Furnace temperature setting method suitable for H-shaped steel rolling heating furnace

A setting method and heating furnace technology, applied to heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of increasing the work intensity of operators, unstable heating process operation, high oxidation burning loss, etc., and achieve real-time and more accurate furnace temperature , reduce furnace temperature fluctuations, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The above and other technical features and advantages of the present invention will be clearly and completely described below with reference to the accompanying drawings, and the present invention will be further described in detail.

[0041] The present application discloses a furnace temperature setting method suitable for an H-shaped steel rolling heating furnace. The appropriate temperature setting value for each combustion control section of the heating furnace is calculated by the dynamic furnace temperature setting model.

[0042] Specifically, the specific method to build the H-shaped billet temperature calculation model is as follows:

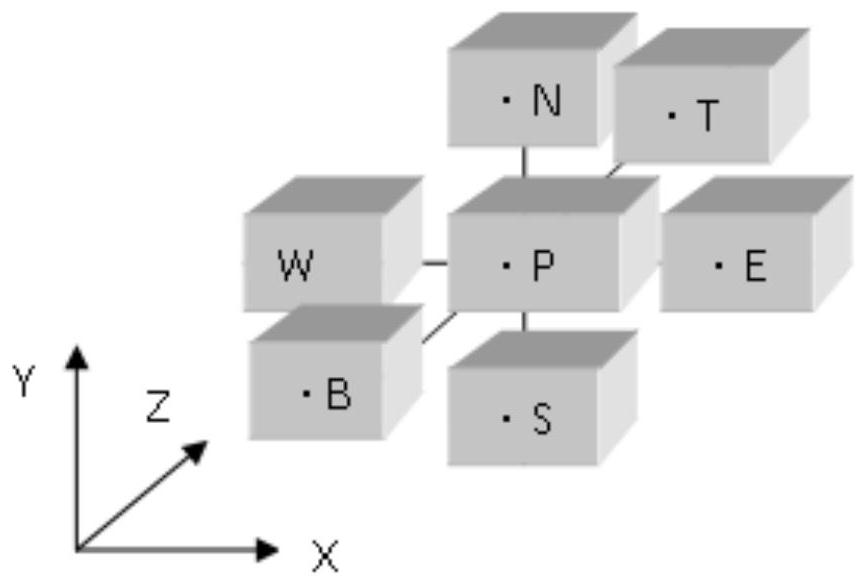

[0043] The H-shaped billet is divided into nodes.

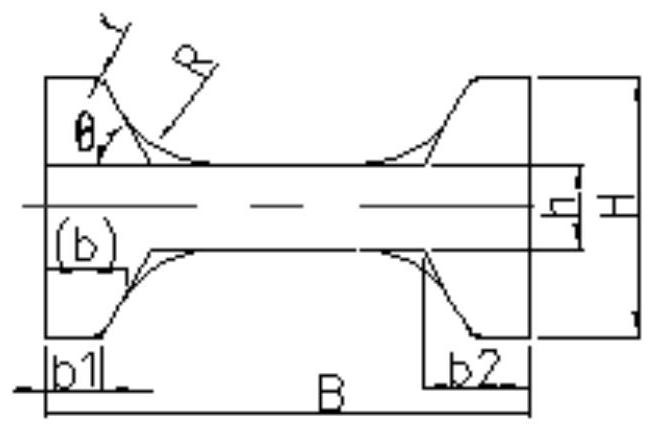

[0044] like figure 1 Shown is the cross-sectional shape of the H-beam, which is a profiled billet. In view of the cross-sectional characteristics of the H-shaped steel billet, the present application uses the multi-rectangular segmentation method to divide the cross-section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com