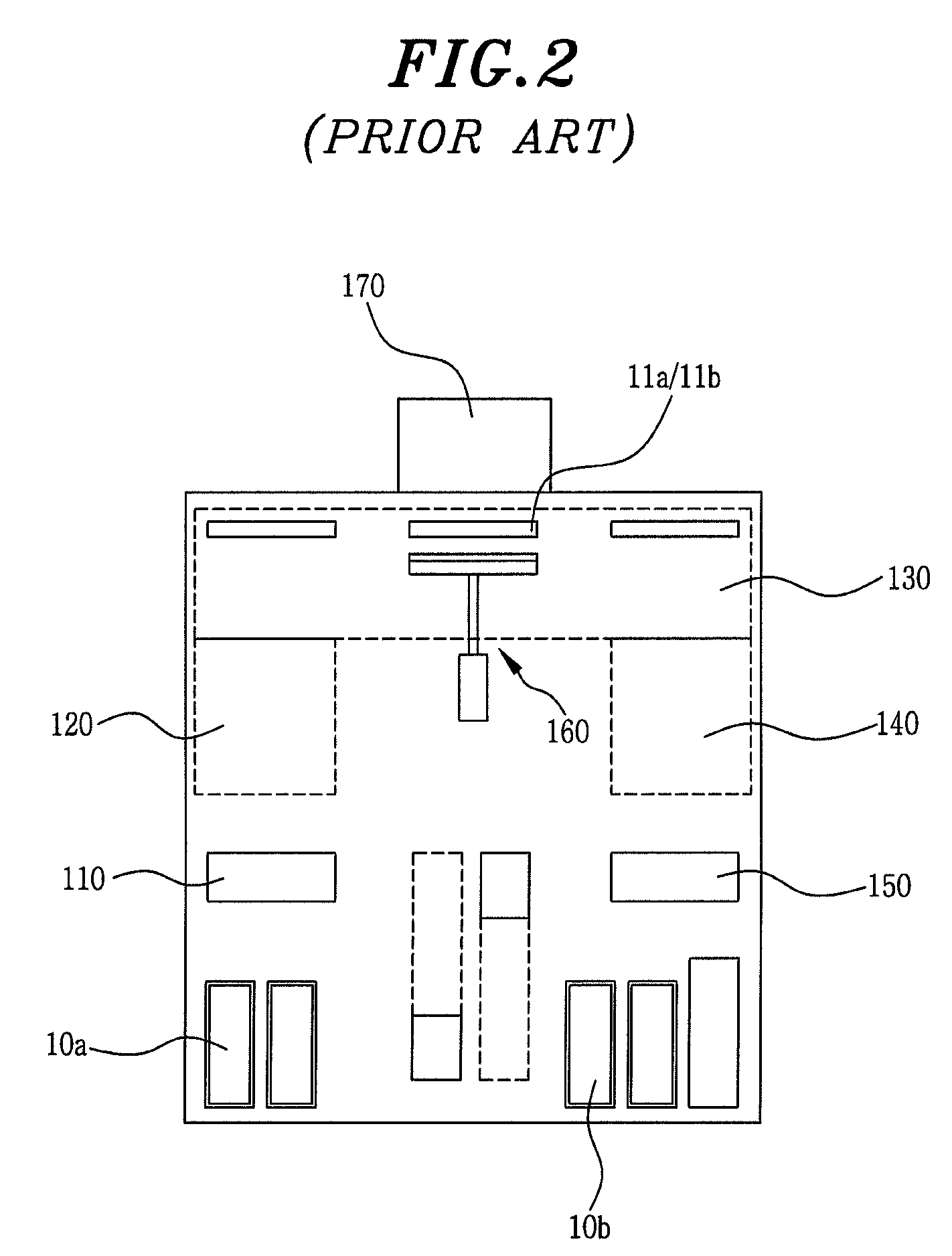

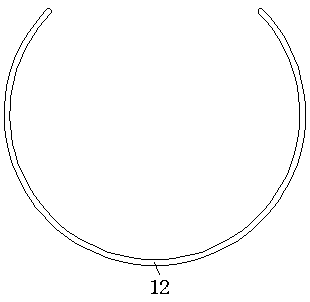

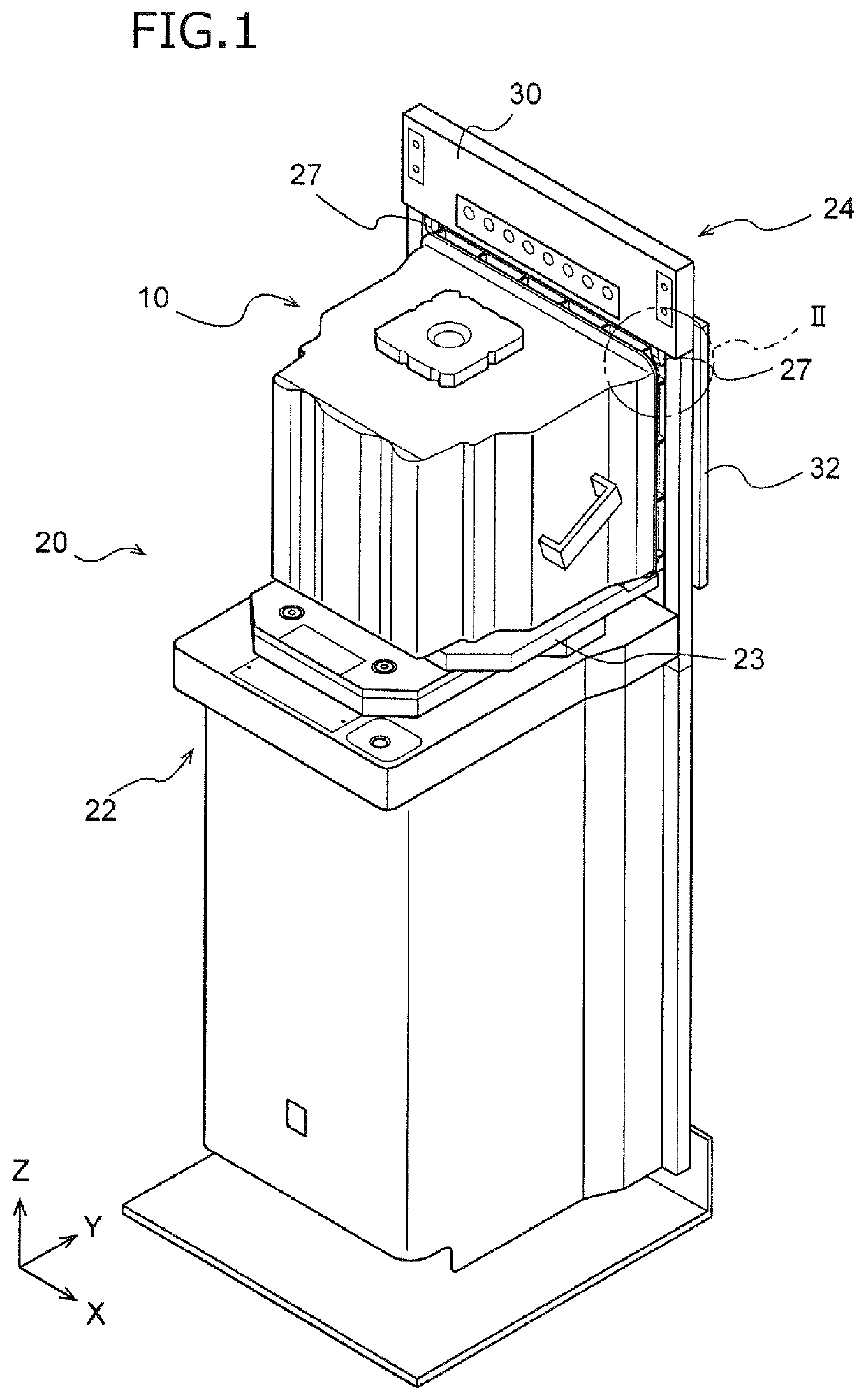

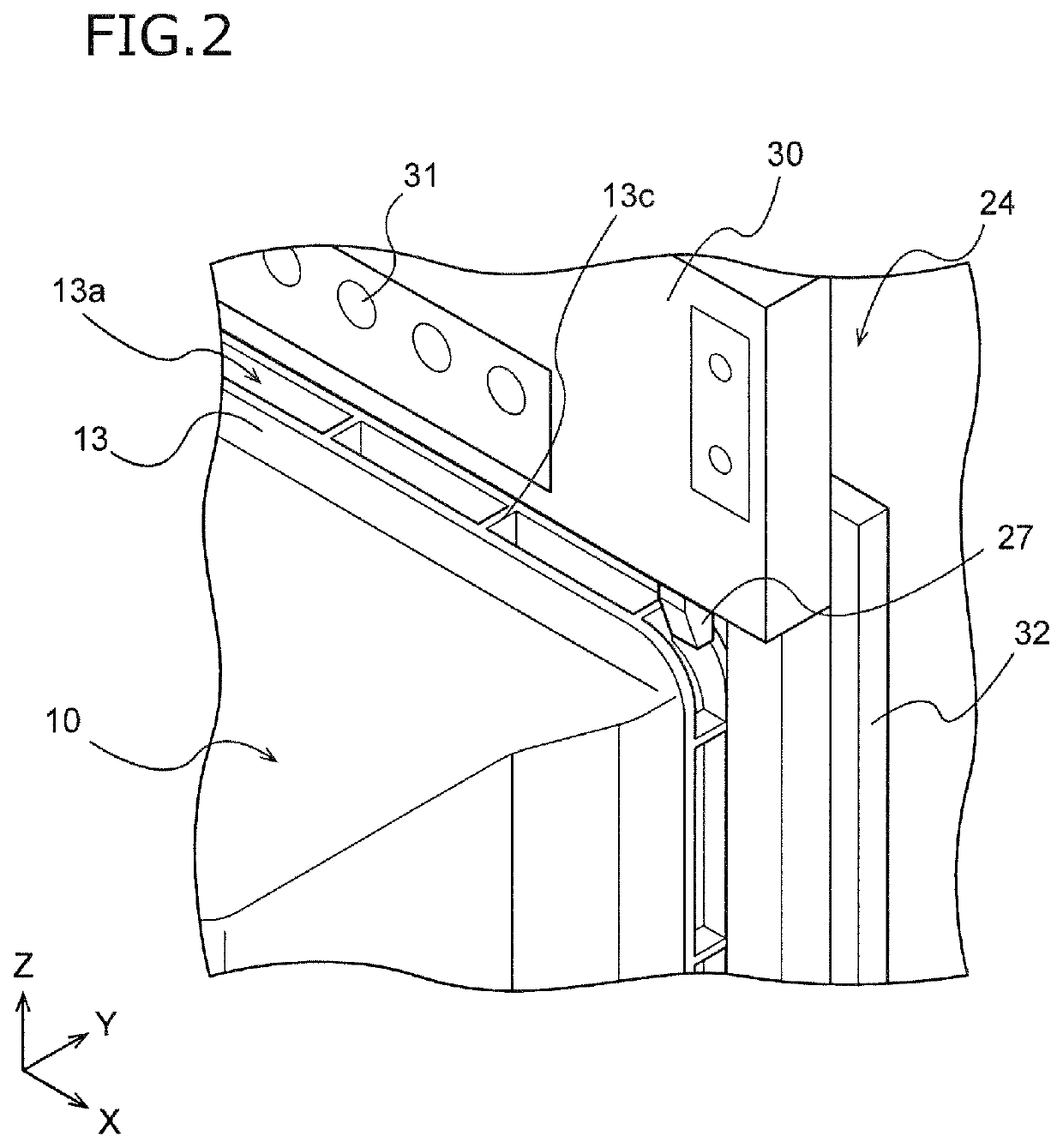

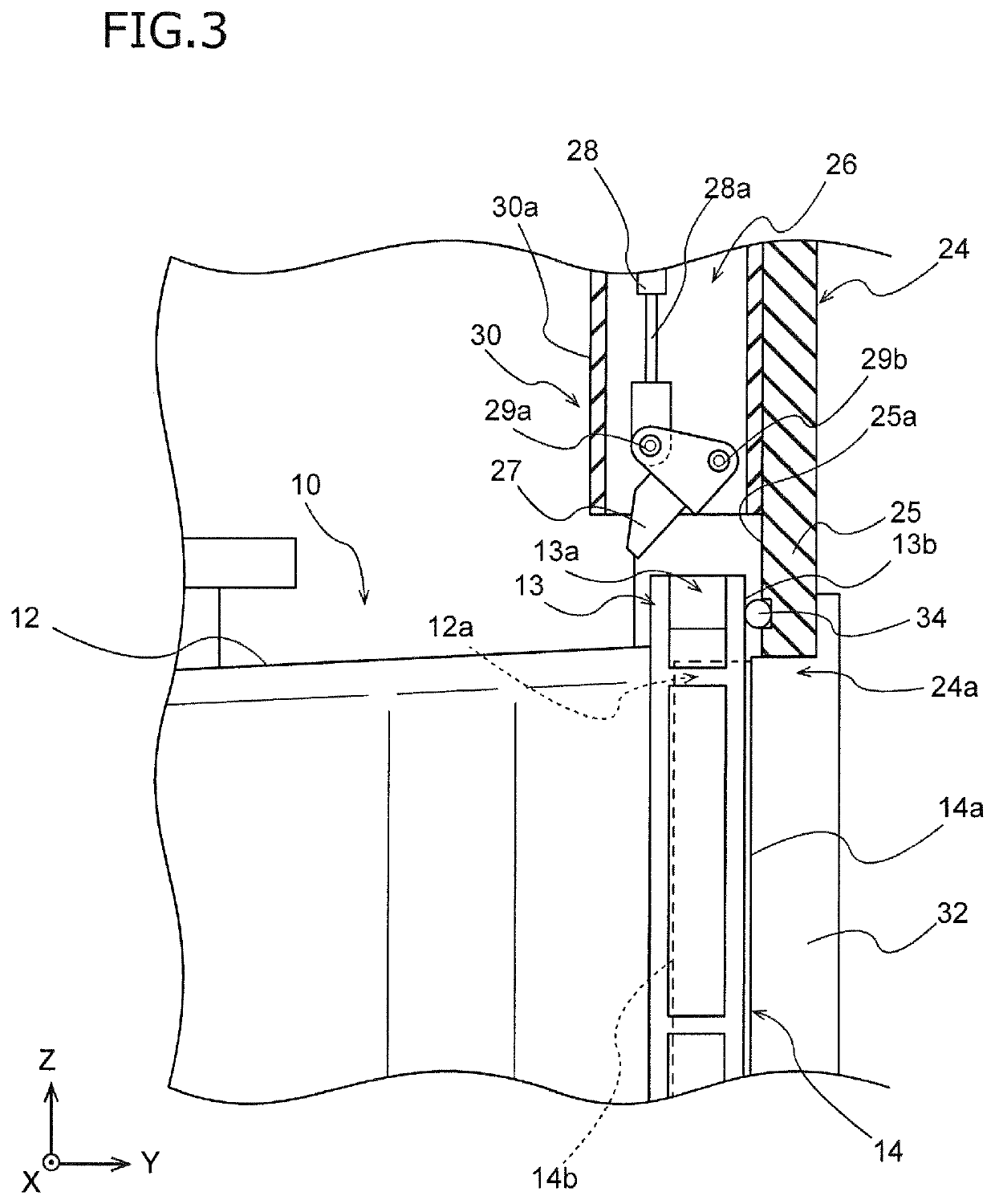

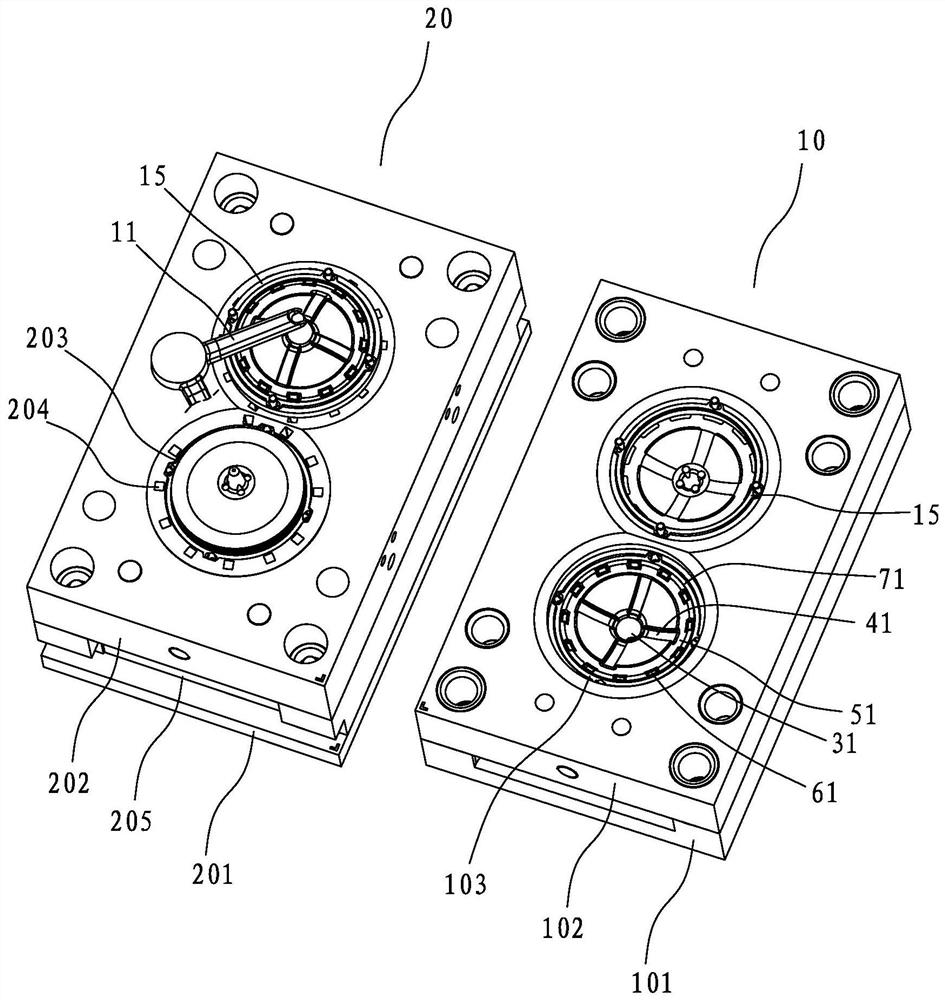

Load port apparatus and method of driving the same

ActiveUS20190096728A1Shorter operationLimit movementSemiconductor/solid-state device manufacturingConveyor partsFlangeEngineering

A load port apparatus connects a main opening of a wafer transportation container with a frame opening. The load port apparatus includes an installation part, a frame, and a flange clamp. The installation part has an installation table configured to install the wafer transportation container and move to and from the frame opening. The frame is upright from the installation part and has the frame opening. The flange clamp includes an engagement portion and a drive portion. The engagement portion is configured to be engaged with a flange surrounding an outer circumference of the main opening. The drive portion is configured to drive the engagement portion. The engagement portion is engaged from above or the side with a flange groove formed in the flange and opening radially outwardly.

Owner:TDK CORPARATION

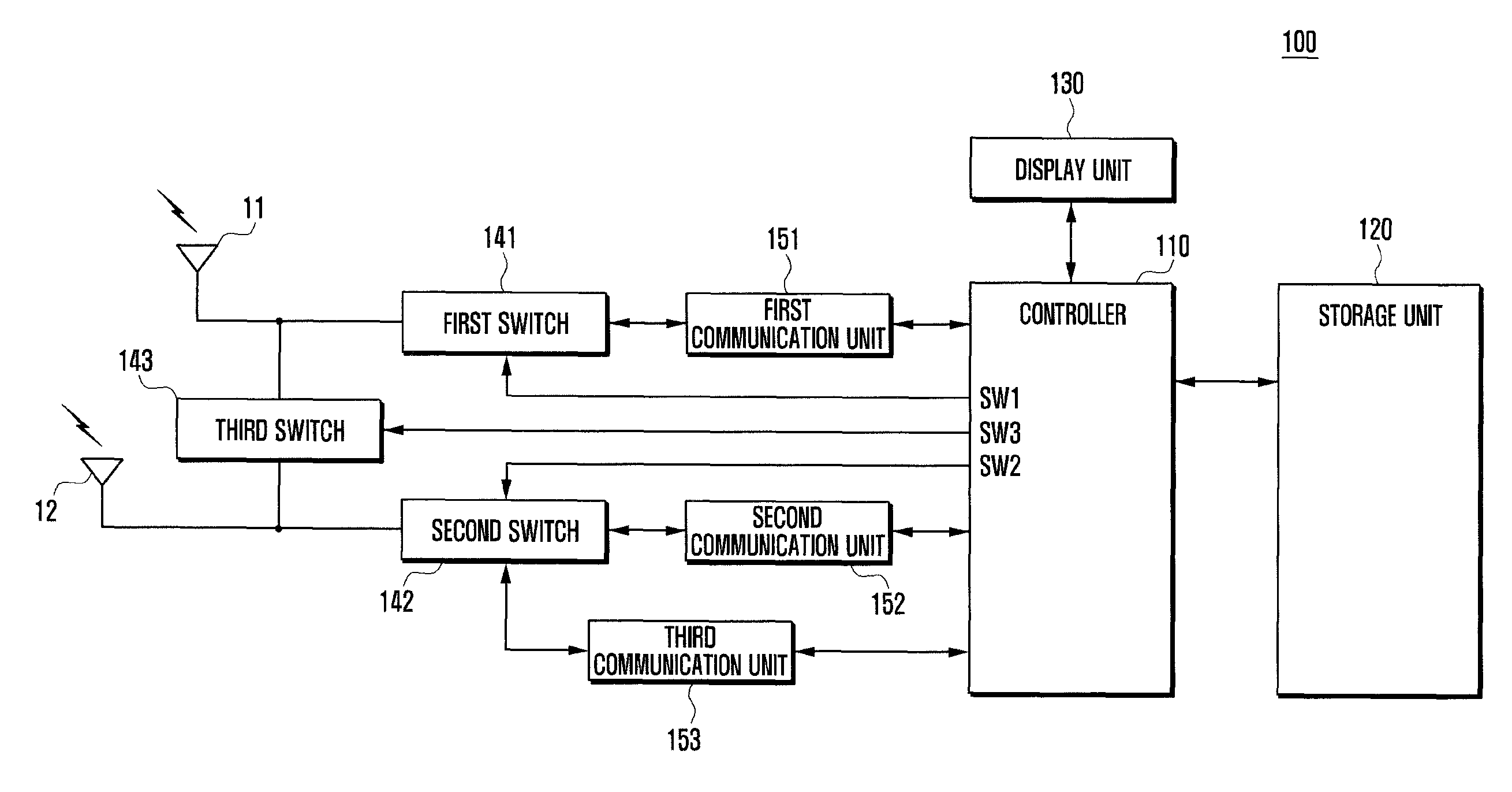

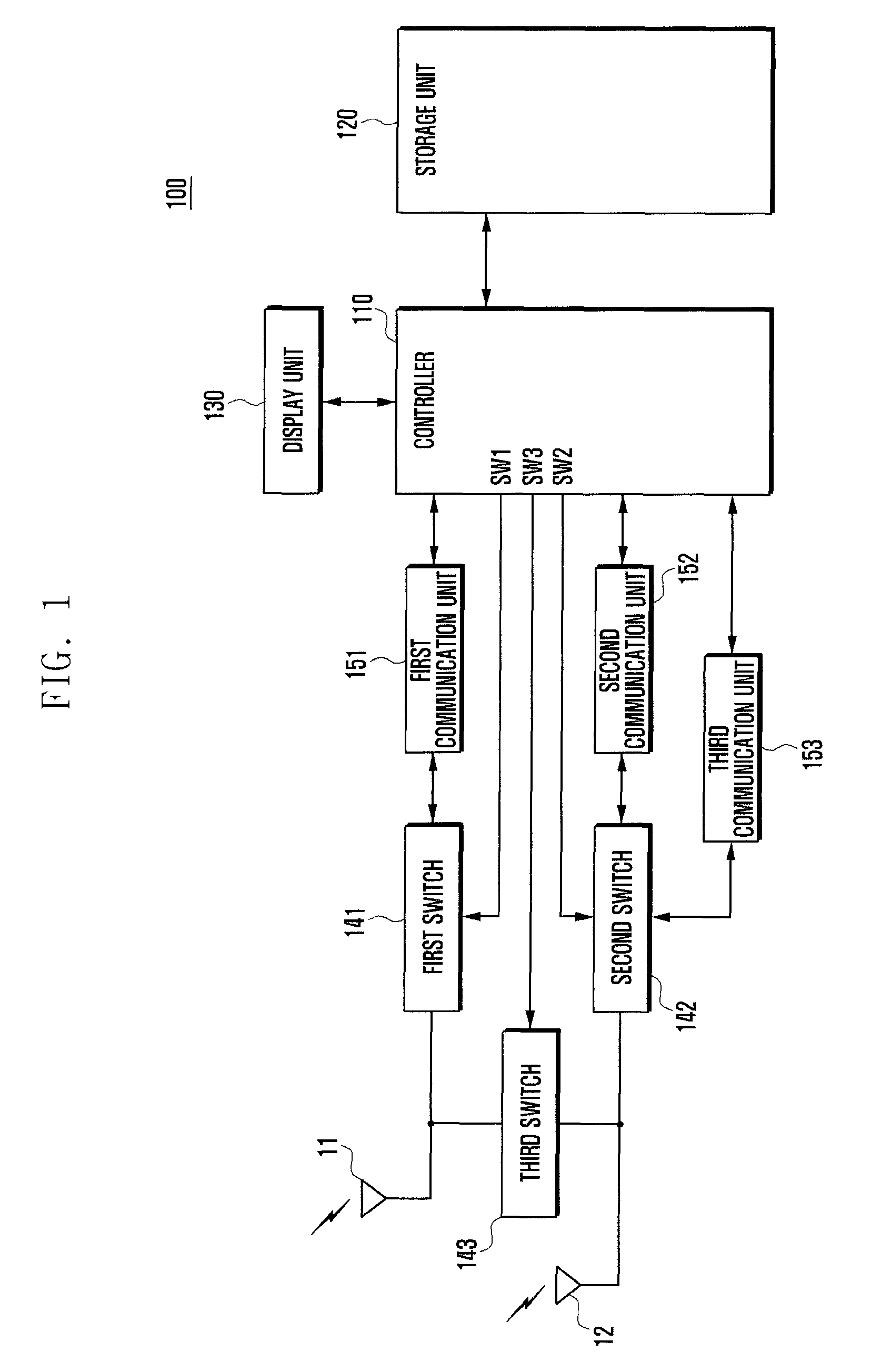

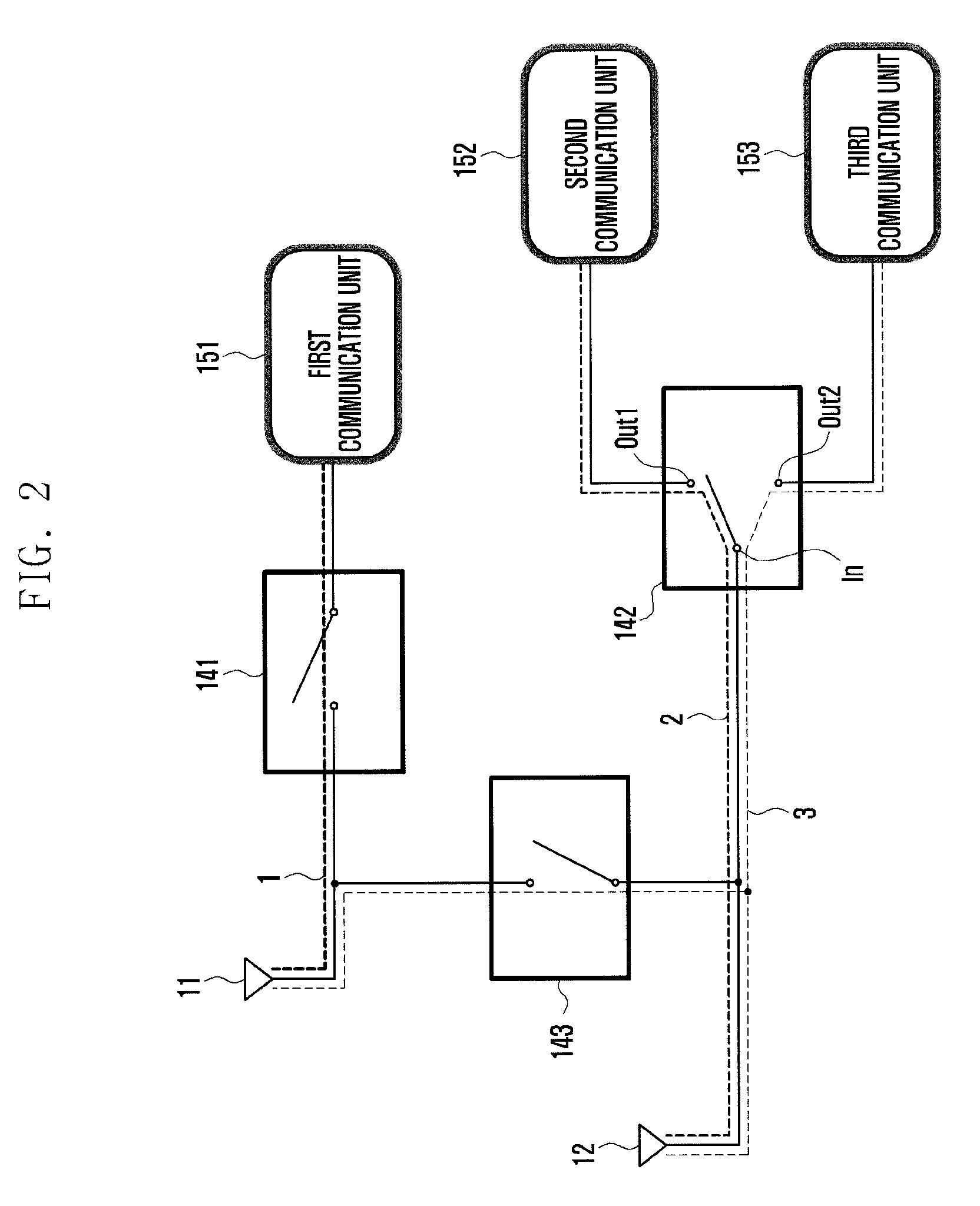

Antenna device of mobile terminal

ActiveUS9172440B2Appropriate connectionImprove wireless performanceSpatial transmit diversitySimultaneous aerial operationsCommunication unitElectrical connection

An antenna device of a mobile terminal for enabling to receive a wireless signal of a new frequency band by appropriately connecting a plurality of antennas through a switch is provided. The antenna device includes a plurality of communication units for transmitting and receiving a wireless signal of a plurality of frequency bands through a plurality of antennas, a plurality of switches for turning on / off an electrical connection between the plurality of antennas and the plurality of communication units, and a controller for controlling the plurality of switches to turn off an electrical connection between the plurality of antennas and the plurality of communication units.

Owner:SAMSUNG ELECTRONICS CO LTD

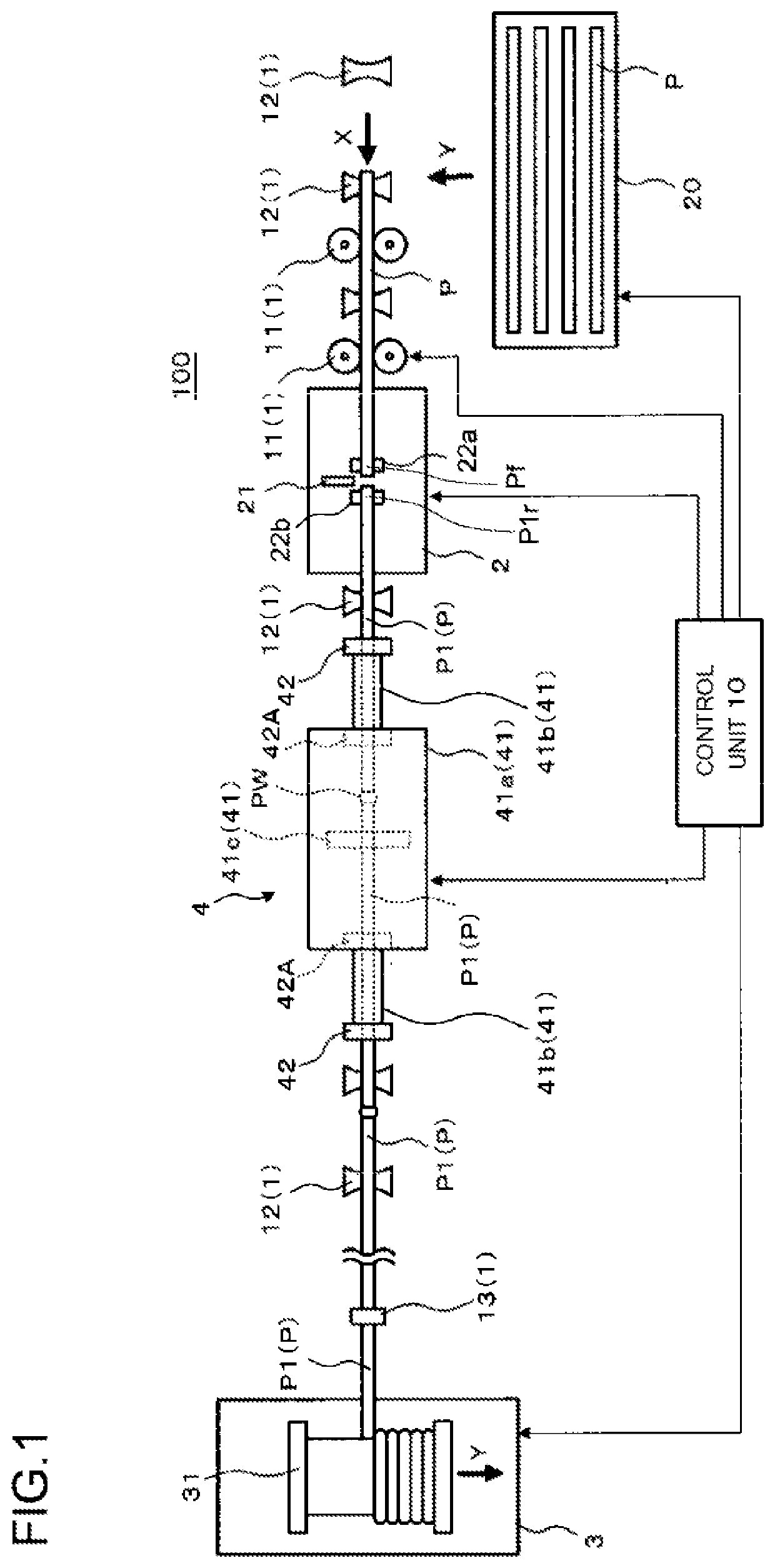

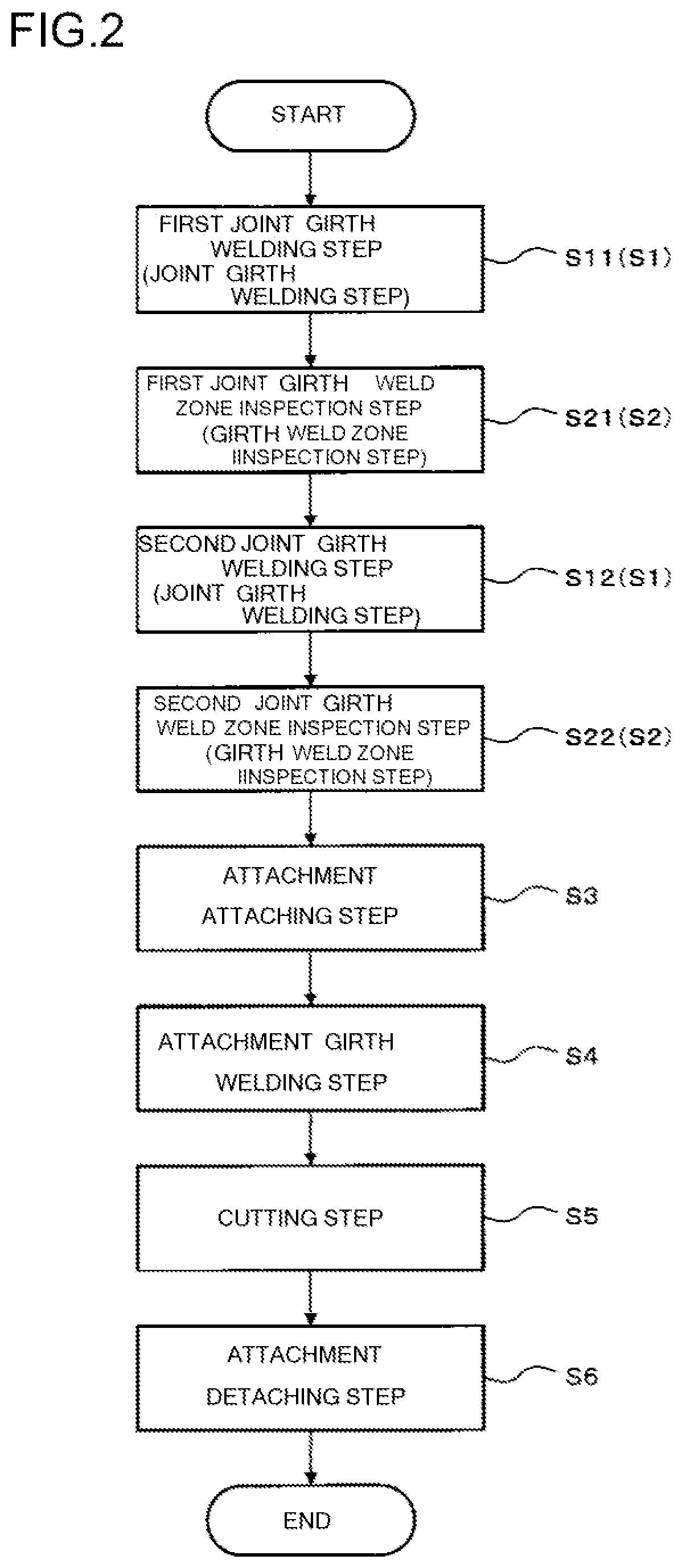

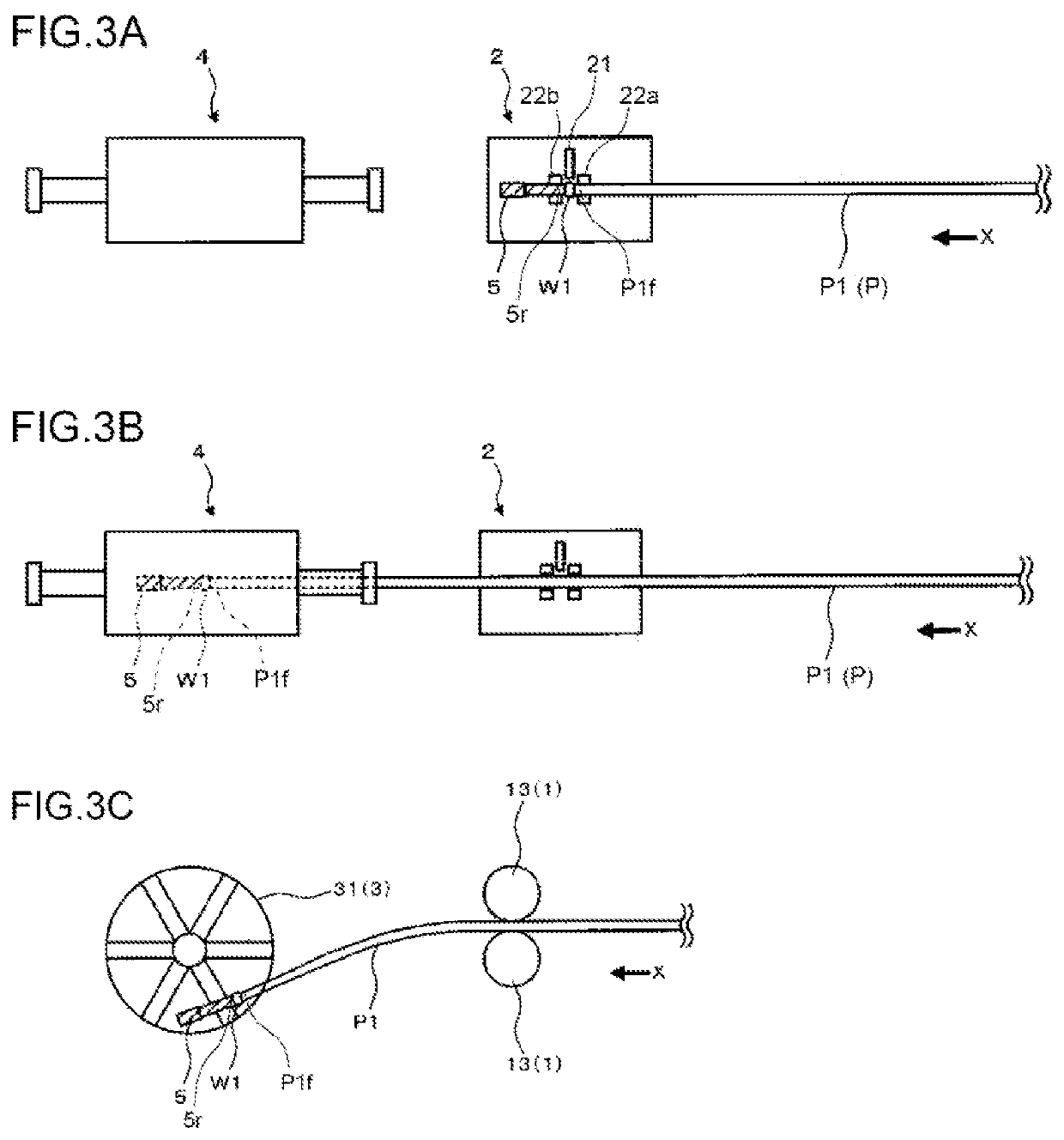

Joint connection method for long pipe, and method for producing coiled tubing with joints

PendingUS20210033237A1Appropriate connectionMaterial analysis using wave/particle radiationWelding/cutting auxillary devicesStructural engineeringManufacturing engineering

A joint connection method is provided that is a method for connecting joints that are used for a hydraulic pressure test or the like to a long pipe by using a production facility which includes a conveyance system, a welding apparatus, a winding apparatus and an X-ray inspection apparatus. The joint connection method includes a step of girth welding a first joint to a front end portion of the long pipe by means of the welding apparatus, a step of inspecting a girth weld zone of the first joint by means of the X-ray inspection apparatus, a step of girth welding a second joint to a rear end portion of the long pipe by means of the welding apparatus, and a step of inspecting a girth weld zone of the second joint by means of the X-ray inspection apparatus.

Owner:NIPPON STEEL CORP

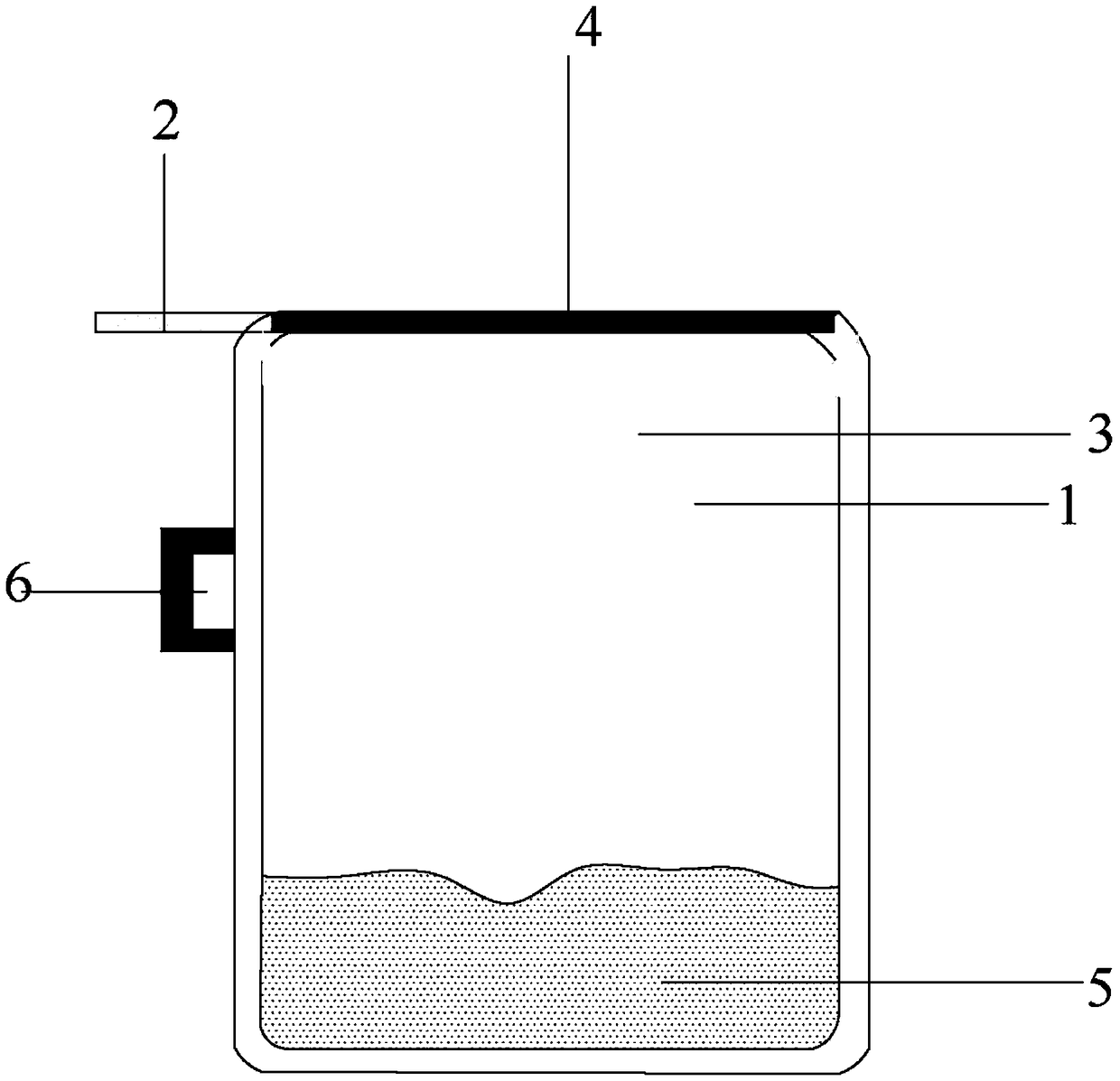

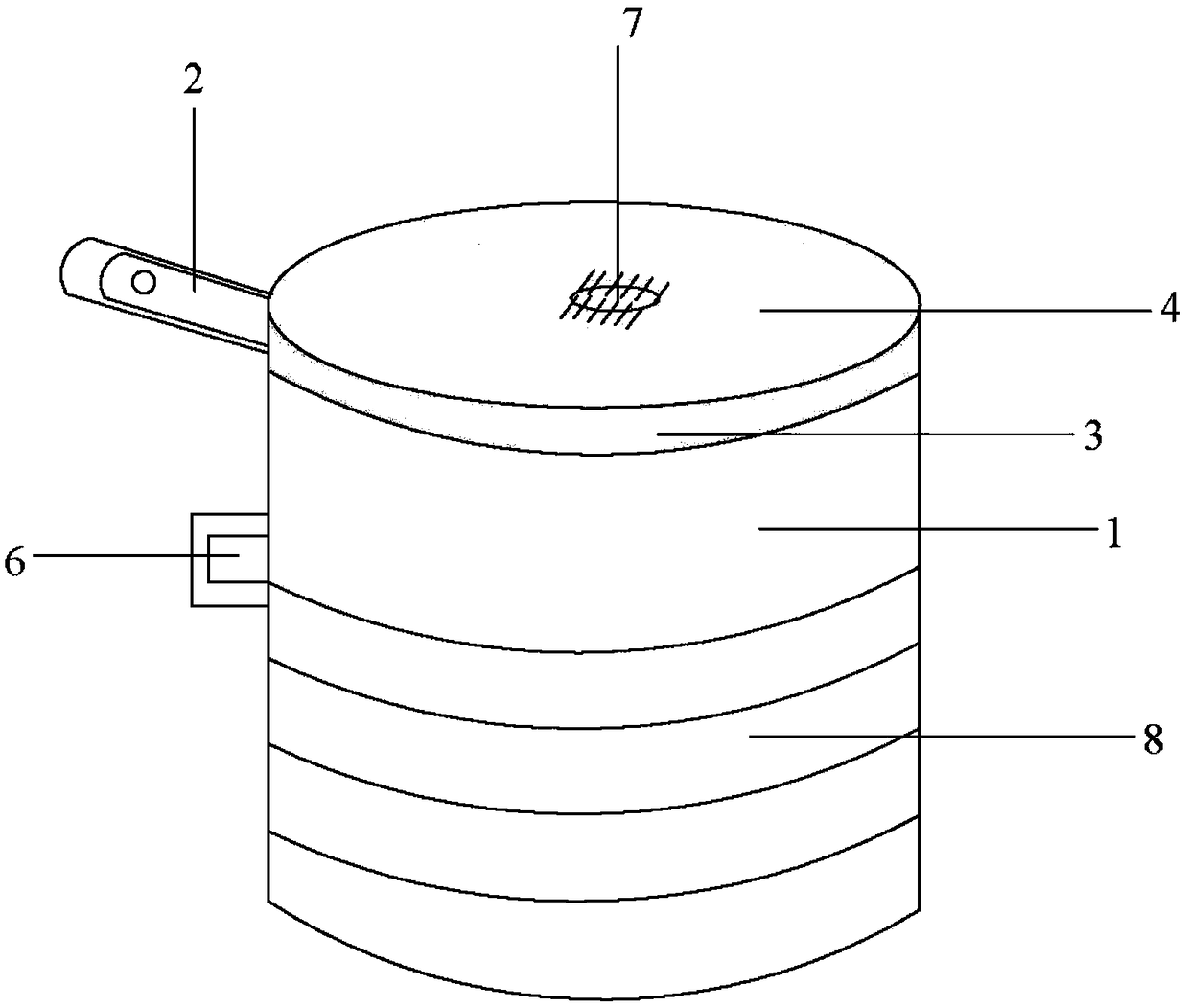

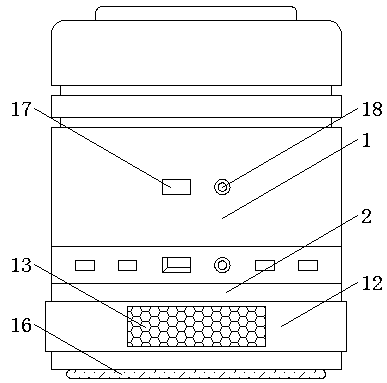

Novel pathological specimen collecting device

PendingCN109264212ARealize collection and storageReduce workloadLiving organism packagingBottlesFiberBristle

The invention relates to a novel pathological specimen collecting device. The novel pathological specimen collecting device comprises a specimen collecting bottle, a flip cover control handle, a rubber cover, a flip cover, specimen fixing liquid, a handle, a fine-bristle brush and a heating device and is characterized in that the flip cover is arranged at the upper end of the specimen collecting bottle, the flip cover control handle is arranged on the left of the flip cover, the rubber cover is arranged below the flip cover, the fine-bristle brush is arranged at the center of the rubber cover,the handle is located on one side of the specimen collecting bottle, the heating devices covers the outer end of the specimen collecting bottle, and the heating device comprises a power supply, a charging port, a switch and a carbon fiber heating piece. The novel pathological specimen collecting device has the advantages that the problem that some biopsy small strip-shaped tissue specimens adhering to a puncture needle is hard to separate and place into a wide-opening glass bottle is solved, the heating device is convenient to use when specimen thermal insulation is needed, and the device ispromising in application prospect.

Owner:SHANGHAI FIRST PEOPLES HOSPITAL

Ultrasonic diagnostic apparatus and ultrasonic probe

ActiveUS8394028B2Reduce the possibilityFirmly connectedDiagnostic recording/measuringInfrasonic diagnosticsCommunication unitFalse recognition

When a transfer signal according to ultrasonic echoes is wirelessly transmitted from an ultrasonic probe to an ultrasonic diagnostic apparatus main body, the main body and the probe are reliably connected without false recognition. An ultrasonic diagnostic apparatus includes an ultrasonic probe and an ultrasonic diagnostic apparatus main body, and the ultrasonic probe includes a probe ID transport unit having a transport distance shorter than that of a first wireless communication unit for transporting a probe ID for identification of itself in contact or noncontact to an outside, the ultrasonic diagnostic apparatus main body includes a probe ID acquiring unit for acquiring the probe ID transported from the probe ID transport unit, and a second wireless communication unit receives the transfer signal from the ultrasonic probe having the probe ID acquired by the probe ID acquiring unit.

Owner:FUJIFILM CORP

Test handler

ActiveUS7923989B2Compensation deviationAppropriate connectionElectronic circuit testingWing accessoriesTest chamberEngineering

A test handler includes a loading unit for loading semiconductor devices from customer trays onto a test tray; a test chamber for performing a test for the semiconductor devices loaded on the test tray; a pushing unit having at least one pushing member for pushing the test tray located in the test chamber to be tested, and a press unit for operating the pushing member; a position control unit for adjusting a position of the pushing member to compensate a deviation between the pushing member and the test tray due to a thermal expansion or contraction of any one of the pushing member and the test tray; and an unloading unit for unloading the semiconductor devices loaded on the test tray onto the customer trays after a test for the semiconductor devices is completed.

Owner:TECHWING CO LTD

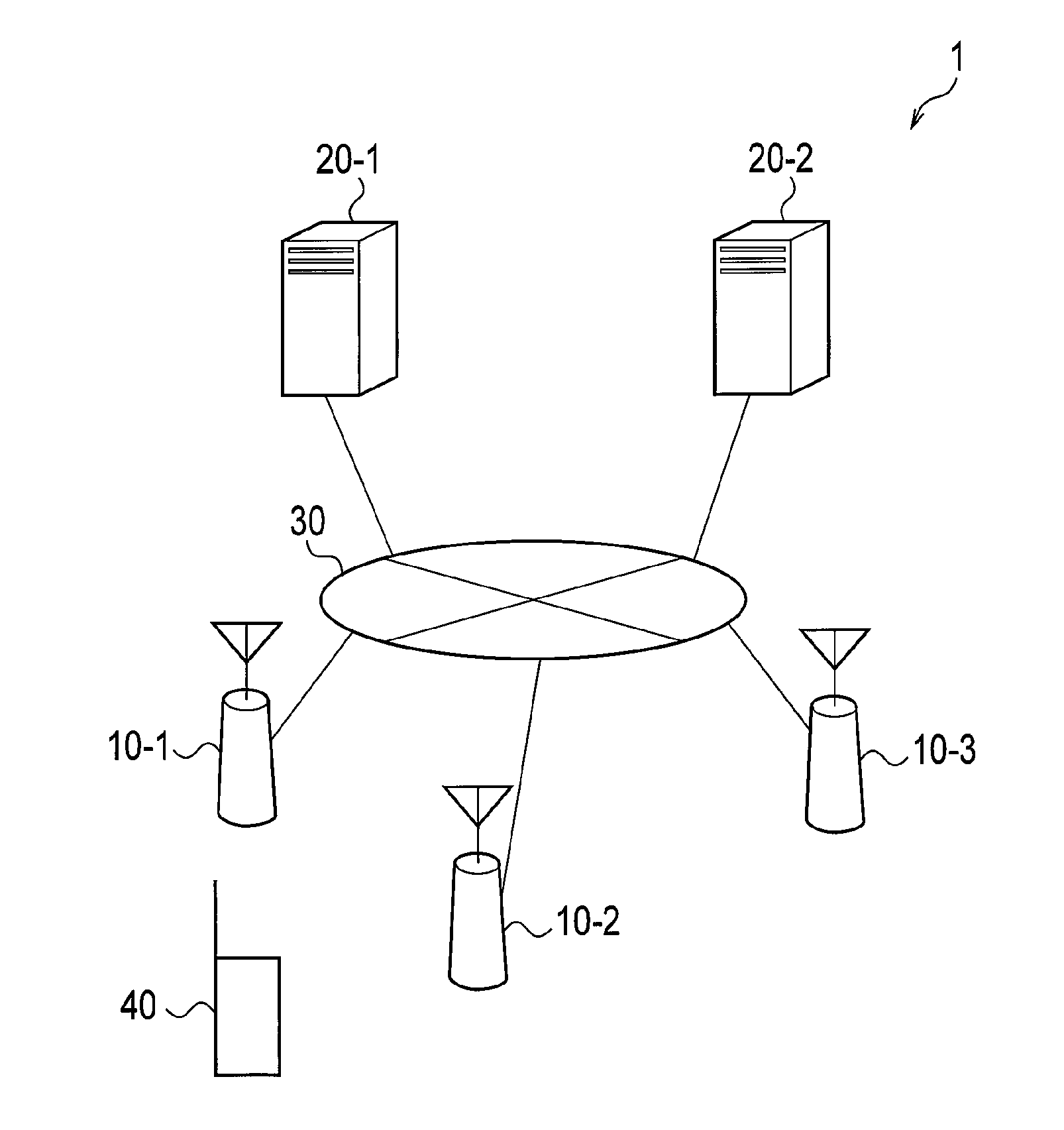

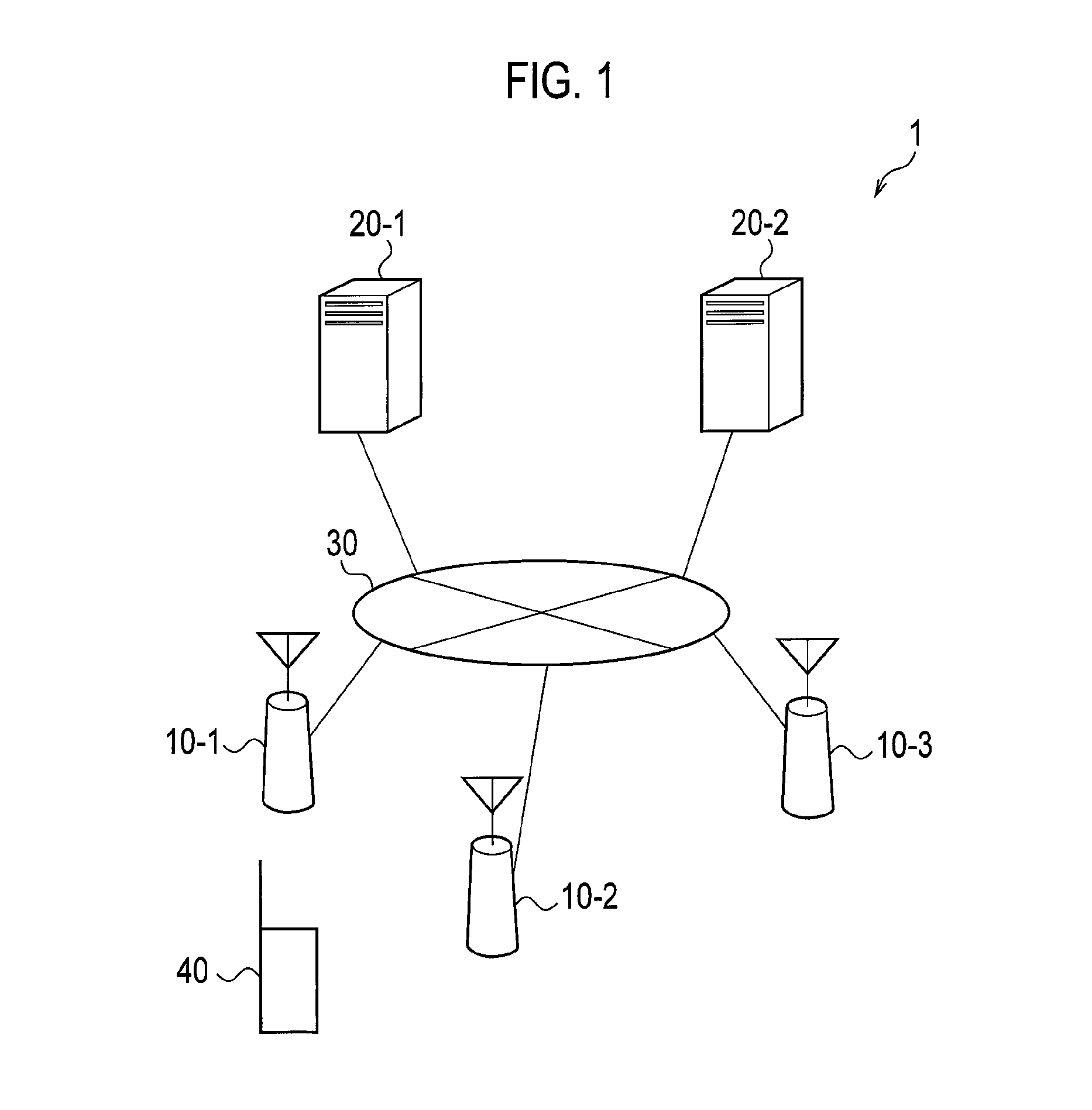

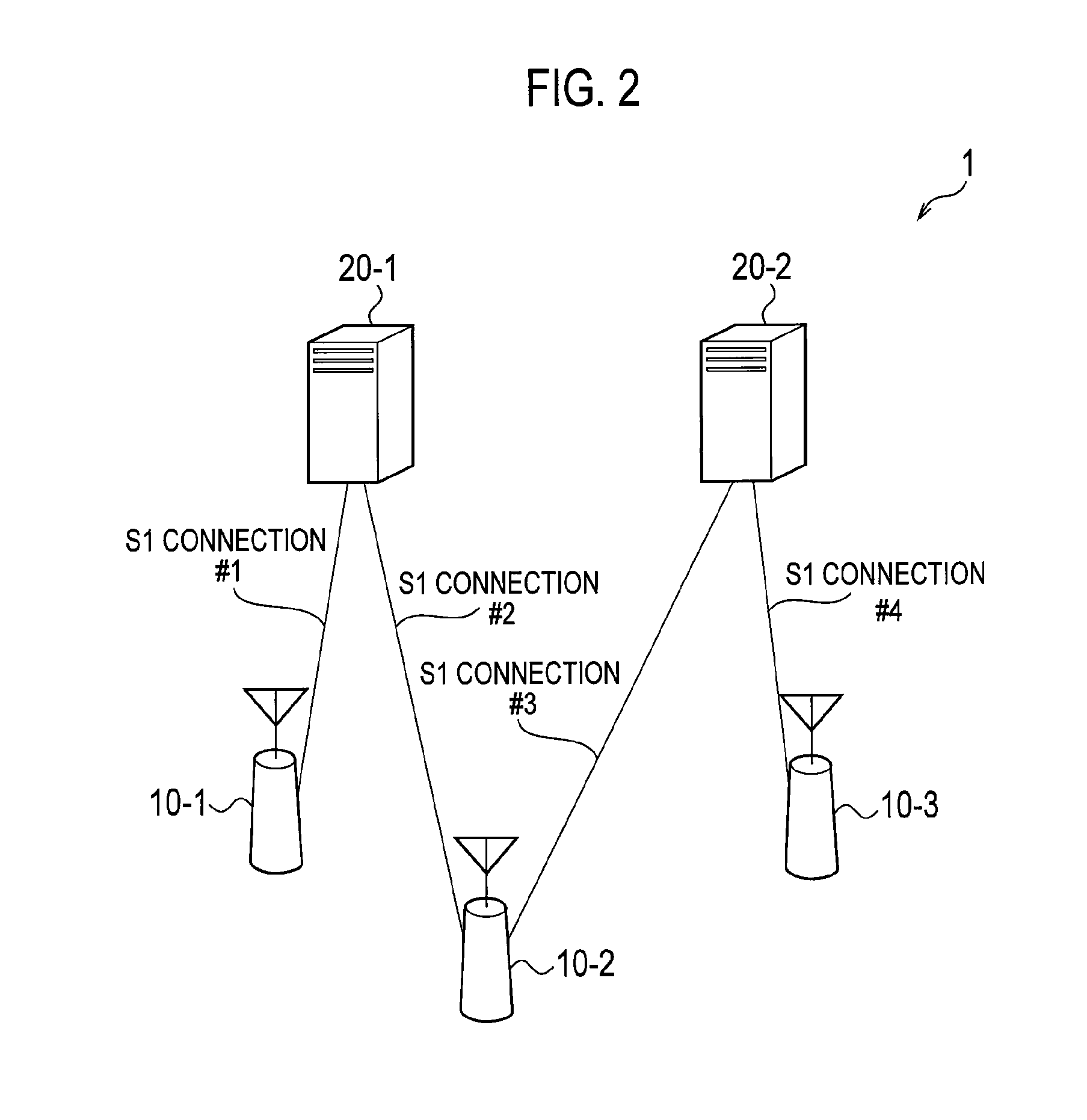

Radio base station and connection establishment control method

ActiveUS8903401B2Restricting establishmentAppropriate connectionNetwork traffic/resource managementConnection managementComputer terminalRadio Base Station

An LTE base station (10-1) acquires handover history information indicating the handover history of a radio terminal (40). On the basis of the acquired handover history information, the LTE base station (10-1) determines another LTE base station with which an X2 connection is to be established.

Owner:KYOCERA CORP

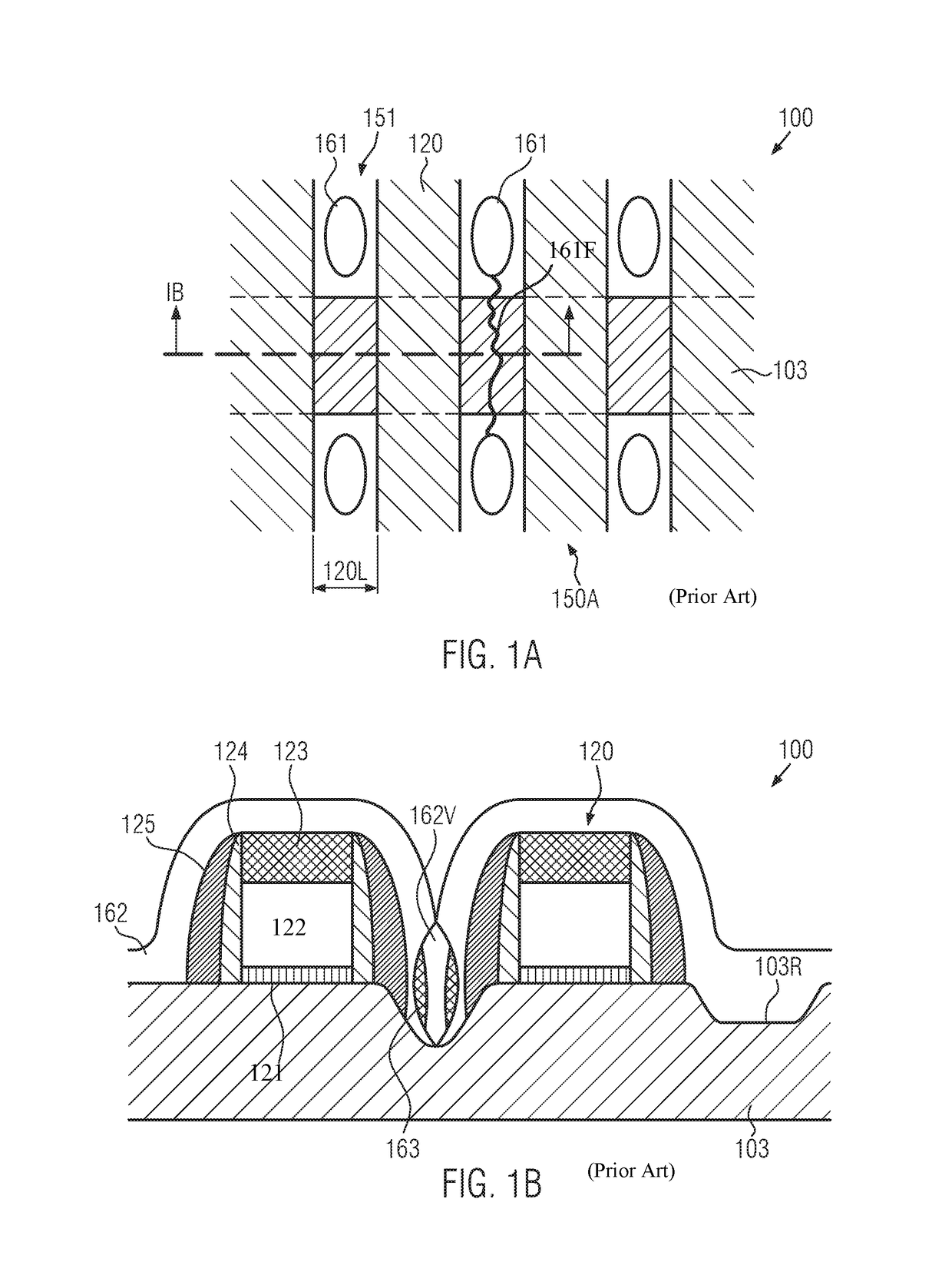

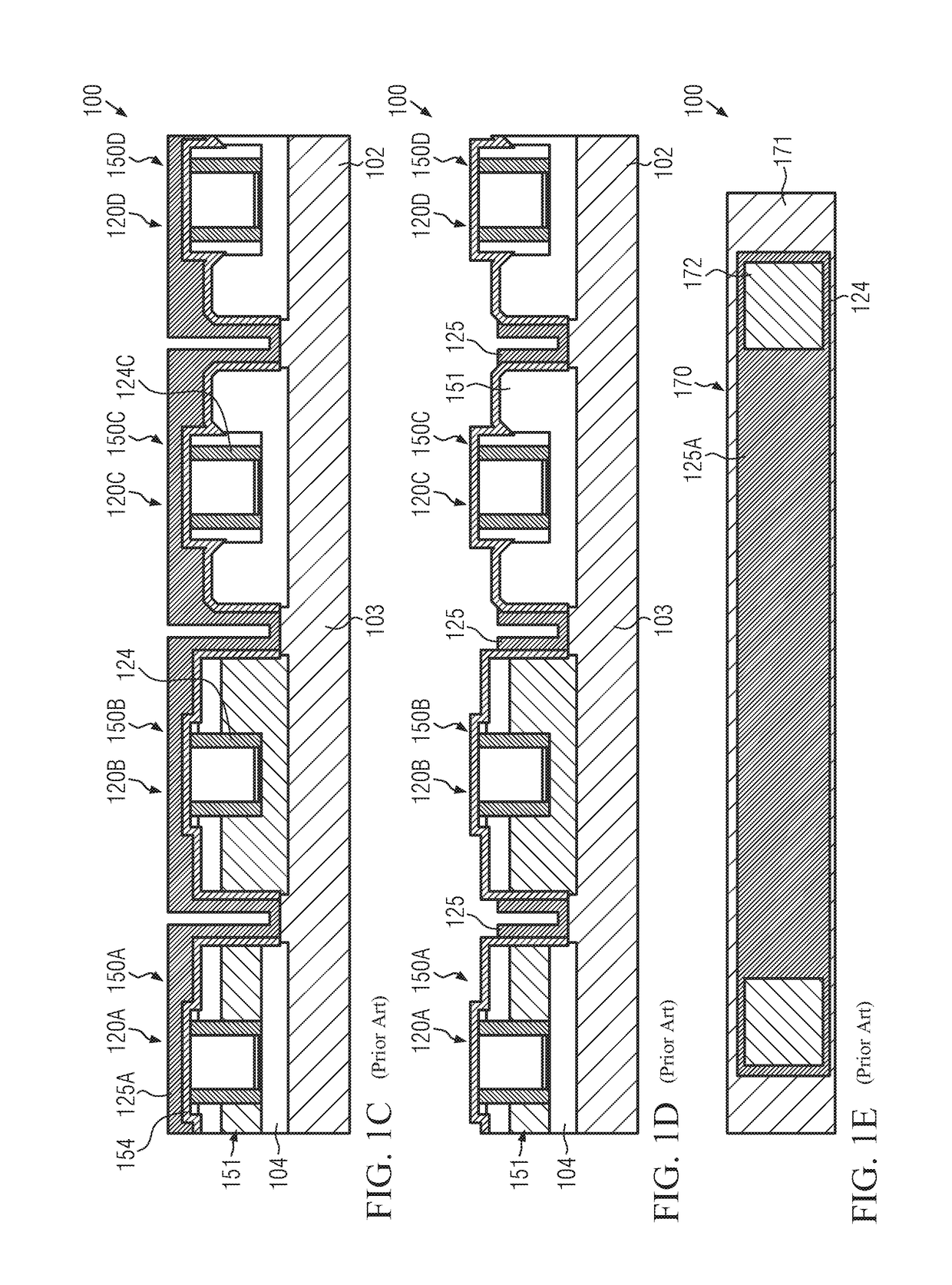

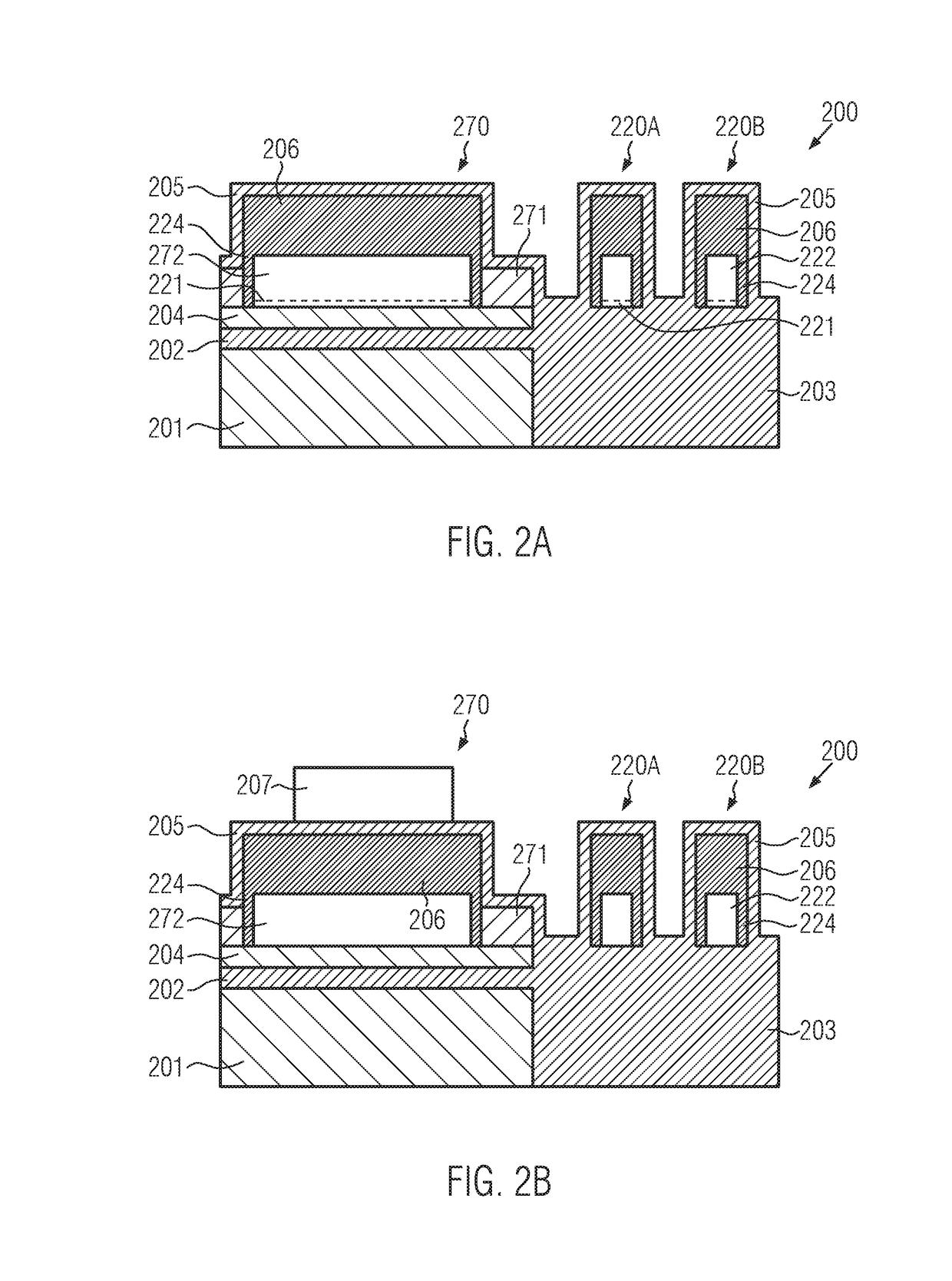

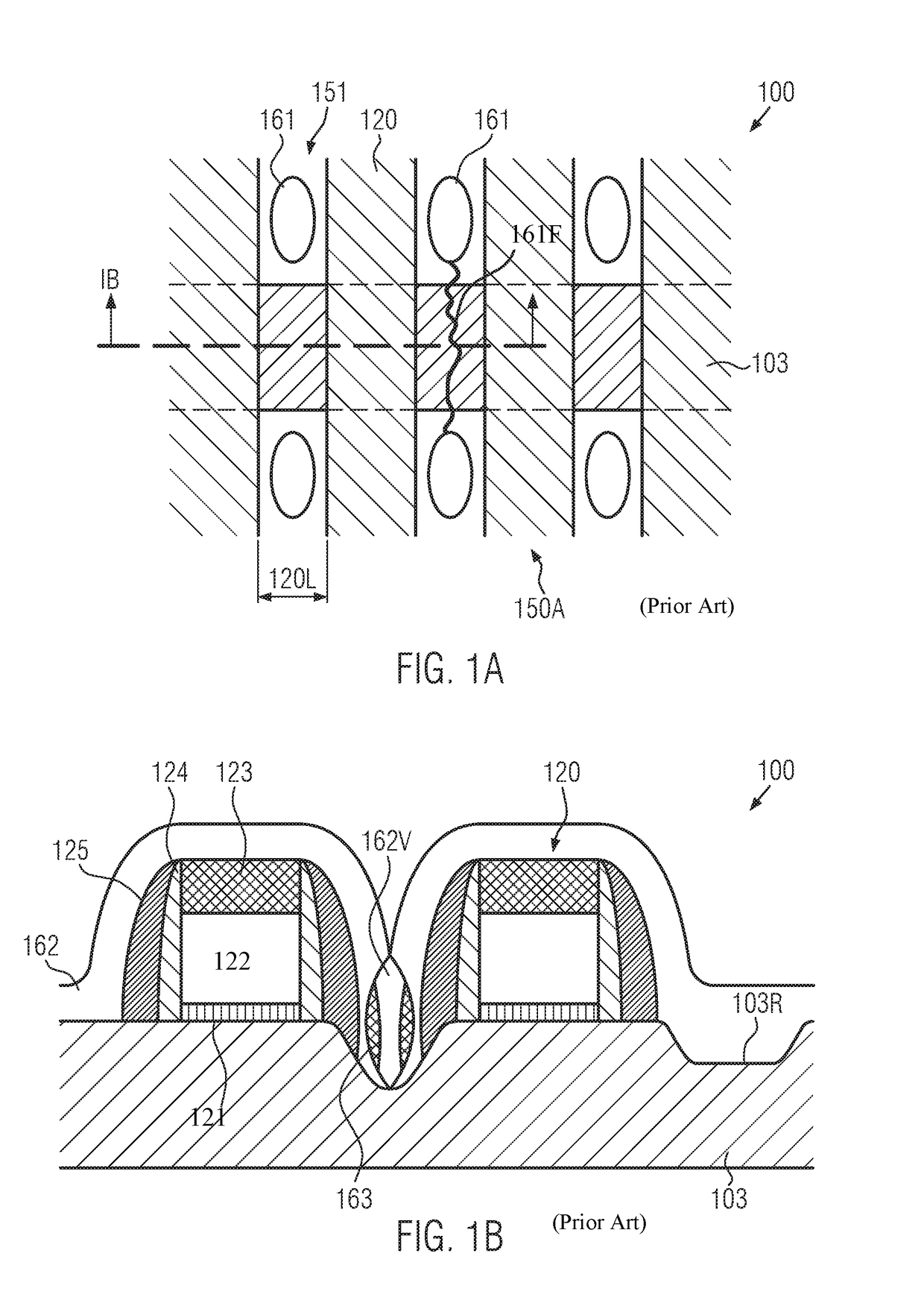

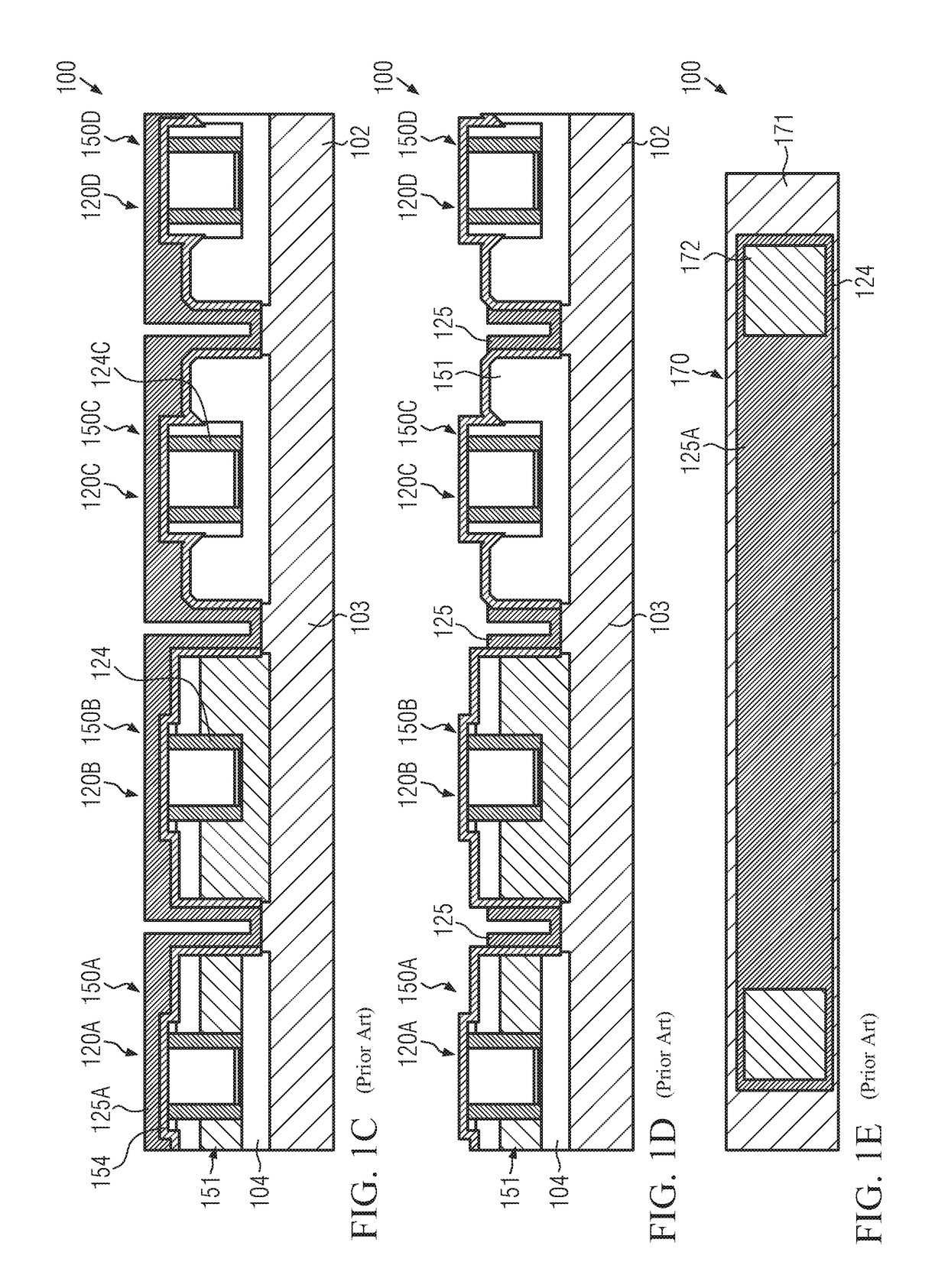

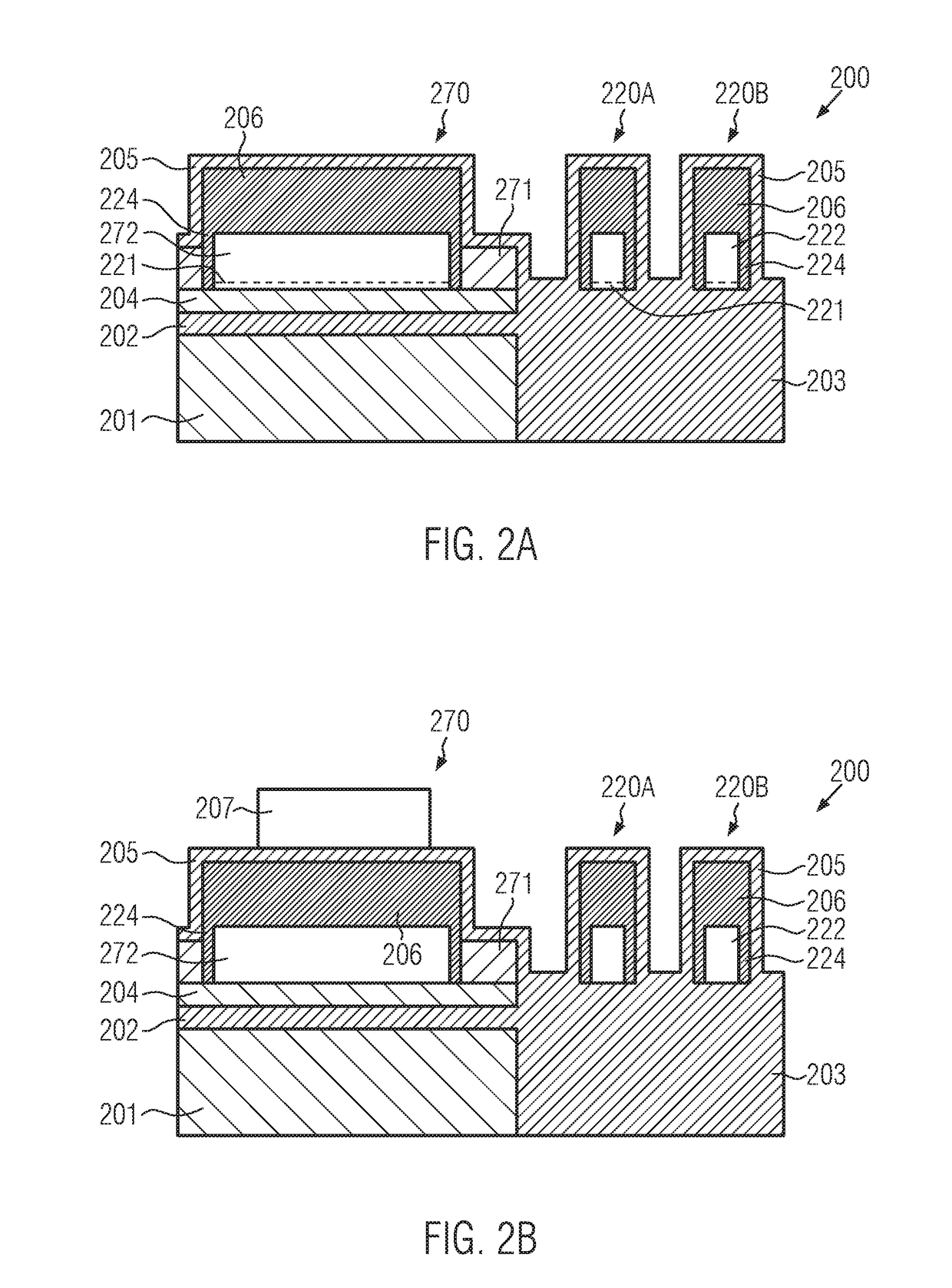

Semiconductor devices and manufacturing techniques for reduced aspect ratio of neighboring gate electrode lines

InactiveUS10224251B2Improve performanceImprove integration densityTransistorSolid-state devicesManufacturing technologyMetallic materials

When forming sophisticated semiconductor devices requiring resistors based on polysilicon material having non-silicided portions, the respective cap material for defining the silicided portions may be omitted during the process sequence, for instance, by using a patterned liner material or by applying a process strategy for removing the metal material from resistor areas that may not receive a corresponding metal silicide. By implementing the corresponding process strategies, semiconductor devices may be obtained with reduced probability of contact failures, with superior performance due to relaxing surface topography upon forming the contact level, and / or with increased robustness with respect to contact punch-through.

Owner:GLOBALFOUNDRIES US INC

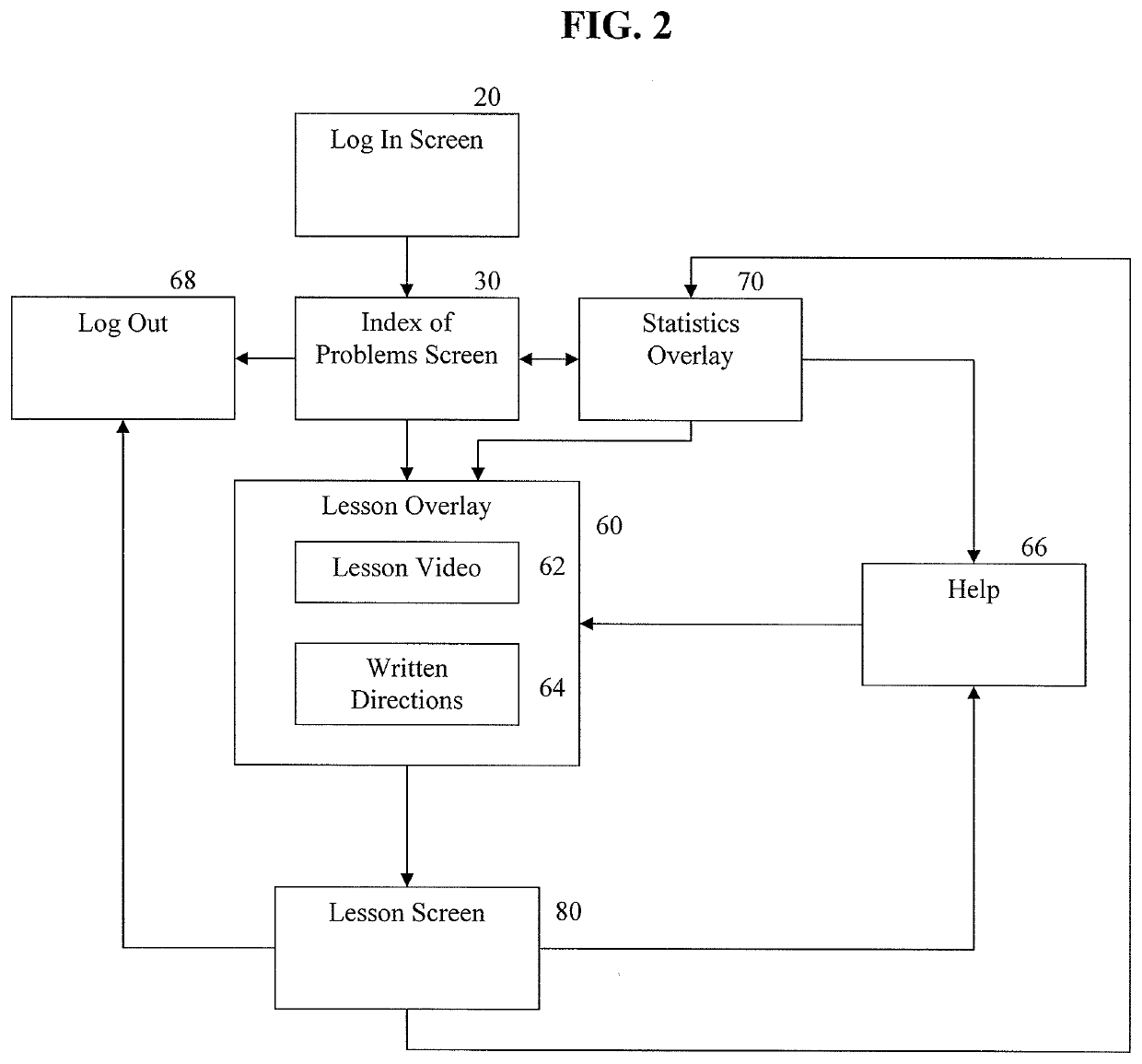

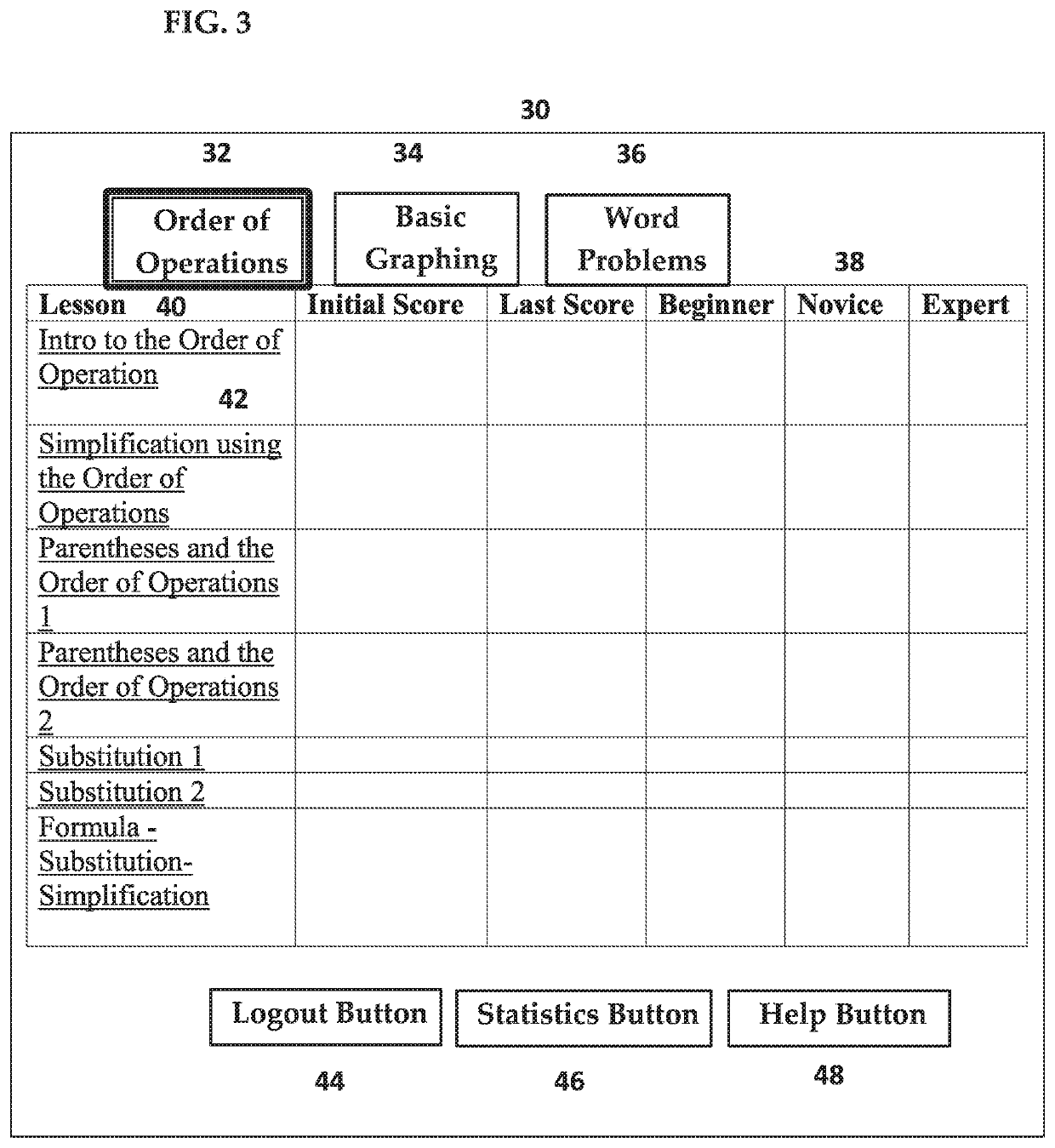

Systems and methods using mathematical reasoning blocks

InactiveUS20200143695A1Appropriate connectionElectrical appliancesAlgorithmTheoretical computer science

This invention supplies a method to make the abstract, step-by-step logic of math problems visible via the use of digitized mathematical reasoning blocks, which can be used to construct an interactive teaching program that allows a student to select problem sets from an index of problems, allows the student to view a brief instructional video pertaining to that skill if desired, allows the student to chose the mode of problem presentation (i.e., various learning or test modes), allows the student to work randomly generated problems from within the chosen mode and set by picking mathematical reasoning blocks that represent the various necessary / possible sub-steps in route to the solution of that problem.

Owner:WEEMS RODNEY A

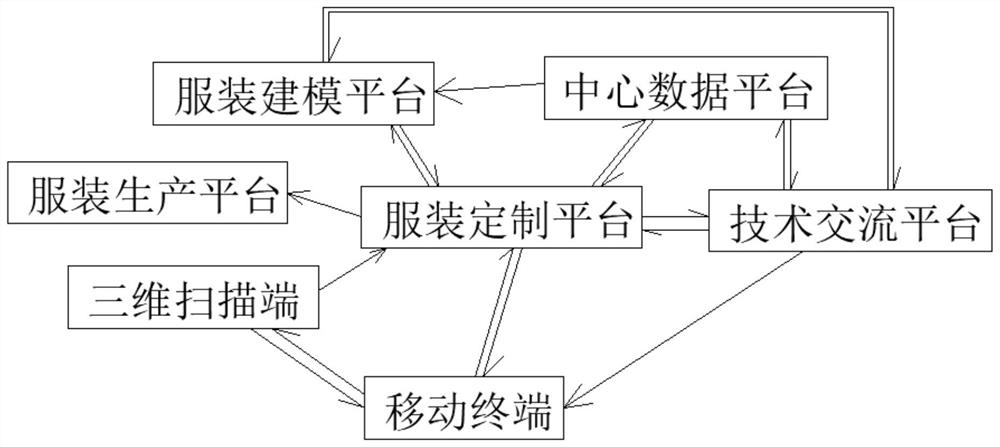

Intelligent personalized garment customization method

InactiveCN112837123ASimple designConvenient for later customizationBuying/selling/leasing transactions3D modellingPersonalizationData platform

The invention provides an intelligent personalized garment customization method, and relates to the technical field of garment customization. According to the intelligent personalized garment customization method, a three-dimensional scanning terminal, a mobile terminal, a garment customization platform, a technical exchange platform, a central data platform, a garment modeling platform and a garment production platform are included; a customer of the mobile terminal registers on the online garment customization platform and issues own garment customization requirements, then the garment customization platform gives the customer of the mobile terminal a use permission of the three-dimensional scanning terminal, and the three-dimensional scanning terminal collects a three-dimensional model and posture data of the customer of the mobile terminal after confirming the use permission. According to the method, the whole process is very rapid, all links are properly connected, it can be guaranteed that customers obtain customized clothes meeting the requirements in the shortest time, all personalized requirements can be met, the method is very flexible, the styles of customized clothes can be comprehensively appreciated before production, and later customization is very convenient.

Owner:NINGXIA HUICHUAN GARMENT CO LTD

Waste liquid collector

Owner:SEIKO EPSON CORP

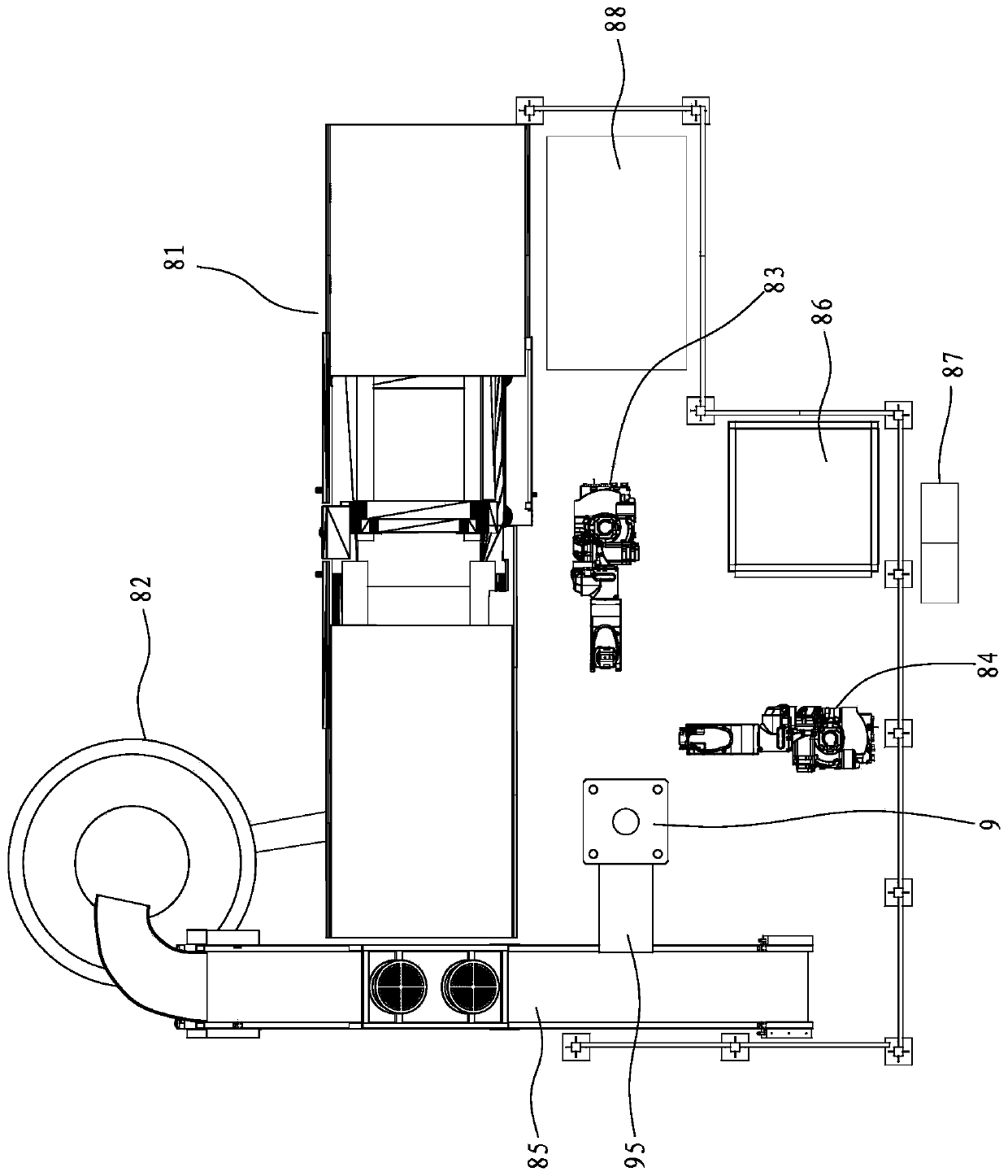

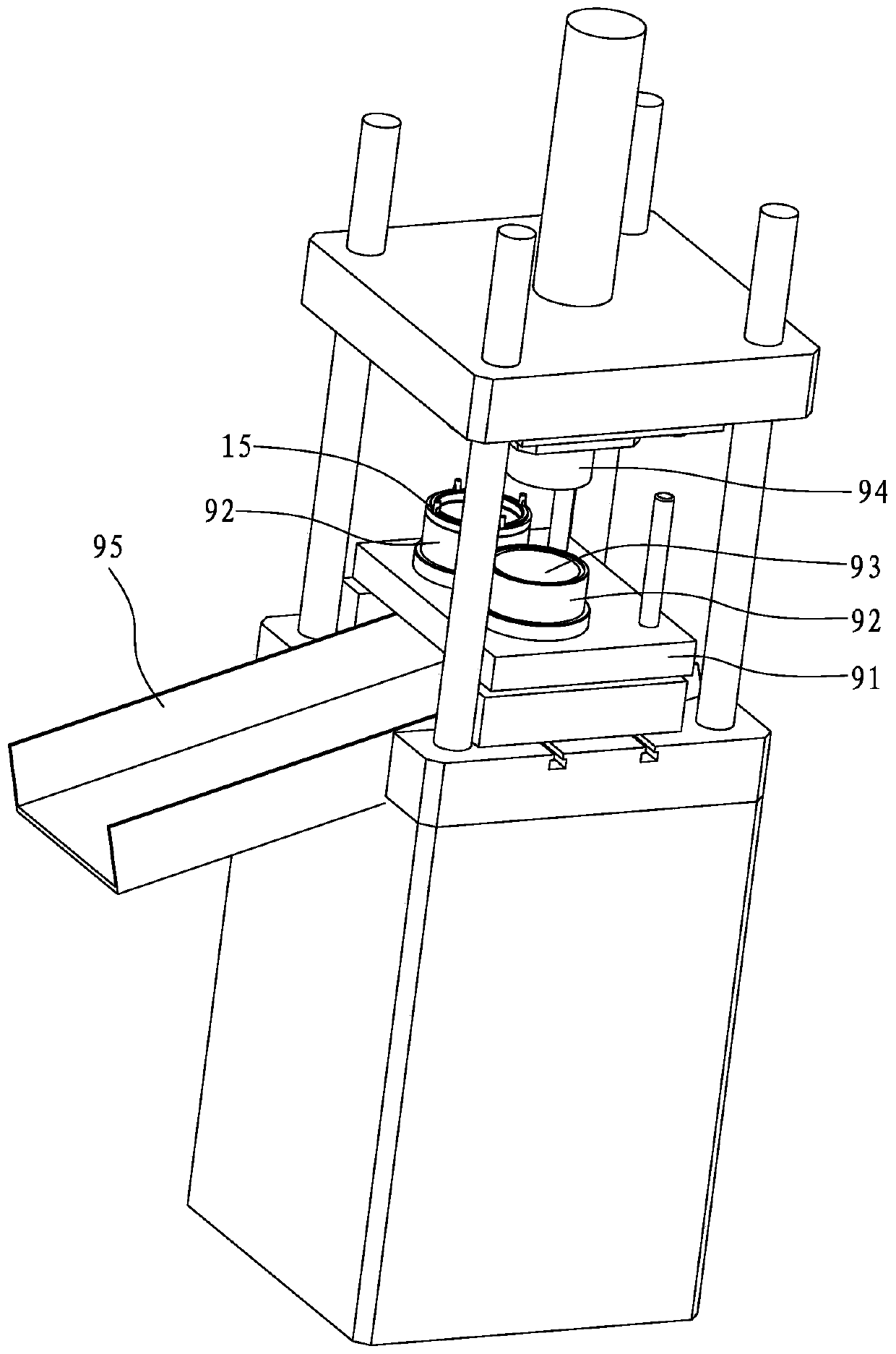

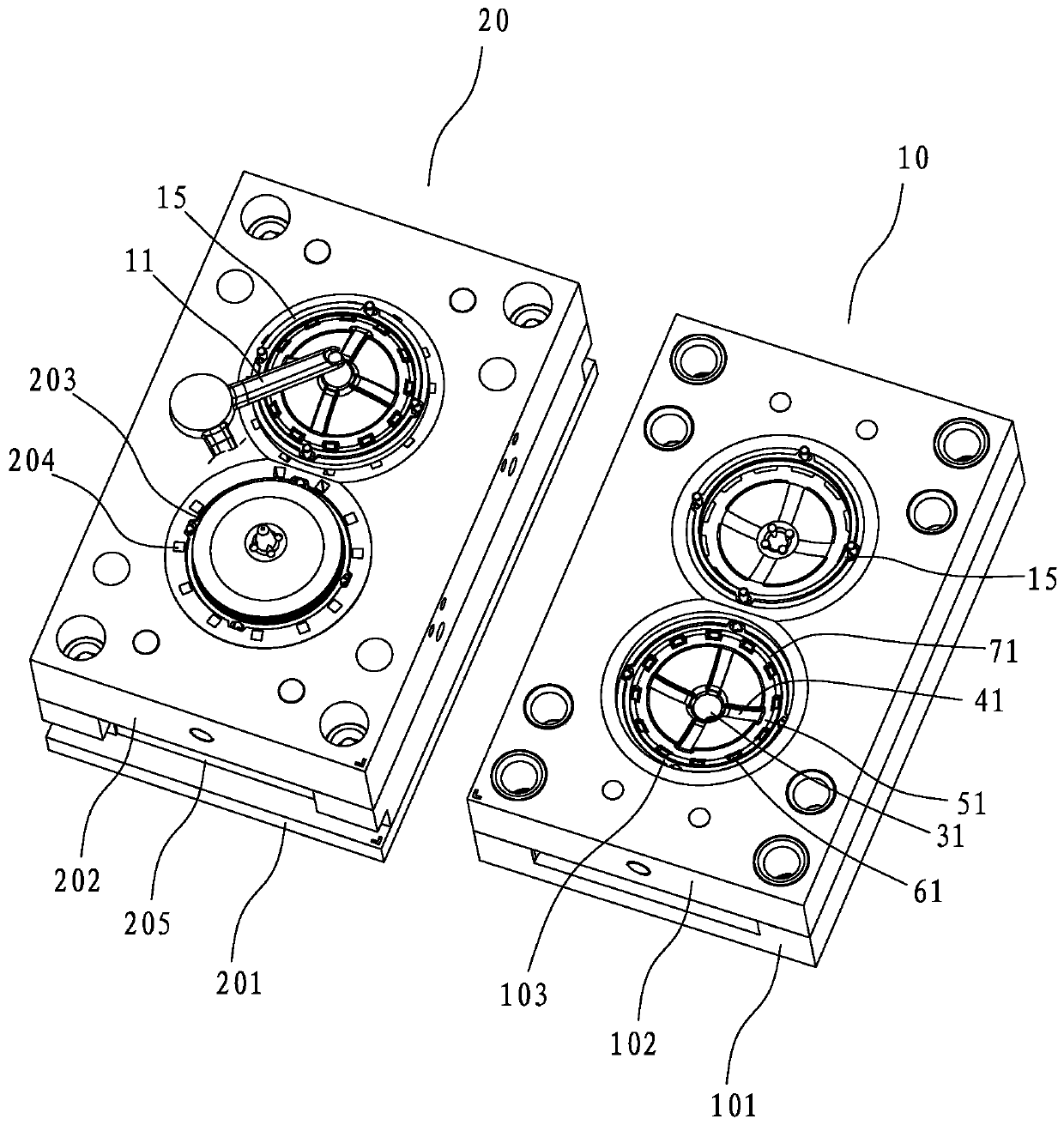

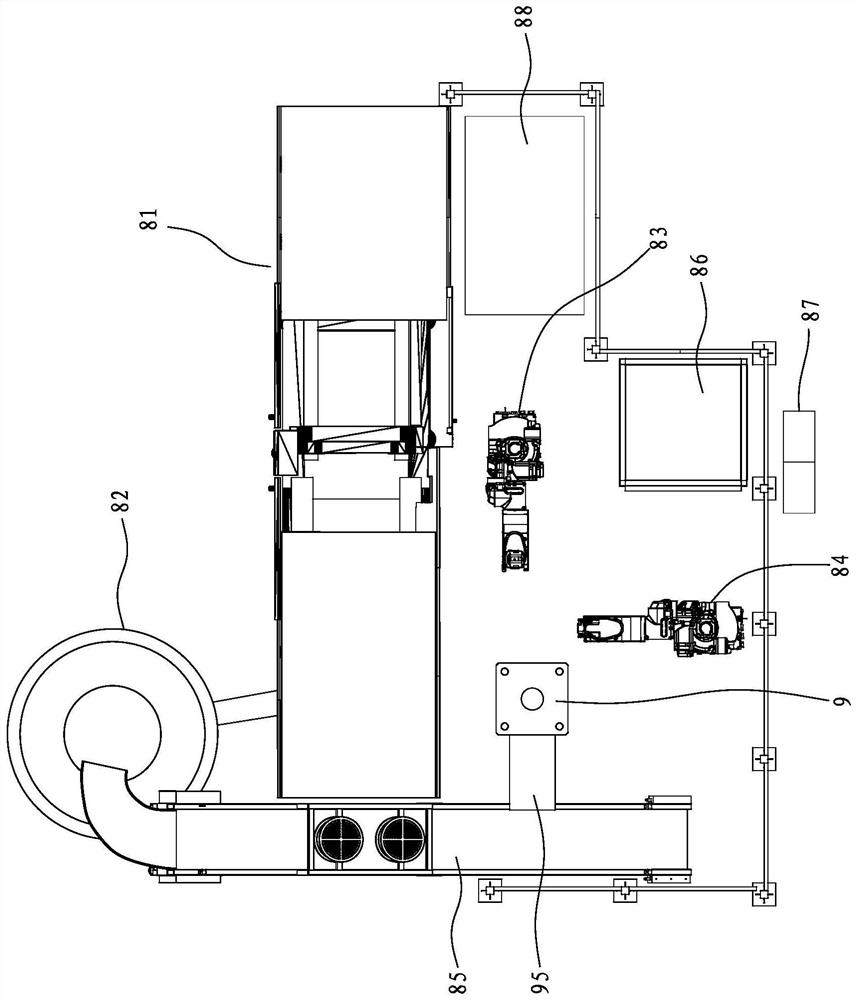

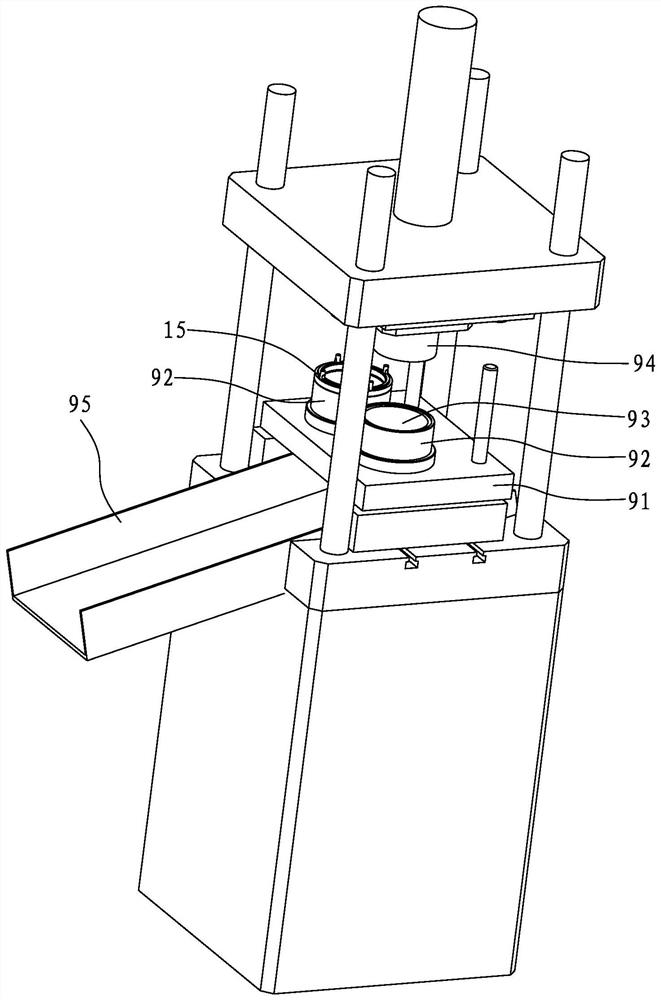

Automatic machining equipment for aluminum rotor of ceiling fan motor

PendingCN111299538AFurnace temperature fluctuation is smallAppropriate connectionCasting plantsCeiling fanFurnace temperature

The invention discloses automatic machining equipment for an aluminum rotor of a ceiling fan motor. The automatic machining equipment comprises a die-casting machine and a smelting furnace, wherein adie-casting die is arranged in the die-casting machine, a punching machine capable of punching a material handle to enable the material handle to fall off from the motor rotor is arranged on one sideof the die-casting machine, a workpiece taking robot used for taking out die castings in the die-casting machine and placing the die castings into the punching machine is arranged between the die-casting machine and the punching machine, a conveying belt used for receiving the material handles punched by the punching machine and conveying the material handles into the smelting furnace is arrangedbetween the punching machine and the smelting furnace, a material collecting frame is arranged on one side of the punching machine, a stacking robot is arranged between the punching machine and the material collecting frame, a control system controls the workpiece taking robot, the stacking robot, the conveying belt and the punching machine to work, automatic production of die-cast forming, takingdown the die castings from the die-casting die, moving the die castings to the punching machine, punching the material handles, orderly stacking the punched motor rotors and returning the material handles punched each time to the smelting furnace is achieved, the production efficiency is high, the furnace temperature fluctuation is small, and the production yield is high.

Owner:NEW CENTURY ELECTRICAL MFG ZHONGSHAN

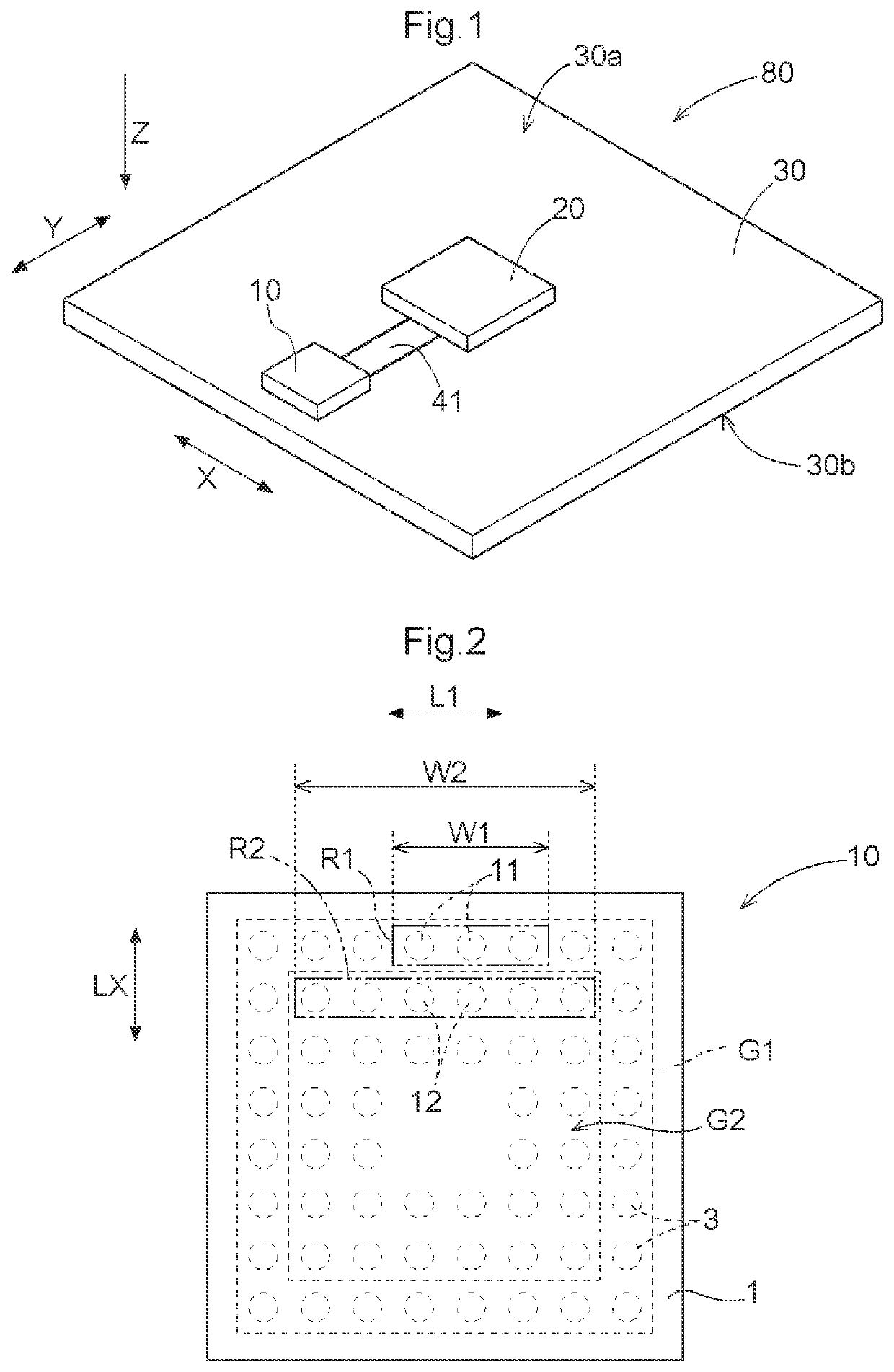

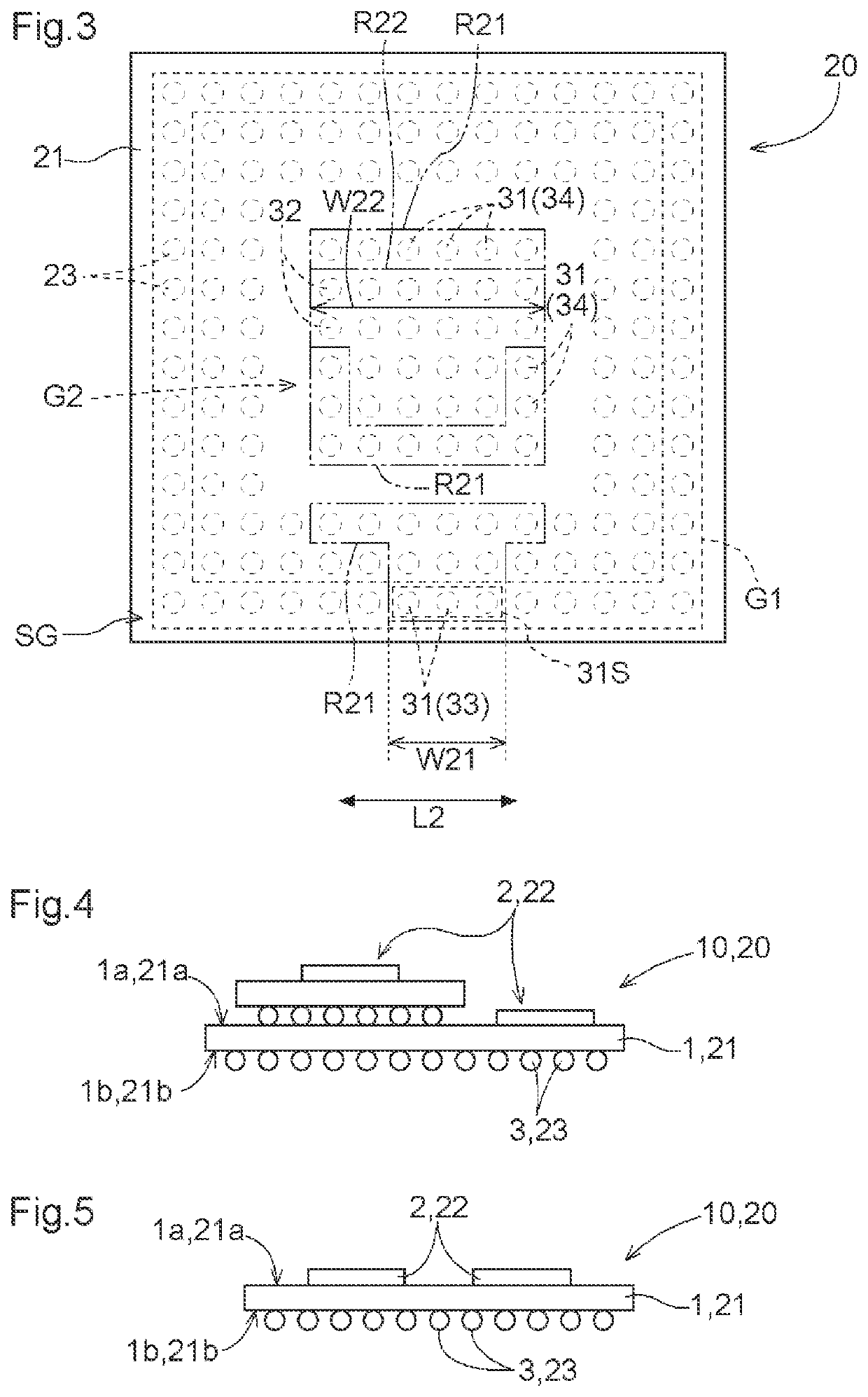

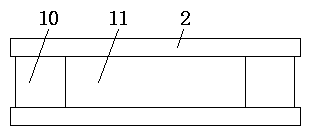

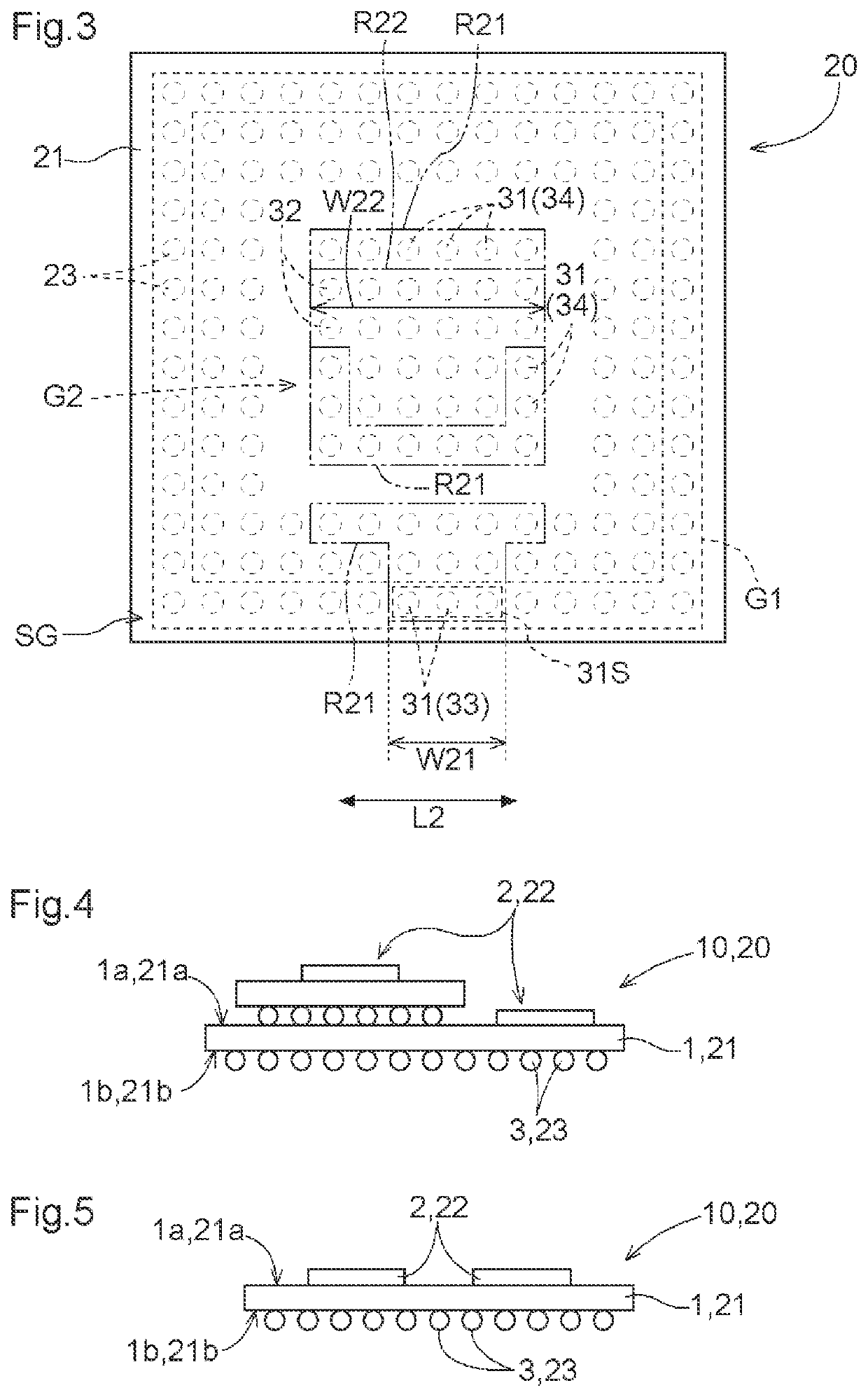

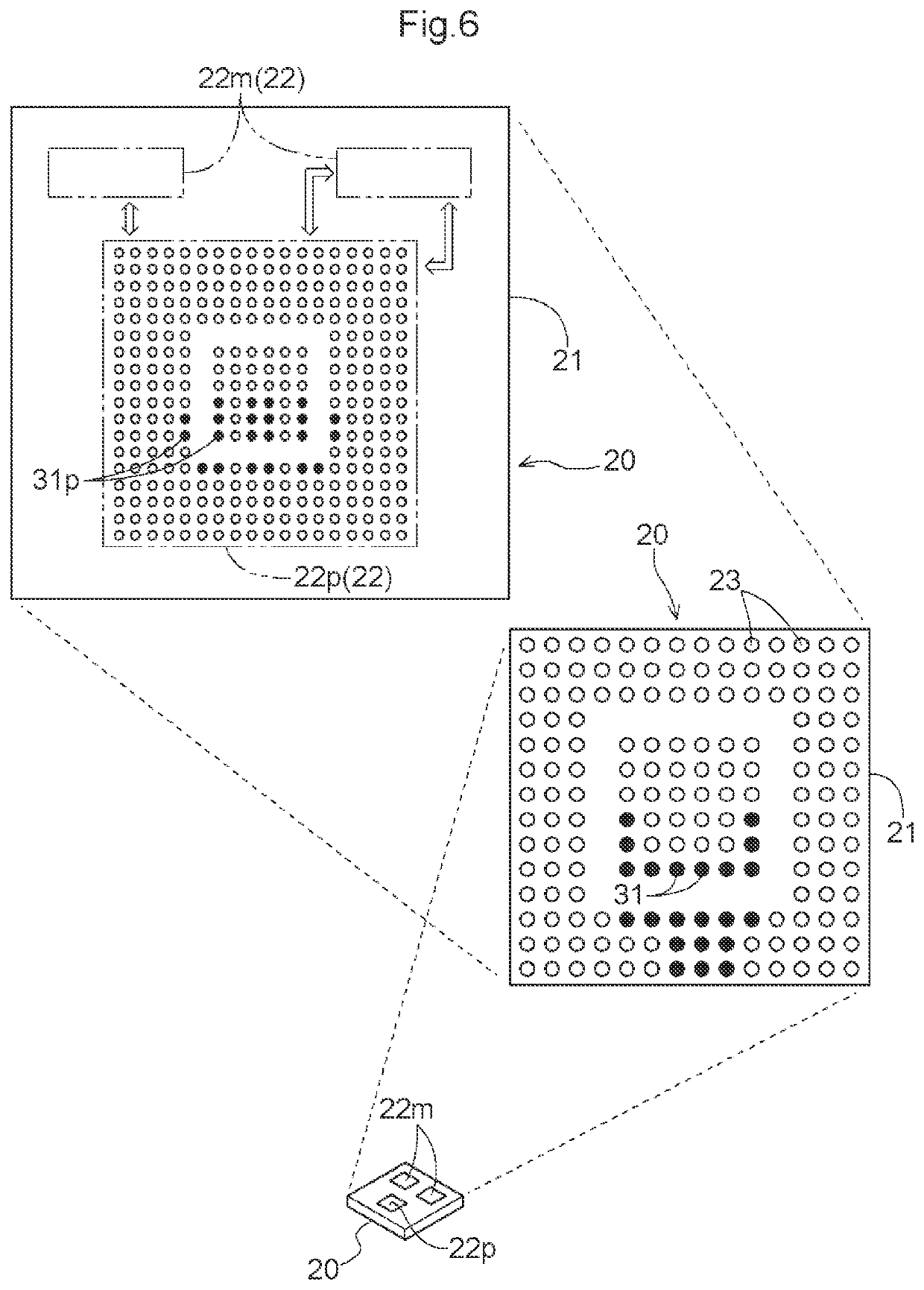

Circuit module and power supply chip module

ActiveUS11335633B2Sufficient wiring widthEnhance layeringElectrically conductive connectionsSemiconductor/solid-state device detailsComputer hardwareHemt circuits

Provided is a circuit module including a power supply chip module, a load chip module, and a system board. A power supply output terminal group of the power supply chip module is arranged side by side in a row along a side of the power supply chip module board, the power supply input terminal group of a load chip module includes a specific terminal group arranged in a specific row that is a row along a side of the load chip module board, and a wiring width along an arrangement direction of the power supply output terminal group of a wiring pattern in which the power supply output terminal group is connected to the system board is equal to or more than a wiring width W31 along an arrangement direction of the specific terminal group of the wiring pattern in which the specific terminal group is connected to the system board.

Owner:AISIN CORP

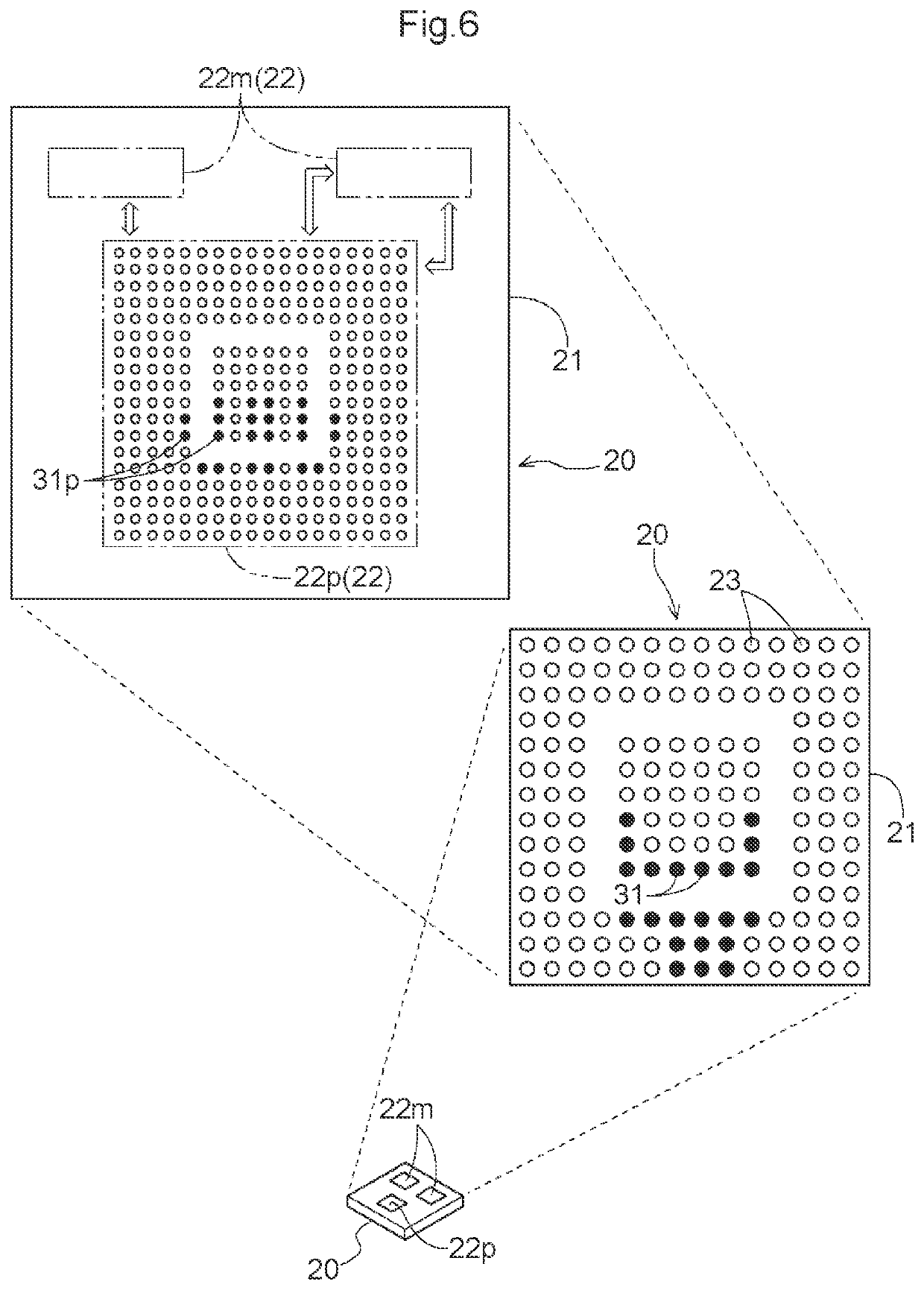

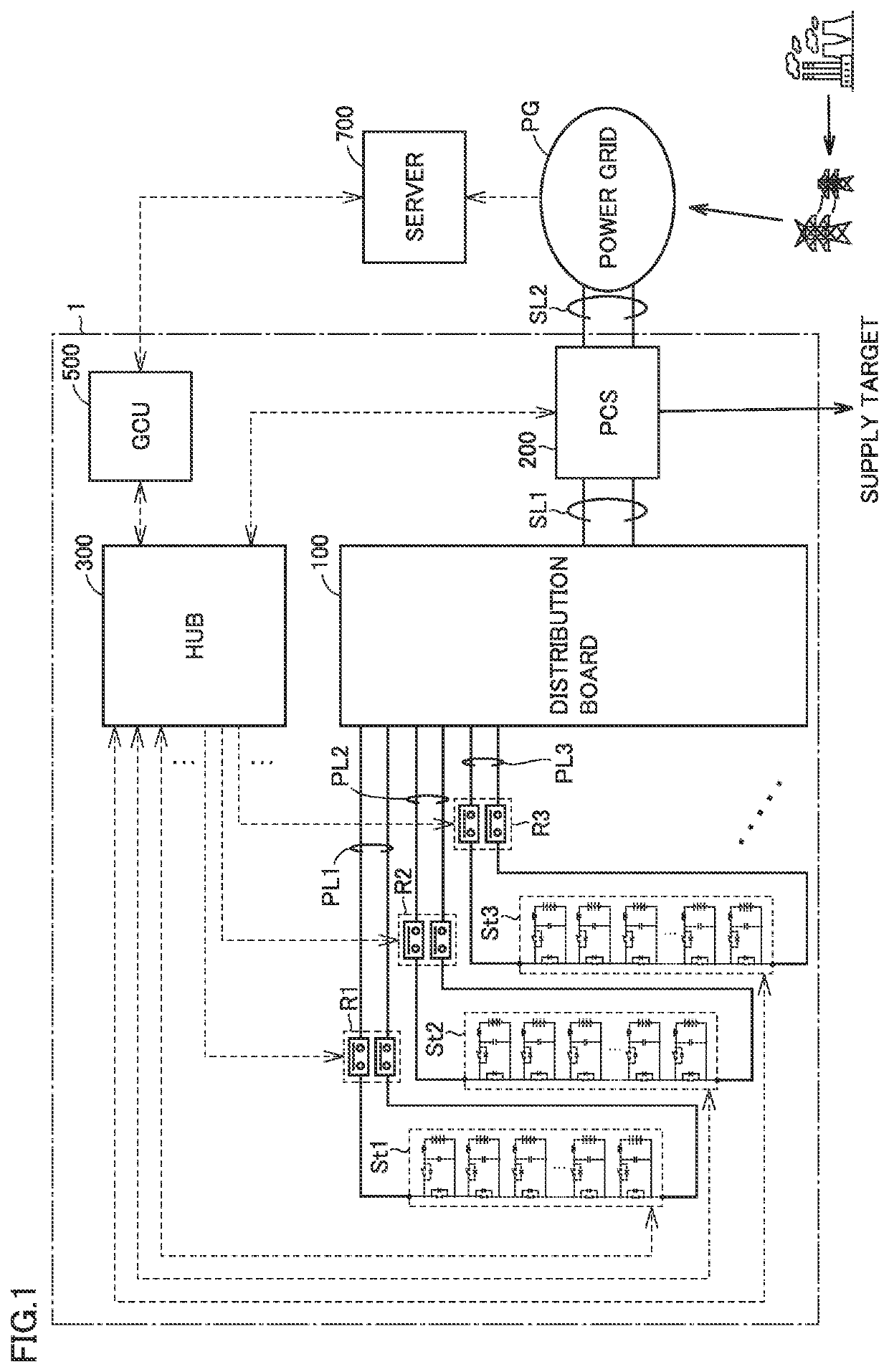

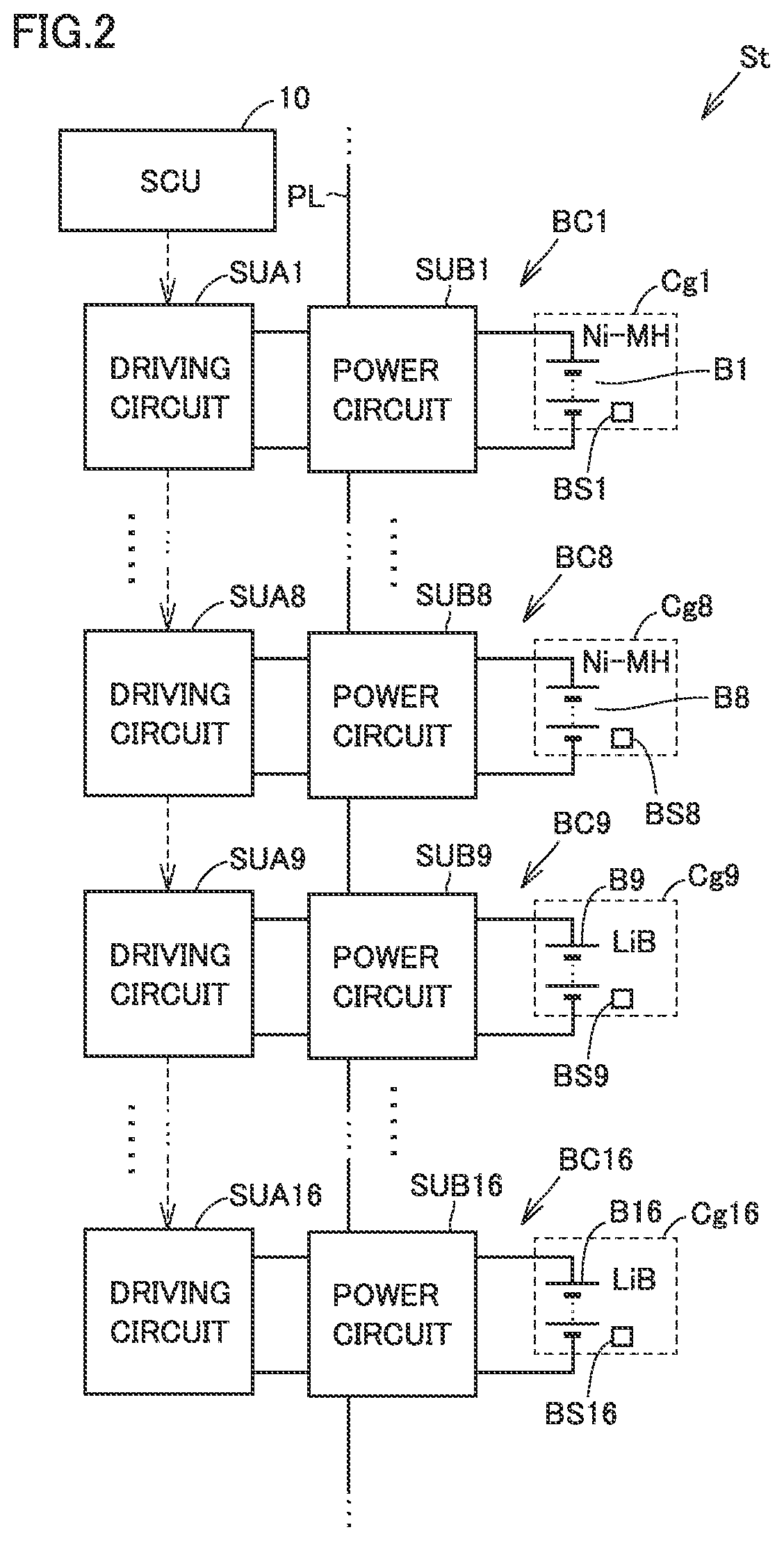

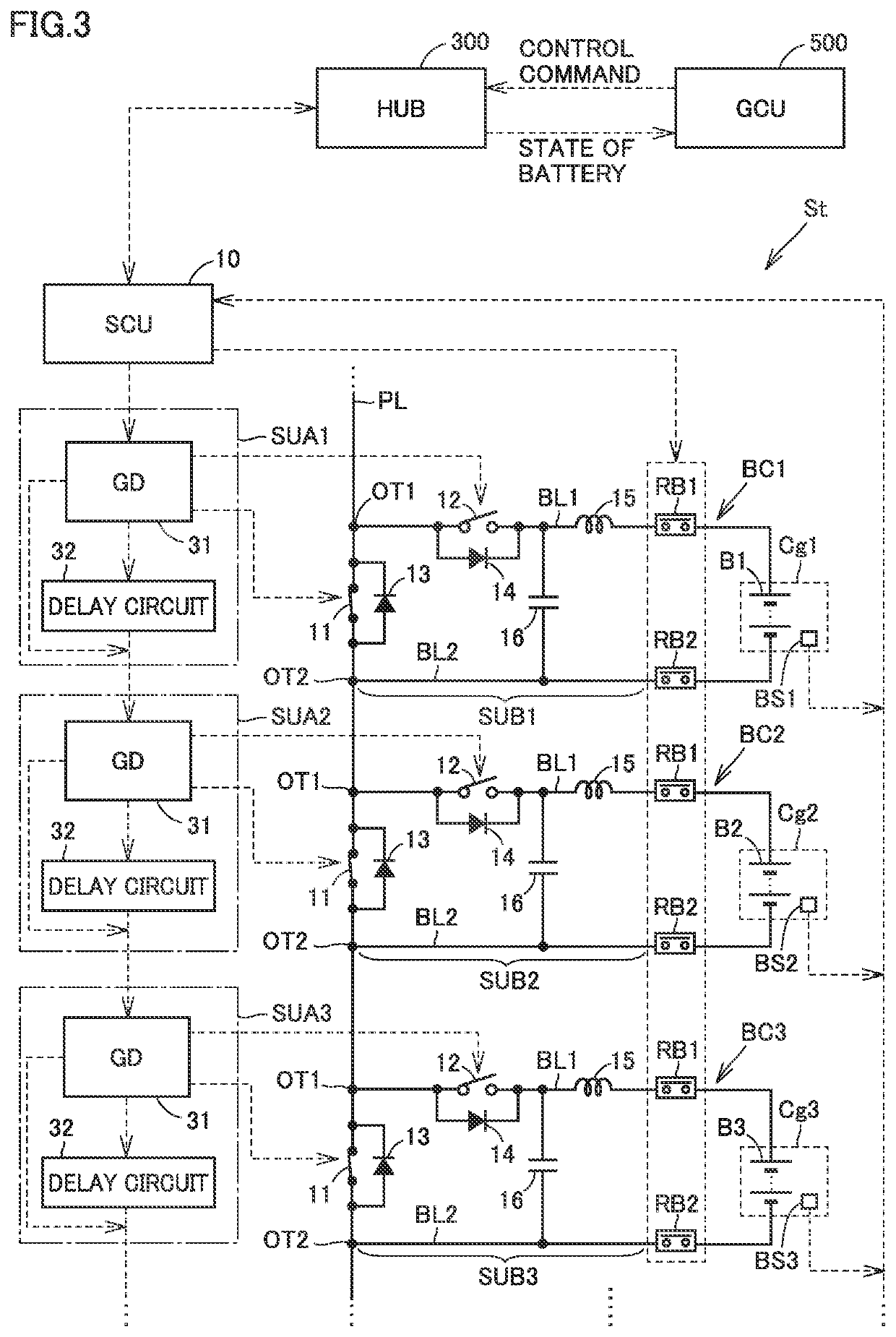

Power supply system and control device

PendingUS20220311250A1Appropriate connectionEasy to controlCharge equalisation circuitCircuit monitoring/indicationHemt circuitsControl theory

Owner:TOYOTA JIDOSHA KK

A wireless music player

The invention discloses a wireless music player, The invention relates to the technical field of music playing equipment, comprising a player body, wherein a cavity is connected with a lower surface of the player body, an inner surface of the cavity is fixedly connected with a connecting body, the inner surface of the connecting body is provided with a tympanic membrane, two squeeze plates are arranged below the tympanic membrane, and the opposite faces of the two squeeze plates are provided with card slots. A wireless music player by setting tympanic membrane and negative ion generator, the anion generator operates when the switch is operated, the negative ion generator can produce negative ions in the course of working, Anion can activate cell, purify blood, promote metabolism, eliminatefatigue, stabilize vegetative nervous system, enhance disease resistance, inhibit tumor cell growth, absorb and shield electromagnetic wave radiation, improve allergic constitution, and play a good health effect.

Owner:湖南宽洋科技有限公司

Circuit module and power supply chip module

ActiveUS20210249344A1Sufficient wiring widthEffective sectional areaSemiconductor/solid-state device detailsPrinted circuit aspectsEmbedded systemHemt circuits

Provided is a circuit module including a power supply chip module, a load chip module, and a system board. A power supply output terminal group of the power supply chip module is arranged side by side in a row along a side of the power supply chip module board, the power supply input terminal group of a load chip module includes a specific terminal group arranged in a specific row that is a row along a side of the load chip module board, and a wiring width along an arrangement direction of the power supply output terminal group of a wiring pattern in which the power supply output terminal group is connected to the system board is equal to or more than a wiring width W31 along an arrangement direction of the specific terminal group of the wiring pattern in which the specific terminal group is connected to the system board.

Owner:AISIN CORP

Semiconductor devices and manufacturing techniques for reduced aspect ratio of neighboring gate electrode lines

InactiveUS20190043764A1Improve performanceImprove integration densityTransistorSolid-state devicesManufacturing technologyMetallic materials

When forming sophisticated semiconductor devices requiring resistors based on polysilicon material having non-silicided portions, the respective cap material for defining the silicided portions may be omitted during the process sequence, for instance, by using a patterned liner material or by applying a process strategy for removing the metal material from resistor areas that may not receive a corresponding metal silicide. By implementing the corresponding process strategies, semiconductor devices may be obtained with reduced probability of contact failures, with superior performance due to relaxing surface topography upon forming the contact level, and / or with increased robustness with respect to contact punch-through.

Owner:GLOBALFOUNDRIES US INC

Load port apparatus and method of driving the same

ActiveUS10665488B2Easy to operateAppropriate connectionSemiconductor/solid-state device manufacturingConveyor partsWaferingEngineering

A load port apparatus connects a main opening of a wafer transportation container with a frame opening. The load port apparatus includes an installation part, a frame, and a flange clamp. The installation part has an installation table configured to install the wafer transportation container and move to and from the frame opening. The frame is upright from the installation part and has the frame opening. The flange clamp includes an engagement portion and a drive portion. The engagement portion is configured to be engaged with a flange surrounding an outer circumference of the main opening. The drive portion is configured to drive the engagement portion. The engagement portion is engaged from above or the side with a flange groove formed in the flange and opening radially outwardly.

Owner:TDK CORPARATION

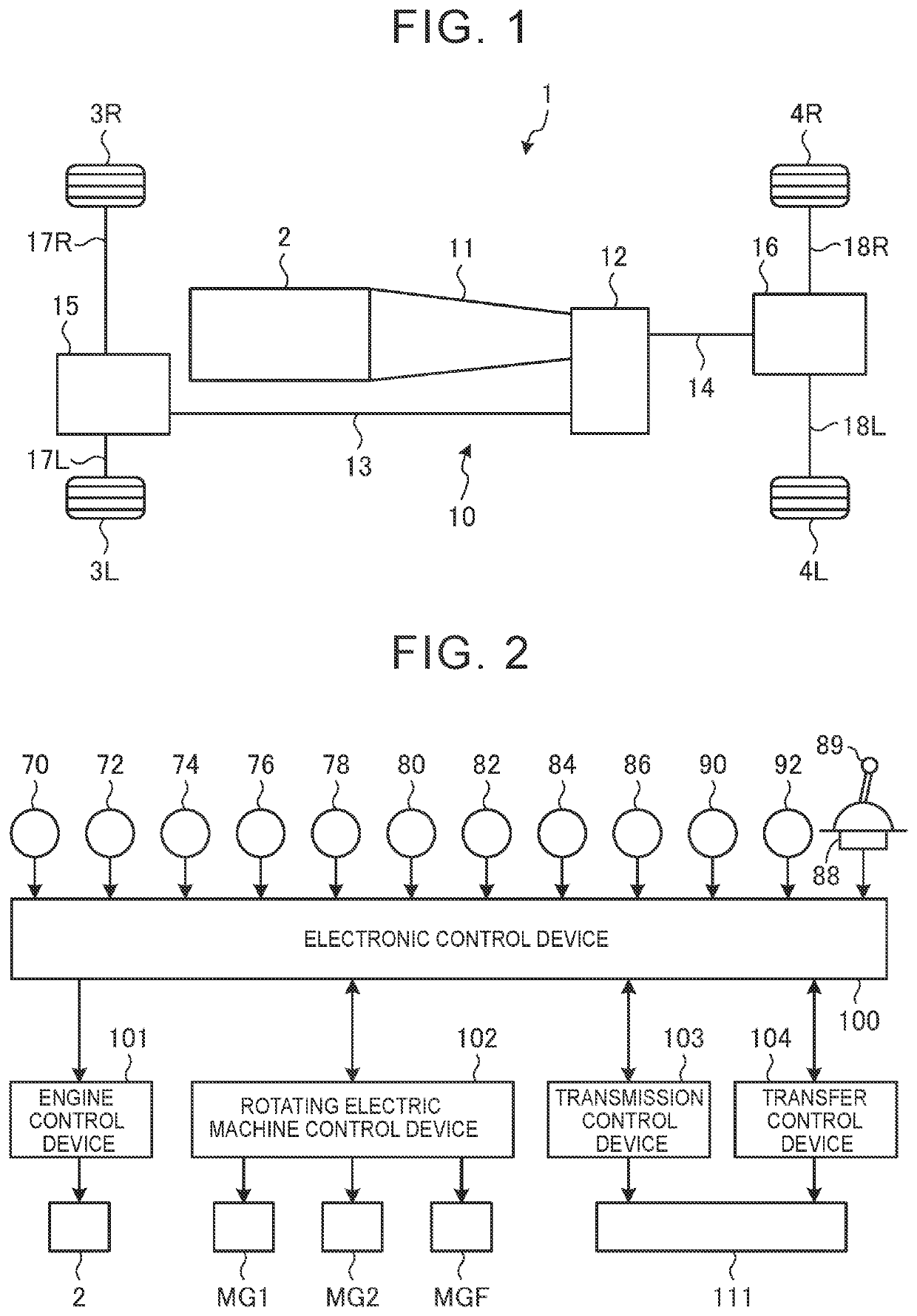

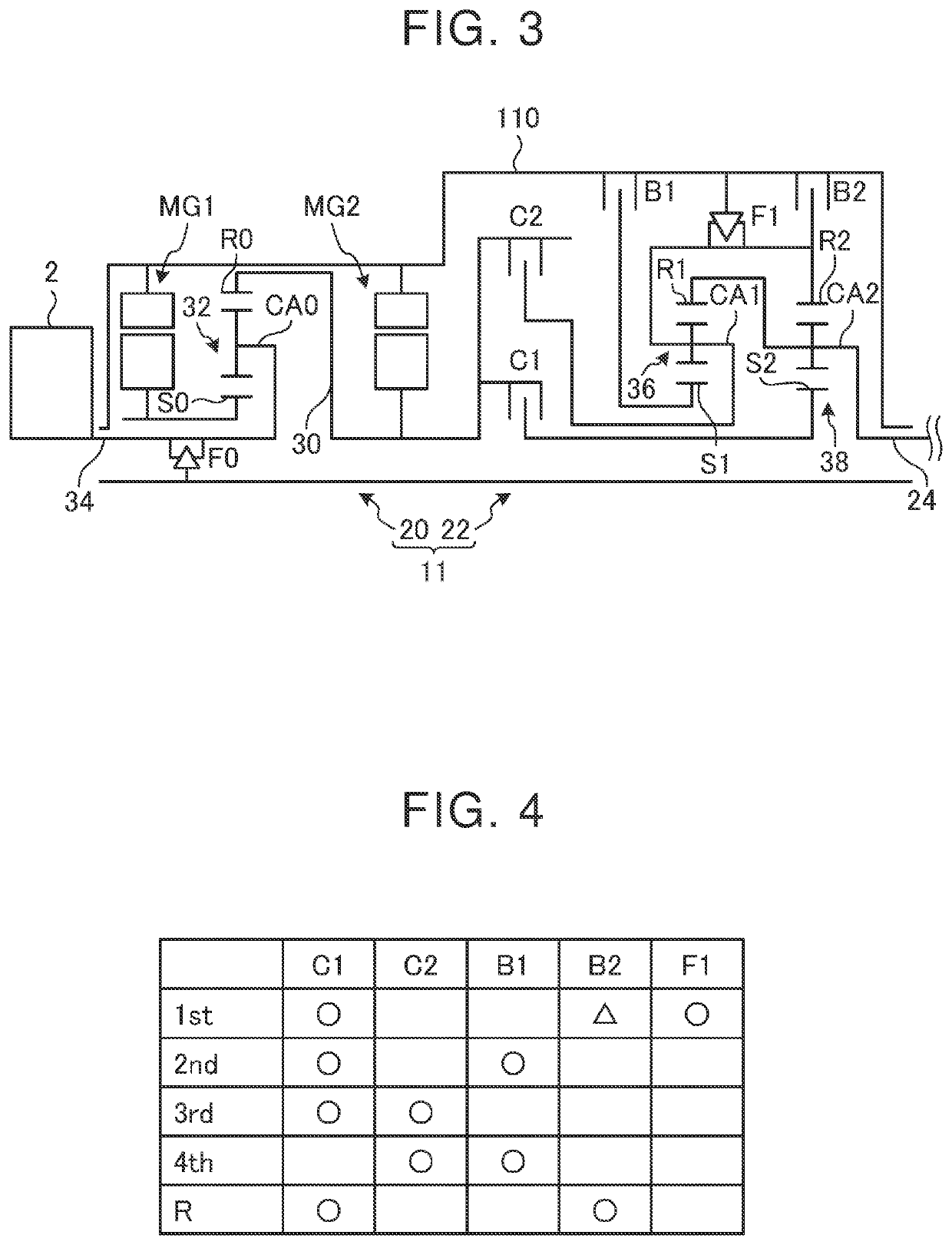

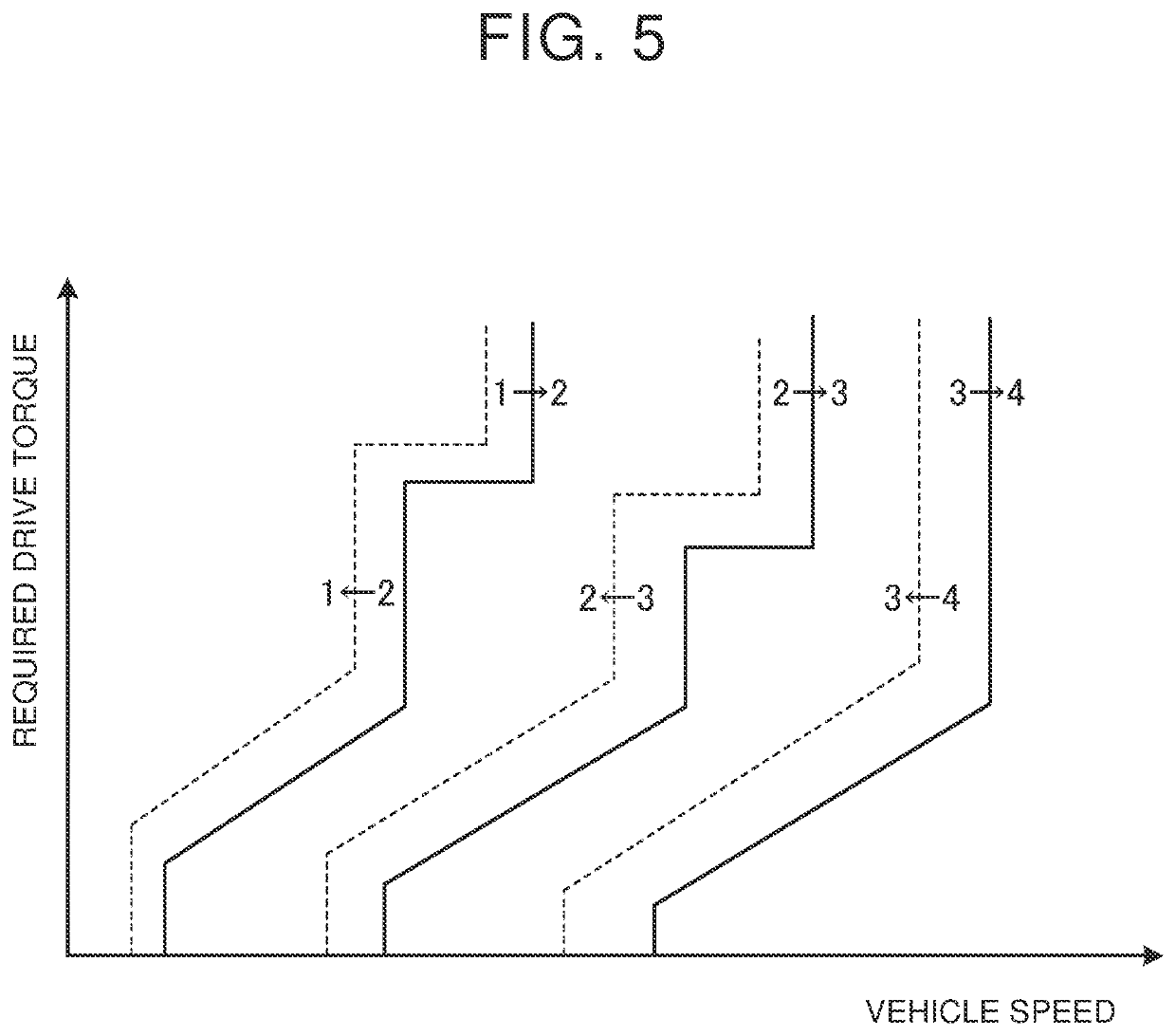

Vehicle drive device

PendingUS20220268347A1Appropriate connectionHybrid vehiclesToothed gearingsTravel modeSynchronous control

In a vehicle drive device, a second power source is connected to a first rotating element of a differential mechanism. The other output shaft of a first output shaft and a second output shaft is connected to a third rotating element so as to be disconnectable and connectable by a disconnection-connection mechanism. A control device places the disconnection-connection mechanism in a disconnected state. When a second traveling mode in which the third rotating element is fixed to a fixing member through engagement of a first engaging element is switched to a first traveling mode in which the disconnection-connection mechanism is placed in a connected state, the control device disengages the first engaging element, executes synchronous control in which rotational speeds of the other output shaft and the third rotating element are synchronized by a second engaging element, and switches the disconnection-connection mechanism from the disconnected state to the connected state.

Owner:TOYOTA JIDOSHA KK

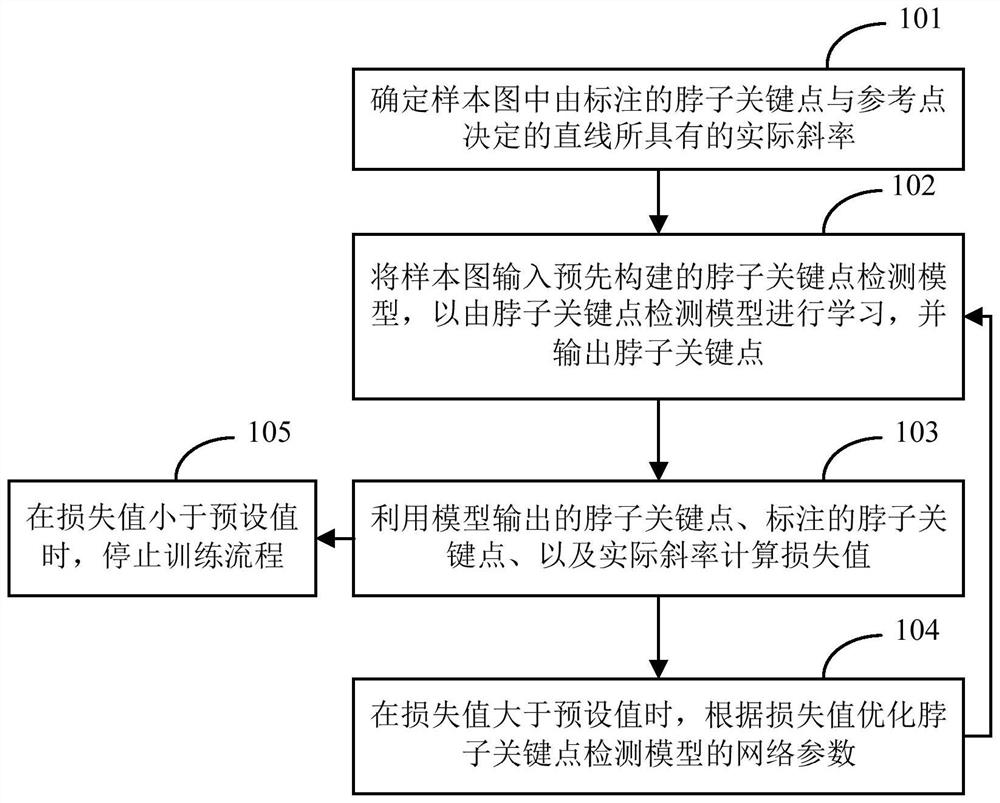

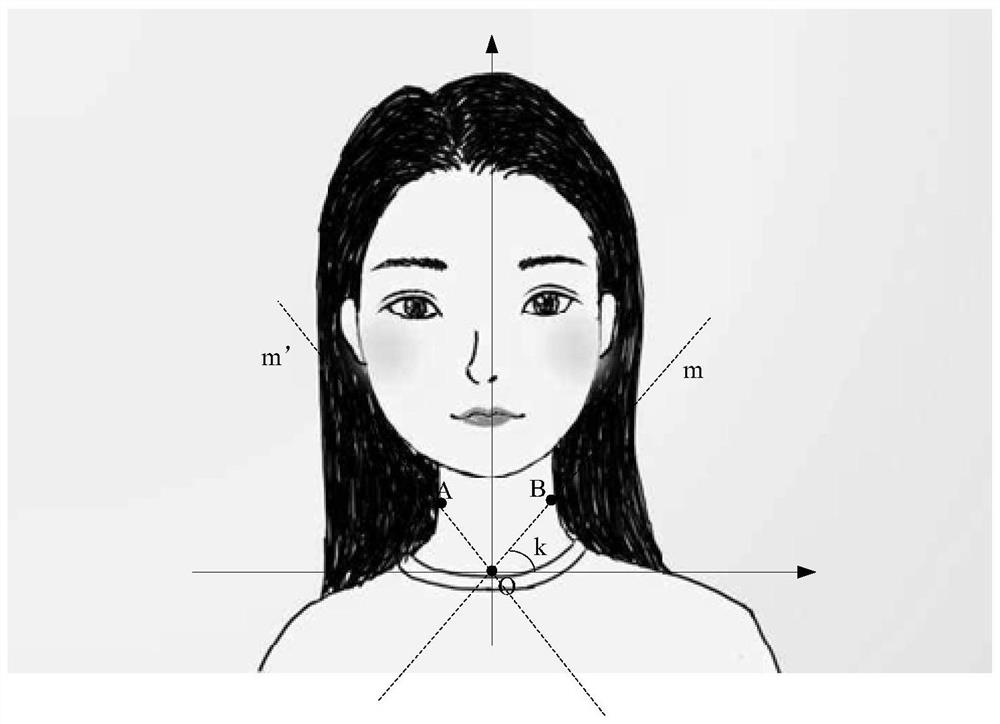

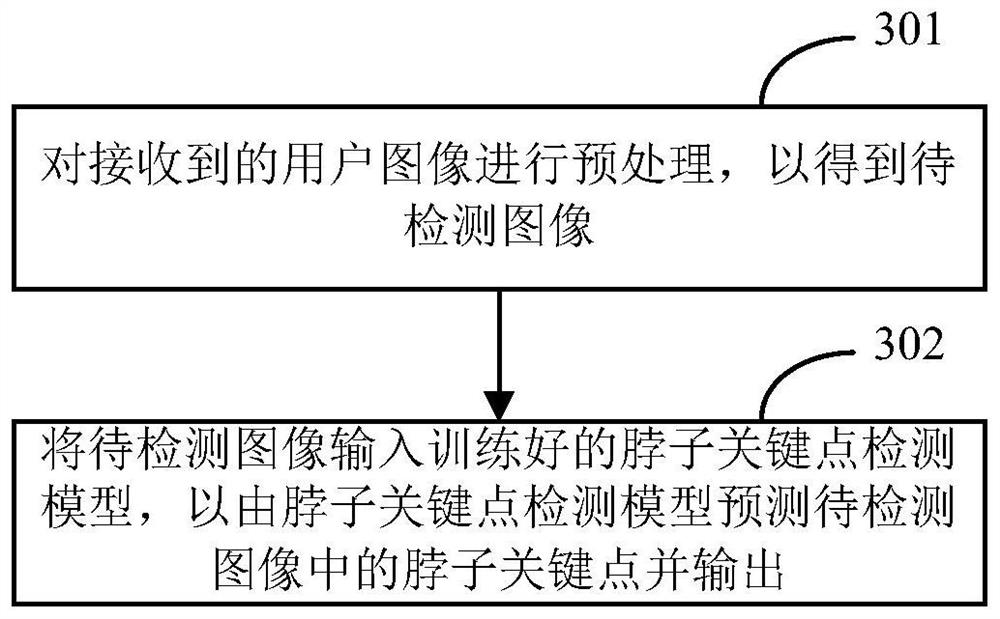

Neck key point detection method and device and detection model training method and device

ActiveCN114550207AAppropriate connectionImprove robustnessInternal combustion piston enginesBiometric pattern recognitionSample graphAlgorithm

The invention discloses a neck key point detection method and device and a detection model training method and device. The training method comprises the following steps: determining an actual slope of a straight line determined by a marked neck key point and a reference point in a sample graph; inputting the sample graph into a pre-constructed neck key point detection model, and learning and outputting neck key points by the neck key point detection model; calculating a loss value by using the neck key points output by the model, the marked neck key points and the actual slope; and when the loss value is greater than a preset value, optimizing network parameters of the neck key point detection model according to the loss value, and continuing training until the loss value is lower than the preset value. According to the method, the actual slope between the marked neck key point and the reference point is obtained, loss calculation is carried out by using the actual slope, the prediction result and the marking result in the training stage, and network parameter optimization is carried out according to the calculation result, so that the robustness and accuracy of model detection are improved.

Owner:北京新氧科技有限公司

An automatic processing technology for die-casting aluminum rotor of ceiling fan motor

ActiveCN111446826BFurnace temperature fluctuation is smallAppropriate connectionManufacturing stator/rotor bodiesCeiling fanFurnace temperature

The invention discloses an automatic processing technology for die-casting aluminum rotors of ceiling fan motors, comprising the following steps: pouring aluminum alloy materials into a melting furnace and heating to a set temperature; die-casting and forming the motor rotors through die-casting molds; The motor rotor with the handle behind the mold is taken out from the die-casting mold and put into the punch; the punch punches the handle off the motor rotor, and the removed handle falls from the punch and flows onto the conveyor belt , and automatically returned to the furnace through the conveyor belt. At the same time, the palletizing robot takes out the punched motor rotors in the punching machine and stacks them on the receiving rack in an orderly manner; repeat the above steps to realize the continuous automatic production of the motor rotors. Realize automatic production from die-casting molding, removing die-casting parts from the die-casting mold and moving them to the punching machine, punching the material handle, stacking the punched motor rotors in an orderly manner, and returning the material handle to the furnace, with high production efficiency. The fluctuation of furnace temperature is small, and the production yield is high.

Owner:NEW CENTURY ELECTRICAL MFG ZHONGSHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com