Automatic machining equipment for aluminum rotor of ceiling fan motor

A technology for processing equipment and motor rotors, applied in the field of automated processing equipment, can solve the problems of temperature fluctuations, high work intensity of production personnel, and uneven rotor gravity, so as to reduce furnace temperature fluctuations, avoid adverse effects, and improve production yields. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing:

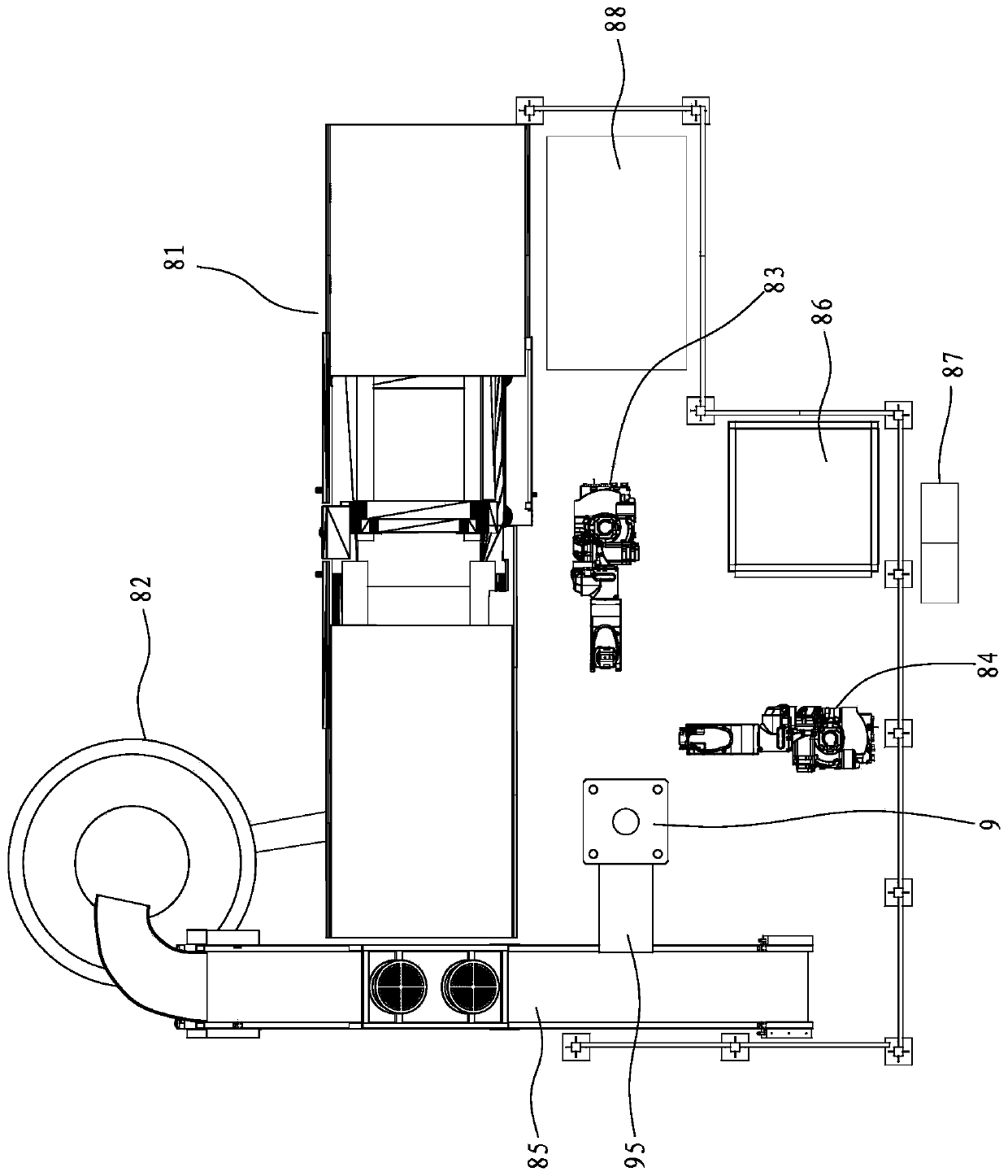

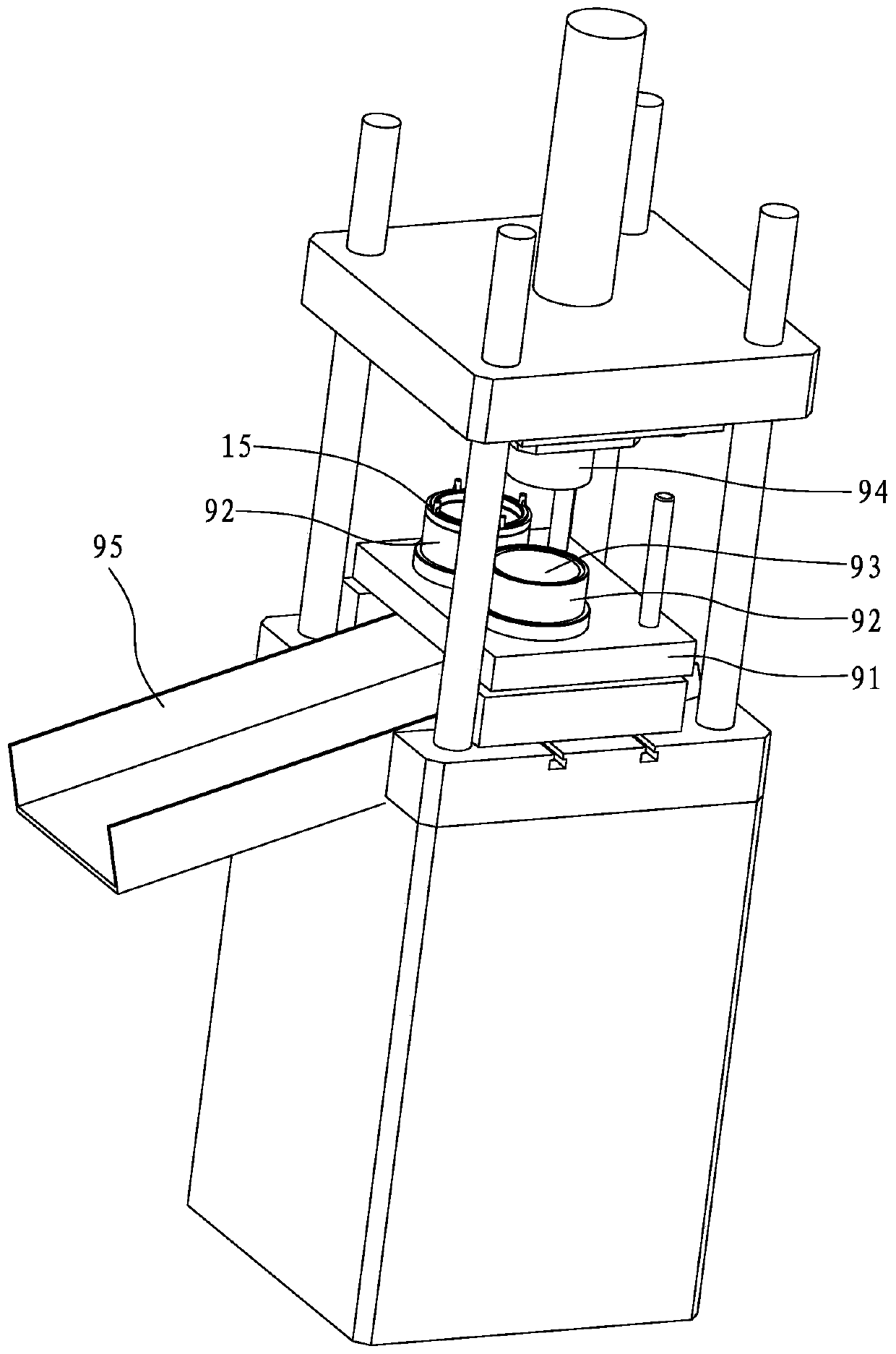

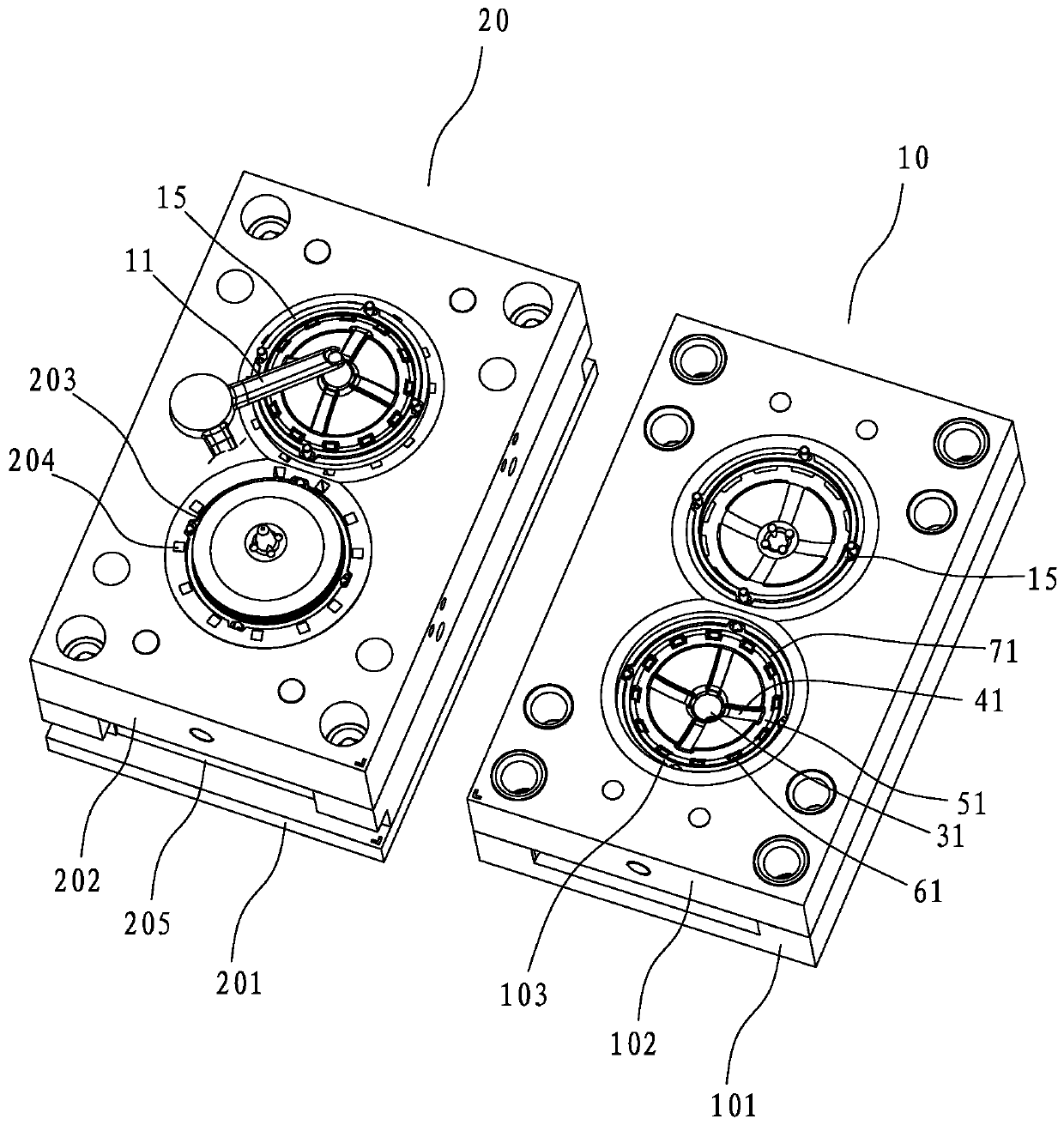

[0040] Such as Figure 1 to Figure 8 The shown automatic processing equipment for ceiling fan motor aluminum rotor includes a die-casting machine 81 and a melting furnace 82. The die-casting machine 81 is provided with a die-casting mold for die-casting the motor rotor 15. One side of the die-casting machine 81 There is a punching machine 9 capable of punching and dropping the material handle from the motor rotor 15, and there is a device between the die-casting machine 81 and the punching machine 9 for taking out the die-casting parts after mold opening in the die-casting machine 81 and putting them into the punching machine 9 A pick-up robot 83, between the punch 9 and the furnace 82 is provided with a conveyor belt 85 for catching the material handle punched by the punch 9 and transporting the material handle to the furnace 82, and one side of the punch 9 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com